yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

hi carl nessessity being the mother of invention???? been twiddling with this idea for a while......havnt tested it yet!!!! been looking in on the amati riva build from time to time. cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

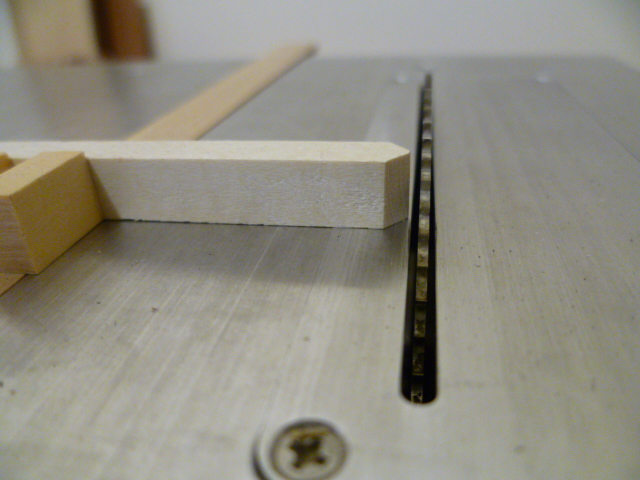

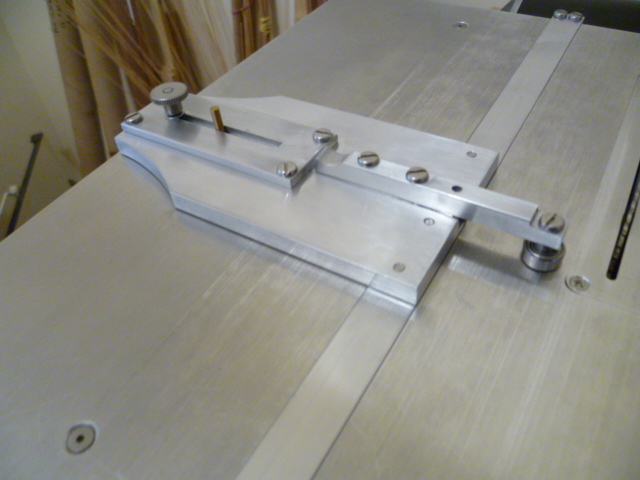

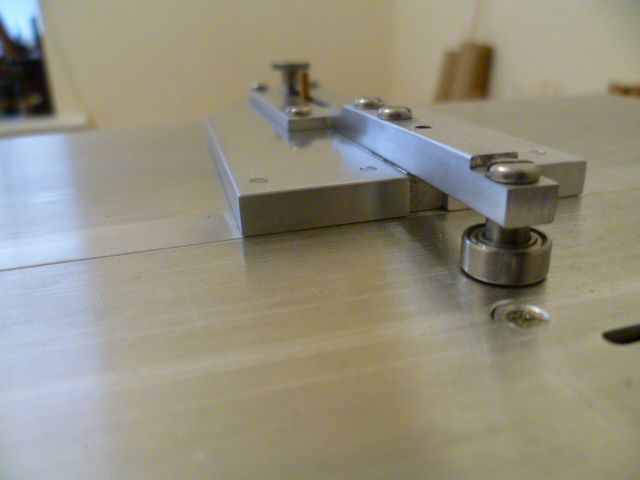

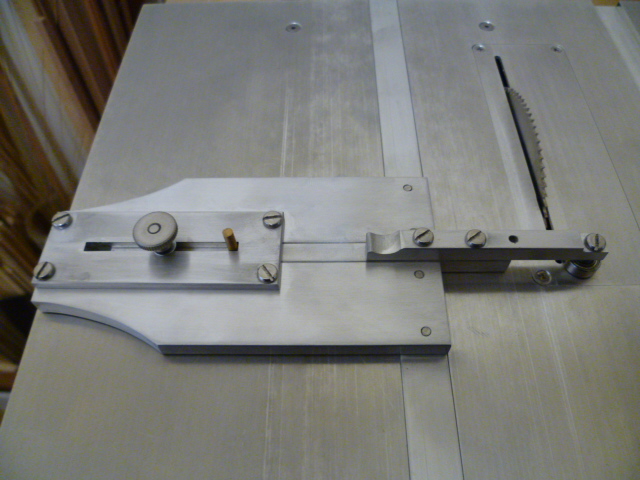

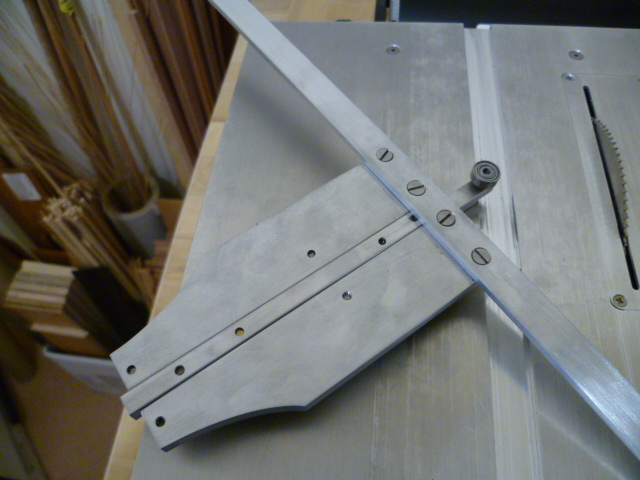

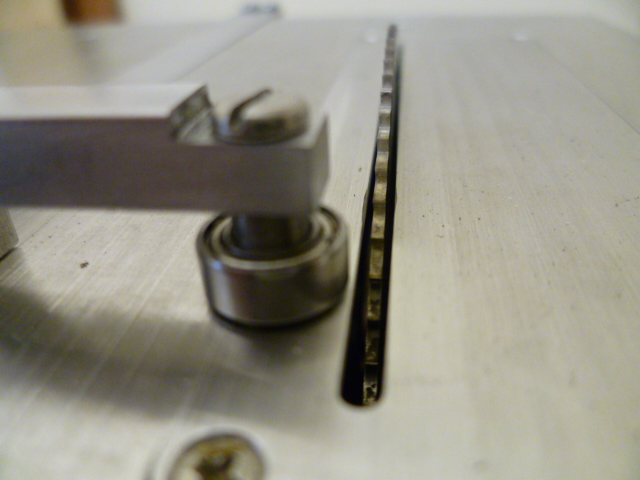

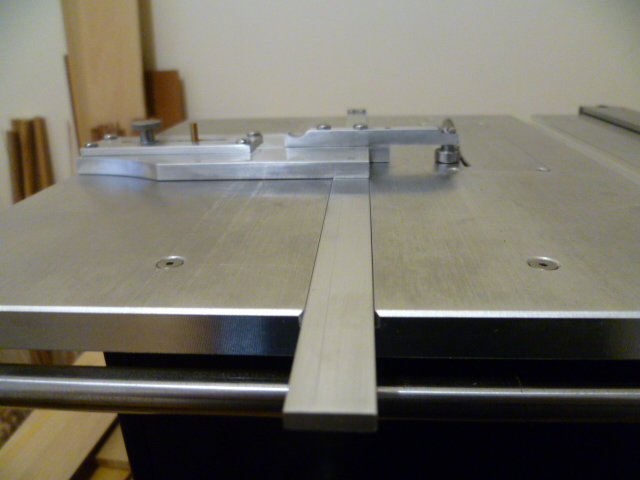

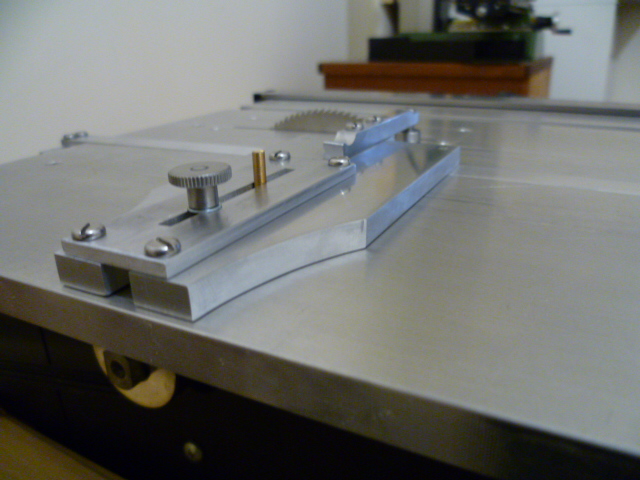

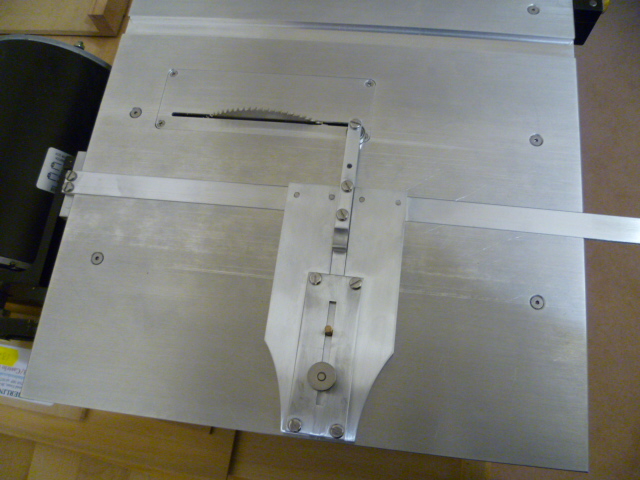

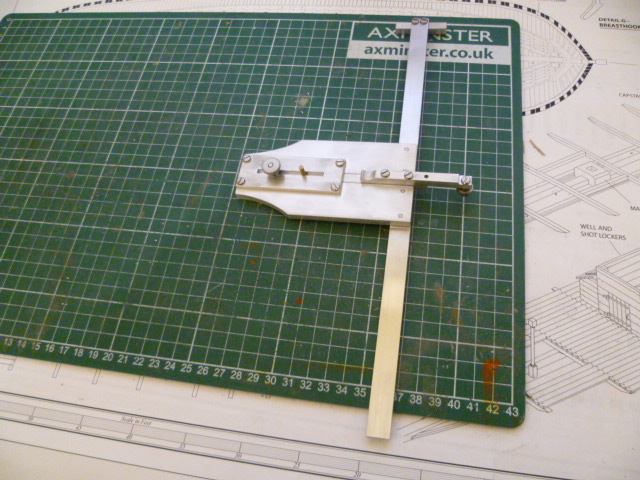

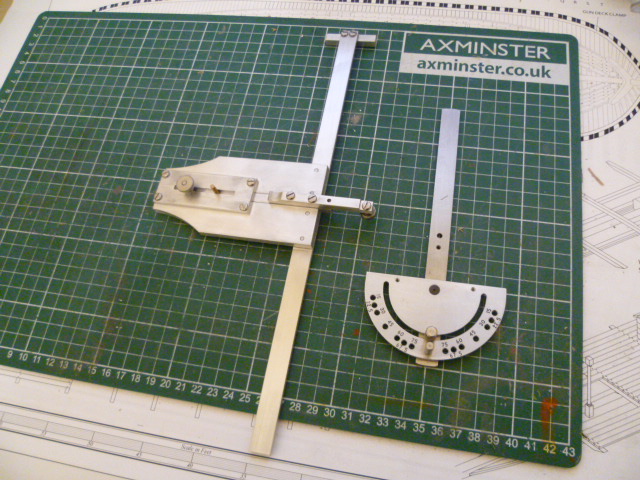

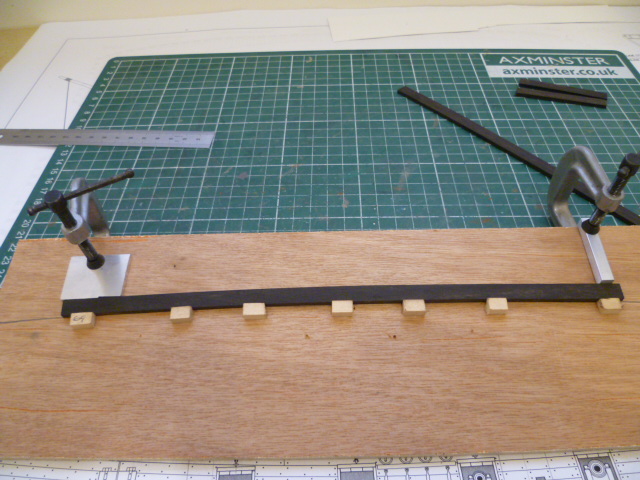

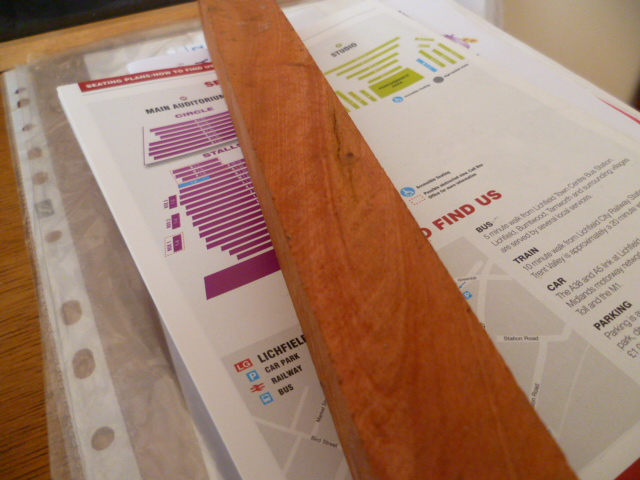

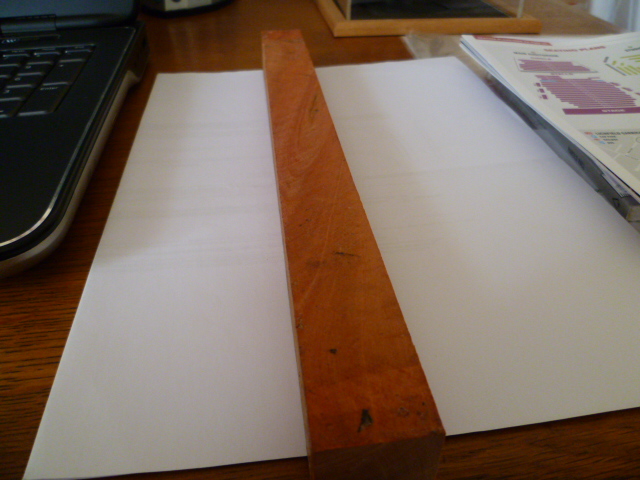

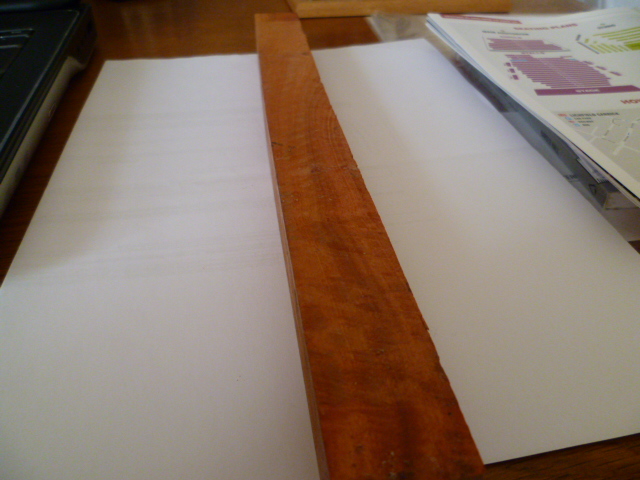

HI ALL TIME FOR AN UPDATE OF SORTS. WHILST WORKING ON THE WASHINGTON GALLEY IT BECAME APPARENT THAT I NEEDED SOME WAY OF CUTTING THIN STOCK FROM LARGER BOARDS. THE HOLLY I HAVE WAS PURCHASED FROM A CHAP WHO HAD JUST FINISHED RESTORING A RIVA AQAUMARINA.......A NICE LITTLE MAHOGANY AND HOLLY RUNABOUT FROM THE 50S / 60S ????? WHEN IT TURNED UP IT WAS AS ROUGH AS THE PROVERBIAL BEARS POSTERIER.......NOT HAVING THE ABILITY TO PROCESS ROUGH SAWN TIMBER I TOOK IT TO A SMALL LOCAL TIMBER COMPANY ,WHO FOR A MODEST FEE, PROCESSED IT FOR ME.......DOWN TO 8MM IN THICKNESS. I NEEDED TO CUT SOME 1/32 " PLANKS FROM THIS FOR THE LOWER DECK......I WILL ALSO NEED TO CUT SOME 1/16" PLANKS FOR THE MAIN DECK AND QUARTER DECK LATER ON. FOR THE LOWER DECK I IMPROVISED A SIMPLE WOODEN JIG AS SHOWN IN THE FIRST PHOTO. TROUBLE IS I WOULD NEED TO MAKE ONE OF THESE FOR EVERY DIFFERENT PLANK THICKNESS I CAME ACROSS. IM NOT OVERLY HAPPY CUTTING THESE PLANKS THE NORMAL WAY USING THE FENCE....THOSE THIN LITTLE PLANKS CAN GET UP TO ALL SORTS OF MISCHEVIOUS THINGS IF YOUR NOT CAREFUL. AS HAS BEEN MENTIONED IN NUMEROUS OTHER LOGS ITS FAR SAFER AND MUCH LESS NERVE RACKING TO CUT THESE PLANKS ON THE OUTSIDE OF THE BLADE AS IT WERE. THE MAKE SHIFT WOODEN JIG PERFORMED PRETTY WELL, BUT I WANTED TO HAVE A GO AND BUILD SOMETHING ADJUSTABLE AND PERMANENT. THE RESULTS ARE ENCLOSED FOR YOUR DELICTATION.......BUT THERE IS SOME FURTHER WORK LEFT TO DO. CHEERS FOR NOW....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi timmo It's teaching me a few things as well! ! Thanks for stopping by Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi albert belissimo!! wunderbar!!! magnificent!!!! beautiful workmanship and a stunning result so far. looking forward to lots more. thank you cheers....mick

-

hi mike look forward to the start of your build log. should be interesting working with basswood.......will be a lot easier to fair than box......but be careful you dont go too far as its quite a soft timber. the african blackwood for the wales and capping timbers perhaps? we have to challenge ourselves mike its the only way we learn and progress. theres enough talent and expertise on the forum to help you through........if in doubt ask!!! if you dont think a component is good enough reject it and start again......basswoods fairly inexpensive in comparison to box or pear.....each rejected piece is a learning process rather than scrap. cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Mike Welcome to the party!I'm sure your skills are more than up to the job. To be honest you don't really need any fancy tools....all my frame components were cut using a jewellers saw....the critical element is the notches on the rising wood for the frames....exactly 1/4 inch wide and 9/64 inches apart.....I used a set up on the mill but a small table saw , proxxon or Byrnes will do the job equally as well. You could even do it with hand tools if your careful. Other than that the most useful tools are good quality chisels kept razor sharp. My timber was milled to the exact thickness by my timber supplier....the rest is down to time and patience and careful study of the plans.....don't forget to reject anything that isn't right....my scrap box grows larger every day!! This was my first pof full hull model....it won't be my last. If I can help along the way don't hesitate to ask. Looking forward to seeing your build log. Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi carl thanks shipmate dirty old job though.....sanding dust gets eveywhere...even with constant hoovering. its been a hard job relatively speaking....quite afew rejected pieces.....but hopefully worth the sweat and foul language. good job i gave up smoking in feb.......i think a few ounces of backy would have been consumed during this process!!! cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi mark worth the effort,hot fingers,sweat,profanity.......etc tough old stuff to work with......but should look nice when finished. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

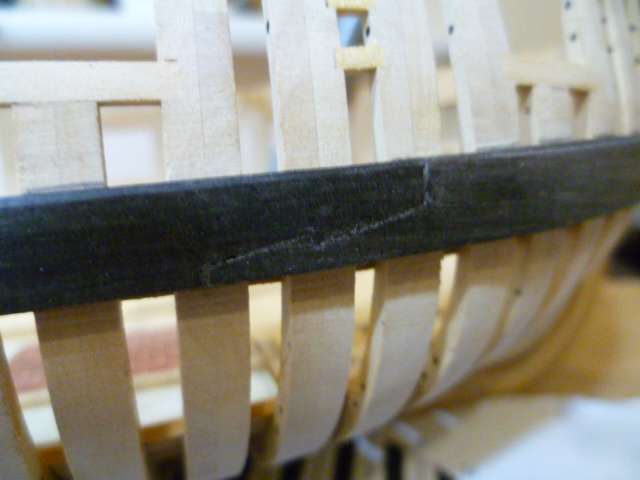

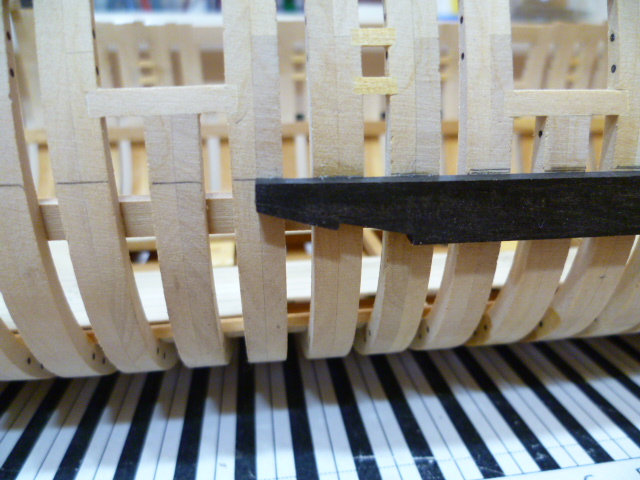

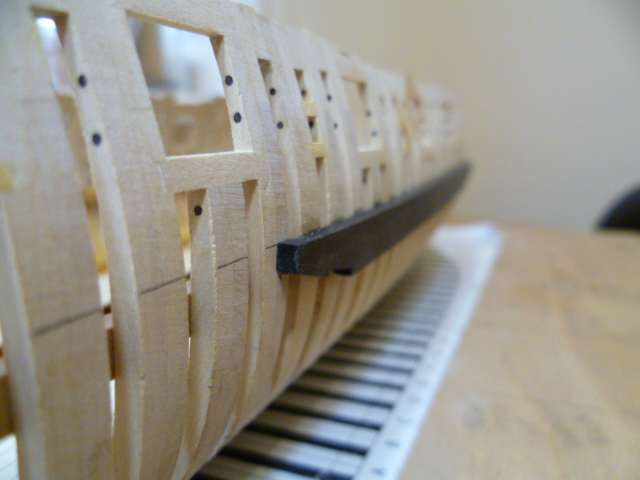

HI ALL A VERY QUICK UPDATE. THE WALES ARE NOW ON!!!!!!!! HOLE FOR THE RUDDER ALSO CUT IN THE COUNTER. LOTS OF CLEANING UP ON THE WALES AND FRAMES TO DO.......WORKING WITH EBONY IS A MESSY BUSINESS. CLAMPS HAVE FINALLY BEEN FINISHED...WILL USE THESE WHEN PLANKING ABOVE THE WALES...NEXT JOB. CHEERS FOR NOW.........MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Mike The bendings not messy but the sanding and scraping sure is!!! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi mike great work fairing the inside...nice to see scrapers being used.....one of my favorite tools along with liogier rasps. nice symmetry on the deck clamps shall be following along with great interest cheers....mick

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

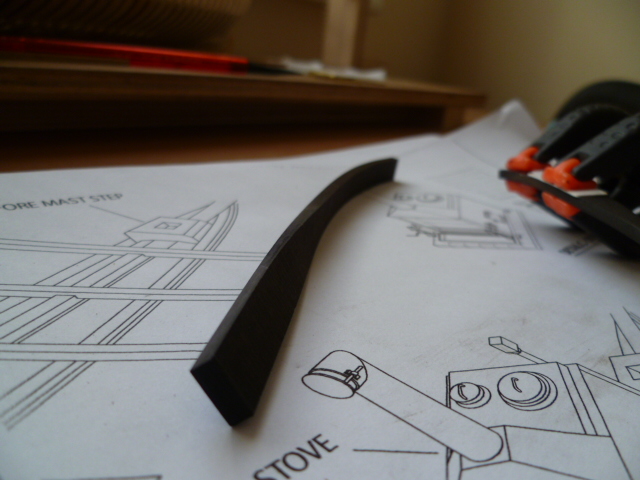

hi wackowolf no soaking or steam req. this is 3.2mm or 1/8" thick ebony you would think that you would need to soak/steam/boil for hours to get it to bend. after seeing chucks video of heat bending on his cutter log i decided to see if it worked on other timbers......it does! the curve of the wale was taken of the draft and an improvised bending jig made.....ebony cut to the right width was clamped at one end and heated with a hot air gun on its lowest setting....about 450 watts.....and the timber was gently persueded up to the stops on the jig and clamped the other end. leave it to cool for 1/2 hr or so and release the clamps........one nicely curved piece of ebony. the same for inducing a twist......clamp one end in the vice........grab the other end with some meaty pliers......heat the timber.......and GENTLY twist in the direction you want......remove heat whilst still holding the plank with the pliers......let cool for a minute or two.....then release the pliers........the twist sould then be set. this can be done with a previously edge set plank and you can then put in a curve to go round the bows for example. three dimensional plank bending in stages with no messy water/ammonia/alcohol.....and once its bent it stays bent. not my idea ......musical intrument makers have been using heat to bend ebony for decades probably even centuries cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl and Patrick Can I interest you in a small pile of bent and twisted ebony? Good job I have a twisted sense of humour...lol Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

HI ALL WALE STRAKES ARE IN THE PROCESS OF BEING FITTED. EASY ONES ARE ON......JUST WORKING ON THE AWKWARD SO AND SO'S. EBONY STRIP BEING EDGE BENT TO MATCH THE SHEER CURVE OF PLAN.FIRST STRAKE IN PLACE.PIECE OF EBONY HEAT BENT 3 MONTHS AGO AS A TESTFINAL STERN PIECE..WITH A TWIST!

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi kurt wow!!!.....feeling somewhat humble!! glad the guys at the meeting liked my humble efforts.........hopefully too many warts didnt pop out with the photos being blown up so large! stiles and bates is a good source of pink ivory here in the uk. generally available as pen blanks approx 3/4" x 3/4" x 6" or as spindle blanks 1" x 1" x 12" the last piece i brought was a couple of months ago, along with a few other bits and pieces , and cost £4.80 for a spindle blank. not sure if they would ship to the us and how much it would cost.......there are i believe certain restrictions on some species of exotic timber being imported into the us. cracking on with the wale strakes as we speak cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi patrick big sister?......another of your miniature marvels! you will have finished three or four by the time im putting washington galley to bed! will be watching avidly as usual.....trouble is ive run out of superlatives!!! cheers....mick

-

hi patrick no probs.....have to order some more brass first.....carls used the last bit!!!! cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl No problem. ...I will get cracking!!!!! Cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

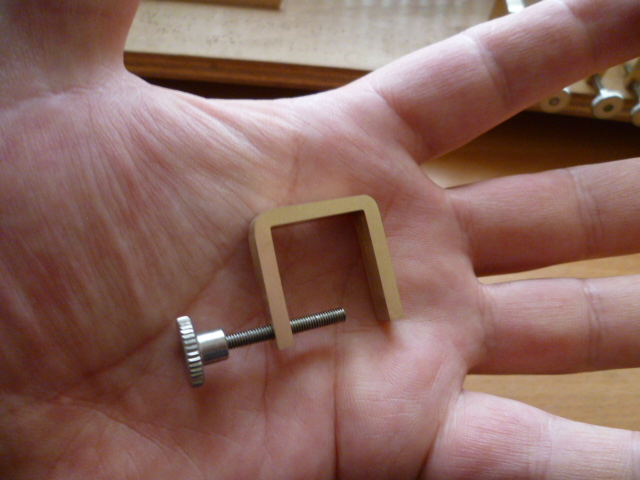

hi carl thanks!! lots more to do yet......some miniature blacksmithing to do with the hinges.......and an attempt to make the stove entirely from soldered brass and them chemically blackened........whilst im at it i may as well make the rudder pintles and gunport hinges.....and anything else made from metal!!!!! how many c clamps would you like? may have to order some more brass! cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

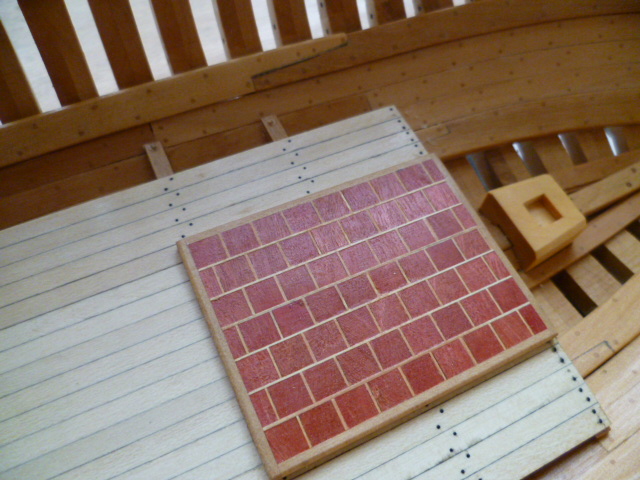

hi kurt tiles have worked out quite well......look even more terracottery with a coat of varnish. the c clamps were inspired by a couple of clamps i brought from a german company called dictum. lovely clamps ,beautifully made....and £8 each!! there also a bit bigger and a lot heavier hence making my own. so 12 clamps would be £96 plus postage................instead £18 for a 6 inch piece of 1inch brass channel with a 1/8" wall thickness plus a couple of quid for some m3 studding and some thumbnuts in stainless............and a bit of metal bashing!!! all the work was done on the proxxon mill,tapped by hand and hand polished. just waiting for some non serrated m3 stainless nylock flange nuts to finish them off. just started to fit the first pieces of the wale. cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi patrick thanks for looking in........i see youve started on another miniature marvel........i shall follow with great interest! cheers......mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

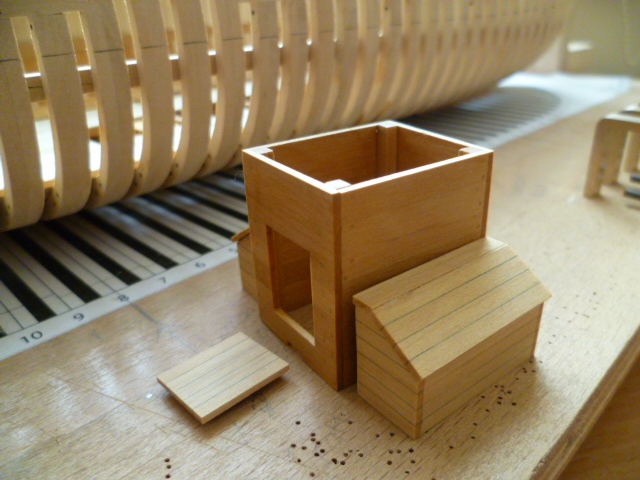

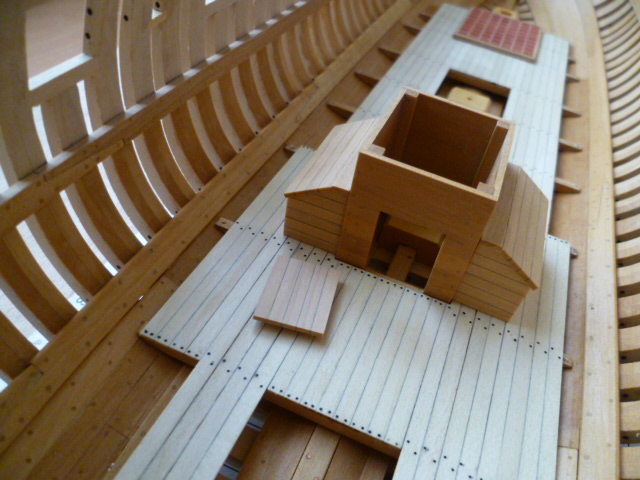

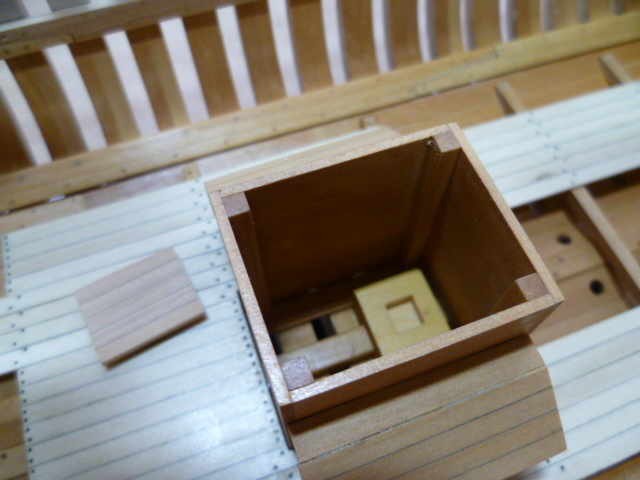

HI ALL TIME FOR ANOTHER PROGRESS REPORT. LOWER DECK HAS BEEN FINISHED AND INSTALLED ALONG WITH TILED HEARTH FOR THE SHIPS STOVE. TREENAILS HAVE BEEN FITTED.....IVE GONE WITH SOME 0.38MM MONOFILAMENT IN BLACK FOR THIS AS ONCE THE MAIN DECK WITH ALL THE CARLINGS AND LEDGES ETC HAS BEEN FITTED ANY TREENAILING WOULD BE DIFFICULT TO SEE. IT LOOKS A BIT HARSH AS WE SPEAK .......BUT WE SHALL SEE. PUMP WELL AND SHOT LOCKERS CONSTRUCTED BUT NOT YET FITTED.....IM WAITING TO CONSTRUCT THE HINGES AND STOVE PLUS RUDDER PINTLES AND GUNPORT HINGES ALL AT THE SAME TIME.....A SORT OF MAD BRASS BINGE. UPPER LIMIT OF WALE STRAKE HAS BEEN MARKED AND SOME PIECES OF EBONY EDGE BENT TO THE APPROPRIATE CURVE. FIRST TWO PIECES ARE WAITING TO HAVE THIER HOOK SCARPHS FORMED PRIOR TO INSTALLATION. THESE WILL RUN FROM FRAME 2 AFT TO FRAME O FORWARD PORT AND STARBOARD. IVE ALSO HAD A COUPLE OF DAYS BASHING METAL......THE RESULTS ARE ENCLOSED BUT ARE NOT QUITE FINISHED YET....STILL WAITING FOR THE FINISHING TOUCHES TO ARRIVE. CHEERS........MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Marcus Thanks for the concise info on pink ivory. Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Patrick and Carl The wheels belong to a 1/8 scale American carriage called a roof seat brake. A sporting carriage used by the well to do to attend race meetings,country outings etc. It's very much on the back burner at the moment....they are only there because I haven't found a home for them yet! Largest diameter is approx 8inches for the rear wheels and approx 6 for the front. Might get round to doing something with them one day. Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.