yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

Hi mark Thanks for the kind remarks. I was thinking of doing a 1/48scale POB model of either HMS cruiser or HMS wolf. Plenty of information available via Ron McCarthy's book and in mcllaughlans recent book sloop of war. I've also just brought the shipyard set of plans for HMS wolf. So altold plenty of information available and I do like these smaller workhorses. Have got the space for a three decker!!! Cheers....mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

-

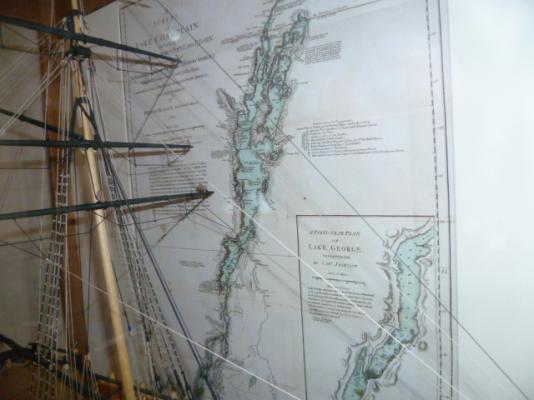

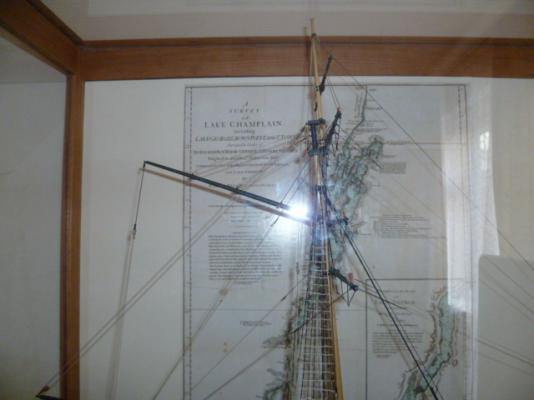

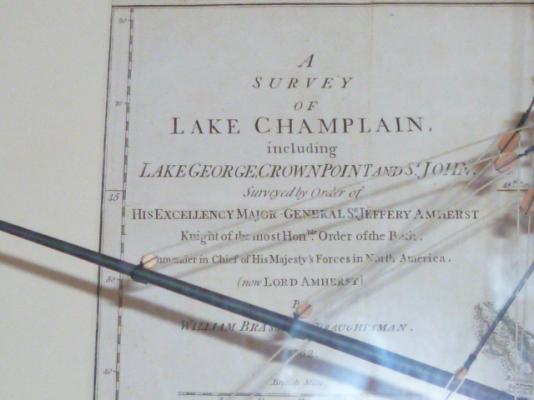

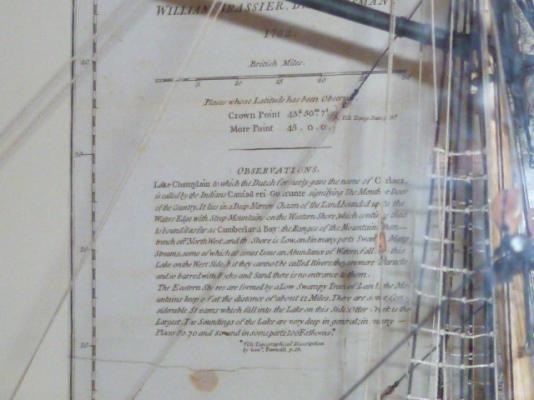

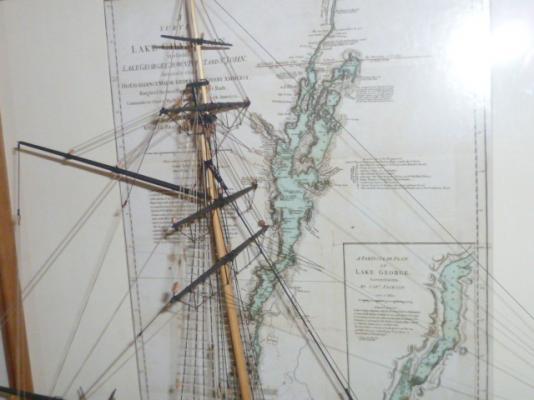

hi all finally managed to get the backboard finished for the display case. should be an appropriate piece of artwork considering the model subject!!! im now going to consider this project finished. been a very enjoyable exercise.......looking forward to the next one. cheers......mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

-

Hi medic Here in dear old blighty we have a choice of two regular magazines , model boats and marine modeling. Unfortunately they don't really cover period ship modeling thatwell,you get the occasional article , but most stuff appears to be rc and semiscale stuff. Not sure how available they are down under. You could always try eBay and buy some back issues of model shipwright ( back in the day it was a quarterly publication) they seem to be readily available and are full of really informative articles. Cheers.....mick

-

Hi rob Thanks for the vote of confidence! This is my first attempt at building even part of a ship using this method. For many years I've studied the work of some serious craftsmen thinking I will never be able to do that! The one thing about this site is its full of very helpful guys and gals only too willing to lend a hand.im fairly pleased with the way things are turning out,its just a matter of taking plenty of time,studying those plans carefully and plodding on! Of course it wouldn't even have been possible without the hard work of the guys who developed the plans for us! Cheers....mick

-

Hi omega Out with the magnifying glass again!!!! Looking good , enjoyed following your ingomar log, but this is even smaller!! Cheers.....(somewhat boggle eyed!) .......mick

- 120 replies

-

- mystic

- motor yacht

-

(and 2 more)

Tagged with:

-

ancre Le Coureur 1776 by obi - 1:48 - lugger

yamsterman replied to obi's topic in - Build logs for subjects built 1751 - 1800

Hi Robert Beautiful work! I assume that the inspiration for this model came from theancre monograph? Could you explain how you achieved your clinker planking? Stunning result! Not sure what samba translates to in English? Cheers....mick -

Hi juergen Thank you again! Still have an awful lot to learn especially with regards to interpreting and working from lines plans. Currently trying to get my head around a line drawing of HMS cruiser from the nmm. Good job of got a plentiful supply of drawing paper I think there will be a lot of waste! Looking forward to further updates on your triton, I shall be watching with great interest. Cheers ......mick

-

Hi all I've just purchased a copy of said programmer. But I have absolutely no experience of using a cad program....where do I start? My ultimate aim is to translate a copy of the nmm plan for HMS cruiser into the program so I can plot and print out every single square and can't frame , plus all the other relevant timbers. Some serious help is required as I am a total beginner at this. Any ideas? Cheers.....mick

-

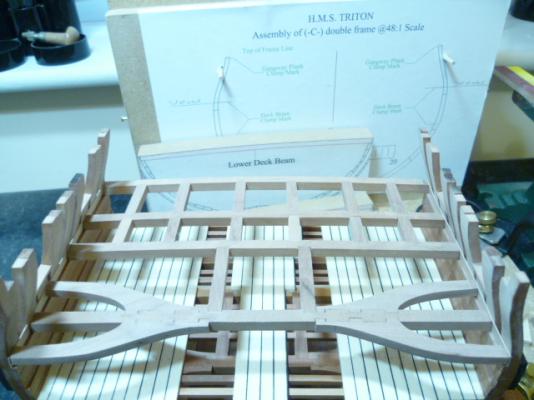

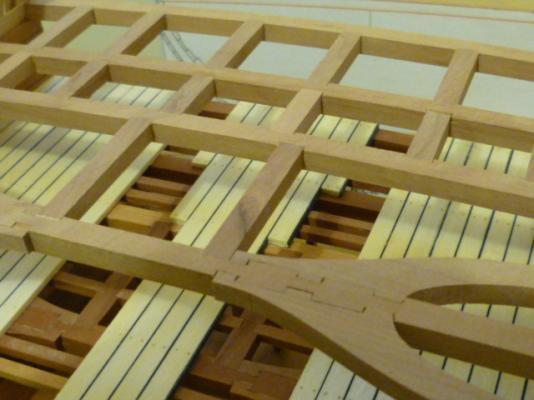

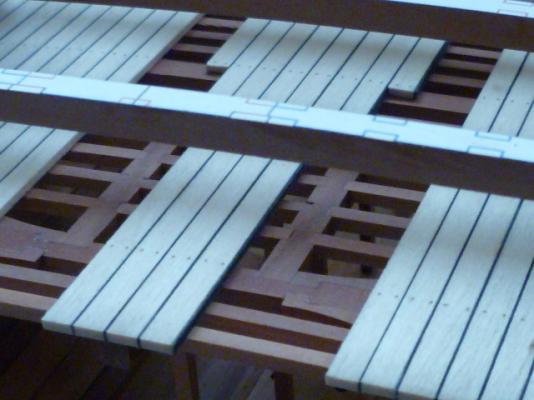

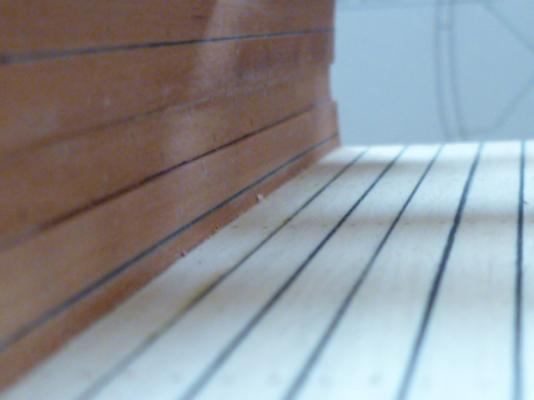

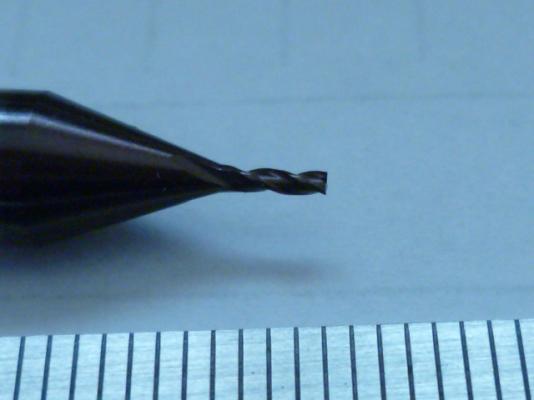

hi all its about time for an update on the cross section progress. unfortunately i got carried away with unbridled enthusiasm and forgot to take any photos of the completed lower deck. however some of the work can still be seen, as ive left some deliberate gaps in the planking. photos show current state of play , just about to start the gun deck , and this time i will remember to take some photos! been busy this morning cutting up some holly and boxwood. also purchased a couple of 1mm 3 flute milling cutters. i will need these when i get round to making the ladders, plus they will come in useful generally! might just get some in 1.5,2 2.5 and 3mm to cover a few eventualitys thats all for now folks cheers....mick

-

hi all the glazing has now been installed in the case and the back panel temporarily placed in position. im waiting for a particular item to be delivered from across the pond in order to complete the back panel......all will be revealed in good time. since ive got a few days off i shall take some construction photos of the case construction, esp for kees as he asked , but it may be of interest generally. cheers for now.....mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

-

Hi kees Very , very impressive! Looks like she's just done a winters fishing in the north Atlantic! P.s. I will get round to taking some photos of the case construction for you, I haven't forgotten! Cheers.....mick

-

Hi chuck Looking good....as usual! Guess I'm going to have to wait a little longer for the plans but looking forward to your practicum on the rest of the hull build. Don't have access to a laser cutter or scroll saw so will be cutting the frames by hand! I plan to build j boudroits le cerf 1779-80 at some point which is clinker planked and French, so a carvel planked English cutter should be an interesting contrast. Cheers....mick

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi need Yes mate entirely made by myself. I was browsing in my local timber yard and came across some 20mm by 45mm cherry in1600mm lengths for £4 per length........bargain! Its difficult to describe in words how it was made, but basically all grooves were routed 6mm wide and deep centered on each length. All timber was left in the original dimensions as purchased and just cut to the relevant lengths. When I get time next week I will take some photos of the construction process and post them on this blog. Cheers....mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

-

Hi mark Not too shabby for a self taught woodworker! I wish the glass was an invisible price! Decided togo for 5mm acrylic instead with an acrylic mirror back. Should be delivered next week. Cheers...mick

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.