yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

Papegojan 1627 by mati - FINISHED - 1/48

yamsterman replied to mati's topic in - Build logs for subjects built 1501 - 1750

Hi Mark Great work so far. Your lion figurehead is a joy to behold! Just a small amount of pear wood! I wish I could get that over here in england! Do you think your supplier would ship? Cheers.....mick -

Hi cnemo I purchased my plywood from an aircraft model specialist in Blackburn,UK. It was quoted as being exactly 1/4inch thick or 6.35mm and after putting a vernier quage at various points was as near as it needs to be. Sometimes 1/4 inch is mixed up with metric 6mm. It was also qoutee as being laser cutting quality. I was pretty impressed with thickness and flatness and I only found one small void whilst cutting out the bulkheads. Cheers....mick

- 25 replies

-

Hi chuck Thanks for the likes. I will more than likely be ordering the rigging material from you. Thanks for the offer with the laser cutting but I'm trying to make this as scratch built as possible! I will even have a go at making the blocks. Armament I had to order from you along with the plans as I'm between lathes at the moment. Looking forward to part three.....if I can get my planking half as good as yours I shall be well pleased. Finally just a thank you for all your hard work in making the plans and fittings available as well as taking the time to write a practicum. Cheers....mick

- 25 replies

-

Hi cnemo Chucks dimensions are in inch's which I will try and follow. However most of the timber I buy is in mm .so it can be a pain trying to reconcile the two....usually ends up in a fair amount of planing and sanding! Cheers.....mick

- 25 replies

-

Hi Patrick Thanks! Took some doing by hand I must get round to buying a scroll saw! Been itching to do this since chuck announced it on his website.let's hope I can do it justice! Cheers....mick

- 25 replies

-

HI PATRICK JUST CATCHING UP WITH YOUR LATEST MICROSCOPIC MARVEL. I AM GOING TO HAVE TO LEARN A NEW LANGUAGE THAT HAS MORE SUPERLATIVES IN IT THAN ENGLISH....QUITE FRANKLY IVE RUN OUT!!!!! TREMENDOUS STUFF!! I STILL DONT KNOW HOW YOU DO IT! CHEERS.....MICK

-

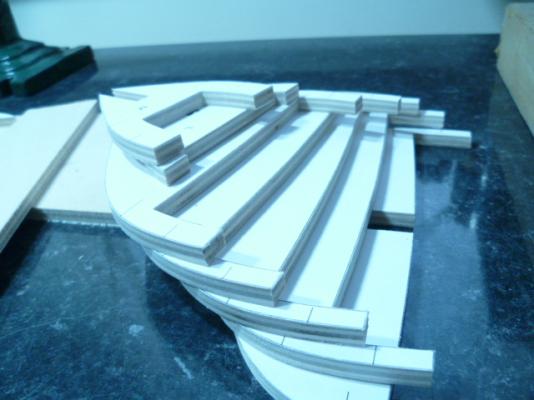

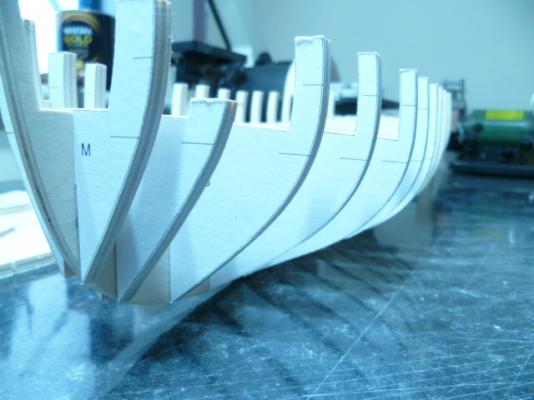

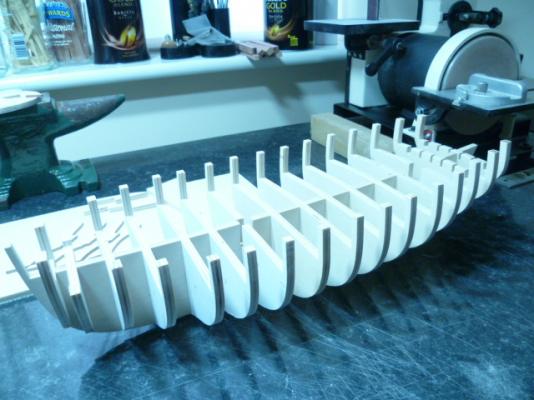

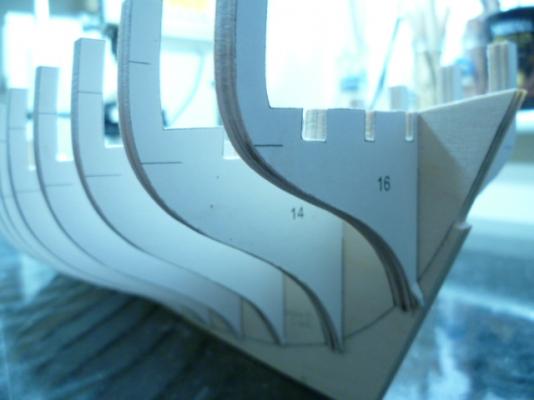

HI ALL TIME FOR THE FUN TO START. PURCHASED CHUCKS PLANS AND TURNED BRASS CARRONADES/CANNON JUST AFTER CHRISTMAS. USUAL EXCELLENT QUALITY SERVICE FROM CHUCK. HAVE DECIDED TO FOLLOW ALONG WITH CHUCKS BUILD BUT I DOUBT IF I CAN COMPARE WITH THE MASTER!!! BUILD SEQUENCE WILL BASICALLY FOLLOW CHUCKS POSTS . HOWEVER INSTEAD OF USING CASTELLO BOX I WILL BE USING SWISS PEAR AND EBONY FOR ANYTHING PAINTED BLACK IE WALES ,BULWARK CAPPING ETC. I MAY EVEN USE SOME PINK IVORY FOR SOME STRUCTURES THAT WOULD HAVE BEEN PAINTED RED OCHRE, BUT THAT MAY CHANGE AS MY LAST EXPERIMENTS WITH PINK IVORY WERE NOT VERY SUCCESSFUL. WORK HAS ALREADY STARTED ON BASIC COMPONENTS, HAVING PHOTOCOPIED THE RELAVANT BITS OF THE PLANS ( SORRY CHUCK I KNOW YOUR PLANS SAY NO COPYING BUT ITS PURELY FOR MY OWN USE AND I COUNDNT BRING MYSELF TO CUT INTO THE PLANS!!) THEY WERE PASTED ONTO 1/4 BIRCH PLY AND CUT OUT. BEARING IN MIND I DONT OWN A SCROLL SAW AND IF I DID IT WOULD HAVE TO LIVE IN THE GARAGE,TOO COLD TO WORK OUT THERE THIS TIME OF YEAR!,THE COMPONENTS WERE ROUGHED OUT WITH A 10 INCH BAND SAW AND THEN SANDED/FILED TO SHAPE. THE ENCLOSED PHOTOS SHOULD SHOW CURRENT PROGRESS. WORK WONT COMMENCE UNTIL IVE FINISHED THE TRITON CROSS SECTION, I DONT HAVE THE SPACE UNFORTUNATELY FOR TWO CON CURRENT BUILDS. CHEERS.......MICK

- 25 replies

-

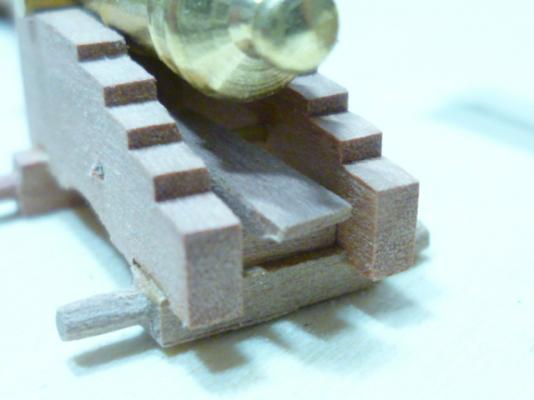

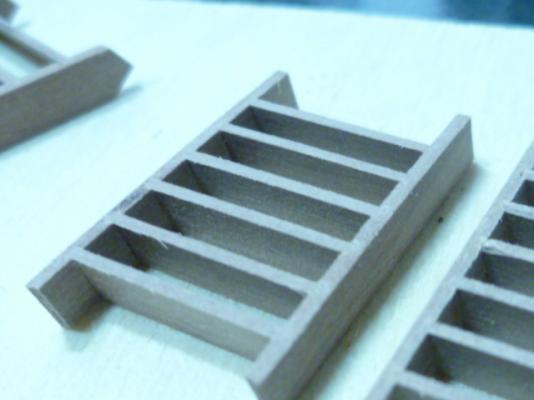

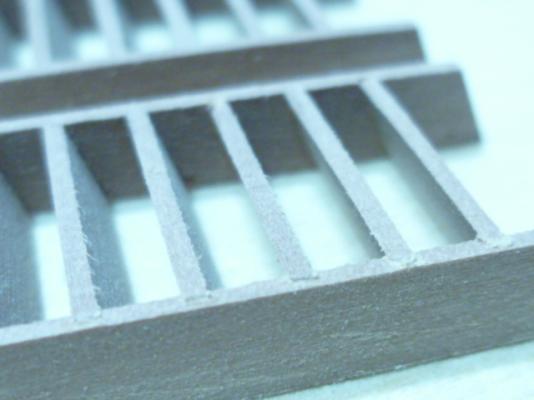

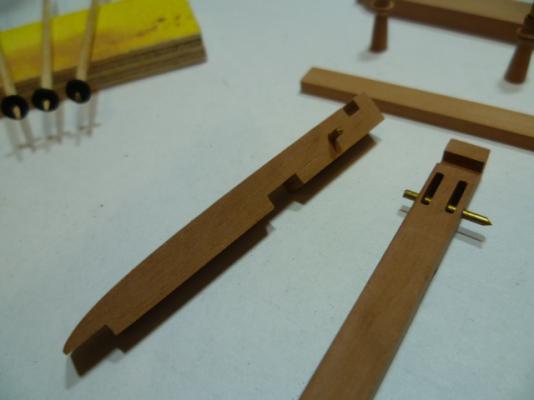

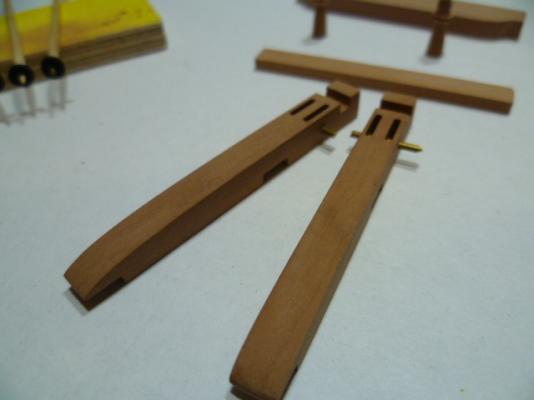

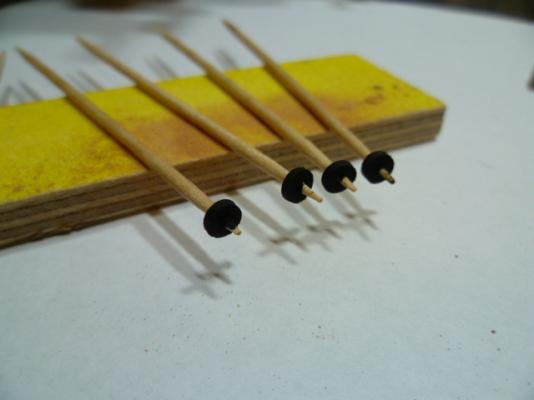

hi all just a small update on tritons progress. been waiting for some chakte kok timber to turn up so i can progress the gun carriages. its finally arrived some work can commence. decided to put my small mill/drill though its paces and make the ladders from 1mm pear. gun brackets and various other components from chakte kok. now the fun starts with all those tiny little bits and pieces!!! photos enclosed. whilst i was waiting for various bits and pieces decided to crack on with some preliminary work on the next project. a new post has been started under scratchbuilt pob 1/48 scale..............? cheers for now mick p.s. cannon barrels from rb models in poland.still havnt got round to buying a new lathe yet!

-

hi daniel nice work on those stern timbers. i echo the sentiments with regards to the draw plate.pull from the non counter sunk side.go through each hole a couple of times or maybe more before moving to the next smaller hole.steady as she goes is the order of the day. so far with a byrnes plate ive managed to get pear down to 0.4 mm in quite long lengths.all the best cheers......mick

-

Hi Daniel Many thanks! Its coming along slowly! Just working on the canons but have run out of red heart. Waiting for the delivery to arrive.once thearmaments done we can start putting everything together. Still watching your progress with the full hull.........will get there someday I hope! Cheers.....mick

-

Hi Richard I used to use jewelers pickle,10% hydrochloric acid,if I remember rightly to clean up parts, brass and copper after soldering. I tend to use ordinary domestic malt vinegar now.....its still a 10% acid solution and does the same job.seemsto work.....no problems up to yet! Prior to soldering I would use iospropanol,acetone or even good old m.e.kto clean the parts.make sure you wash it of before soldering! Clean the areas to be soldered with a scratch brush and away you go. Cheers......mick

-

Anybody built these kits - moved by moderator

yamsterman replied to latestarter's topic in Wood ship model kits

Hi have built several caldercraft kits over the years.....sherbourne,balahoo,hatch HMS snake. Quality of the kits is above average fittings are generally excellent plans are usually very good but the actual instructions are pretty basic.I think along with a lot of European manufacturers that the builder already has some degree of prior knowledge.laser cutting has been replaced by CNC routing which is just as accurate and no laser char to remove. I would have to say by comparison model shipways instructions areprobably the best in the business. Cheers.....mick -

hi all just a quick update to show current progress. pretty much finished with the majority of the woodworking just got to make the various ladders and gun carriages. ordered some brass canons from rb models in poland as ive just got rid of my cheap chinese made lathe. considering purchasing a peatol/taig , reviews seem good, any thoughts? metal work for the gangboard supports , stanchions for entry ropes and stanchions for gangboard rails are made and blackened but not overly happy with the blackening process so they will be cleaned off and redone. cheers.....mick

-

Hi omega Awesome stuff!!! I wonder what's next? Belated merry Christmas and happy new year. Cheers....mick

- 120 replies

-

- mystic

- motor yacht

-

(and 2 more)

Tagged with:

-

Hi kees Looking good already! I shall be following along with great interest. Always wondered how vac forming was done properly......always worth a YES!!!!!!! When everything goes to plan! P.s I still haven't done that explanation of how I made the case for the sloop but I haven't forgotten! Hope your health stays good Festive greetings Cheers.....mick

- 205 replies

-

- kw49 antje

- trawler

-

(and 1 more)

Tagged with:

-

Hi omega Wonderful stuff,just keeps getting better and better! How about some oars and thole pins for the dingy? No cheating with photo etch!!!!!!! Festive greetings Cheers.......mick

- 120 replies

-

- mystic

- motor yacht

-

(and 2 more)

Tagged with:

-

hi hexnut thanks for the likes its appreciated. cheers and festive greetings........mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

-

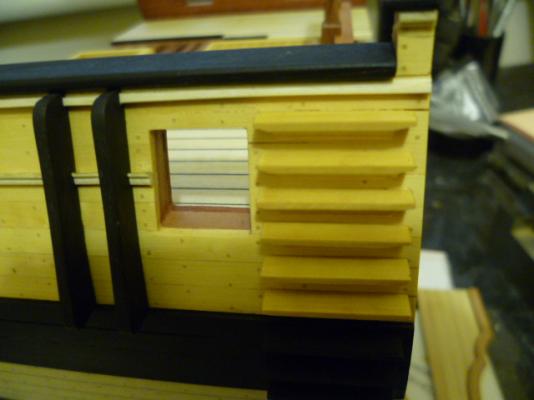

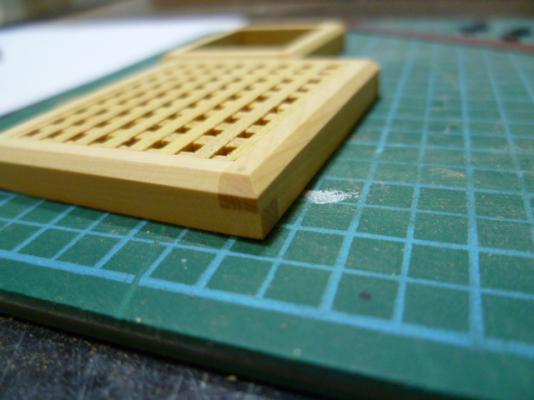

hi all been beavering away,inbetween getting the sloop finished, and have managed to get some more done on the cross section. external planking above the whale completed in pyrenean boxwood , treenials in castello box. internal bulwarks planking also done in satine bloodwood. treenails in pear. i was going to use pink ivory but the darn stuff has so much interlocked and wavy grain its bloomin difficult to thickness by hand , no matter how sharp the plane. i think im trying to justify buying jims thickness sander!!!! currently in the process of cutting some holly for the external planking below the whale. bits built ready to be installed. deck hatches built and gratings fitted. any and all comments welcome!!!!!!! p.s. the last photo shows what happens if you dont think ahead.having glued everthing together feeling quite pleased with myself it came time to trial fit the bits............doh!!!.......wheres the isopropanol!!

-

Hi omega Many thanks. I was looking for something appropriate for the subject and I found the map from a chap in the north west of the us.....only 7 days to deliver to the UK......well pleased! Still following your motor launch.....and now you've gone to the truly microscopic and made a 2cm dingy in wood! Well impressed!!!!!!! Problem is I'm running out of space.....I may have to consider going down to 1/96 scale. Merry Christmas and a happy new year for 2015. Cheers....mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

-

Hi matija Many thanks .been a longtime in the making and am pretty pleased with the result.......but always looking for improvement! Cheers.....mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.