-

Posts

341 -

Joined

-

Last visited

About jdbondy

- Birthday 08/30/1968

Profile Information

-

Gender

Male

-

Location

Dallas, TX

Recent Profile Visitors

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Keith Black reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

Keith Black reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

MAGIC's Craig reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

MAGIC's Craig reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

Dr PR reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

Dr PR reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

berhard reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

berhard reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

dvm27 reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

dvm27 reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

Siggi52 reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

Siggi52 reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

shipmodel reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

shipmodel reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

shipmodel reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

shipmodel reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

gsdpic reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

gsdpic reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

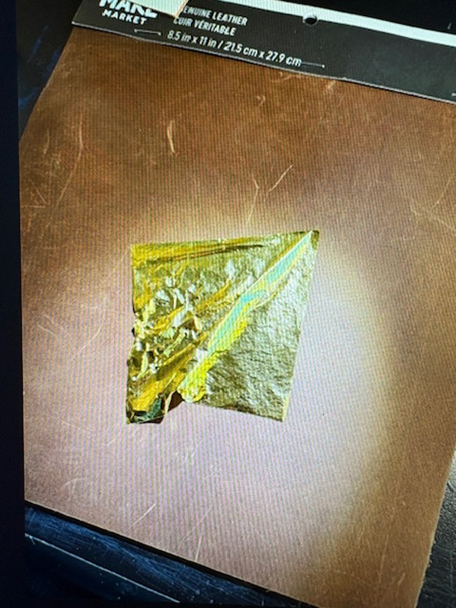

In addition to working on this model of the Mary Day, my other particular creative interest has been in small-scale carving. So it’s nice to be able to have the chance to add some carvings to this model project, such as the transom carving that was covered in a previous post. Here I will focus on the trailboards that are mounted at the bow. The first step was to create a piece of wood that closely conformed to the stem and the adjacent hull shape. Then the outboard surface of the trailboard was carved into this piece. And this had to be done twice, with reasonable symmetry, while also keeping each piece in proper scale relative to the hull and stem. After working out the gross shape of each trailboard and test fitting them on the hull, they were each mounted on holding blocks with glue. The scrollwork was drawn with soft lead pencil, using freehand technique while having actual photos of the trailboards close at hand. The drawing was then inverted and transferred to each workpiece using a hard lead pencil. The detail was then filled in prior to beginning the carving process. Also outlined were the margins of the trailboard and the decorative scroll at the tip of the trailboard. Using the microscope, the background was carved away, leaving the scrollwork and the margins at the top and bottom edges of the trailboard. At this point I felt very proud of myself… …until a fellow modeler pointed out that if left as is, the scrollwork would look like piped-on icing on a birthday cake. (My son who works in digital animation agreed with this assessment!) In order to fully resemble the actual trailboard, the scrollwork would need contouring that resembles the actual trailboard, shown here as they receive a new layer of gilding. I initially doubted that I had the skill to duplicate this at such small scale. But with the right tools and adequate magnification, it was possible to carve out bevels on the concave surfaces of the scrollwork, while rounding the convex ones. The entire surface was painted the same shade of gray as the hull surface. The piece was parted from its backing using alcohol, and was test mounted on the hull and stem. Instead of painting the scrollwork with gold colored paint, gilding was recommended. This was a new process for me. Just learning how to handle the fragile gold foil took some practice and some review of YouTube videos! And don’t have the air conditioning blowing too much in your work area… There is a product line out of Germany made by Kolner, called the Instacoll system. It involves an adhesive base that is applied and allowed to dry. Then an activator is applied, followed by application of the gold foil. The foil is then burnished down to the surface. I had a spare trailboard with carving on it that allowed for some testing of the system before moving to the actual pieces. Here is a trailboard that has been gilded, with excess gold leaf on the background. And here is one that has been fully cleaned up, with the excess gold leaf scraped off of the background. Hopefully my next post will follow pretty quickly, regarding the bulwarks planking. Stay tuned!

-

If you figure out what the name is for that unusual ruler is, be sure to let us know! I am not finding anything like it on my initial searches.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Just a brief post to let you all know I am still alive. The subject is the hawsepipes, and this was a perilous adventure! Even though I have finished the process, I am curious to know how others handle such a delicate matter. The entry point on the knighthead has to be precisely located, as does the exit from the hull planking. I started with very fine drill bits and estimated the path the pipe should follow, drilling in a very shallow manner starting at the knighthead, then doing the same starting at the hull surface, then deepening each hole with the hopes that they would meet in between. While I was still working with relatively small bits, I could tell I was off on the starboard side, as the pipe was emerging too low on the hull. But as I gradually scaled up, it became possible to work on the pipe with the tip of an X-Acto blade and open up the passage in a favorable direction. And in the end, I ended up with two symmetrical passages. The diameter is currently 1/16". They will probably still require further enlargement, and additional wood will be applied to the inboard and outboard surfaces to duplicate the appearance on the real vessel. That will be helpful in that it can potentially cover up other imperfections. So how does everyone else handle this delicate matter?

-

When repeatedly test fitting these pieces, care had to be taken in order to maintain consistent placement of the two articulating planks against their stanchions. For this reason, I drilled a couple of holes in the aft plank and its underlying stanchion, large enough to accommodate a T-pin. One was also placed in the forward plank. These ensured that the planks were landing against the stanchions the same way every time. The forward end of the forward plank was shaped to meet the filler block. But besides the filler block, this end of the plank currently has nothing to land against. So, it’s time to model the visible portion of the knightheads, the solid gray pieces of wood on either side of the bowsprit. The hawsepipes for the anchor chain travel through these pieces. It’s worth noting that this picture exemplifies a difference between my model as built to the original builder’s plans and how it exists today. During the refit in 1999-2000, additional stanchions were added toward the bow that were not part of the original design. Those stanchions are visible in this photo but are absent from my model. The knighthead pieces were built up from a couple of pieces of scrap, and their surfaces sanded down to accommodate their angle against the deck and the area of the bowsprit. There is a small hole for the anticipated location of the hawsepipe where it emerges from the planking, previously estimated by eye. However, this photo from 2024 suggests that my initial attempt is located too far aft. So the position was adjusted and marked with a pencil mark. Then the old hole was filled with a dowel and cut smooth, then painted over. I placed a small pin in the bottom surface of the knighthead and drilled a corresponding hole in the underlying covering board, to give it some strength. Now it is fitted in place. This piece will be trimmed down in the future to accommodate the width of the 8-inch-wide bowsprit. The beginnings of a hawsepipe have been started in it; the hawsepipe will not be brought to its outer surface until the overlying planking is installed. Now it’s time to dry fit the first of the four bulwark planks, again ensuring that there is no gap between it and the covering board, but also ensuring that the plank is pressed up against the stanchions. I made these little things to sit on top of the plank so that a clamp could push against them and the underlying plank, forcing the plank down against the covering board. After a lot of dry fitting, and after purchasing many more clamps, the glue-up was performed and left to dry overnight. But first I attempted to reach any squeeze-out of glue between the clamps that would be visible inboard. Here is the next morning, with the clamps removed and showing the various support pieces of scrap that enabled a proper grip of the clamps on the plank. The scrap pieces on the stanchions ensured that the grip of the clamps on the plank was directly inboard and not on an angle. Voila!! No gaps! There are some areas on the inboard surface of the plank that will require some touch-up painting, but the overall result is really nice. These pictures remind me to say that the inboard surface of the plank was pre-painted, and any paint drifting into the areas where the plank meets a stanchion had to be scraped away before applying glue. Here I am dry-fitting the forward plank; I have not yet glued this one in place. Let’s have another look at that scarf joint area! (This one is actually for the opposite, port, side.) Very pleased with how that looks. So, once the remaining 3 planks are installed, then planking of the rest of the bulwarks should go pretty quickly, followed by installation of the rail. At the same time, I am working on marking out the waterline, plus I am continuing to work on the miniature carving of the trailboard. So much to do!

-

So, now on to the first bulwark plank. In this picture, I am mocking up how many planks there will be in order to get to the undersurface of the rail. The first plank is slightly thicker than the rest, and again it will feature that bead that is visible in the initial picture above. Next step is to create the bead in the top edge of the first bulwark plank. This required me to learn about how to make a scraper. There will be four strips of wood for modeling this plank, 2 on each side with a scarf joint at midships. I used a cutoff wheel on a Dremel to carefully cut into the edge of this X-Acto blade. I found that the gap between the top edge (on the left) and the barb of metal adjacent to it was too small to accurately cut using the cutoff wheel. The solution was to make the strips overly wide, then scrape in the bead feature, then run the strips through the thickness sander while tilted up on their edges. In this way, I could end up with planks of the right width, with the bead feature right at the top edge and in scale with the actual appearance. I had these great pictures taken through the microscope showing some of the process of cutting in the scuppers, but MSW has decided not to accept those pictures! Oh well. This picture shows that the first plank needs to be steam bent to accommodate the curve of the hull, of course along its thin dimension, but also including edge setting. This is particularly necessary in the bow, where the hull has a degree of “powderhorn” that leads to the first plank initially curving upward, but then curving in a downward direction as it approaches its end at the bowsprit. The powderhorn is accentuated in this picture. The plank ends against a temporary spacer applied to the stem, which corresponds to the width of a support block located below the bowsprit. The bowsprit itself will be much wider than this spacer. Here we have one of the aft planks, with its scuppers cut into it. Placement had to be precise due to the location of the scuppers as well as where the aft end of the plank meets the transom planking. In addition, the bottom edge of this plank had to be shaped so that it cleanly met the level surface of the covering board, accounting for how great or little the underlying stanchions leaned in comparison to the covering board. This picture illustrates that simply placing a clamp on the plank leads to a gap at its lower edge, in part due to the force placed on the upper edge of the plank by the clamp, but also due to the shape of its bottom edge. Shown here is the scarf joint and its placement relative to the underlying stanchions, as well as some gapping between the covering board and the plank. Here I am beginning to work the other side of the scarf joint into the forward plank. It’s always satisfying to see a scarf joint come together! And this one has the added complexity of a scupper within it, as will the joint on the port side. This shows how the scupper is worked into the joint. More posts will follow shortly...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.62d1d69fed1f32364417cb1f9cdeb009.jpg)