-

Posts

4,377 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Egilman

-

Mark, Thanks for the question, IPA is useable until it becomes loaded with resin... when that happens it becomes cloudy and starts taking longer to clean the parts..... What is recommended is to remove it from the vat, put it in a clear jug and leave it out in the sun to allow the resin in it to cure and settle out..... Then run it through a filter to remove the small particles and it's useable again..... It's useable for this until it just doesn't clean anymore.... The recommended way to get rid of it when it's done, is to pour it into an open pan, then leave it set in the open sun outside until it evaporates leaving the resin residue behind.... At that point dispose of the solidified inert resin residue in the trash.... Disposing of unwanted/unused resin is similar, put it in a disposable clear container and leave it out in the sun to harden, once it is hardened, it is inert and harmless, dispose of it in the trash.... That is the EPA's recommendations on how to deal with it.... I'll take this opportunity to cover something I've been knocking back and forth in my head if I should or not, the toxicity of 405nm UV Resins.... In all jurisdictions UV curable resin is a very, very low grade hazardous waste... Not dangerous at all when properly handled, in fact most household cleaners are more toxic that UV Resin... The worst thing you could do with it is pour it down the drain, it is generally non reactive to human life although there is the chance that prolonged exposure will cause sensitivity to it, this shows up as rashes and itching, the cure is to wash the affected area with soap and water and wear gloves when using it... Prolonged inhalation of the vapors, (If any) could cause mild throat irritation, so use it in a ventilated area... Causes moderate eye irritation, if you happen to splash a bit in your eye, flush it out with clear water immediately, and seek help if the irritation persists. splashing bleach or window cleaner in your eye is worse... I have over a dozen of MSDS's from all the various worldwide jurisdictions that call it a low grade toxic material, lower grade that common household bleach.... More telling is the shipping/mailing restrictions on it, ABSOLUTELY NONE! as long as it is in a proper container you can ship it anywhere in any quantity..... If it was truly a dangerous toxic material there would be all kinds of shipping restrictions.... Basically if you treat it like you would common antifreeze for your car, your good to go.... It is no more harmful than that.... This printing process uses a very specific UV resin, 405nm, in general, UV resins have been sold in hobby stores for decades, it is a well known hobby material to anyone into casting, mold making and jewelry.... (check Hobby Lobby and Michael's for your general UV resin needs) I'm sorry for those that think you need to get suited up in a hazard suit (or characterize it like that) cause it is classified as a toxic material. In todays world the word "Toxic" has become like the word "Plague" raising all kinds of fears of dire consequences if you encounter such a material..... ALL OF IT IS FALSE! The reality is it is less dangerous to you than the oil you put in your car, the ammonia you clean your windows with, the cleaner you put in your dishwasher.... (and a thousand other common everyday products) The acetone thinners you use for your enamel model paints is twice as toxic as UV resin..... Enough of that, I don't want to create a firestorm over environmentalism.... But the truth is the truth.... EG

-

Ok I was going to post some things about the finishing process.... This is what it looked like fresh off the printer.... Inserting it in the IPA bath.... The Wash & Cure Plus takes a maximum of 8.5 liters of IPA and when cleaning, it cleans the plate as well as the parts.... Now, when you set the time it set on 2 minute increments, the reason for this is it runs in one direction , stops after two minutes and then reverses itself.... Also the circulation is powerful enough to create a three inch wide & deep vortex when there is nothing in the vat..... Very powerful wash... Also, it winds up slowly, sounding like a jet engine spooling up, but goes quiet when at full speed.... Post wash... You can see where the IPA is evaporating leaving the parts dry.... I'm using the clear resin that Anycubic sent me, as you can see once washed, it goes opaque... (like frosted glass) When dry, you remove them from the build plate.... At this point, I clean the printer plate and reinstall it on the printer ready for it's next print..... My understanding from Anycubic is you can leave the liquid resin in the vat no longer than two days, after that you need to dispose of it... Now if I was not going to print anything immediately I would strain the resin back into the bottle, and then run the washer with the printer vat, funnel and strainer in it for 8 minutes this get them clean of all resin and then allow them to air dry.... Curing..... This is the setup for final curing of the parts..... You remove the washer tank and place the reflective plate over the bottom of the chamber, it fits in the recess.... (most just leave it in place when they put the IPA vat in place) You install the turntable and place your parts on it... You angle the top portion of the LED bar over the parts and place the cover over the whole thing.... Set the timer for 2 to 6 minutes depending on your parts and turn it on... She rotates a 4 rpm... I know it doesn't seem all that long, but they are very powerful UV leds.... When done, this is what you come out with..... First thing you notice is that they come out completely frosted with a brownish tinge.... I wouldn't call this clear resin, I assumed that clear meant clear when finished and this isn't it.... And the brownish tinge just doesn't do it for me.... So finishing will have them cleaned up and painted.... Red, just like the Admiral wants them..... Overall, this wasn't a difficult process to figure out, and the machine is dynamite once you learn how to configure the parts you want printed... I'm even more impressed with it than when I ws watching the videos on the net.... If "I" can do this, ANYONE can...... No doubt of that in my mind.... EG

-

Hi Henry, Well in my ignorance the first time I just put them on the plate, sliced it and fed it to the printer.... It didn't work and I learned about removing cured resin from the vat as the parts were pulled off the build plate... But I examined my error and went forward... My second time, I used a different slicer, Lychee, which I'm liking a whole lot.... I set them up again in Lychee and angled them over on the side, lifted them off the plate and let it automatically do the supports and rafts... This printed fine except Lychee set the lift speed down by half so it took twice as long to print.... When it was done what I found was that Lychee put so many supports on the parts that it was next to impossible to get them off without breaking them... There were so many supports, (all thin btw.) that they printed together in a great many places... I learned that I went from one extreme to the other, no support to maximum support... (which isn't needed for this print... My third time, I went into Lychee and let it automatically do the supports and then went in and manually removed many of them including all the ones it so graciously inserted into the inside of the rose... (which could easily be seen outside the bud) and in my innocence I left them vertical, and at about 10% they started pinging off the build late attaching to the vat... I didn't let that one finish... On my fourth attempt, I set it up in Lychee again and this time slanted them and allowed it to set up the supports and again went in and manually removed all the ones that were going to print together into massive supports and removed the inner ones as well... This is the one I am about to report on.... It successfully printed.... It's being a learning experience, I've been told that I should have started with something simpler and easier to work with... (like a figurine, which I have no interest in, or the Eiffel tower like all the you tube video recommend) Nope I wanted something that I was going to have to learn how to do right... I think I found it.... It's partly assembled now, getting it ready for paint.... The Admiral like red.... Will see what I can do with it..... Thanks for looking in Henry, but I will say, Lychee makes figuring it out easy peasy, I would recommend it to any innocents just starting out.... (like me) EG

-

Yeah, first adopters usually have the fun of figuring out all the faults and acquiring all the upgrades to make the tech work like it was advertised... I almost fell into the automatic paper cutters, when they came out... They were barely able to cut paper at that time... Today, they are powerful enough to cut heavy card and have been used to cut thin sheet styrene.... (for scratching ship superstructures) Still might get one for that oddball thing that needs cutting.... {chuckle} Technology always moves forward, sometimes fast sometimes slowly.. FDM printers will still have a use, but SLA and it's derivatives will take over the market......

-

Well another failure.... This time too many supports for a very delicate print.... It broke, both of them.... This is what I'm trying to print.... It's paper thin on the petals & sepals... Figuring if I can get this printed successfully I've done something... Getting closer....

-

I set up the current print with Lychee, yes it supports the Mono X, but it changes the lift spec from Photon Workshop, drops it from 2mm/sec to 1mm/sec this effectively makes a 4 hour print into an 8 hour print... It is noticeable right away when you start the part printing.... Slicers; (and my experiences) Photon Workshop: Anycubic's slicer is kinda basic, and you have to hunt for info cause it isn't intuitave.... ChituBox: Elegoo's Slicer is kinda techy, much like a full bore 3D program, it has a learning curve, and it bailed out on me a couple of times... Hard to find reliable info on how to effectively use it... Lychee: Comes to us from Mango 3D, a producer of 3D printer op systems and motherboards... It is based upon the Mango Slicer, a proprietary slicer software that can be modified to suit any Printer Manufacturers specifications.... Lychee is very intuitive.... (although it requires a Mango 3D account and e-mail verification, it is free) It took me just a few minutes to figure it out..... The first two left me asking questions and searching for info on the web... The third I had figured out and up and running in a few minutes.... This nube will recommend it, (Lychee) over the other two, but bear in mind, I've only 1.5 successful prints under my belt so take it for what it's worth... If your new to this, give it a try, I don't think you will be disappointed... Another 4 hours till the rose print is finished... I will do pics of the finishing process... EG

-

Well, My first print failure... The rose failed to stay attached to the print plate.... My Mistake... Not enough supports..... Second try starts now.... Should be done in 8 hours.... Hopefully, two steps forward for every step backwards... {chuckle}

-

They'll become available eventually... The generic Chinese manufacturers are just beginning to discover the 1/64th scale market that Mijo stumbled across... They are already beginning to market the nudies in that scale on evilbay... That tells me the figures in that scale are here to stay for a while.... Gaming is a niche of what is actually possible, it's a big market yes, but a small fraction of the entire market... and currently desktop 3D printing is dominated by them, over the next ten years that is going to change as the tech spreads out to other areas and people find out just how useful it is going to become... Heavy industry has been using 3D composite additive manufacturing for 50 years, resins for 70 years, 3D printing is just an easier cheaper way to do what they have been doing all along... Once it finishes breaking out of the manufacturing scheme, (it already has) it will explode over many industries.... (creating some, destroying others) It's the nature of technological advancement....

-

1/64 scale figures.... Not a problem.. https://www.ebay.com/b/1-64-Figures/180506/bn_7023455365 Simple google search, you probably would have to doctor a few into the poses you want.... (on a 3D printer, you can make them any scale you want just find the files) I hovered over a year on the Mono X the recent $200.00 drop in price tripped it for me.... From what I hear, middle of next year for DLP from Anycubic, (that's an estimated time) also the print standards will only be marginally better than MSLA.... (I think it is speculation cause the info really hasn't been officially released yet, but there is this ideal floating around in the heads of our younger crowds that newer is always better, that belief keeps the cell phone makers & car manufacturers in business) I've read some fora where the manufacturers are already considering the future of filament printing now that high resolution resin printing is the cutting edge and prices are dropping..... Still a lot of flux in the industry and gambling, the one thing for sure is it is the future and it's coming quickly....

-

Any suggestions on where to read up on it Patrick? One of the biggest problems with learning to do this is the absolute plethora of conflicting opinions being posted all over the net... Using IPA isn't an issue except for the cost for some of us on limited incomes.... Nice tire, which printer are you using?

-

I've had no smell whatsoever from the Anycubic resin, and the admiral who is sensitive to such hasn't either... Of course the IPA smells like a medical wound care ward when the wash tank is opened but it dissipates quickly.... (and is a non toxic cleaner disinfectant, safe as long as you don't drink it) I too am eventually going to go to waterbased resin as well... 2 gal of IPA is $25 from wally world.... (sold in quarts) Water comes from the faucet for pennies a gallon... I believe that WB resins are about 25% cheaper than their industrial cousins as well... Yeah, I saw that site, lotsa models most of them free, some of them very, very nice... Predominantly for gamers though like most of the 3D file sites are... And that French cannon setup would be perfect for say a Waterloo diorama/vignette.... Thanks for the link, I'll add it to my collection of links...

-

That is an interesting piece, but it's not a subject I'm interested in unfortunately... (but, miniature figures are the biggest draw to 3D modeling at this time) I'm more into traditional modeling of real world things... And I've found a test piece that fits all the conditions I set up for my second test.... A rose, (in Anycubic's slicer) I'm doing two of them at the same time, they will have parts that need to be glued together... A better test of my intentions... The Anycubic test cube has finished and has been washed and is getting it's final UV cure..... Complete and sitting on my desk.... This is the neatest thing since the Exacto knife..... Damn impressive if you ask me... I've got the rose printing now, another 4 hr print, the turnaround from finish to starting the next print is all of abut 15 minutes and that was my first time... I'm very impressed... A very easy process.... EG

-

The promised update when I could actually see what it's doing... Clear Resin, absolutely amazing.... A shot of the LED's doing their thing.... I know I'm gonna have fun doing this... Half way through, 1.5 hours to go before washing and curing.... (still praying that it doesn't fail) EG

-

Well yesterday, my Resin arrived from Anycubic, as well as my backup resin order from Amazon... She is happily printing away on the test subject.... Got my finners crossed that it finishes correctly.... Yes resin prints can fail as well as FDM prints.... About three more hours to go... Here's a pretty good youtube video of the setup process Setting up the Anycubic MONO X Shows the process in the clearest presentation I've been able to find.... Currently looking for a piece that I can grab online to do a test print and assembly to give it a try in actual glue together modeling.... Maybe something Sci Fi with several pieces or something like that.... Will update this when I can show actual evidence of it working.... The Wash & Cure is set up with 1.75 gal, (6.624 liters, takes a maximum of 8.5 liters) of 91% alcohol ready to go.... Will report on that as well... EG

-

Good question... I don't think I have any good answers.. Wish I did.... Outside the initial cost factor, you have to decide how big your going to build... What scales your going to be working in and what type of projects.... Think towards the largest single part you will need towards what your going to build... Get it's measured size in real life, down scale it to your working scale, and buy build volume accordingly... One of the advantages of larger build volume is you can make repetitive parts in one printing, you need a dozen of a certain part you can do it in one print rather than a dozen separate prints... That's my situation, I'm going to need a dozens of tall parts that are identical or close to identical, that measure around 8" so a 9.5" print height is required... The Mono X will print a dozen of those all at once easily... That how I reasoned it out.... It all depends on what you want to do with it....

-

Hi Jacek, I need the larger build area specifically cause I'm going to be building one of these...... Easiest way is to 3D print it rather than scratchbuild it.... 1/72nd scale to fit the Dragon Saturn V.... But first, I have to create the files..... Big mountain to climb....

-

Hi Henry, Phew, Thingiverse.... What a mess.... Everyone says get something from Thingiverse, most suggest a particular Eiffel Tower..... High res of course, problem is no one provides a link to it.... and there are 600 pages of Eiffel Towers... Some look great some not so great... There are several online you tube walkthroughs of Chitubox and how to use it but I haven't found one yet that hasn't put me to sleep.... Reminds me of Blender in the early days, trying to find useful info that is presented well is a challenge..... You would think that something that is this revolutionary would now have a source of good verifiable info easily available after what 5 years? I think the biggest difficulty in getting into this is finding good reliable info... Thanks for the offer of help, I will be asking questions when I run into problems and will post my solutions, (with linkage) when I discover them... Still trying to figure out the workflow to getting from an STL file output from whatever software, (in my case solidworks) to a finished print... New mountains to climb.... {chuckle} Right now I just want to get the printer working and make sure there is nothing wrong with it.... once I get the print-wash-cure process down, I'll start working on fine tuning the process... A door to a big huge world is opening, and I still have to get through the door... All help is appreciated... EG

-

Thanks Ron, I bookmarked this for future reference... I'm very familiar with how brittle resin is in general....

-

Hi Mike, I went with the Mono X for it's build area of 192x120x245... Anycubic didn't respond to my email about the missing resin today, probably take a couple of days so I went ahead and ordered a liter from amazon... I've downloaded Chitobox free and see I have another learning process to go thru... Right now, I just want to get this up and running.... I will probably turn to water based resins eventually once I learn a bit more to save the costs of large quantities of IPA... I think even with water based resins the Wash & Cure will be an asset to keep things efficient.... Then I have to create something.... The Admiral is waiting..... {chuckle}

-

Well, My Anycubic Mono X finally arrived today, (2 days late after a 1k miles side trip around southern California) along with it's accompanying Wash & Cure Plus...... Unfortunately, the 1 kg of resin that was supposed to be delivered with it didn't arrive.... I hope Anycubic is as good as the reviews say they are and they get it out quickly.... So until then, I'm still waiting... Will say more when there is something to say... {chuckle} EG

-

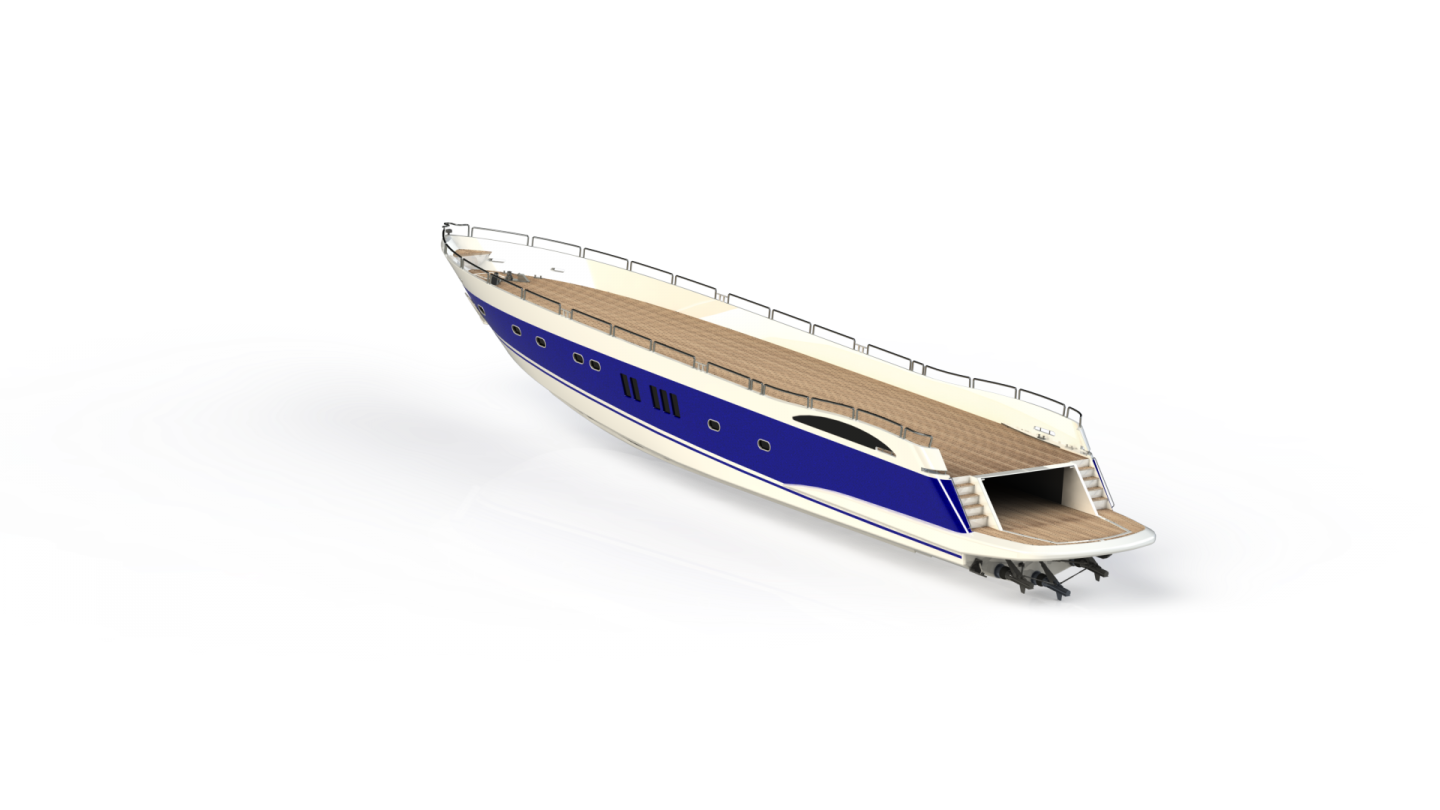

I'll be talking about it Craig, once it gets here and I've had a chance to set it up.... Still need to finish my Solidworks courses... (as life allows) But I think I'm making progress..... For example.... A Sunseeker Predator 108 in Solidworks..... I think I'm learning something..... I'll keep everyone informed... (and stop hijacking the thread)

-

It was a combo deal direct from Anycubic... got the Mono X and the Wash n Cure 2 as well... The build cube is 7.5"w x 4.5"d x 9.5"t ... The Elegoo Saturn has the same build cube volume... DLP is the coming thing, FormLabs is already out there with it for commercial use... (at a commercial price tag as well, well north of $4,000) but it will eventually get here... Mine hasn't arrived yet, It shipped from Chino CA, the Anycubic warehouse, shipped by FedEx, after almost 1K miles and a weeks time it arrived at Lodi CA ..... (20 miles down the freeway) {chuckle} Currently is is in Happy Valley OR, and two days late.... I hope it gets here before the next millennium passes.... Your work is impressive my friend, that wheel looks nice, and you printed it in clear, probably gonna be asking questions eventually... I'm a complete 100% newbie to 3D printing.... It's gonna be a trip....

-

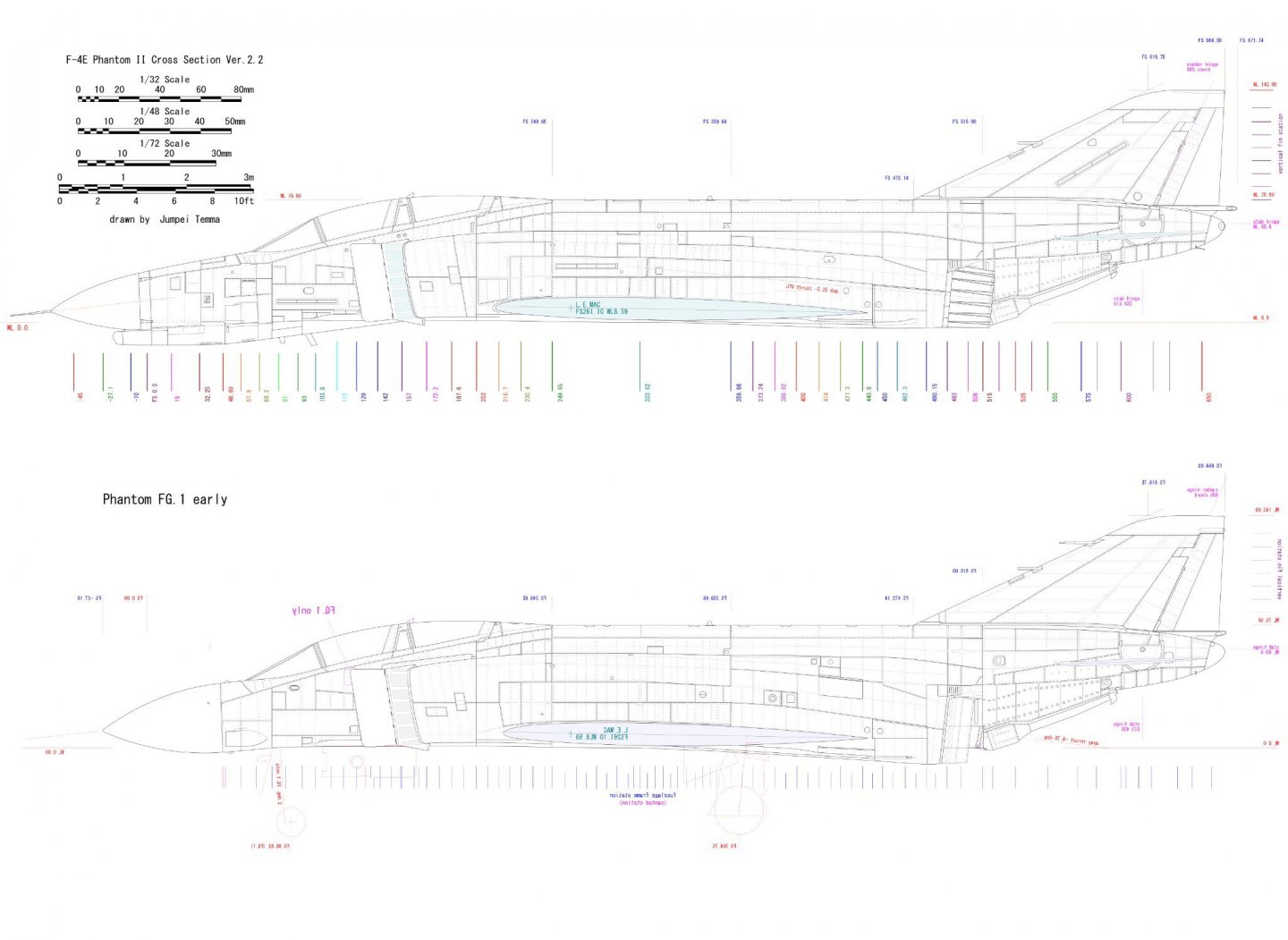

Just to make sure.... Here is a comparison of the F-4E profile with the FG.1 profile .. (FG.1 is the Royal Navy's F-4C/J) Clearly the nose is 6 feet longer..... (the most noticeable variation, there are others though on close examination.... Probably the best site for detailed scale info on the F-4's various profiles is this.... Wings of Pegasus.... Great site for modeling various aircraft....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.66915353d5a2d37de25b195f7c65bb3c.jpg)