yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

Hi Pete Many thanks for the compliments. Been an interesting and at times challenging project.......always aspired to a proper plank on frame build ever since I read Peter danks hms mrymidon articles in model boats magazine many years ago. Never thought I'd ever get there but.....steady as she goes! The next project along with chucks cutter cheerful will be.......... The Washington galley courtesy of the nrg , currently studying the plans and practicum and waiting for my boxwood to arrive. Looking forward to a fully framed build Cheers....mick

-

Hi Kevin Thanks for following along! It's been an interesting experience as an introduction to p.o.f. building.......I think I'm hooked and the dark side cometh! Thanks have to go to all the staff/moderators who did the primary research and drew up the plans and made them available on the forum. I recommend the project to any body with a couple of kits under their belt. Next up is a fully framed hull with all those lovely frames and cants! Cheers....mick

-

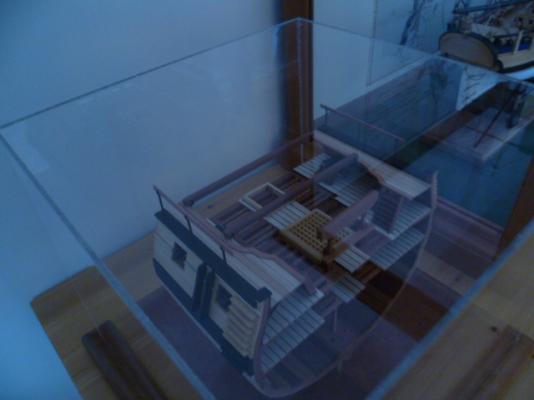

Hi Carl Once the training tackles are made up and the stanchions for the hatchway I will take some final photos for the gallery...in natural daylight not at 11o clock at night hopefully there won't be any blue tints. Most=mdf. Predictive texton my tablet.....I will work out how to turn it offone day! Cheers.....mick

-

Hi Carl Thank you!its been a labour of love.....you're right about the blueish tint...strange that...looks crystal clear in daylight. I didn't make the acrylic case I brought it from an online supplier,but not the usual company I use.....mainly because it was half the normal price! Maybe they use a slightly different acrylic....or it could be me half asleep taking photos! I did make the base....most core with cherry veneered quadrantmoulding and a bit of madronna burr for the base. Cheers.....mick

-

Hi Patrick A microscopic boat inside a miniature model? I think mark summed it up in the last post! Outstanding stuff! I think I will just go an hide in the corner! Cheers....mick

-

Hi Nils Thanks for sharing this build log. Obviously a poignant subject for yourself with the tragic family connection. But a beautifully executed model , the metal workingis superb as is the hull construction and realistic plating. This is the self adhesive aluminium foil that you referred to i n your current log......what's it normally used for? I take its not specifically designed for us ship modelmakers! Shall be following your current log closely Cheers....mick

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

hi nils looking good! very sharp lines looks like atrue thoroughbred.waiting with bated breath for the start of the metal plating. will you be using aluminium litho plates ? i know its quite a common building material for some a our "grey" warship modelling colleagues. following with great anticipation. cheers....mick

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

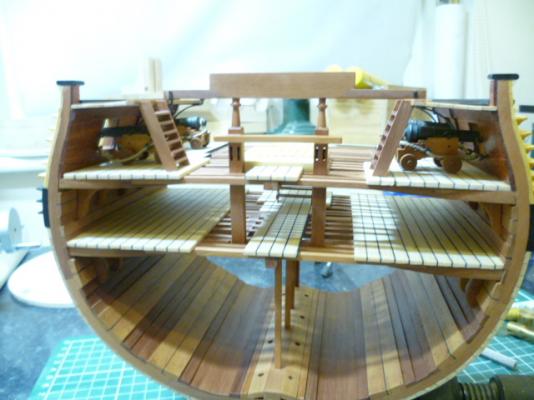

Hi mark It may be that even making the breeching ropes 3x the length of the bore I should perhaps have added even more than I did to allow for the turn around the cascabel and the loop and seizing around the ring bolt. A couple look slightly shorter than the rest. Problem is I've glued the ring bolts in with epoxy resin and the trucks are spot glued to the deck with the same.I don't want too damage anything taking it apart so I may have to leave things as they are and putvit down to experience.....it can join the growing list of things to do better on the next build. Constructive criticism and advice is always welcome....I think I will beneeding plenty when I get round to doing a full hull build! Cheers......mick

-

Hi mark I made the breeching rope three times the length of the bore of the gun as per info in swan class practicum. The guns are positioned almost behind the gun port. Still reckon it needs a few extra mm to get to its proper length? No worries there's a couple of other things that need to be redone aswell! Thanks for the heads up Cheers.....mick

-

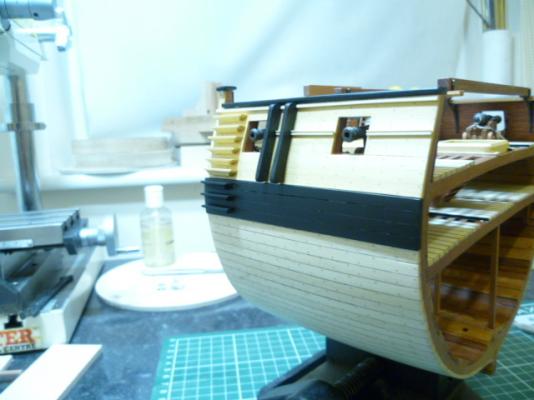

hi all its about time i did some more work on the cross section. armament and breeching ropes completed. ring bolts in place for training tackles. gangboards in place and brackets for skid beams. now the problems. i was unhappy with the stropping on the training tackles so have discombobulated the lot and will start again. should be enough room to get them in! the other two pairs of brackets dont fit! rather than mess about with them i will remake them. apart from the gangboard railings and turning some pedastals down from brass were nearly there. photos of current progress attached. cheers for now.........mick

-

Hi Mr Delacroix Have just received my copy of le rochefort. Beautifully drawn plans and the monograph will be of great help especially with the 3d drawings. Goes a very long way in explaining the relationship between the various timbers. I look forward to making a start in the near future......just triton cross section and chucks cutter cheerful to do first! Merci !!!! Cheers....mick

-

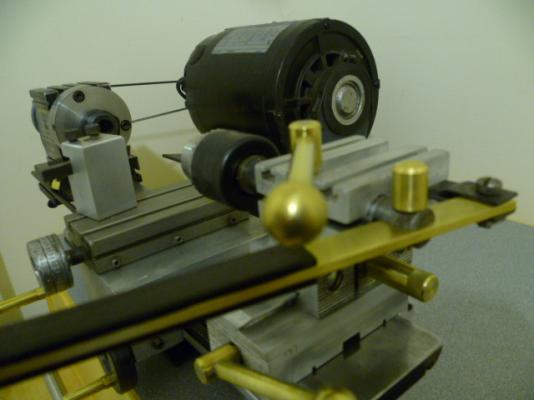

Hi Tony No worries about diverting the thread! The peatol is in imperial but the collets I'm using are metric!I tend to measure in metric units these daysbut will use imperial if necessary. The lathes from arc are all set machines.I have there miniature mill/drill and compound table which I can't fault. However I did have their co baby lathe which I was less than happy with. The larger lathes may be better. Personally I would prefer to buy UK/us its significantly better made and any electronics are far superior. But its down to personal choice as UK and US machines are significantly more expensive.......but you gets what you pay for! Cheers....mick

-

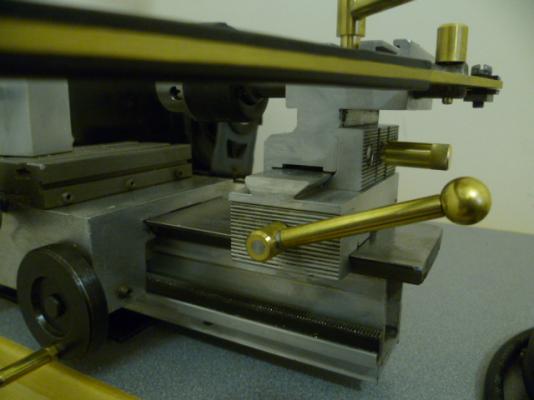

Hi Tony Lathe is a peatol or taig if you're in the US. I managed to find one on eBay in reasonable condition for £135. Unfortunately all the extras have to be brought separately. The one thing I didn't like was the three jaw soft aluminium Chuck supplied. Arc eurotrade sell a nice little er16 collet Chuck and collets which is what I shall use for the majority of my turning. However er16 only go up to 10mm . arc also sell a four jaw self centring Chuck and back plate which I shall get asap. Various locking points are provided but are 10-32 unf bolts......soon got fed up of reaching for an Allen key so devised some locking handles in brass using a longer unf bolt as the foundation. Overall I'm quite impressed with the machine....for smaller scale work its ideal...its also whisper quiet. I would recommend it but be prepared to make a few modifications! Cheers.....mick

-

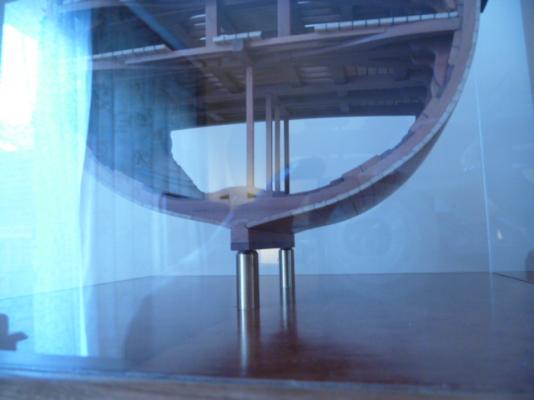

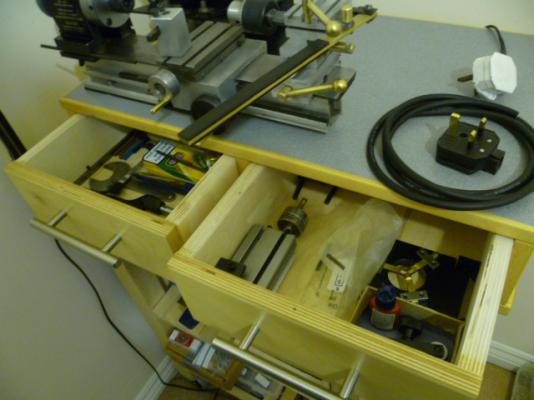

hi all been a little busy of late on other non ship building projects. however have managed to do a few bits and pieces. the display case for triton has been built. i just need to turn down two support columns from brass. i have a pile of bits ready to go on the basic hull form. been diverted by making a new base and some new locking handles for a recently purchased lathe. cheers for now mick.

-

Been there ...done that nils. Always tricky holding multiple parts for soldering. I recently invested in a couple of jewelers ceramic boards.....the ones with lots of holes in and some appropriately sized tapered steel pins. I may yet get some carbon wire as well . definite help withtricky soldering jobs. Cheers....mick

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi nils Lovely stuff! Beautiful rendition in brass...fiddly too! You and Johann must have had the same metal work teacher! Looking forward to lots more. Cheers....mick

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi all More off topic comments so I will keep it brief. I believe your lovely guilotene dates back to the days of letterpress printing......specifically for cutting muttons and ends In the compositors workshop these would have been used to space out the text so that it could be tightly fitted into a frame. Nice alternative use for an old piece of kit! Back on subject ...nice anchor stock deck planking. I shall be following avidly. Cheers....mick

-

Hi I an Try timberline in kent. Ring them and tell them what your doing and they can probably source some suitable timber from their box making dept. Another company I have used is original marquetry .co.UK. They sell a range of saw cut veneers including box butit tends to be either 3mm or 1.5 mm in thickness. Hope this helps Cheers......mick

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.