Avi

-

Posts

320 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Avi

-

-

It was a lot of work, including cutting through copper and then adding plates where they got ruined or where I cut too high, but rudder looks better.

I think this stage finally is done. Next post will be about starting the gundeck.

- ERS Rich, catopower, Bill Morrison and 2 others

-

5

5

-

I plan on removing them from the rudder and cutting in to countersink them. This whole discussion has been quite helpful, thanks!

- catopower, Bill Morrison, ERS Rich and 1 other

-

4

4

-

Yeah I saw that as well. But I’ve no idea how to get that. The gudgeons and pintles are as flush as possible with the hull and rudder. How would you get it in closer?

-

Rudder shipped. The gudgeons and pintles aren’t permanently attached to each other, in case I need to remove them for work. But they are glued to the hull and rudder, respectively.

I had them primed and painted, then attached them. And when I did, most of the paint came right off. I had to do another coat or two. And I suspect more in the future. But good for now.

-

-

Yeah. I’ve got someone visiting near him in a week, she will bring it back. Phew.

-

-

Redid the rudder. Used an iron to heat up the copper, removed all the plates, cut my finger (optional), sanded it down, then sanded a curve, primed, painted, and applied new copper.

Giving it a day, then will wax and varnish.

Bluejacket is sending me replacement gudgeons and pintles of the correct width, but they will not arrive for a few weeks.

-

49 minutes ago, Gregory said:

How hard would it be to make another rudder?

Not terribly so, but I do have this one. Remove maybe 15-20 copper plates and I can shape it.

- ERS Rich and mort stoll

-

2

2

-

1 minute ago, Gregory said:

The forward edges should definitely be rounded, otherwise the movement would be highly restricted.

That’s a fair point, unless there were a large enough gap between rudder and sternpost, which would not be great for the fluid mechanics.

The picture from the museum shows it.

Even rounding it won’t help much, without some serious tapering. Those gudgeons and pintles are ⅛”, the wood stock for the rudder is 5/32”, add the copper and it’s up to 7/32”.

I’m somewhat perturbed that the guide didn’t say anything about rounding. It’s obvious once someone smart like @Gregory says it, but not before that 🤦♂️

I would like to get that rounding in anyways. But even if I do, I need gudgeons and pintles with wider spacing in the gap.

I’ll have to get from bluejacket.

As for the rounding, I could remove the leading edge copper plates, and then either add material or sand it down.

Anyone remember how to remove contact cement? 😁

- SUBaron, ERS Rich and Bill Morrison

-

3

3

-

24 minutes ago, JSGerson said:

If you look at Khauptfuehrer's Bluejacket build log, he states:

"There is a pitfall concerning the rudder installation. The rudder is made from 5/32" stock. If your kit is like mine, you will have gudgeons and pintles whose interior dimension is 1/8". The folks at Bluejacket swear up and down that the dimension is 5/32" but, trust me, it is 1/8". Bending these to suit is difficult and yields less than satisfactory results. Bluejacket also sells gudgeons and pintles with a 1/4" inner measurement. These are easy to adapt and work well. Drops of glue are used to simulate bolt heads I recommend that you buy 1/4" gudgeons and pintles. They will bend easily to suit, and you will be fine."

This might to a solution to your problem.

Jon

I probably read that at some point or another, as I read every build log that might help. I must have forgotten. I’ll just have to get those. Thanks @JSGerson

if anyone comes across this in the future, here’s the link https://www.bluejacketinc.com/shop/fittings/under-water/gudgeons-and-pintles/f0852-1-4-to-fit-rudder-thickness/

item F0852

-

3 hours ago, Gregory said:

Do the plans show a profile for the rudder?

Maybe there should be some more taper on the forward edge.

No they don’t. Nor does the book say anything.

-

Ok I primed them and will paint soon.

Ok I primed them and will paint soon.

Never a boring moment. Despite the promises of the book, the gudgeons are too narrow to fit over the coppered sternpost and hull, and same for the pintles over the coppered rudder. Oops. I’m not quite sure what to do here. The metal is soft, so I try to shape it, but I’m more concerned I’ll snap the pieces off.

- Bill Morrison and ERS Rich

-

2

2

-

-

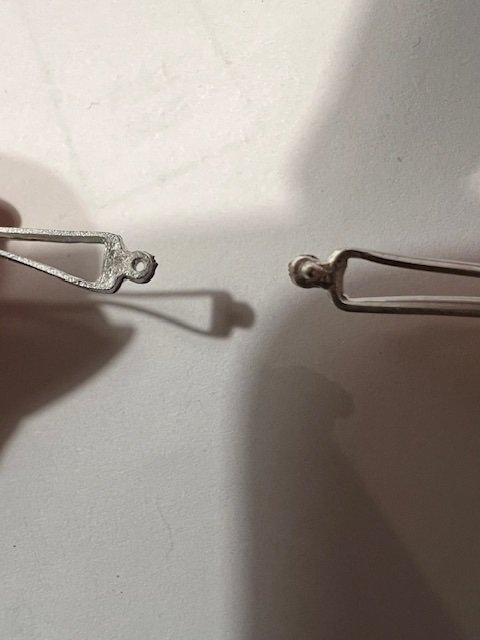

One issue down, thanks to @ERS Rich

I filed the triangles down to more of a post, then used fine drill bits to smooth out the bores on the pintles. They all go in smoothly now. 😃

Now to decide about how to finish them before mounting.

-

Thanks @ERS Rich; did you paint them?

-

Hard to believe it has been two months since I posted. Life has been a wee bit busy here.

Before I start on the gundeck, I’m going to place the gudgeons and pintles (my phone keeps trying to auto correct those 😂)

The book recommends not shipping the rudder permanently yet, but to wait until some of the harder work on decks and masts is done, since the rudder is fragile, which makes sense.

I ran I into two issues.

First, the gudgeons and pintles are of that metal. Should they be finished or painted in some way?

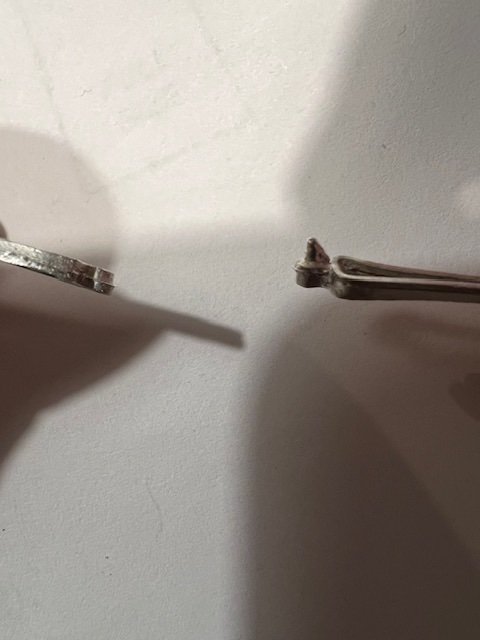

Second, I don’t understand how you attach the rudder to the sternpost, or more correctly, the pintles to the gudgeons. There are holes in the pintles, which the guide suggest running a stiff wire through for alignment. But the gudgeons have more a triangle than a post on them. It isn’t something you can set the holes from the pintles onto. I could put the gudgeons in with them facing down, and then just glue the pintles to the gudgeons, but then it would have no motion. I guess I also could carefully trim down the triangles to a post with a file? Not sure.

Pictures attached.

- Bill Morrison and ERS Rich

-

2

2

-

23 hours ago, Brian Falke said:

Avi, my only recommendation would be to do all you can to ensure the corners are pressed down. I too have given it thought on how to achieve a "smooth" surface with the platting and feel that pressing using a mini-roller would be my best option. Here is what I am referring to

With a slight bit of pressure, you should be able to get the corners pressed down.

Brian

Dang that is great! I’ll pick one up. Thanks!

-

19 hours ago, Bill Morrison said:

Avi.

Have you seen the videos on coppering a ship on YouTube?

Bill

Yup. Long time ago though. I started copppering early this year.

Is there something specific to which you refer?

-

Hi Nic, good to have you on here. 😃

Is there anything that will act as a sealed layer, like a sheath, over the whole thing? I was hoping a few layers of polyurethane varnish would do it (as implied in the manual), but no such luck.

-

It probably is. Some don’t overlap, which is why it’s a good thing I painted the planks with that good Vallejo copper paint (real flakes in it). Either way, the question is, what can I do to help with it.

-

Ok I am a bit frustrated. With the planks, I was able to smooth them down, especially at the edges, with sanding. I did it lightly, to keep some texture, but it worked.

Obviously I cannot “sand” copper plates. They also are thinner and are metal, so there are sharper “edges and corners” that can get caught on something over time. No matter how good a job I may (or may not) have done in applying them with cement, there’s some edge or corner on many that won’t be 100% flush.

While the wax did a good job sealing and protecting each copper plate itself, my hope was that the varnish would create something like a sheath over it. A few coats, a few hours drying in between, and I would end up with that protected smoother surface (“sheath”).

That didn’t happen. I didn’t skimp on the varnish, but I didn’t get what I was hoping for. I can continue building, but I’m concerned about the fragility of the plates and their ability to get caught and yanked off.

Open to suggestions.

-

-

Two coats of wax on all of the copper - about 10 plates needed to be reinforced or remove and recemented - but waxing is done. Next is varnish. I’m sure the wax provides more than enough protection, but the sheer “pointiness” and “edginess” of the plates means something is going to get stuck on an edge or corner and yank a plate off, or bend it, no matter how long it’s been there. A few coats of varnish will provide a thin layer of sealant, like a tight raincoat or wetsuit, on the whole thing.

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

in - Kit build logs for subjects built from 1751 - 1800

Posted

About that gundeck. I’ve got the glued up planking, which is four sheets. Each deck (gun and spar) is two sheets side by side. My plan is to cut the sheets for the spardeck but not quite snug, just a bit too big, 1-2 mm around. Then I’ll take one of the cannon and glue it together with glue that comes apart easily, as I’m not planning on painting yet, just using it for measuring. I’ll probably use Elmer’s glue, which I hear can be removed with vinegar. Open to suggestions.

Either way, I’ll use the cannon to determine what the correct deck height should be at each point, by placing it on the deck planking at the gunport. Where the deck needs to be higher, extra hull planking under the deck planking will provide the boost. Since it is so very thin, I can get tiny gradations.

I expect to start around mid to late August.