yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

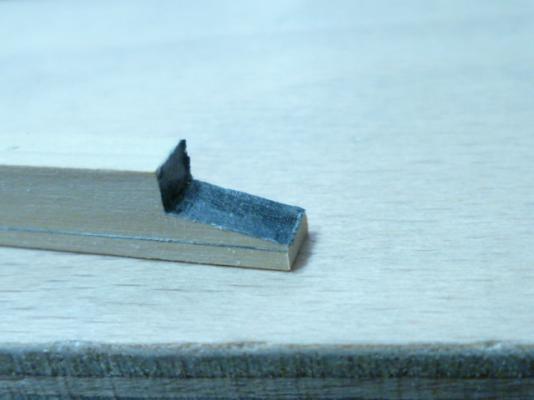

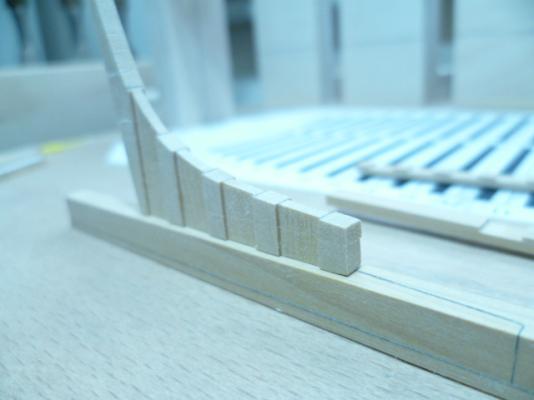

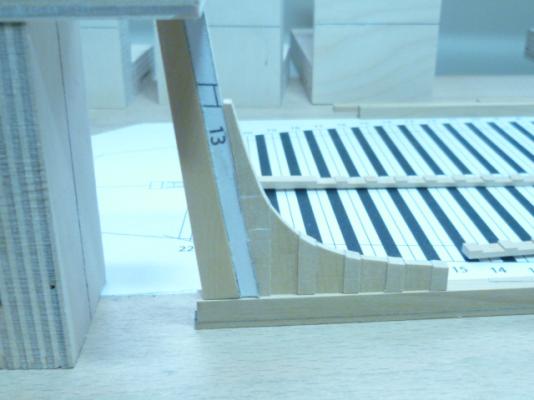

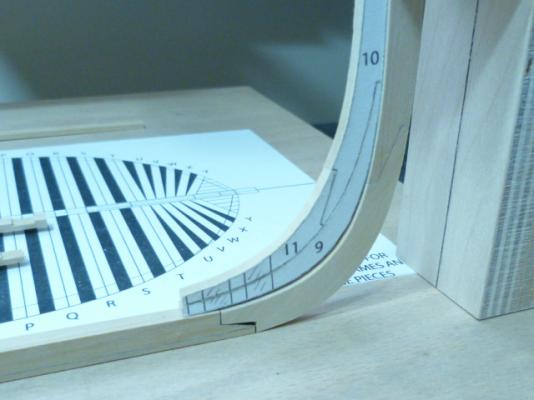

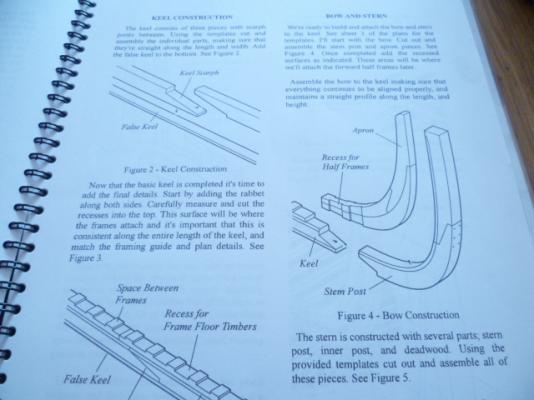

WASHINGTON GALLEY PART 2 HI ALL WORK HAS CONTINUED ON THE KEEL.SCARF JOINTS HAVE BEEN CUT AND TARRED AND FALSE KEEL ADDED. KEEL IS SLIGHTLY OVERLENGTH AT THE MOMENT TO ALLOW FOR FINAL ADJUSTMENT. STERNPOST CUT AND TAPERED ,INNER STERNPOST SIZED AND READY FOR JOINT FOR TRANSOM TO BE CUT. AFT DEADWOOD ASSEMBLED AND REBATES CUT FOR FRAMES. STEMPOST CUT AND INNER SURFACE FINISHED, OUTER SURFACE AND GRIPE YET TO BE FULLY FETTLED. THE SAME APPLIES TO THE FORE DEADWOOD. THE AFT DEADWOOD REBATES WERE CUT ON THE BYRNES SAW AS PER GREGS METHOD. THATS THE STATE OF PLAY AT THE MOMENT.....GETTING READY TO CUT THE RABBETS!!!! CHEERS.....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Greg Thanks for the alternative method.....never thought of using my Byrne's saw.....went straight for the Miller! There are various other joints to be cut and I shall give your method a go. Must re read the swan practicum and pick up some more tips Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

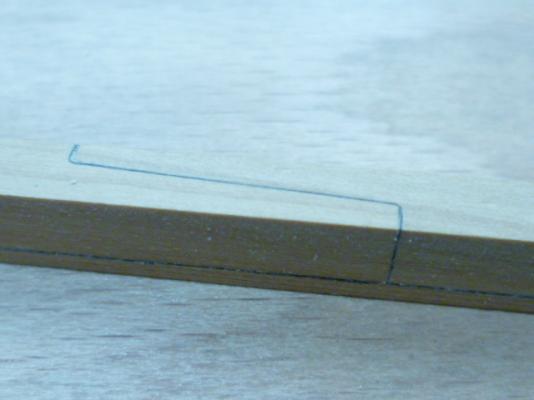

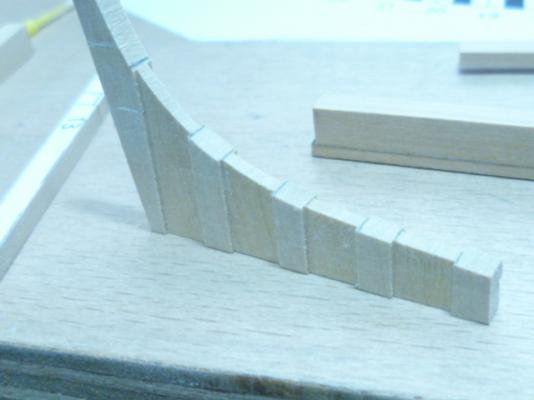

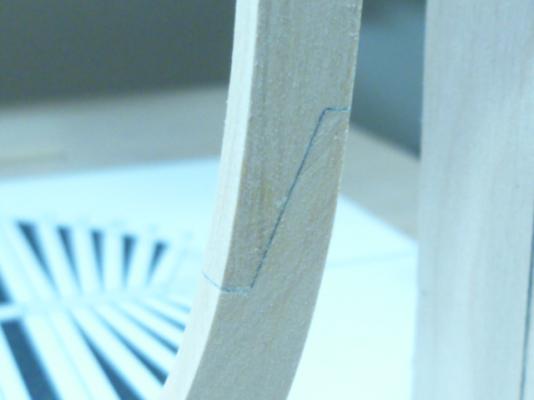

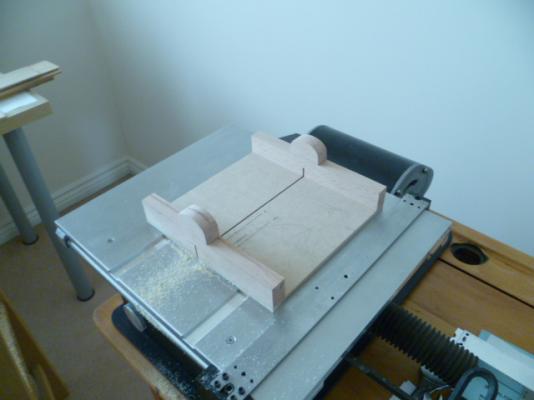

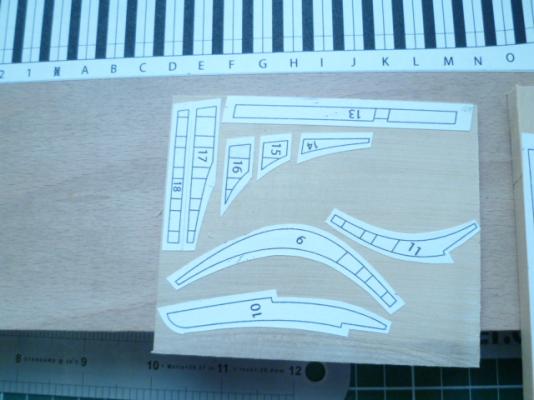

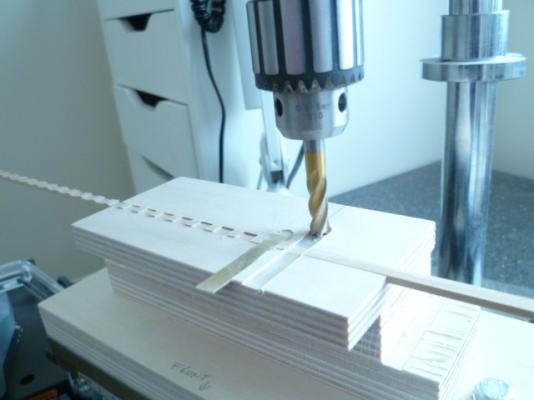

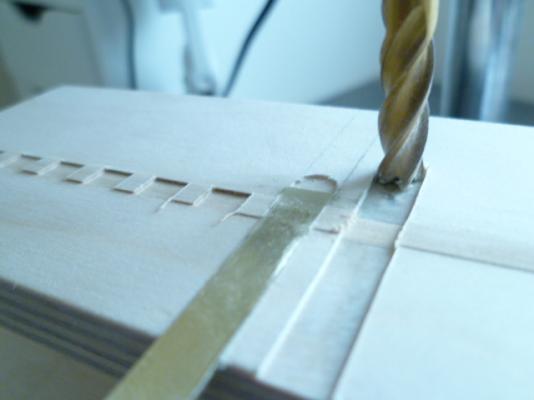

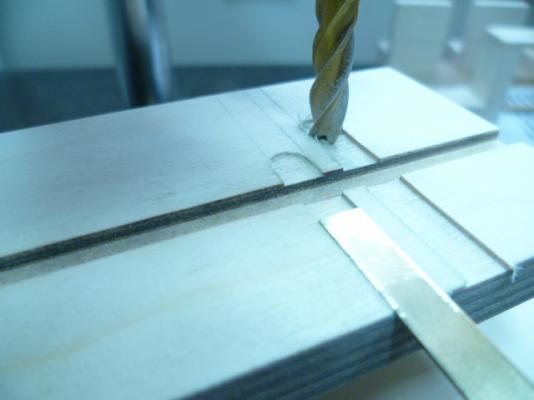

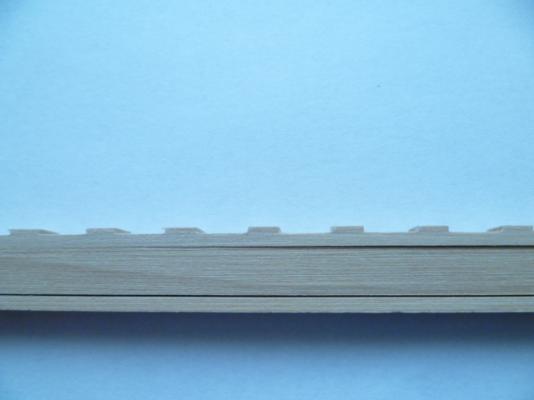

WASHINGTON GALLEY PART 1 HI ALL WOOD HAS FINALLY BEEN CUT. STARTED WITH BASIC KEEL COMPONENTS. MAIN KEEL CUT 3/16 WIDE BY 7/32 DEEP. FALSE KEEL 3/16 X 1/16. HOG 3/16 BY 3/32. ALL CUT FROM SHEET MATERIAL ON THE BYRNES SAW. I DECIDED TO DO THIS IN THREE SEPERATE PIECES AS IT WOULD BE EASIER TO PROFILE THE REBATE. THE HOG(?) HAS PROVED TO BE QUITE A TASKING PIECE TO MAKE ACCURATELY. THE PIECES IN THE PHOTOS ARE THE FOURTH ATTEMPT!!!! I ORIGINALLY ASSUMED THAT THE SPACE BETWEEN THE DOUBLE FRAMES,WHICH ARE 1FT THICK(SIDED) OR 1/4 INCH ON THE MODEL WOULD BE EQUAL TO 0NE FRAME THICKNESS OR 6INCHES IN REAL LIFE (1/8inch) ON THE MODEL.A QUICK MEASUREMENT LATE A NIGHT SEEMED TO CONFIRM THIS. WRONG!WRONG!WRONG!............MEASURE TWICE OR EVEN THRICE.......CUT ONCE! THE ACTUAL MEASUEMENT IS 9/16 ON AN INCH. IN ORDER TO CUT THIS ACCURATELY I HAD TO DEVISE A JIG FOR THE MILLING MACHINE ( SEE PHOTOS) BUILDING BOARD AND FRAME PLAN PREPARED AND ALMOST READY FOR USE. A FEW JIGS HAVE ALSO BEEN MADE FOR HELP IN FRAME ALIGNMENT....BUT THESE MAY HAVE TO BE REDONE AS THEY MAY BE ON THE CLUNKY SIDE. THATS ABOUT ALL FOR THE MOMENT.....BACK TO WORK WE GO CHEERS....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi carl wood has finally been cut!!! see next post cheers......mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Chuck Thanks for looking in. Currently doing some prep work.....building board , bow and stern support blocks etc. Will post some pictures of current progress asap. Haven't actually cut any wood for the model yet! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi David Hopefully! The only way we learn is by asking questions. Looking forward to my first full hull pof. Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl Sounds like fun......but you might not be capable of paddling back!!!! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl Only a quick hop across the channel for you.....nice couple of days in dear old blighty...maybe a trip to Chatham for theropery and model ship collectionand then on to timberline to pick up all that lovely hardwood.....just a thought! Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Christian It is somewhat different. I decided to have a go as it looks like an ideal subject for a first attempt at a full pof hull.....not too many awkward half and can't frames and some interesting stern framing.....also only one main deck and fairly simple rigging. Should be a nice contrast to the previously built sloop from 1776. Let's hope I can do it justice. Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi mike Yep its lovely stuff! Almost a shame to cut into it.must have been fully awake when I lookedat the plans! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Kurt No probs...must have been a rare occasion when I was actually awake when I looked at the plans and practicum!.....I have a feeling I will be asking quite a few more questions when I get to the more " funky" parts of the build. Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi mike Thanks for the reply. Let's hope I can do Jeff's plans and research justice. Itching to get started on my first full hull pof. Cheers....mick

- 175 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Kurt I will be going with chucks advice and placing the keel scarfs in the vertical plane...it makes sense to me and itwas common 18c practise. Looking forward to getting started! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi mike Very nice build...been following with great interest as I'm just about to start work on the same model. I have a couple of questions if you don't mind me asking! Firstly regarding the keel scarfs....as far as I understand 18c scarfs were cut in the vertical plane whilst Washington's seem to be cut in the horizontal plane? I'm assuming it's correct but just wanted some clarification as I don't want any historical boo boos. The second question relates to the room and space of the framing. Measuring directly from the plans the frames are 1/4inch (2x6 inchs in real life) and the space is 1/8 inch,again 6 inches in real life. This is consistent for the full length of the keel, including half frames and cants? I'm measuring to very slight desrepancys on the plans. Maybe due to the printing? Any help you can offer greatly appreciated. Nice work on those hawse timbers aswell....I shall be copying your method!!!! Cheers.....mick

- 175 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Dave Yep...can't wait to cut some timber. Gonna haveto get the next four nights back to grindstone out of the way first! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi all I forgot to mention it in the opening post. Regarding the keel scarfs....the plans and practicum show the scarf in the horizontal plane , I was under the impression,especially after looking through Goodwin,that 18c scarfs were cut in the vertical plane? Is this a peculiarity of colonial shipwrights? I'd hate to make a boo boo during the first piece of timber! Also are there any written references/text books concerning the building of colonial naval ships at or about this time,1776? Any help greatly appreciated! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

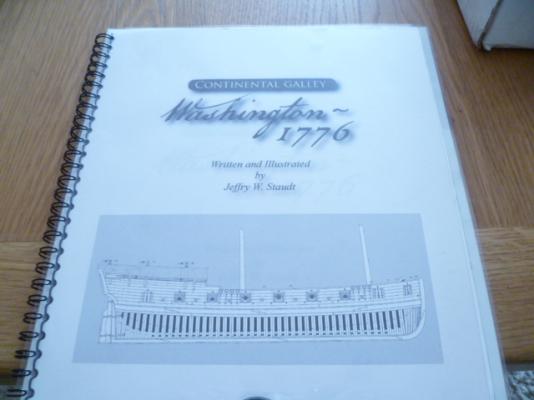

HI ALL I THOUGHT ID LAUNCH A NEW TOPIC TO RUN IN PARALELL WITH CHUCKS CUTTER CHEERFUL. PLANS HAVE BEEN PURCHASED AND STUDIED FROM THE NRG. PRACTICUM HAS BEEN DOWNLOADED.....I HAD THIS SPIRAL BOUND AT A LOCAL PRINT SHOP JUST TO KEEP EVERYTHING TOGETHER. BOXWOOD HAS BEEN ORDERED AND DELIVERED....IN 2 DAYS!!!!! I WAS ORIGINALLY GOING TO ORDER THE PRECUT PACKAGE FROM CROWN TIMBER.......HOWEVER WHILST I DO NOT DOUBT THE QUALITY OF JASONS PRODUCTS THE COST OF DELIVERY PLUS 20% VAT AND POST OFFICE HANDLING FEES WOULD HAVE PUSHED THE PRICE TO CLOSE ON £400. I USUALLY USE A COUPLE OF COMPANYS FOR TIMBER ONE BEING ARKOWOOD AND THE OTHER BEING TIMBERLINE IN KENT ,UK. I PHONED TIMBERLINE AND SPOKE TO BOB GIVING HIM A LIST OF REQUIREMENTS ( SCANTLING LIST IN BACK OF PRACTICUM) ALL IN IMPERIAL DIMENSIONS. THAT WAS YESTERDAY MORNING. AT LUNCHTIME TODAY TNT TURNED UP WITH A NICE BIG PARCEL. ALL BOXWOOD TIMBER PROCESSED TO THE RELAVANT THICKNESSES IE THE CLOSEST METRIC EQUIVALENT. THE 1/4 INCH THICK WORKS OUT AT 6.35MM.......AND IT IS!! THE SAME APPLIES TO ALL OTHER THICKNESSES. HOWS THAT FOR CUSTOMER SERVICE? I CAN HIGHLY RECOMMENDED BOB AND HIS TEAM HAVING DEALT WITH THEM FOR A NUMBER OF YEARS NOW. THE ONLY THING WORTH MENTIONING IS THAT YOU WILL HAVE TO PLANE A STRAIGHT EDGE ON SOME OF THE TIMBER SHEETS.....HOW HARD IS THAT FOR A MODELMAKER?....AS THE SHEETS ARE CUT FROM A FAIRLY ROUGH SAWN BILLET. I DIDNT ORDER ANY 1/16 AS IALREADY HAD SOME ON STOCK. THE 1/32 IS MAINLY FOR DECK PLANKING FOR WHICH I INTEND TO USE SOME ENGLISH HOLLY. AND THE PRICE FOR ALL THAT LOVELY BOXWOOD (IN 1METRE LENGTHS) ? INCLUDING VAT AND DELIVERY IT CAME TOO £164 A SIGNIFICANT SAVING FOR ME. BUILDING BOARD HAS BEEN PREPARED SO I GUESS WERE READY TO START. BUT FIRST FOUR NIGHT SHIFTS HAVE TO BE GOT OUT OF THE WAY! CHEERS............MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

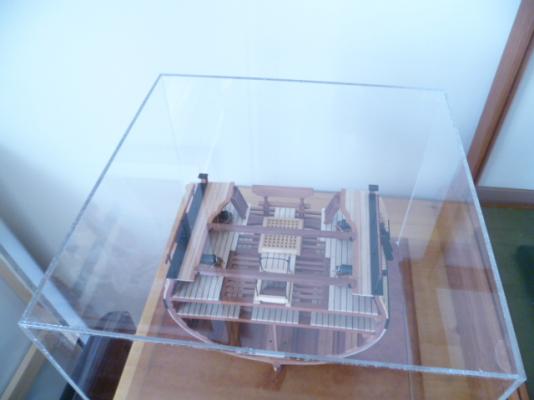

hi all hms triton cross section is now finished! i havnt rigged the training tackles. i like the model in its simple uncluttered form. the relieving tackles were never going to be fitted as ive left the deck planks off to help show the deck construction.....this was a contributing factor in not fitting the rest of the tackles. i have however fitted the stanchions and rails around the hatchway.....pretty much a direct lift from the swan class practicum. once again thanks to all the staff and moderators whose work in preparing the plans made my humble attempt even possible! final photos enclosed. cheers....mick p.s. excuse the junk in the final photo.old flatscreen awaiting collection by a fella who i work with!

-

ancre La Belle 1684 by Nenseth - 1:36 scale

yamsterman replied to Nenseth's topic in - Build logs for subjects built 1501 - 1750

hi hans christian great work so far.i shall be following very closely as this ship is on my "to do" list. look forward to your progress. cheers.............mick

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.