-

Posts

74 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Rochester Hills, MI

-

Interests

Woodworking, Scuba Diving, Reading, Video Games (Zelda!), and now model ship building.

Recent Profile Visitors

-

mtaylor reacted to a post in a topic:

Planking before or after transom install

mtaylor reacted to a post in a topic:

Planking before or after transom install

-

GrandpaPhil reacted to a post in a topic:

Planking before or after transom install

GrandpaPhil reacted to a post in a topic:

Planking before or after transom install

-

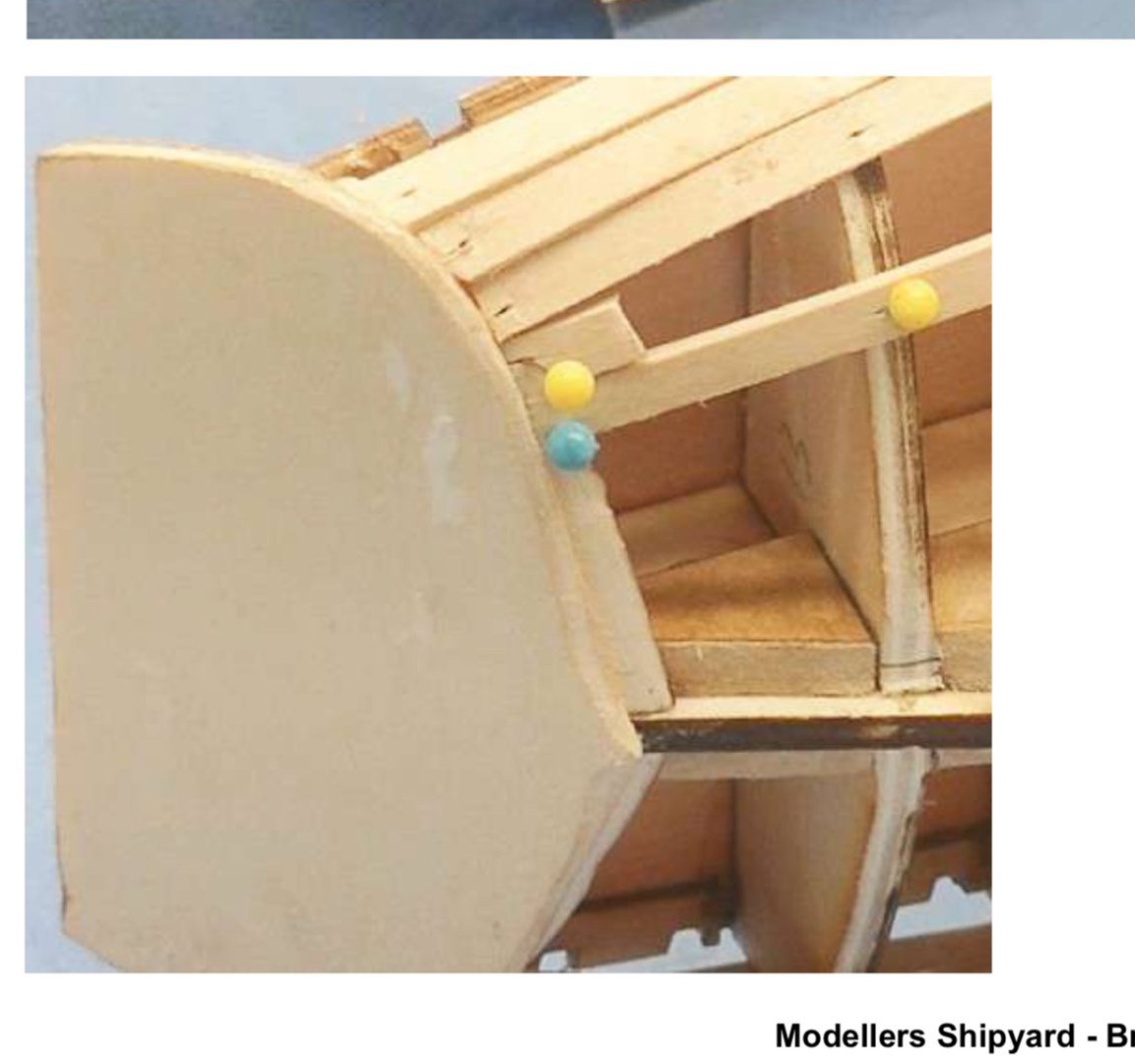

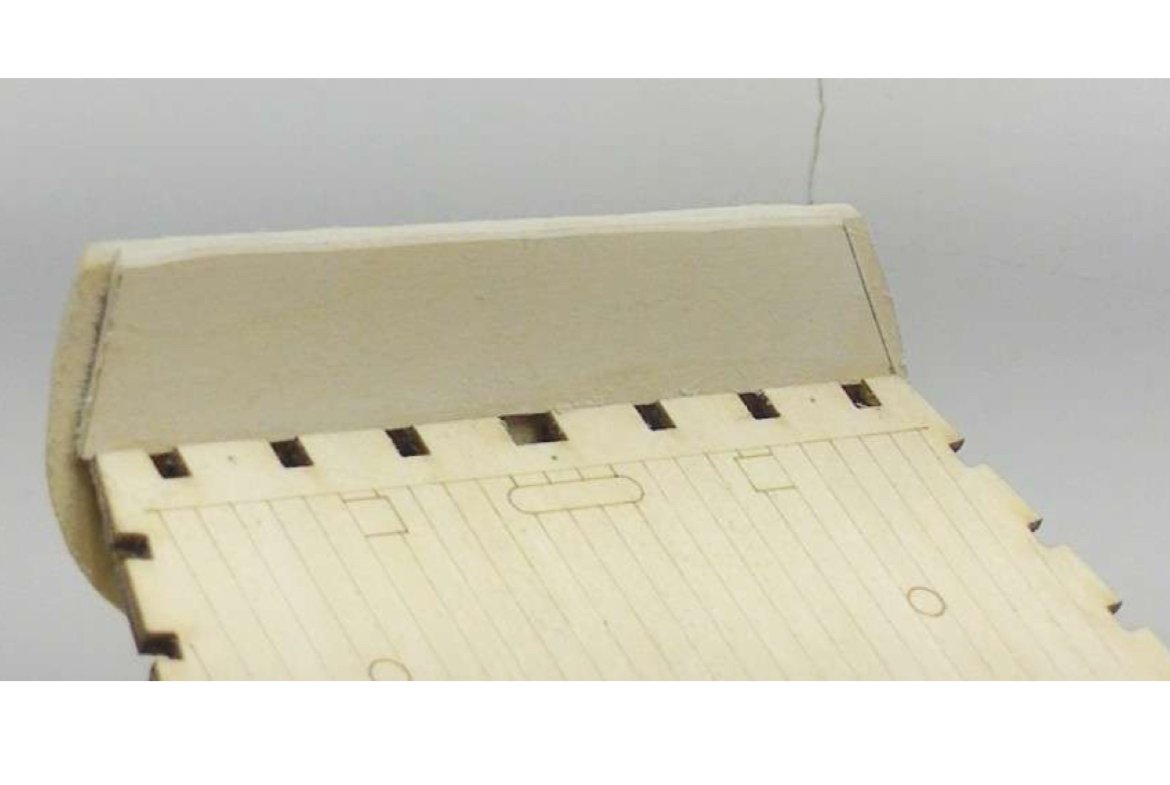

I’m working on the modelers central Matthew turner. In the instructions it calls out installing the transom before planking. This would require fitting both ends while planking. I’m thinking I could let them run wild at the rear, trim flush with the transom support, then add the transom at the end. Am I missing something that the transom adds at this stage?

-

etubino reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

etubino reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

Bill Morrison reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

Bill Morrison reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

Bill Morrison reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

Bill Morrison reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

Ian_Grant reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

Ian_Grant reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

GrandpaPhil reacted to a post in a topic:

Thermopylae by Jamie Coleman - FINISHED - Scientific Models - Scale 1:96 - First ship build

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

-

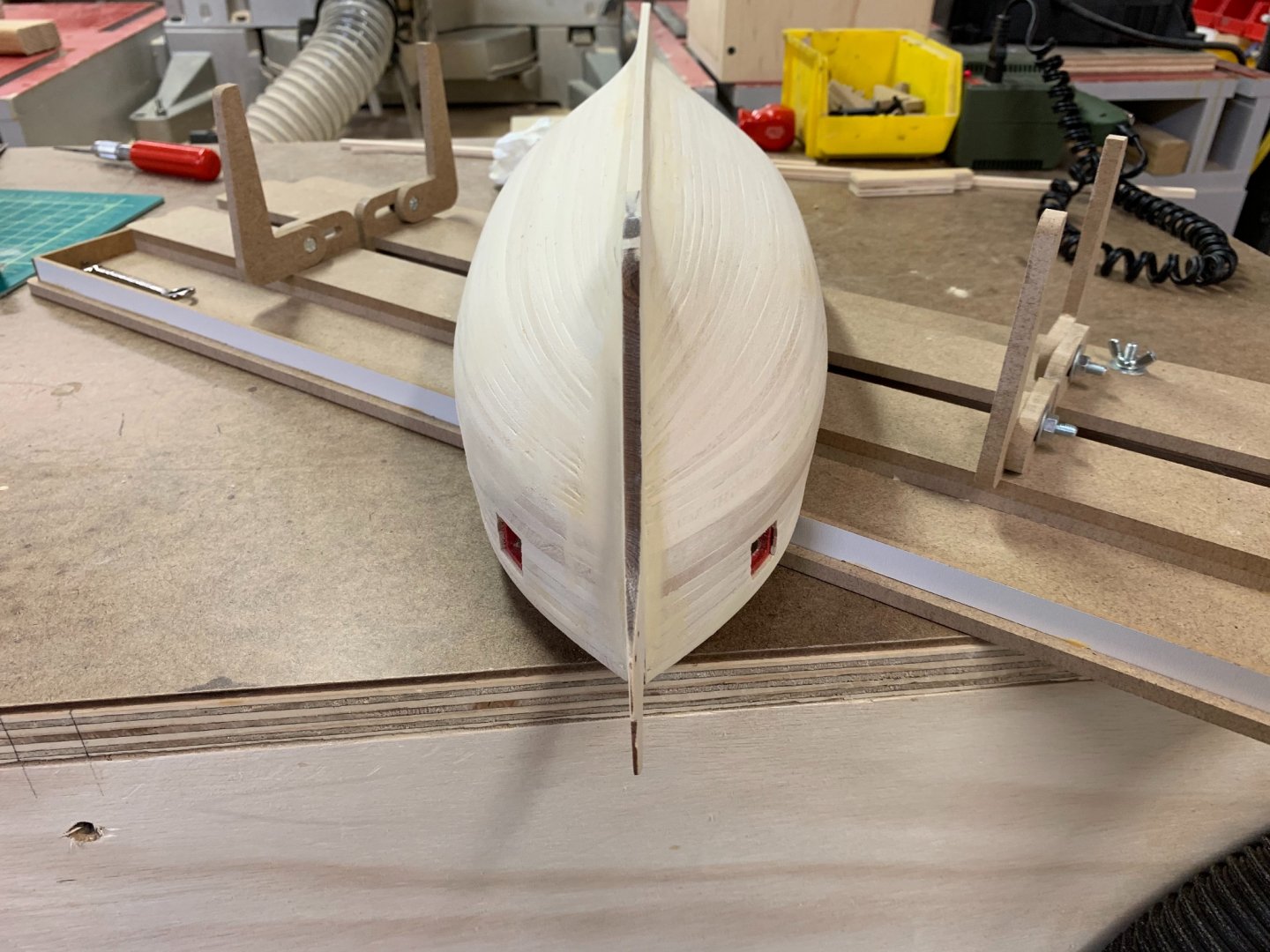

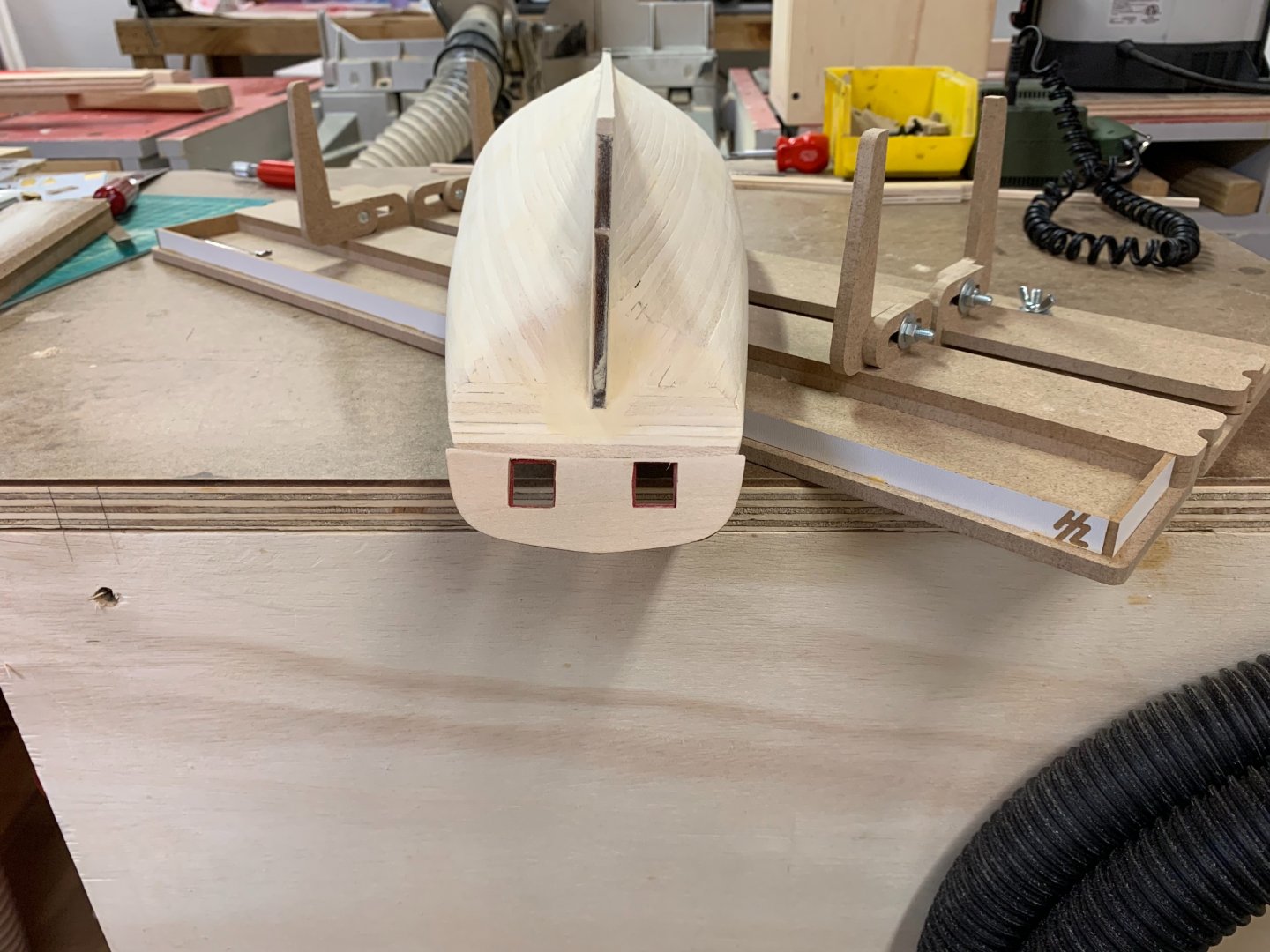

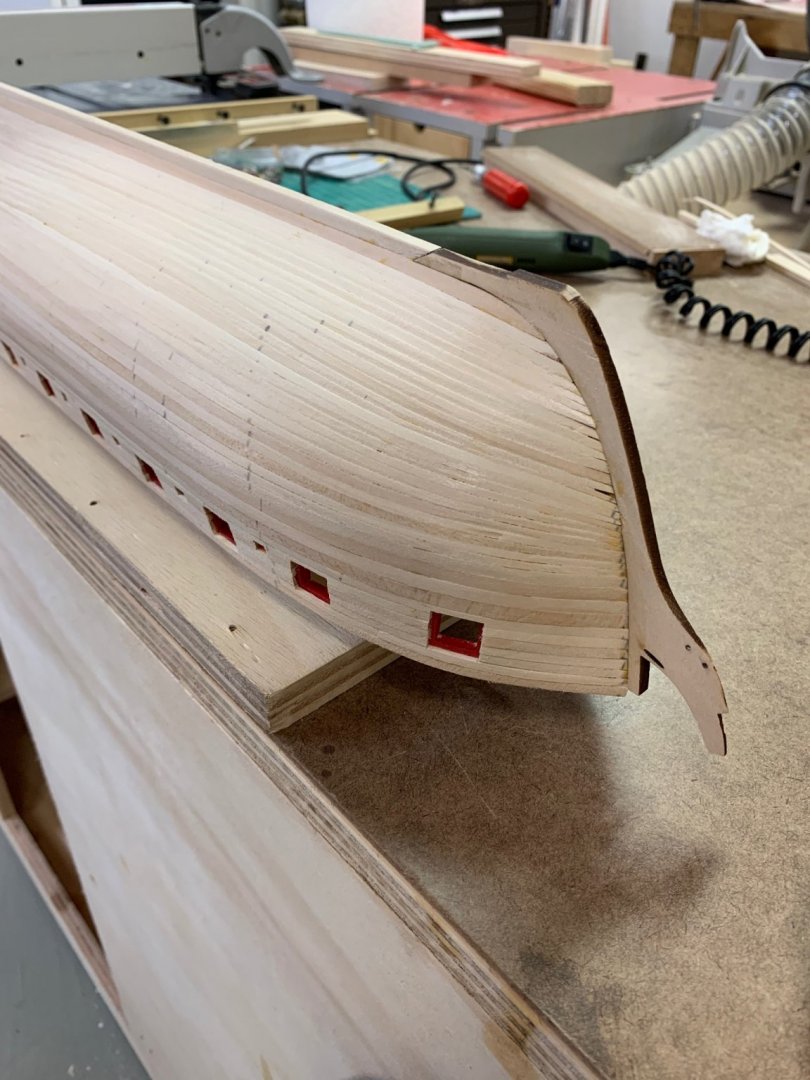

I’ve finished off the planking (except the second layer at the wales). I’ve filled and sanded a bit and it’s cleaning up. Needs a bit more filler and sanding before I move on to the wales and the stern. I was very relieved to put the stern piece on and cut the keel to length, that was just waiting to catch a shirt sleeve and wreck something. Last ship I did, I was really focused on getting to the rigging (it was a solid hull model), but I feel like building the ship with bulkheads and planks has been a lot more rewarding.

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Jamie Coleman reacted to a post in a topic:

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

-

Well, port side planking is basically wrapped up. Definitely a tricky process, I ended up needing to taper a few planks quite differently than their surroundings to get the final plank to fit, and I’m going to need some filler at the stern, but overall pretty happy how it came out for a first time. I’m going to fill and sand both sides once the starboard side is complete.

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren by Jamie Coleman - Model Shipways - Scale 1:64

Jamie Coleman reacted to a post in a topic:

US Brig Syren by Jamie Coleman - Model Shipways - Scale 1:64

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

-

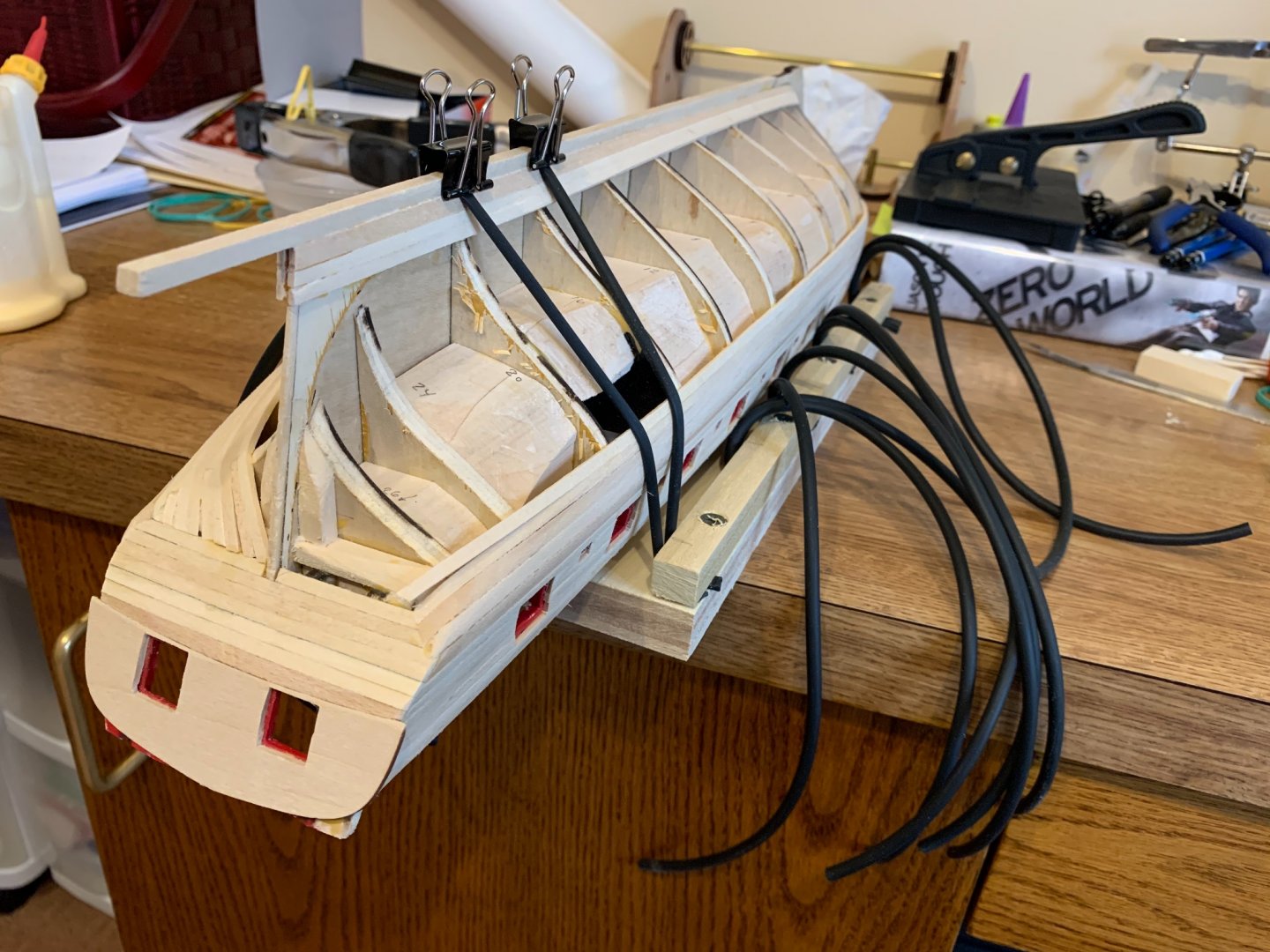

Patent pending, the Coleman Octopus is a success. Instead of clamps and rubber bands, I took a strip of wood and screwed it down over about 10 pieces of surgical tubing, now I can strap down a plank over pretty much every bulkhead at once. Probably a little overkill, but I think it’s going to work pretty nice.

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

-

A bit more progress, starting to plank the tricky stuff. Got the garboard planks in, plus the rest of the non-tapered pieces. The I used strips of paper cut to fit the empty bulkhead areas and a planking fan to line out the bulkheads. 22 planks one side 22.5 the other, planning on 22 for both, I'm sure there'll enough gaps to take up a 1/2 plank. I'm using a lot of clamped down rubber band pieces to hold the planks in place while the glue dries, and I've been pretty happy with how that's working, kind of like a band clamp, but small and cheap. Noodling on some ideas on how to make a better fixture that executes the same idea. So, got the first batch of planks on the starboard side, basically to the centerline. I'll move back over to the port side and get the same amount of planks. After that my plan is start down at the keel and work my way up wards so I have a better idea how much room I've got for that tricky remaining corner. Going to have to do some filing and sanding, but so far so good. Definitely spots I should have beveled a bit heavier to tighten the gaps, but as this section will be copper covered, I think I can fair it out. In other news, I picked up a Lie Neilson violin makers plane, I was just not having a lot of success with a standard size block plane for the small work. This thing is tiny and perfect (well, low angle might have been nice, but I'm not doing a lot of end grain). I'm using it to taper the planks now, rather than cutting. Much like some others, I found the kit wood a bit fussy. Just start close to the end, take a few passes and keep slowly moving further back until it matches up with the lines on the bulkhead. Anyway, more to follow, thanks for watching.

-

Welcome aboard, no apologies necessary, seems every time I turn around I find another Syren that I've got to take a look at. This whole covid thing got me started on a ship that had sat idle for more than a decade, and finishing that got me going on this one. For the jig, the camera angle makes it look like a compound curve, but in reality the nails are straight up and down, so just a single curve. It gave the wood enough bend to fit well at least above the wales without needing to fuss too much.

-

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

Jamie Coleman reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

-

She truly is gorgeous, to echo a lot of others, everything is crisp and neat, love it.

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I made a jig to pre-shape the planking, and it'll hold about 8 planks at once, so I can soak and let them dry overnight. It ended up working very well, but as these were just plain steel nails, it did end up leaving a bit of a rust streak I'll have to sand out later. I painted the ports and then laid down the first plank after laying it out with some battens and pins. Continued to plank from the wales up. Clothes pins were the clamp of choice here, but I did end up using rubber bands for the final bow planks, as the were high enough the rabbet wasn't holding it inboard.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)