yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

Hi Mike All timber oxidises with age....surface finishes help delay this process. Not sure how this will affect pink ivory...depends on how light a shade you start out with...what finish you use...whether it's got uva/b filters built in etc etc. Should be interesting to watch over the coming years. Cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Mike I brought the pink ivory from an English company called stiles and bates. A Google search will bring them up...then look under exotic spindle blanks. Various company's on eBay dealing with pen blanks also stock it.....postage might be expensive to Sweden from an English co. Cheers......mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

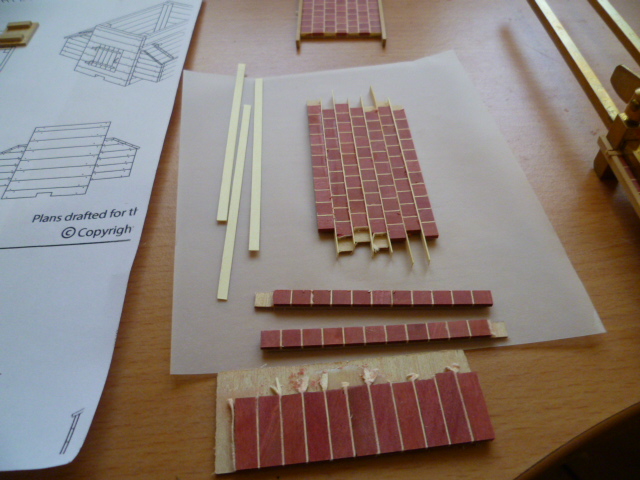

hi kurt pink ivory.........rhamus zeyheri........originates in southern africa. reputed to be the royal wood of the zulu peoples. dense..1000kg per meter cubed fine grained.........and pink!!!! can be quite red through to terracotta coloured.....hence me using it for tiles. hope this helps cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

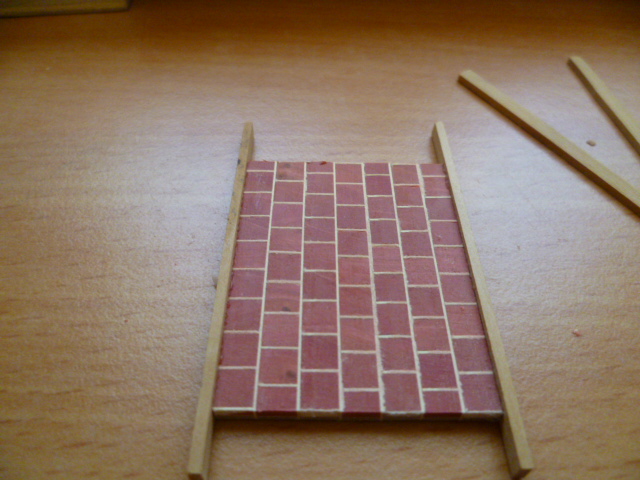

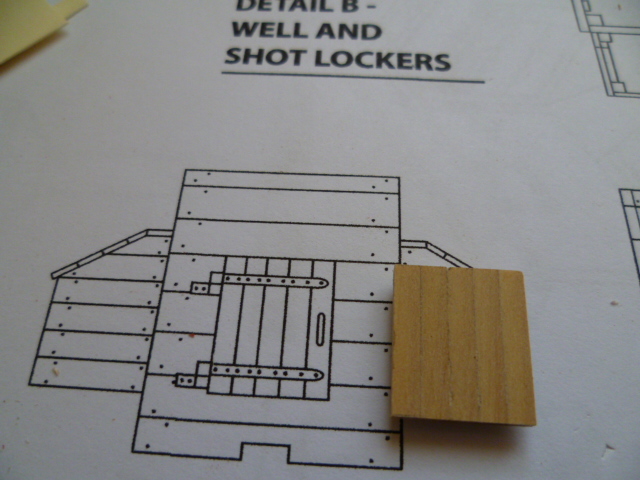

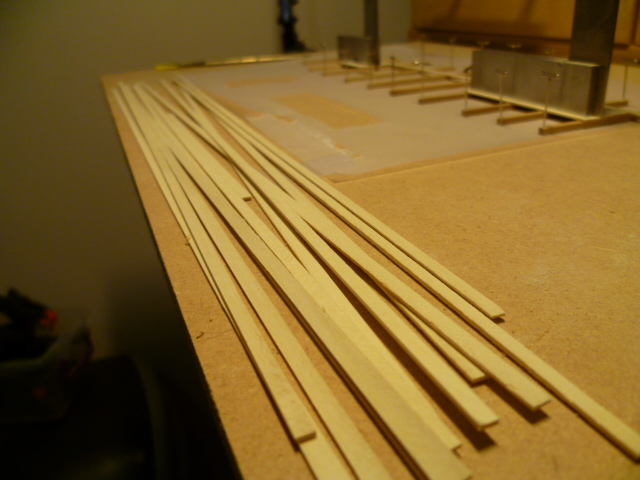

HI ALL JUST A QUICK PROGRESS REPORT. WHILST IM WAITING FOR SOME EBONY TO BE DELIVERED I DECIDED TO CRACK ON WITH THE LOWER DECK AND START SOME OF THE DETAILS. WELL STARTED AND TRIAL FITTED TO DECK OPENING.....LOTS MORE TO DO ON THAT. TILED AREA FOR STOVE WELL UNDER WAY......I DECIDED TO "PAINT WITH WOOD" AND USED SOME PINK IVORY FOR THE TILES.....THE TILED AREA WILL HAVE A WOODEN SURROUND,NOT SHOWN ON THE PLANS,BUT HAVING LOOKED AT VICTORYS BRODIE STOVE THERE MUST HAVE BEEN SOMETHING THERE IN ORDER TO KEEP THE TILES IN PLACE.....CEMENT CRACKS...TIMBER MOVES ETC ETC. PHOTOS ENCLOSED AS PER USUAL IVE ALSO REORGANISED THE WORK SPACE AND AQUIRED SOME MORE TIMBER.......HERR KOENIG AT ARKOWOOD EVEN THICKNESSED IT EXACTLY TO 4.76MM OR 3/16".....WUNDERBAR!!!! CHEERS FOR NOW....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi adam nice work so far! just be careful with some of those drift bolts on the forward and aft frames......some of the frame drawings dont show any bolt locations.....if youre tempted to put them in you may find them getting a tad close to the frame edges when you come to fair the hull.......or it could just be my build!!!!! shall be following avidly cheers....mick

-

Ah ah ! Curiosity is now fully alert!! Will be keeping a beady eye on the night home page! Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi patrick thanks for looking in and the continuing words of encouragement. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi aviaamator go for it! about time there were some more build logs. shouldnt be a problem with posting to russia........?? i have browsed a couple of the russian ship forums.....magnificent work. just surprised a few more of our american and canadian friends havnt jumped in and started a build log. thank you for you kind comments. cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi kurt thanks for the encouragement.......68 plans sold? i would have thought there would have been a plethora of build logs by now......quite a noteworthy little ship in american history. any ideas for another nrg practicum and plans set? cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi greg thanks for stopping by. yes opening for rudder does need to be opened up......but i was leaving that until the rudder was made.....after the wales go on and before any further work goes on internally......should be too onerous a job ,plenty of room to work! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

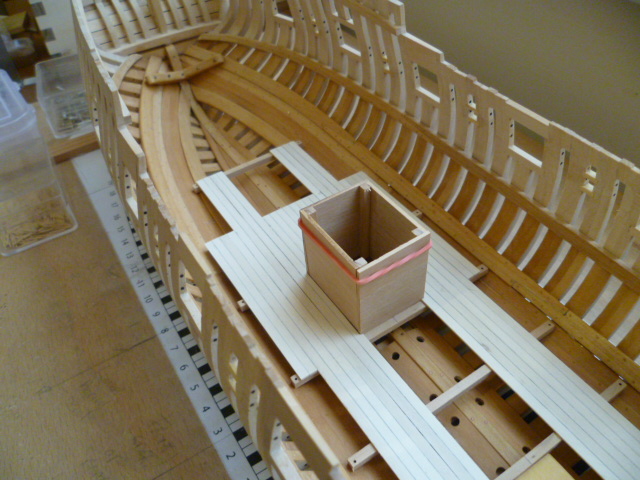

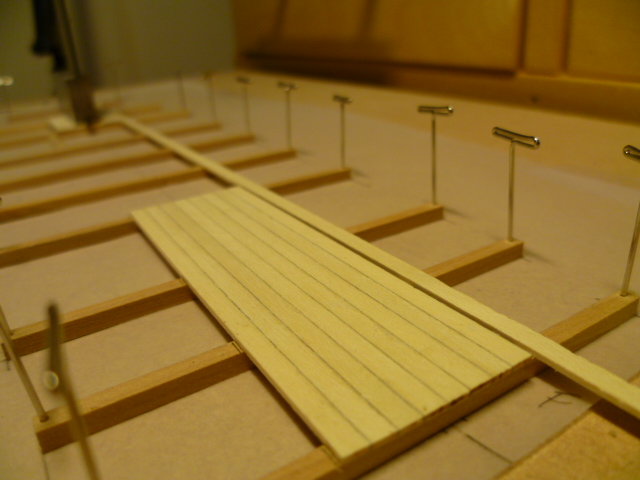

HI ALL PROGRESS CONTINUES TO BE MADE....SLOWLY. INTERNAL TIMBERWORK FINISHED OFF WITH ADDITION OF CRUTCH AND BREASTHOOK. A TENTATIVE COAT OF DANISH OIL HAS BEEN APPLIED.......MAKES THOSE TREENAILS STAND OUT. ALL BOLT HEADS HAVE BEEN BLACKENED WITH LIVER OF SULPHUR. LOWER COUNTER PLANKED AND TREENAILED PRIOR TO FITTING THE WALES. LOWER DECK HAS BEEN STARTED BOXWOOD FRAMES AND HOLLY PLANKING.......DECIDED TO EAT INTO MY PRECIOUS SUPPLY OF ENGLISH HOLLY FOR THIS MODEL. ONCE THE LOWER DECK IS FINISHED AND TRIAL FITTED IT WILL GO ON ONE SIDE UNTIL THE WALES AND SOME OF THE EXTERNAL PLANKING IS DONE. THATS ALL FOR NOW FOLKS CHEERS......MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi albert thanks for looking in. little bit more accuracy required i think....too many mistakes. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi christian thanks for the kind comments......just been browsing your triton build log,along with jurgens,in the german forum......google translation can be a little "funky" at times.......but lovely work.....havnt seen jurgens updates for a while. triton is on my list of projects for the near future. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

HI ALL FILLING TRANSOMS FITTED AND PARTIALLY FAIRED. STERN TAFFRAIL FITTED....JUST SOME FILLING TIMBERS TO GO IN. IT LOOKS LIKE I WAS A FRACTION SHORT WITH THE STARBOARD STERN FASHION PIECE.....SHOULDNT BE A PROBLEM AS THE PLANKING WILL EVENTUALLY COVER THIS INDISCRETION. BASICS OF THE HULL ARE THEREFORE NEARLY DONE. I WILL CUT THE MAIN SHEERLINE TO FINAL SIZE ONCE THE WALE STRAKES ARE ON. CHEERS FOR NOW........MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi mike thanks! the 80 grit was only for the very basic profiling..........my nerves wouldnt stand too much use!!!!! The bolts that are a little too close to the frame edges will be covered by the wale and top planking so should work out ok in the end. cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi carl she is pretty small for 1/48 scale........might just make up a frame for triton or echo just to see the comparison. the fairing was straightforward because of the precut bevels on the frames as they were installed. may have been a bit heavy handed in places but it should work out ok.........i hope. lots more dust and shavings to make today! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi kurt thanks for stopping by. its coming together slowly......getting ready to make a mess with some ebony and make some nasty smells with l.o.s. time to process some holly for the deck planking as well. enjoyable build so far,despite a few mistakes. should keep me busy for another 12 months or so! cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi patrick thanks for looking in......gives an idea of the overall scale i think. smallish ship....but not by your standards! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

HI NILS BEEN A WHILE SINCE I STOPPED BY.........YOUVE PROGRESSED MAGNIFICENTLY!!! BEAUTIFUL WORK...I LIKE THE FULL HULL SHOT ON THE PREVIOUS PAGE..VERY EVOCOTIVE. LOTS OF FIDDLEY BITS TO DO WITH ALL THOSE DECK FITTINGS.....LOVELY WORK. CHEERS....MICK

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

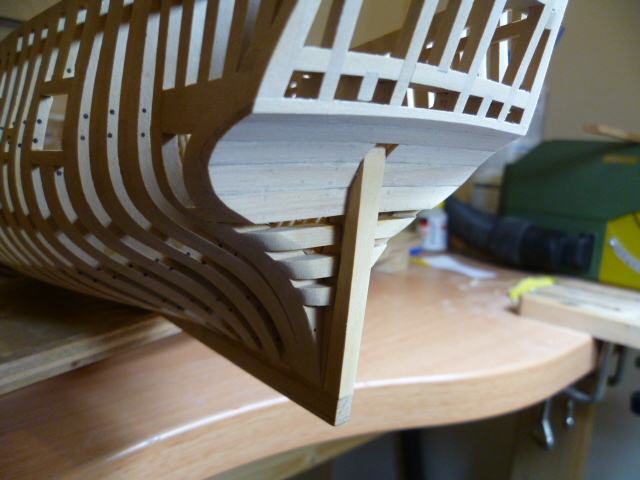

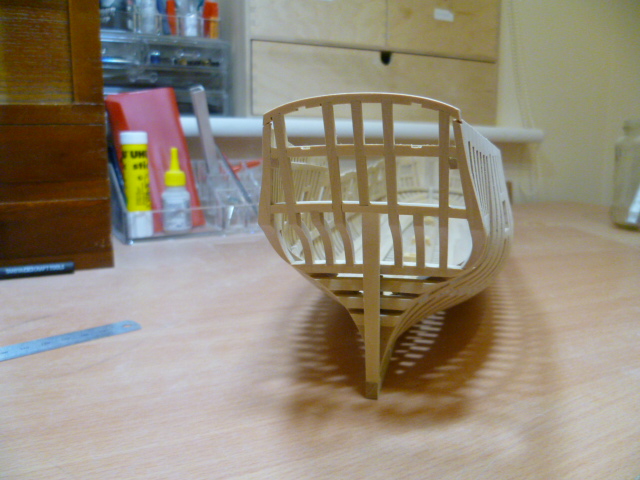

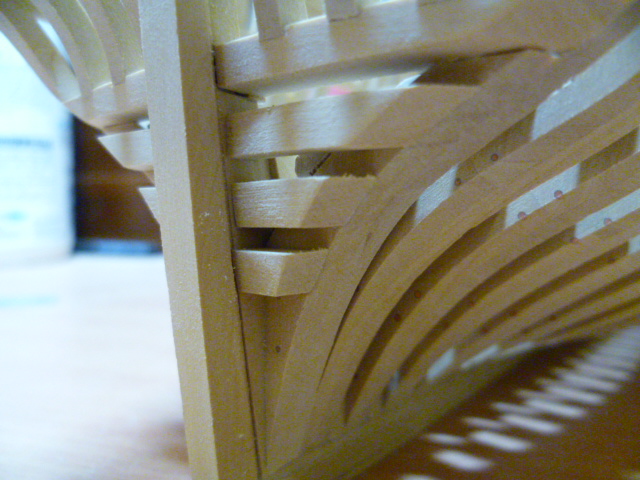

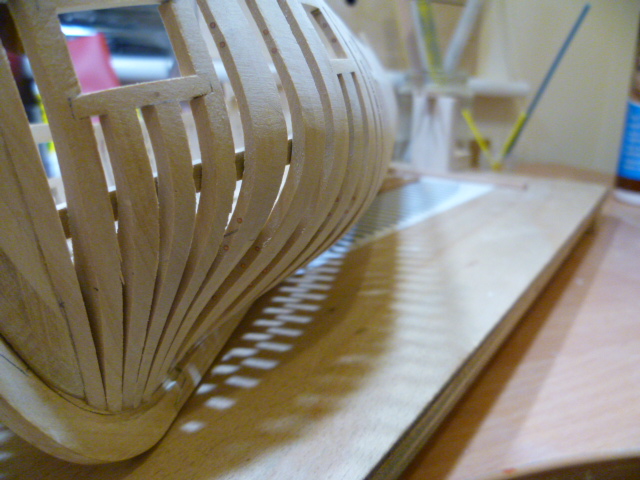

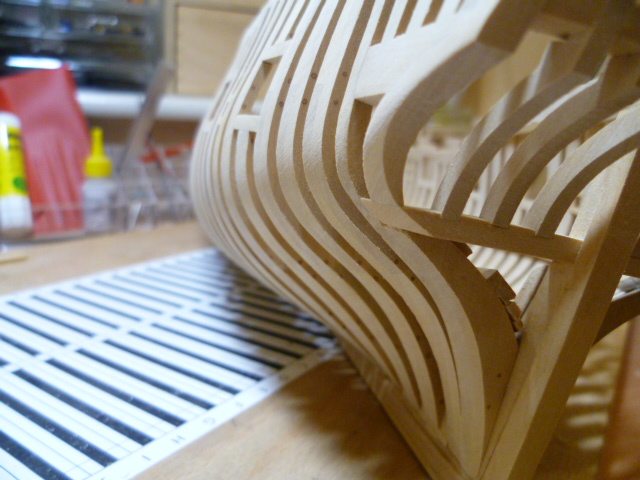

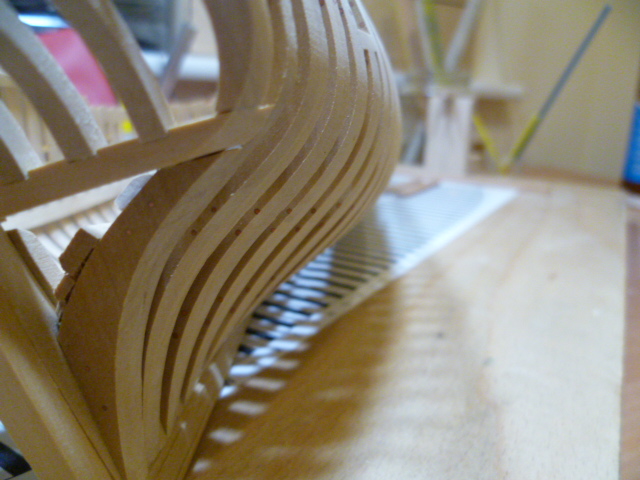

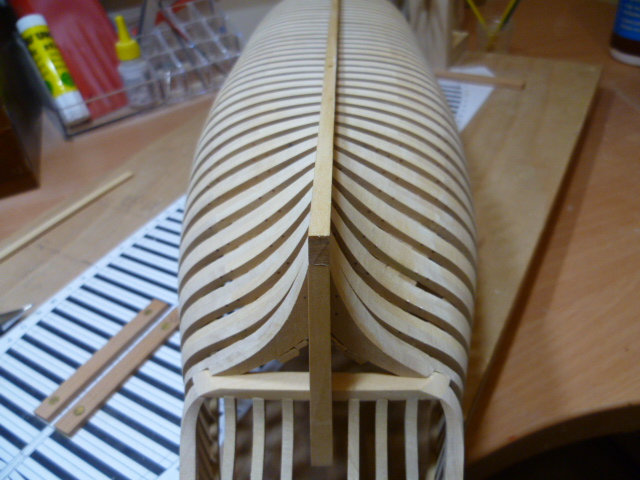

HI ALL FAIRING OFF THE HULL IS NOW PRETTY MUCH COMPLETE. LAST OF THE THICK STUFF IS BEING FITTED AND TREENAILED . MAST STEPS AND LIMBER BOARDS HAVE ALSO BEEN PERMANENTLY FITTED. JUST A QUICK OBSERVATION WITH REGARDS TO FAIRING. ON THE FORWARD AND AFTERMOST FRAME DRAWINGS THERE ARE NO BOLT POSITIONS INDICATED. BEING PERHAPS OVER KEEN I DECIDED TO FIT BOLTS TO THESE FRAMES. DURING THE FAIRING PROCESS, EVEN THOUGH THE FRAMES HAD THERE BEVELS CUT PRIOR TO BEING INSTALLED, SOME OF THE BOLTS ON A COUPLE OF FORWARD AND AFT FRAMES ARE PERILOUSLY CLOSE TO THE EDGE OF THE FRAME. FOR ANYBODY ELSE CONTEMPLATING BUILDING THIS MODEL I WOULD SUGGEST LEAVING THESE BOLTS OFF. FORTUNATELY I THINK THE WALE STRAKE AND LOWER STRAKE OF PLANKING WILL COVER THESE UP. BECAUSE OF THE PRECUTTING OF THE FRAME BEVELS FAIRING TURNED OUT TO BE REASONABLY STRESS FREE. I DID HOWEVER MANAGE TO LOOSEN ONE GUNPORT SILL AND BREAK OF A PART OF THE UPPER STERN FRAMING......NICE CLEAN BREAK SO EASY AND CLEAN TO FIX. FAIRING WAS ACHIEVED WITH SOME 80 GRIT PERMAGRIT GLUED TO A ONE INCH QUADRANT MOULDING FOR THE INITIAL ROUGH WORK AND THEN WITH PROGRESSIVLY FINER GRADES DOWN TO 240 GRIT. ONCE THE FINAL PIECES OF THICKSTUFF HAVE BEEN INSTALLED AND TREENAILED I AM GOING TO MOVE TO THE OUTSIDE OF THE HULL AND FIT THE WALES AND UPPER PLANKING BEFORE CARRYING ON WITH ANY MORE INTERNAL WORK. THATS ABOUT ALL FOR NOW. PHOTOS ATTACHED...WARTS AN ALL....FOR YOUR DELICTATION. CHEERS....MICK P.S. THE LAST PHOTO IS OF THE HULL SITTING ON ITS KEEL.......ITS STABLE AND DOSNT FALL ONE WAY OR THE OTHER.........SYMETRY ACHIEVED?????????.......ISH???????

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi patrick thanks for the kind words....fairing has proceeded quite fairly! getting ready for varnish and liver of sulphur before i start on the wale strakes in ebony will be catching up on your build log,and a few others later in the week. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi carl fairing is now more or less done......just some final sanding with some 320 grit or finer......then its time to start putting some varnish on and pick out all those bolt heads with some liver of sulphur. congrats on finishing your latest project.....i will be studying it in greater detail later this week!!! more photos to follow later. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

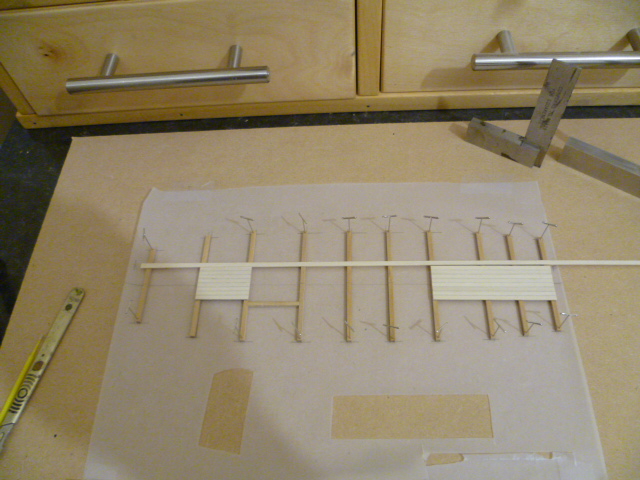

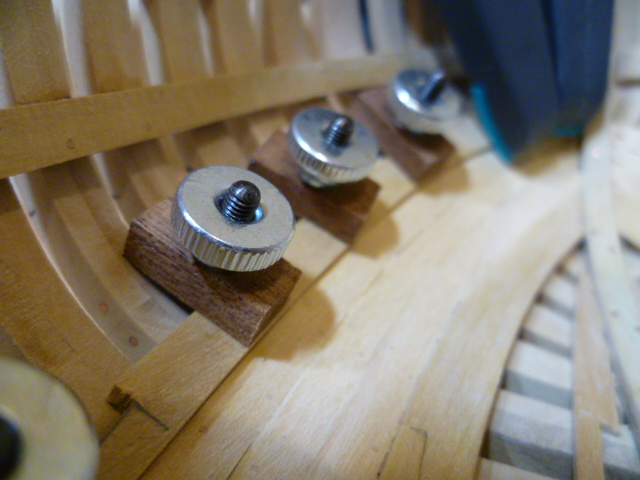

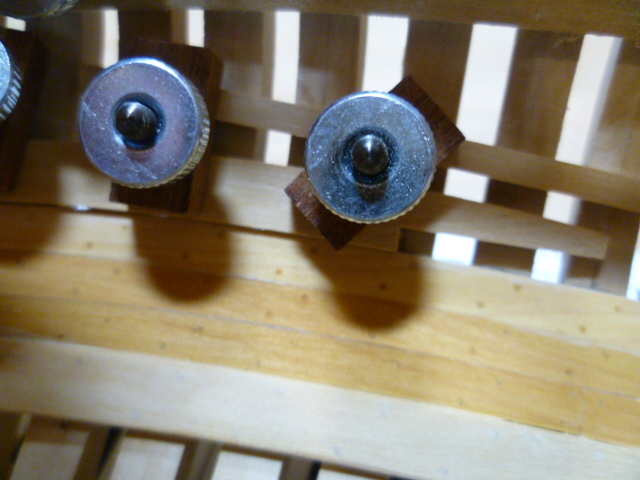

hi david heath robinson solution to a clamping problem!!! they also work quite well so i think i will keep them for susequent models.........and make some more. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

HI ALL WORK CONTINUES ON THE THICK STUFF AND INTERMIDIATE PLANKING......NEARLY FINISHED JUST THE UPPER STRAKE OF THICK STUFF TO GO ON. ONCE THIS IS DONE ITS TIME TO FINALLY FAIR THE OUTSIDE. JUST A QUICK UPDATE FOR NOW. CHEERS....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi mike looking very good. i tend to use precut boxwood for my treenails.......available from most good veneer suppliers in 1 metre lengths. the grain tends to be nice and straight and ive managed to pull 0.4mm diameter treenails with the byrnes drawplate. it does break but usually end up with lengths that are more than usable. in england they are available in various dimensions .....the smallest i ve found are 0.5mm sqaure. original marquetry and timberline are two good companys. looking forward to more progress. cheers....mick

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.