yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

hi Patrick tricky is probably the politest word I could use! hawse timbers are now complete...see next post.....and my hands ache from holding relatively small...for me,positively gigantic for you Patrick! , components in order to rasp and scrape into shape. time for a rest......if it wasn't so grey an "orrrible" I could tell if the sun was over the yardarm yet......time for a livener......maybe a bit later on reflection! cheers......mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

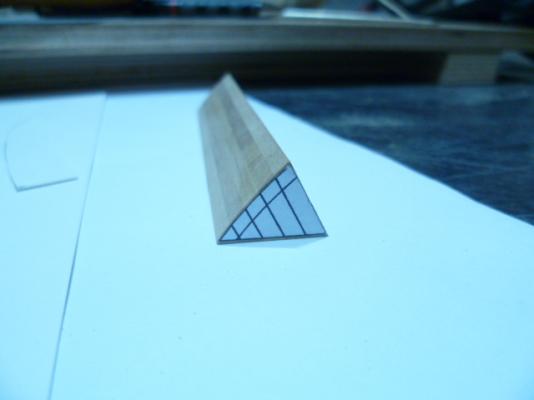

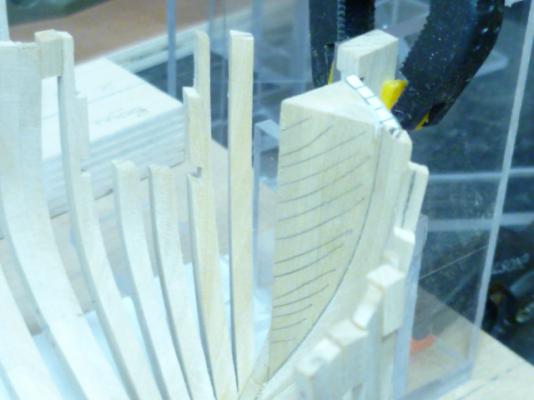

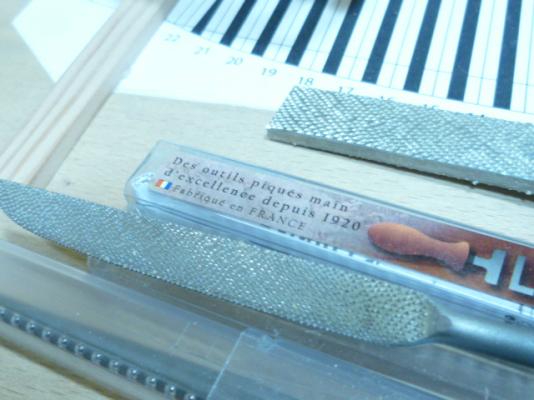

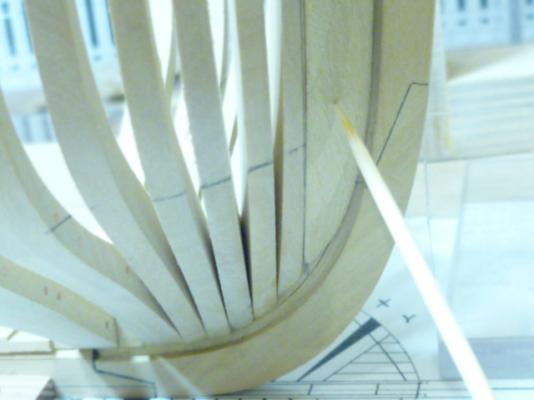

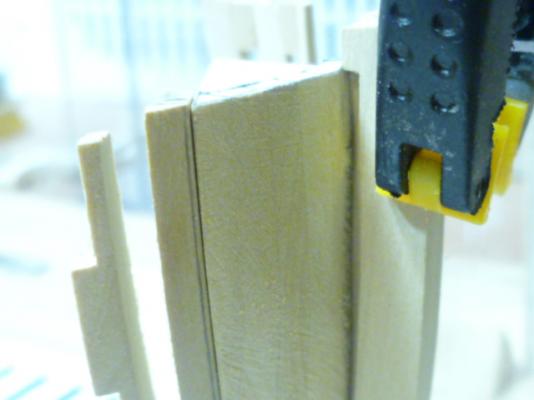

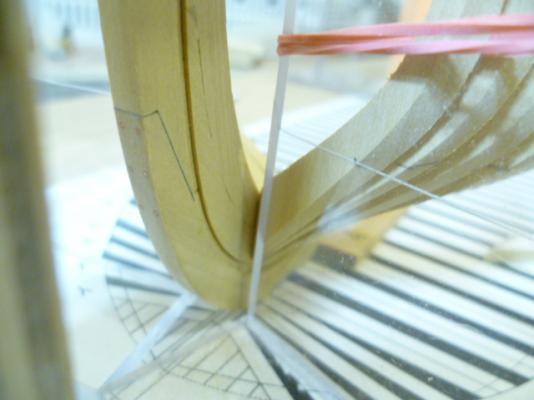

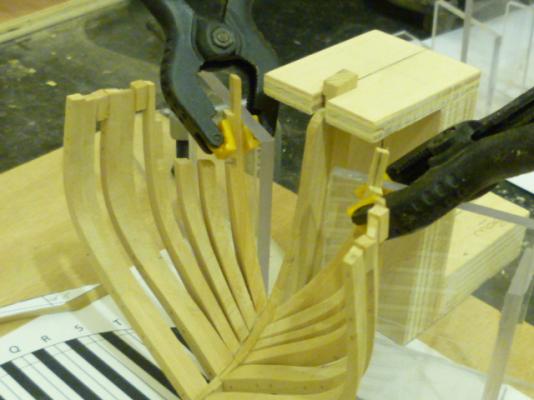

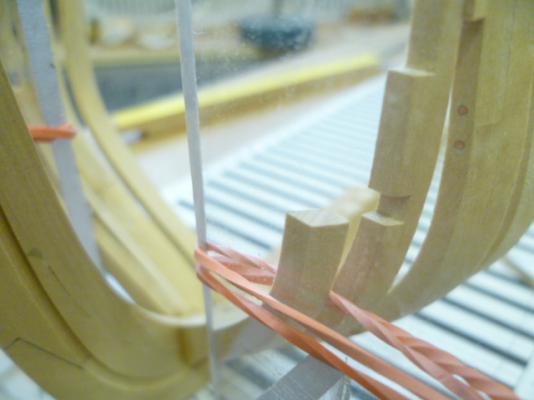

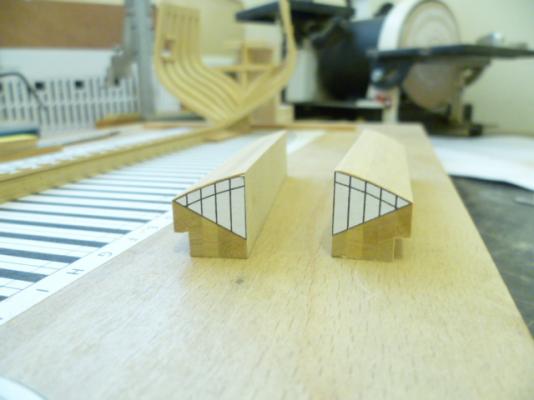

HI ALL NOW THAT THE FORWARD CANT FRAMES ARE ALL IN ITS TIME TO START THE DREADED HAWSE PEICES. THE LAMINATED BLOCKS FOR THESE WERE MADE UP PREVIOUSLY FROM SOME 1/8 INCH STOCK SOMEWHAT OVERSIZE MAINLY SO ID GOT SOMETHING TO HANG ON TO WHISLT I SHAPED THEM. THE BLOCKS WERE SHAPED TO THE PLANVIEW OVER THER ENTIRE LENGTH FIRST. A CARD STOCK PROFILE OF THE STEM REBATE...AFTER EDGE...WAS THEN MADE AND USED TO MARK OUT FOR THE FIRST SHAPING CUT WITH A JEWELLERS SAW. THE STEM PROFILE HAS BEEN TWEAKED WITH SOME RIFLER FILES UNTIL ITS ABOUT RIGHT....FINAL FINISHING WILL COME LATER WHEN THE HULL IS FAIRED. THE ANGLE OF THE BLOCK MATCHES NICELY WITH THE ANGLE BETWEEN THE FORWARD FACE OF THE FINAL CANT FRAME AND THE STEM DEADWOOD SO HOPEFULLY IVE DONE SOMETHING RIGHT!!!! THE NEXT PROFILE CUT WAS AGAINST THE FORWARD FACE OTF THE LAST CANT FRAME AGAIN WITH A JEWELLERS SAW AND FINISHED WITH RASPS. SOME MORE SMOOTHING OF THE OUTSIDE FACES IS NEEDED AND SOME FINAL FETTLING OF THE EDGE THAT MATES UP WITH THE STEM REABTE. THE NEXT AWKWARD BIT IS PROFILIG THE INSIDE FACE......AND THEN REPEATING FOR THE OTHER SIDE. HOPE THIS ALL MAKES SENSE!! PHOTOS ENCLOSED ALL COMMENTS MOST WELCOME. CHEERS FOR NOW......MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi Christian a project for the very near future.......ive ordered the cd of plans for the echo cross section as a taster first......a bit more practice making frames and components wont hurt before I commit to a full hull build of that scale. cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi christian your english is fine and perfectly understandable.......i wish my schoolboy german was up to the same standard! i do have the seawatch practicum and plans for swan class (hms echo ) and also for hms euryalus.....these are high on my priority list for p.o.f construction. there are several monographs from jean boudroit at ancre which are also clamouring for my attention i think it will eventually be a case of stuff the lack of space im going to build them anyway and i will worry about where to put them at a later date! lifes to short to spend too much time cogitating.....i need too build!!!!! cheeers for now.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi bob 1/48 would have been cool! trouble is youd need a mansion to display it! id love to do a first or 2nd rate in 1/48 but just dont have the space. look forward to following your build log......best of luck with the build. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

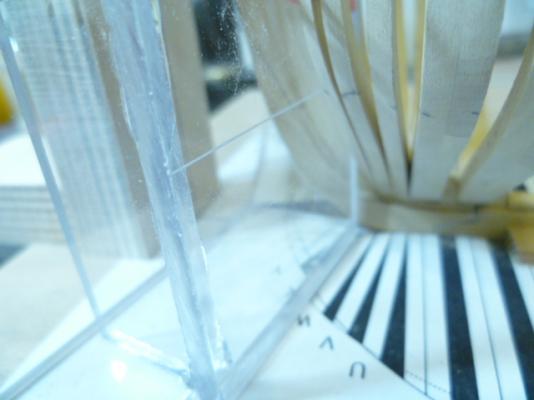

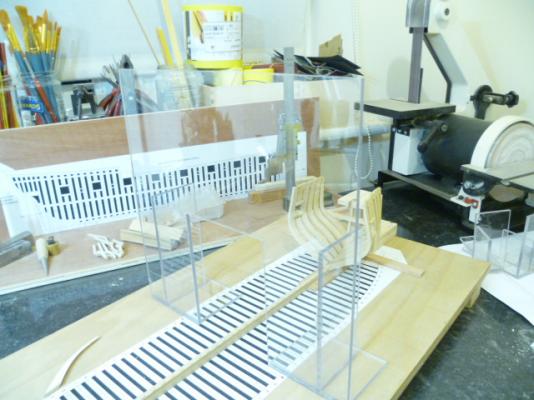

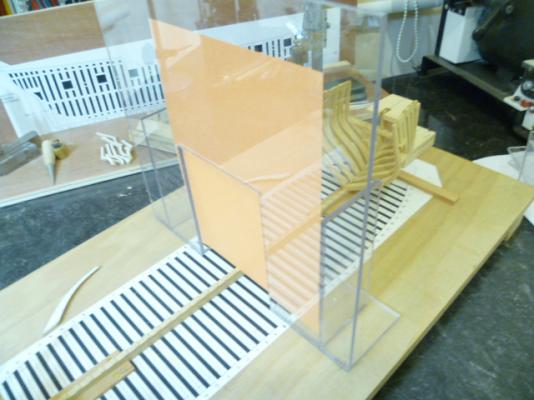

hi bob the acrylic was a bit of lateral thinking...I too was having trouble lining up my marks....the original ply jigs were too "clunky"......I will be sticking too acrylic in future! look forward to your build of edt s extreme clipper....1/96 or 1/72 scale? great thing about this forum is theres so many highly skilled guys and gals on here its the best resource on the planet! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi carl the "colander effect" is well known to me.....age related i think!!!!! cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

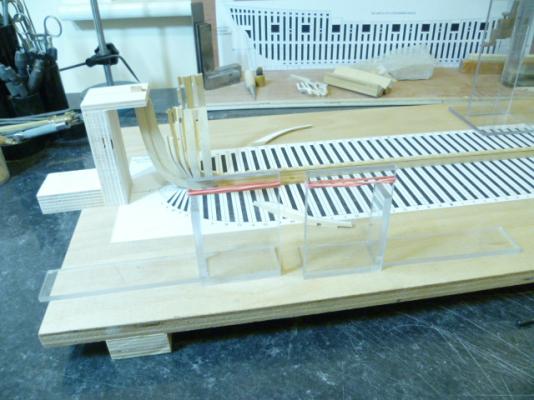

hi ken and dave glad to be of any help with my heath robinson jigs. it would have been better if I had left another 1- 1 1/2 inchs between the stem and the stem support.......would have provided much better access to the cant frames.......we live and learn hopefully! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi ken glad to be of help.......somewhat mystified as to which picture was of help??? cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

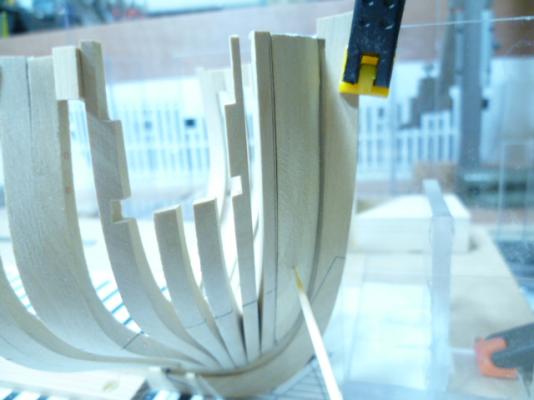

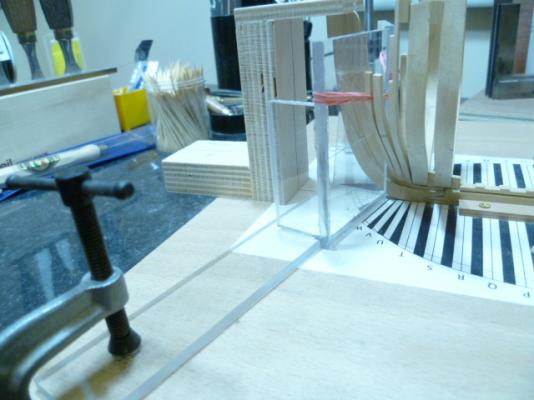

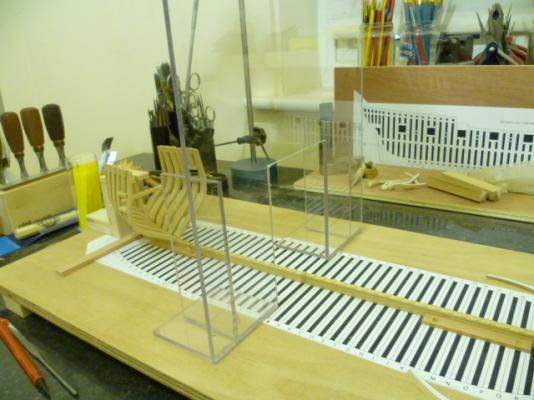

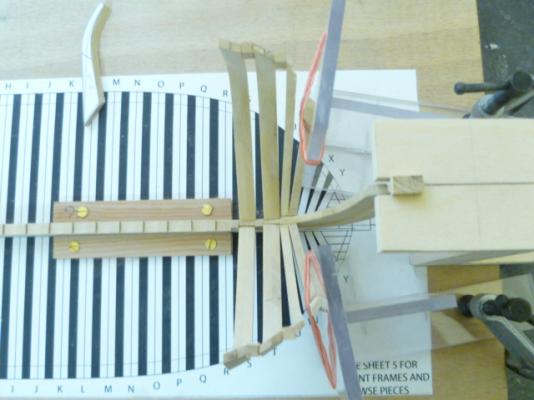

HI ALL NEW JIGS ARE IN USE......LAST PAIR OF CANTS DUE TO BE FITTED THIS EVENING AND THEN WE MOVE ON TO THE HAWSE PIECES. BACK TO WORK FOR THE NEXT FOUR NIGHTS SO NO MORE UPDATES FOR A WHILE! PHOTOS ENCLOSED CHEERS.....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi alan already made and in use! upload some more photos later when the camera batteries finished recharging. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

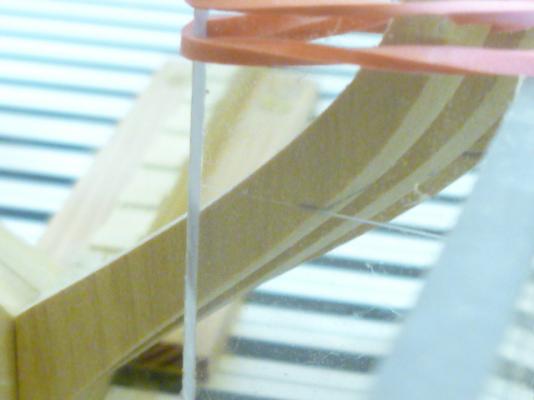

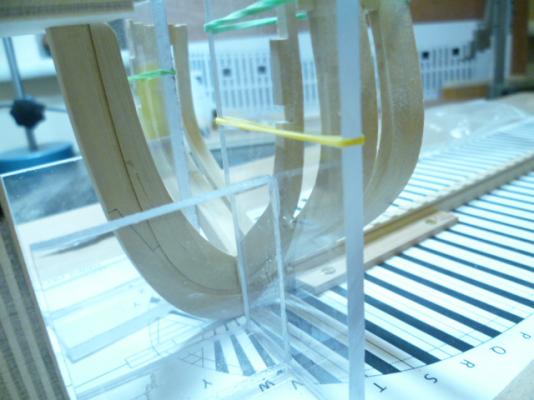

HI ALL WORK ON THE CANT FRAMES CONTINUES......NEXT PAIR HAVE BEEN FITTED. THE ACRYLIC JIGS HAVE HAD A LINE SCRIBED ACROSS AT THE LWL LEVEL....HOPE THIS SHOWS IN THE PHOTOS. THE NEXT TWO PAIRS OF CANT FRAMES WILL HAVE TO BE SUPPORTED BY A FRESH PAIR OF JIGS.......THIS AFTERNOONS JOB WHILST THE GLUES SETTING......UNFORTUNATELY DESPITE ALANS SUGGESTION TURNING THE CURRENT JIGS AROUND MEANS I CANT GET MY CLAMPS IN PLACE. NOT A MAJOR PROBLEM THE BYRNES SAW WILL MAKE SHORT WORK OF MAKING A NEW SET......I SHOULD OF GIVEN MUCH MORE THOUGHT TO THESE JIGS IN THE FIRST PLACE........FILE THAT IN THE MEMORY BANKS FOR THE NEXT BUILD! ANYWAY PHOTOS ENCLOSED FOR YOUR DELICTATION. CHEERS.....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi alan the machinists squares do come in handy ......I have about four pairs in different sizes......the awkward bit is keeping the base of the cant frame fixed to the deadwood as there is no rebate for it to sit in its just glued to the deadwood......and then keeping the lower water line at the right height.....turns into a juggling act. I can see where the square comes in....but the frame still needs to be clamped in some way to hold it in position......I have a multiplicity of clamps.....but none the right size!!!! even my smallest toolmakers clamps are too big ( 1" capacity) not too mention far too heavy......this is a small model even in 1/48 scale. I think some time spent making some clamps a la EDTs build logs would be time well spent! on reflection I should have gone for acrylic supports for the stern and bow aswell as they could have been made less cumbersome.....I may well rejig before I go any further. thanks for the second pair of eyes!!! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi greg life may suddenly become a little easier if I follow alans suggestion in the previous post.........ive bevelled the cants to just outside the printed line on the plan.....so with the thickness of the line as well there should be enough meat left on for final fairing........but if not then the iso will be unleashed and frames remade.........I need the practice prior to starting the echo cross section...and swan....and euryalus....and half a dozen ancre publications should keep me busy till I'm feeble in the cerebral!!! on a different note ive been lurking in the shadows watching your hms speedwell build........plans in the pipeline at any point soonish? the framing seems a lot more complex than ron McCarthy envisaged in his book building hms cruiser I'm presuming that speedwell was the 1752-53 program for 140 ton sloops......ref to ian mclaughlins book pg 213 ? which would make her contemporary with cruiser,wolf and happy albeit with minor differences. I do have the nmm draught for cruiser but my draughtsmanship skills are primitive to say the least hence the question regarding plans. look forward to following your outstanding work on speedwell. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi alan ha ha ....hadnt thought of the obvious.......will see if lifes easier with them the other way round! bit of a DOH!!!!!! moment.......nice one! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi albert many thanks....early days yet but those cant frames are proving somthing of a pain! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi carl and Patrick had to have a rethink with the support jigs for the cant frames........the original wooden ones were far too "clunky".......theres not much space at the front end so something thinner was required........the acrylic was stuffed up a corner in the engineers shop at work.......so it was duly liberated,with permission of course! and is now stuffed up a corner in my workshop..........useful stuff! more cant frames to do this weekend and then on to the hawse pieces.......should prove interesting and frustrating in equal measure. cheers for now.......mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

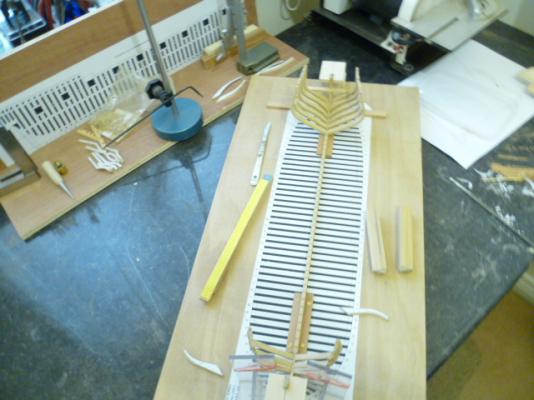

WASHINGTON GALLEY PART 8 CANT FRAMES HI ALL ABOUT TIME FOR ANOTHER UPDATE. BEEN DISTRACTED BUILDING FURNITURE FOR ONE OF THE LADS I WORK WITH AND STARTED BUILDING ANOTHER PROJECT......18 CENTURY LANTERN CLOCK . HOWEVER ITS TIME TO GET TO GRIPS WITH THE FORWARD CANT FRAMES.....AWKWARD LITTLE SWINES!!!! FIRST PAIR HAVE BEEN SET.....WAITING FOR THE GLUE TO DRY....NEXT TWO PAIRS WAITING TO GO IN. PHOTOS ATTACHED.....COMMENTS ,CRITISMS...HOWLS OF DERISON GREATLY APPRECIATED!! THE ONE THING I WILL BE DOING IS REPLACING THE LOW ENERGY BULB IN THE SPARE ROOM WITH AN LED BULB...A BRIGHT WHITE ONE......IT SEEMS THAT THE CURRENT BULB IS TOO YELLOW HENCE THE CRAPPY PHOTOS. I ALSO REPLACED THE PREVIOUSLY MADE WOODEN JIGS WITH SOME MADE FROM 5MM ACRYLIC,IT WAS LURKING IN A CORNER AT WORK SO IT HAD TO GO! THE WOODEN ONES WERE FAR TOO CUMBERSOME TO FIT IN THE FAIRLY TIGHT SPACE AT THE BOW, THATS ABOUT IT FOR NOW........MORE CANT FRAMES TOO FIT! CHEERS.....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi don ive sent you a pm with an answer , or two! , too your question. only to glad to offer what assistance i can cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi don false keel cut from 3/16 x 1/16 stock hog cut from 3/32 x 3/16 stock as a seperate piece on top of the keel.......makes it easier to cut the rebate in the keel this way. ask as many questions as you like,hopefully i will be able to provide an answer but if i cant we can throw it out to the forum.......bound to find out the answer!!!! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Nils Wow! Fantastic result! I love that bow shot now that the postings gone on......like a knife blade....ready to slice through some rough Atlantic waters.......superb! Cheers....mick

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Patrick Sorry to hear about your predicament. Wishing you a speedy recovery and plenty of laughing gas when they go up the whats it!!!!!! Wishing you well asap Cheers....mick

- 1,083 replies

-

Hi druxey Thanks for looking in. Yep that's pretty much the way I'm going about it.....this is quite a small model even in 1/48 scale....being a clumsy sod sometimes I think if I tried to cut the rebates for sills and sweep ports after the frames are assembled I'm inviting a disaster.....so rebates are cut as frames are built....the acid test will be when the frames are up and a nice flexible batten is run along the the bottom edges do we arrive that lovely gentle sweep as per the plans? But then again there's always isopropanol and some early Anglo Saxon language!! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.