-

Posts

125 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AnchorClanker

-

-

- GrandpaPhil, druxey, allanyed and 1 other

-

4

4

-

- Cathead, Chuck Seiler, GrandpaPhil and 2 others

-

5

5

-

Yes; I have an idea about how to do this. I'm going to read your build log first to see what comes after attaching the frames to make sure I set up attaching the frames properly. As a kid making plastic models, I used modeling clay as a 'third set of hands.' So as not to risk staining the wood with the modeling clay I will use a small piece of wax paper over the wood where the clay will be applied. I'll see how this works. May something more 'robust' will be needed.

-

- Chuck Seiler, GrandpaPhil, Cathead and 4 others

-

7

7

-

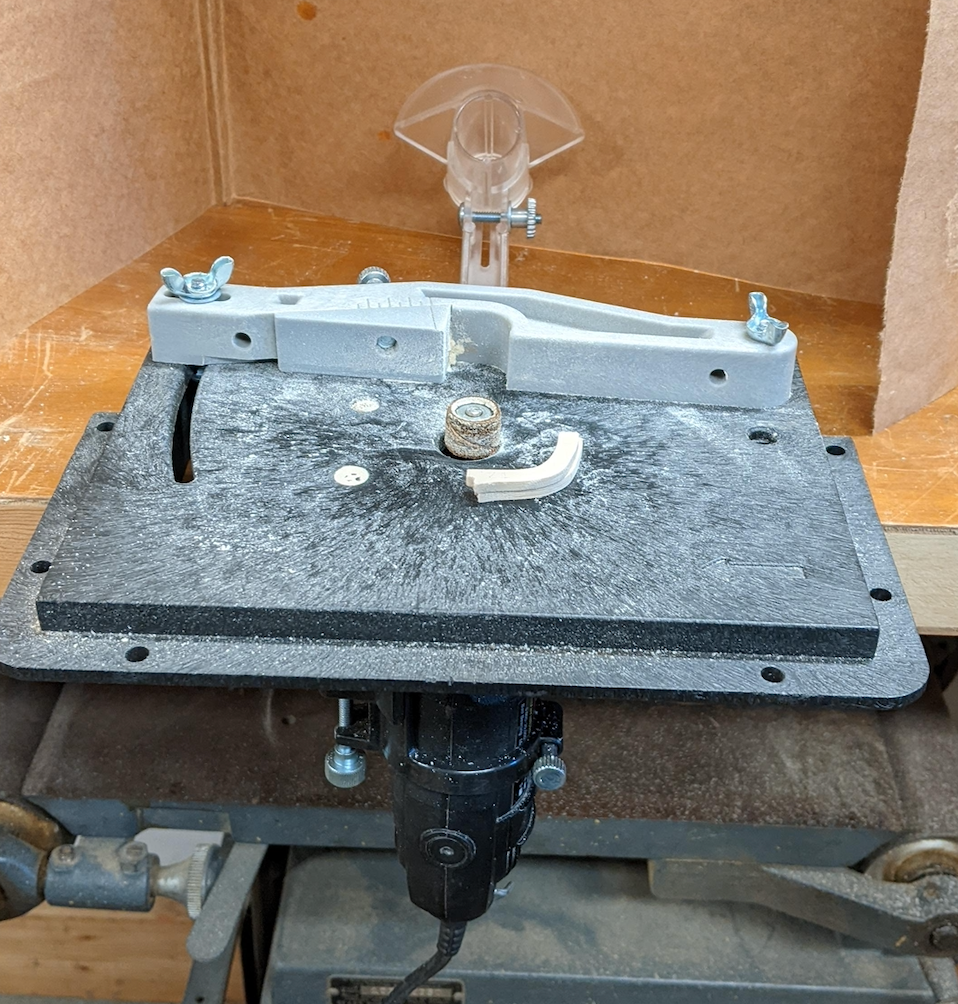

Today time was spent sanding the frames in pair to make them uniform between the two halves. This is performed on a Dremel Router Table with the Dremel tool rotating at a slow speed to reduce the chance of the sanding drum sending the pieces flying. Refer to the attached photo. I am very pleased with the results. Next I will mark on the keel (herein includes the stem post and the stern post, unless otherwise designated) where the frames are to be attached. After sanding with the Dremel tool, I sanded the edges with find sandpaper to rid the frames of the 'fuzz'. It was tedious work, but well worth it! I want to spend some time reading Louie da Fly's build log before proceeding too much further so a step of this portion of process is not missed.

- GrandpaPhil, Cathead, mtaylor and 1 other

-

4

4

-

-

-

Using a scroll saw to cut small pieces can be touchy. Since I am very attached to my fingers, it seemed prudent to make it safer. I made a custom table top with a slot for the width of the blade. This made cutting the keel notches easier and safer. It has two coats of a clear and very liquid polyurethane. See the two attached photos. Soon the sanding of the keel and frames will be completed.

- Cathead, GrandpaPhil, Louie da fly and 4 others

-

7

7

-

- Harvey Golden, ccoyle, Chuck Seiler and 5 others

-

8

8

-

- Cathead, Louie da fly, GrandpaPhil and 2 others

-

5

5

-

I get the picture, Steve!

They are forth coming.

- Louie da fly and mtaylor

-

2

2

-

I may make a second model of the Winchelsea Nef to see if I can 'duplicate' my own efforts. It will also be to try a different method of making and attaching the frames to stem post, keel, and stern post. Also, I may try lapstrake planking instead of carvel planking.

- mtaylor, Chuck Seiler and Cathead

-

3

3

-

-

-

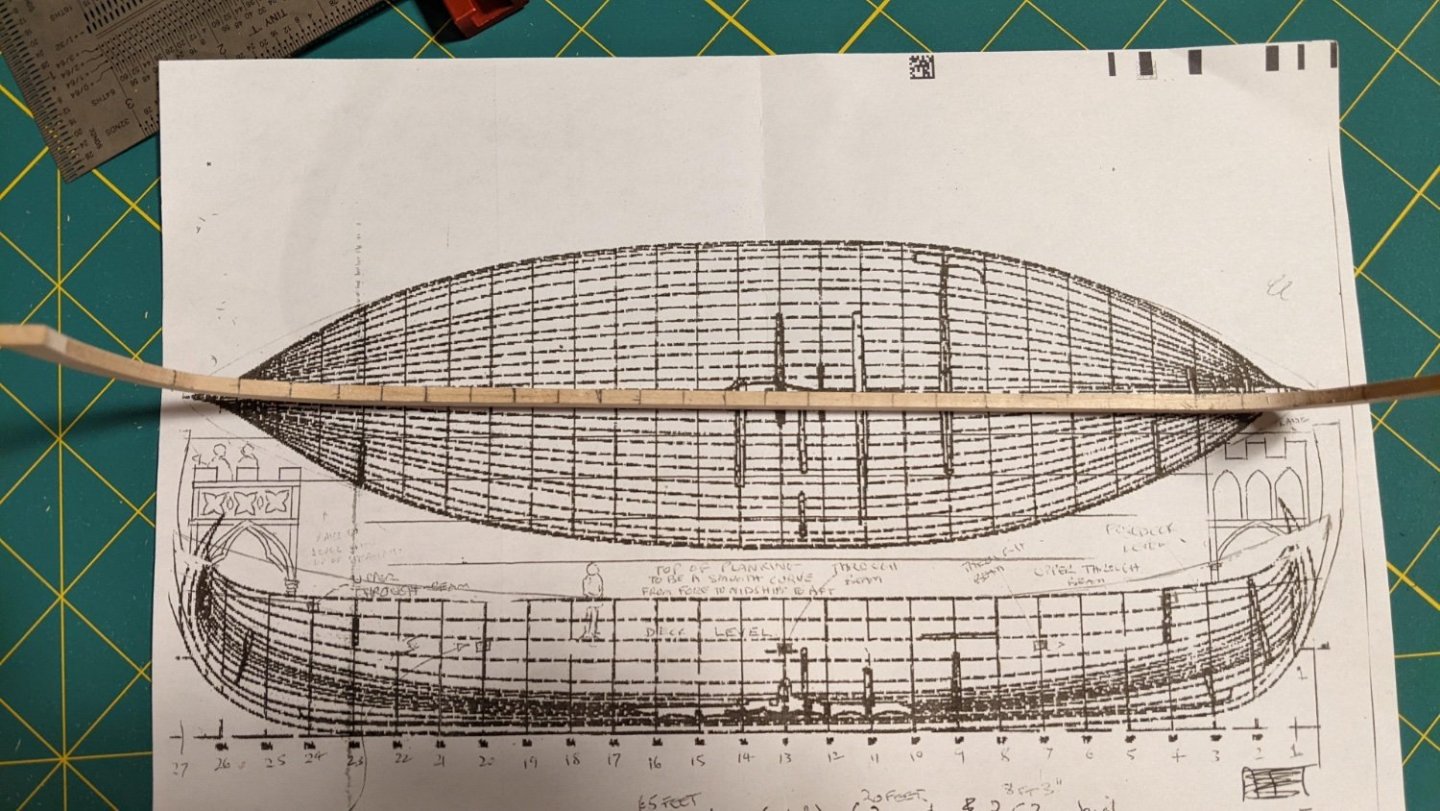

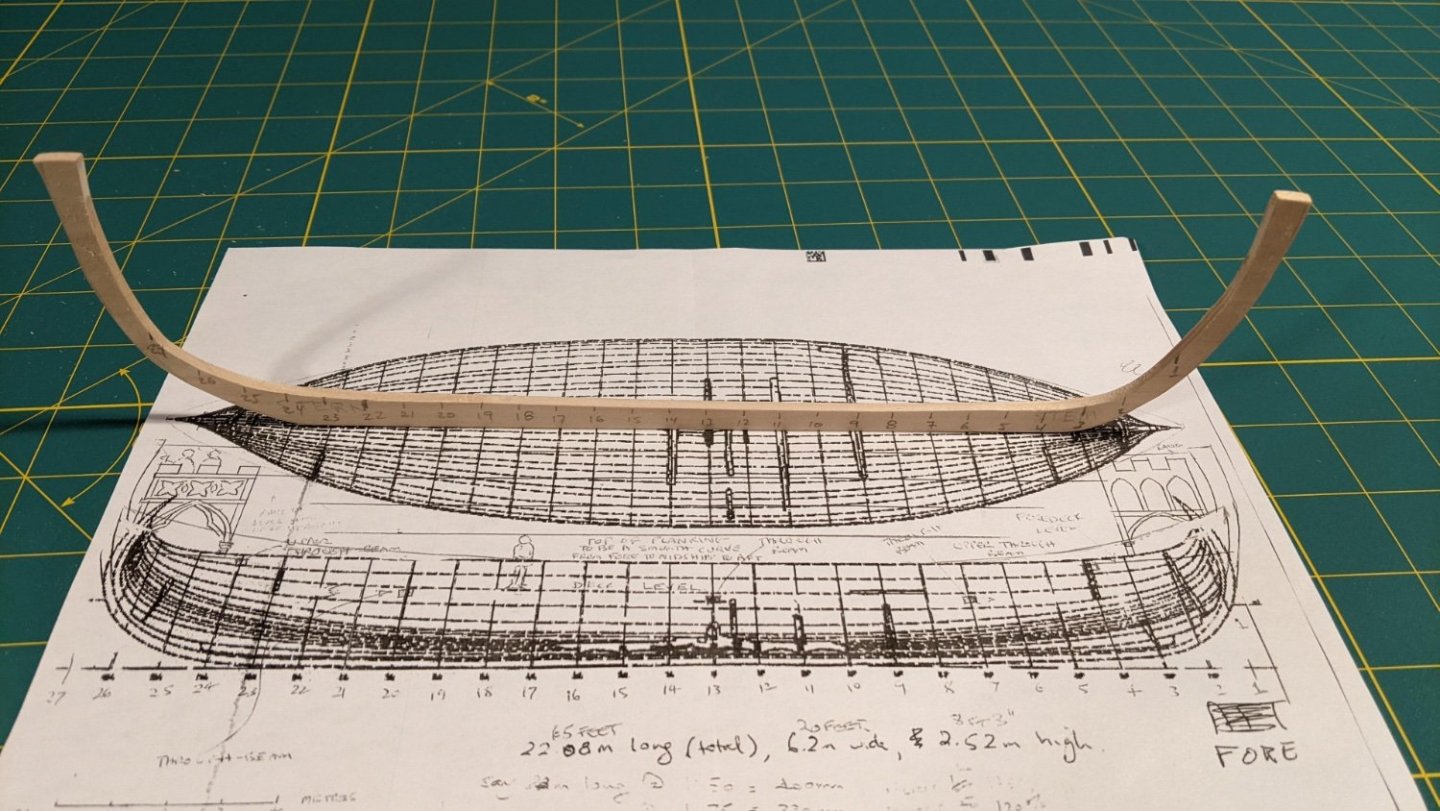

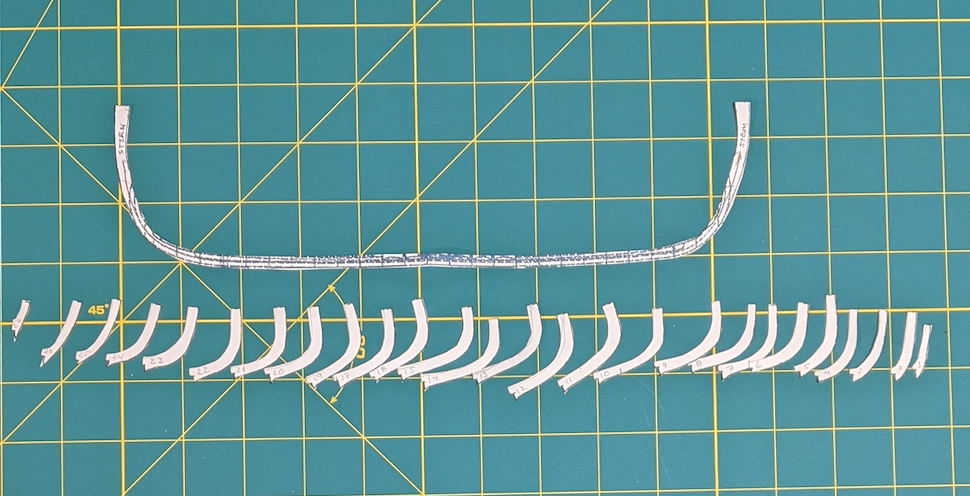

The stem, keel, stern, and the frames are laid out on the basswood. I need another piece of basswood to get the remainder of the frames laid out. It may be hard to see the outlines, but they are there. The basswood is 1/8" thick. I will use 3/32" thick basswood for the planking. As one may guess, this will be a plank on frame model.

-

A relative who has his bachelors degree in model making suggested getting the largest self-healing mat my workspace could handle. The craft store which has the largest variety of sizes and types had a two-pack on clearance. Each mat is 23 X 35 inches. The price was 70% off the regular retail price. I am very pleased to have had only that option on clearance. One mat is for the house and one is for the garage. At least for now that is the way it is.

-

-

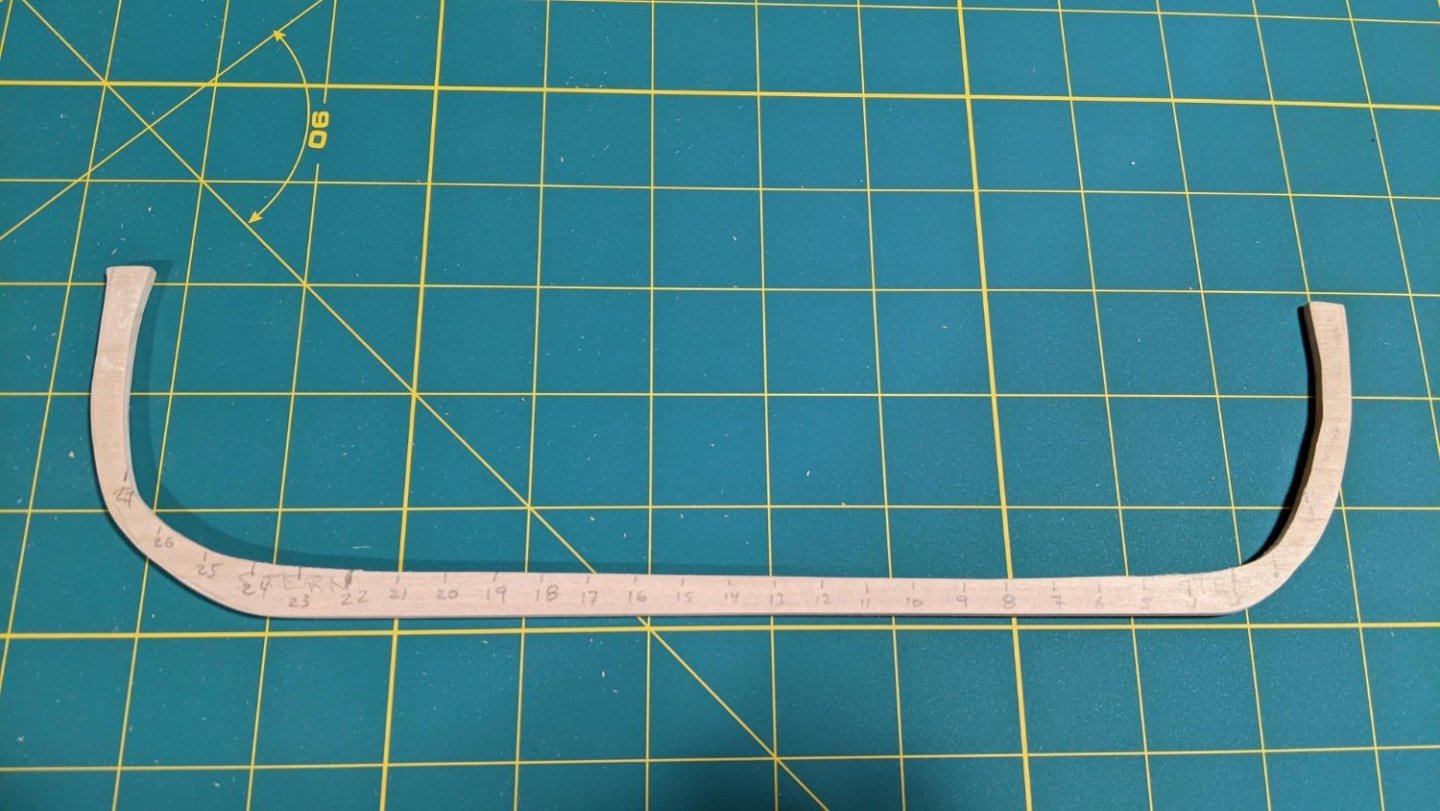

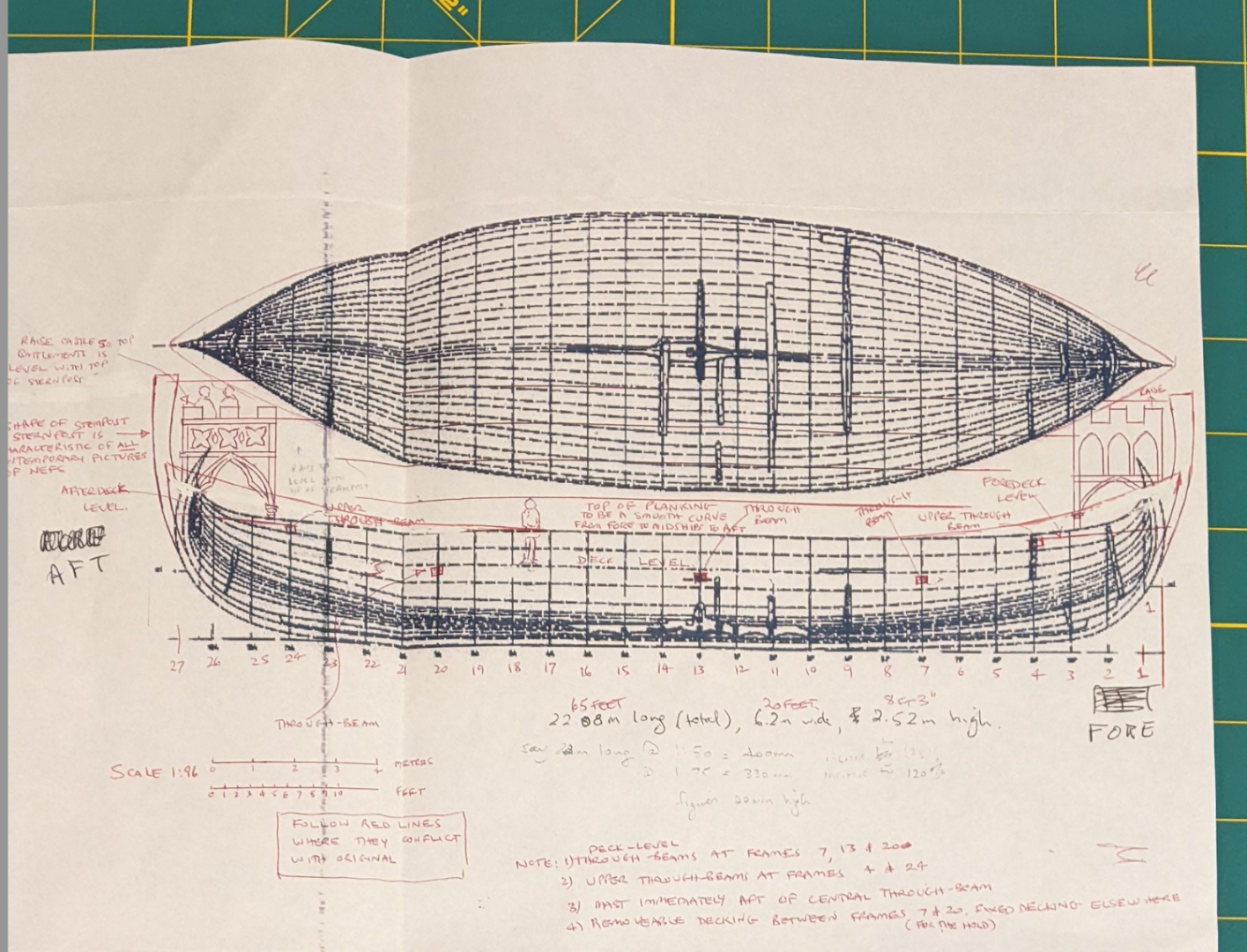

With Christmas and New Years over, I am commencing upon building my model ship. Louie da Fly provided the hull plans including the shape of the frames. After penciling in the remainder of the shape of the frames and the stem post, keel, and stern post, I cut out the shapes. See the attached photos.

I will be using basswood. It is a popular wood for making models in these parts. There is plenty available in various sizes and shapes in hobby shops and hardware stores at a reasonable price.

Next, I will cut out the stem post, keel, and stern post. After that, is cutting out the frames, two each. Before gluing the frames to the keel and posts, I will make a jig to keep the keel and posts upright while gluing.

I named my nef, The Tyburn Treader.

- Brinkman, ccoyle, GrandpaPhil and 6 others

-

9

9

-

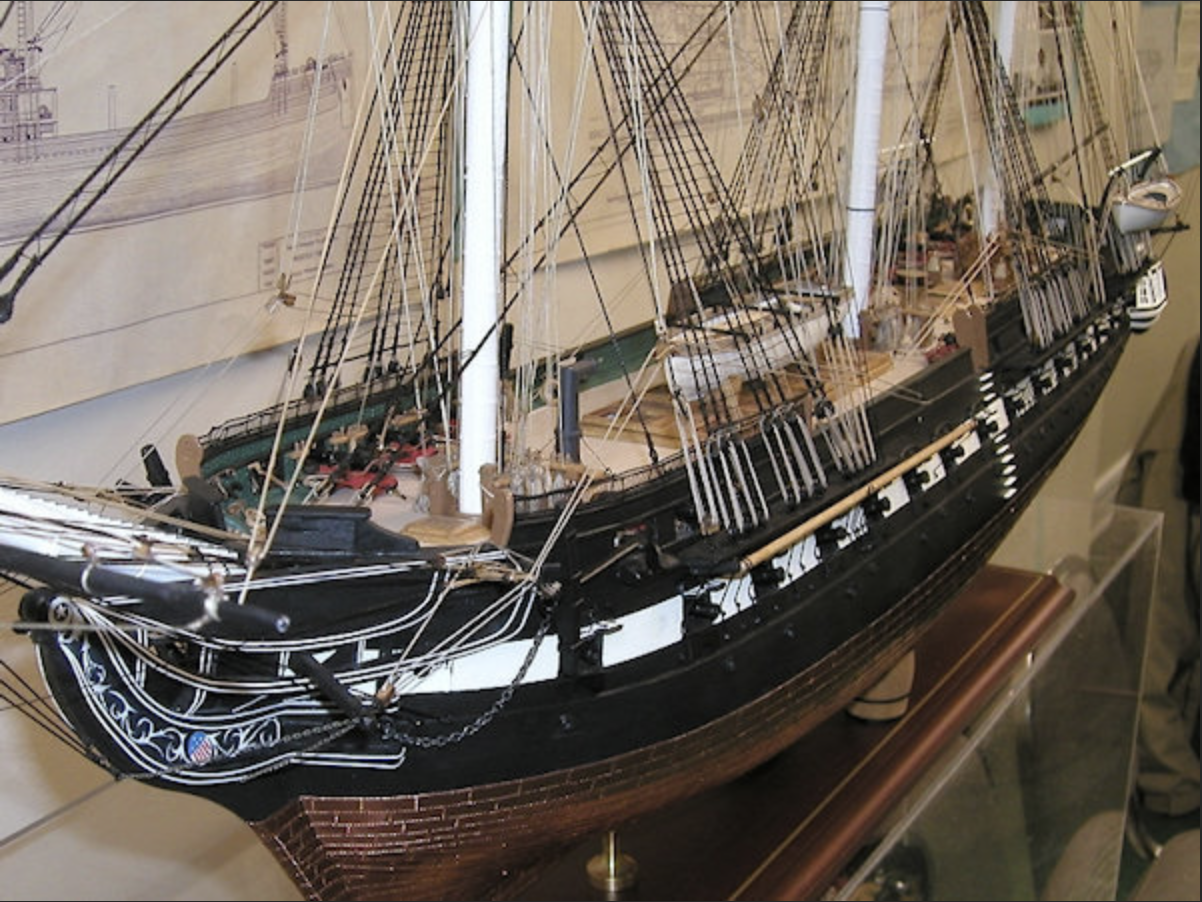

Congratulations, Louie da Fly!! It looks awesome. Way to go.

- Louie da fly, Keith Black, tarbrush and 1 other

-

3

3

-

1

1

-

Your ship is looking very good!! I am looking forward to seeing the final product.

- Cathead, mtaylor, Keith Black and 1 other

-

4

4

-

Awesome job on carving the crewmen!

- Keith Black and mtaylor

-

2

2

-

Great job! Did you carve the figures yourself?

- mtaylor and Keith Black

-

2

2

-

-

Thank you all for the warm welcome! I am also looking forward to my progress.

My garage needs organizing, including a workbench, so it can be used as my workshop.

My garage needs organizing, including a workbench, so it can be used as my workshop.

Mark

- Keith Black and mtaylor

-

2

2

Winchelsea Nef 1274 A.D. by Louie da fly - FINISHED - 1:75

in - Subjects built Up to and including 1500 AD

Posted

Steve,

About a year ago I came across Time Team and Time Line. They are great shows indeed!

Mark