-

Posts

372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by PRS

-

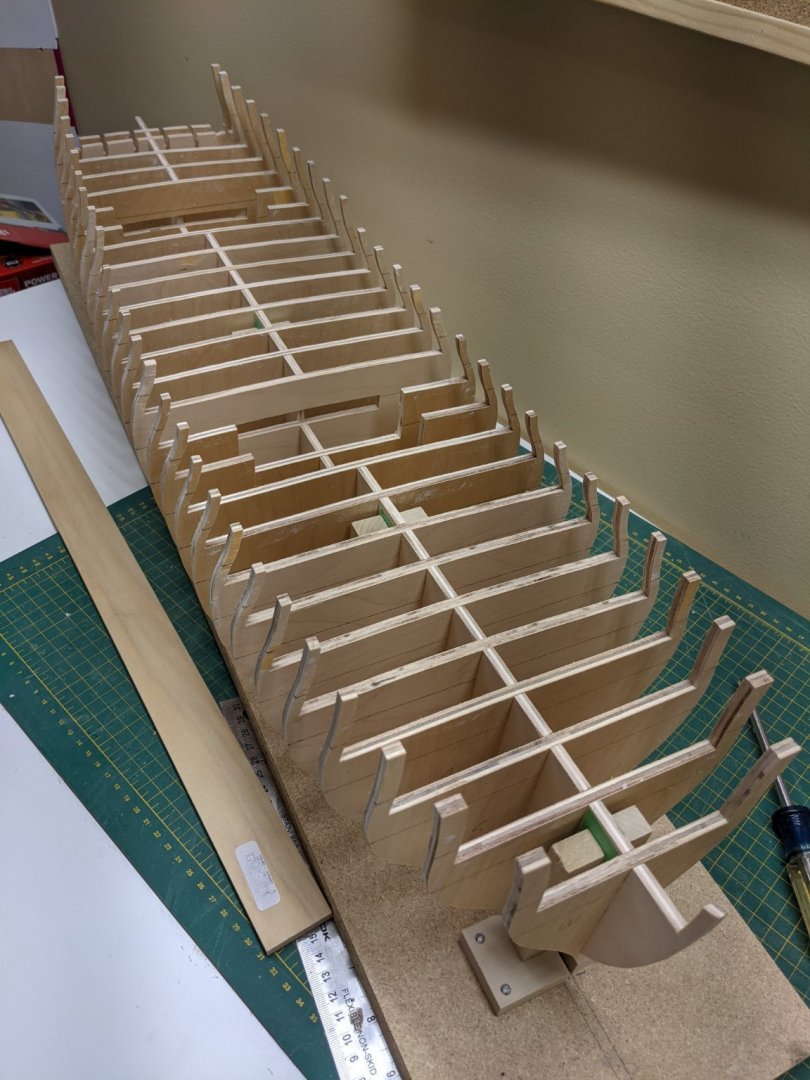

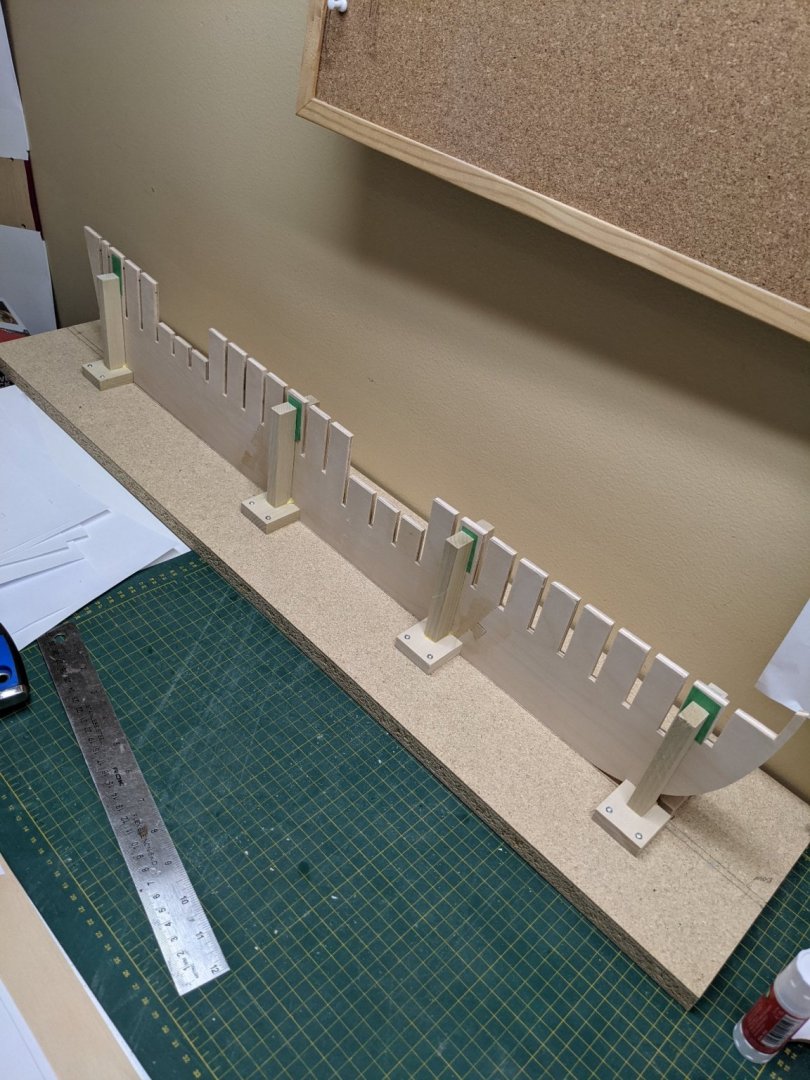

Lining up the gun port lays. I took a lot of time with this and left it overnight to look at it again the next day and did see where I could make some adjustments. I am going to frame the upper and lower port openings before fairing as to give some support at the top. The piece of wood I am using is the exact opening dimension on the large end which makes lining up the top piece easy. I must say having a table saw and a crosscut sled sure makes duplicating these pieces easy.

-

Thanks Chuck. I wasn't able to find lite play locally so went with this. I am used to sanding aircraft ply which is real tough stuff so I will see how it goes. I initially looked at MDF but the panels were warped really bad and I know that stuff is hard on blades because of the glue if the blade gets hot. Thanks Matt. Just time consuming and slow work. Good to know. Wasn't sure if the rubber cement would get into the wood and make it hard to come off.

-

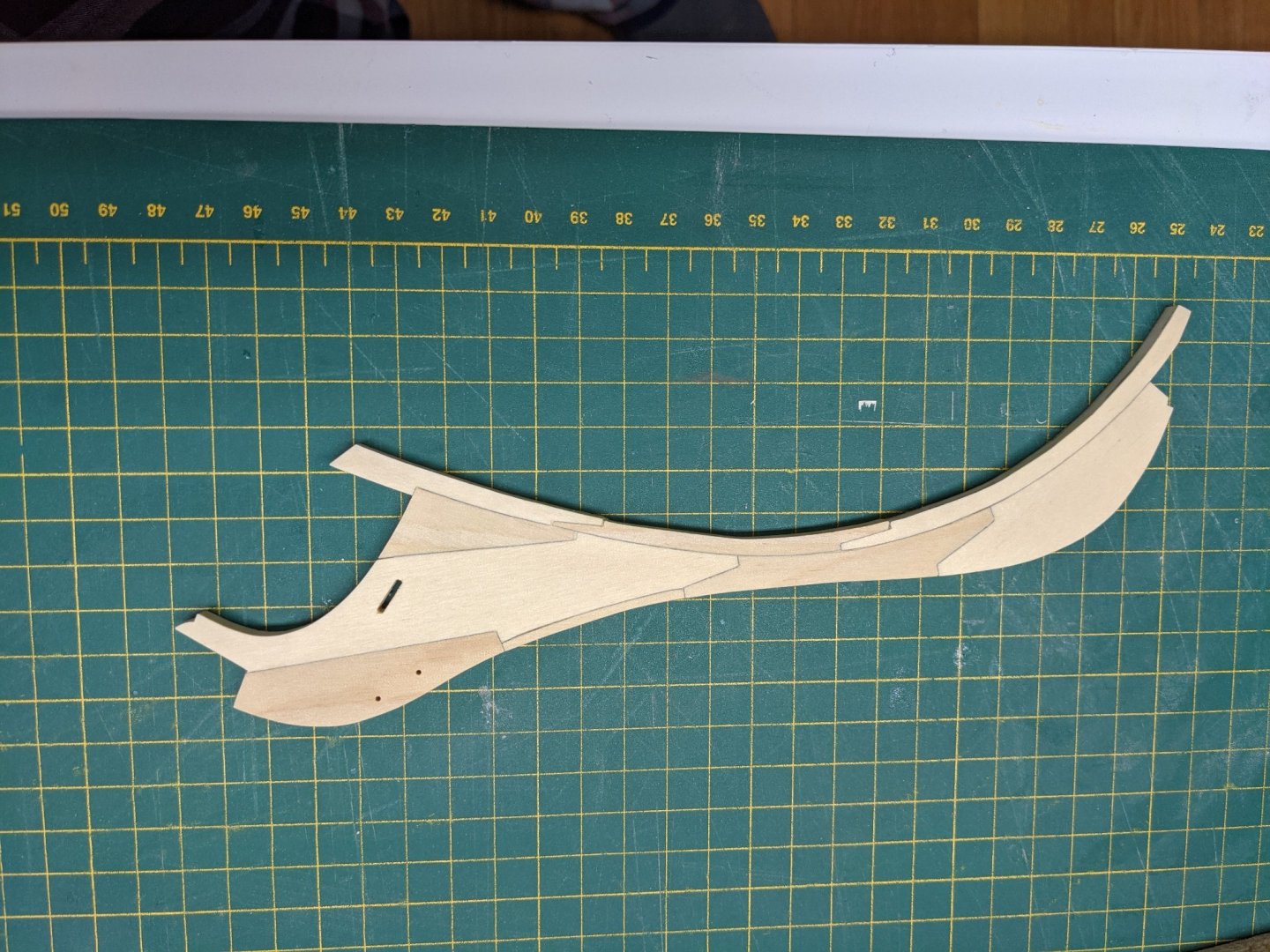

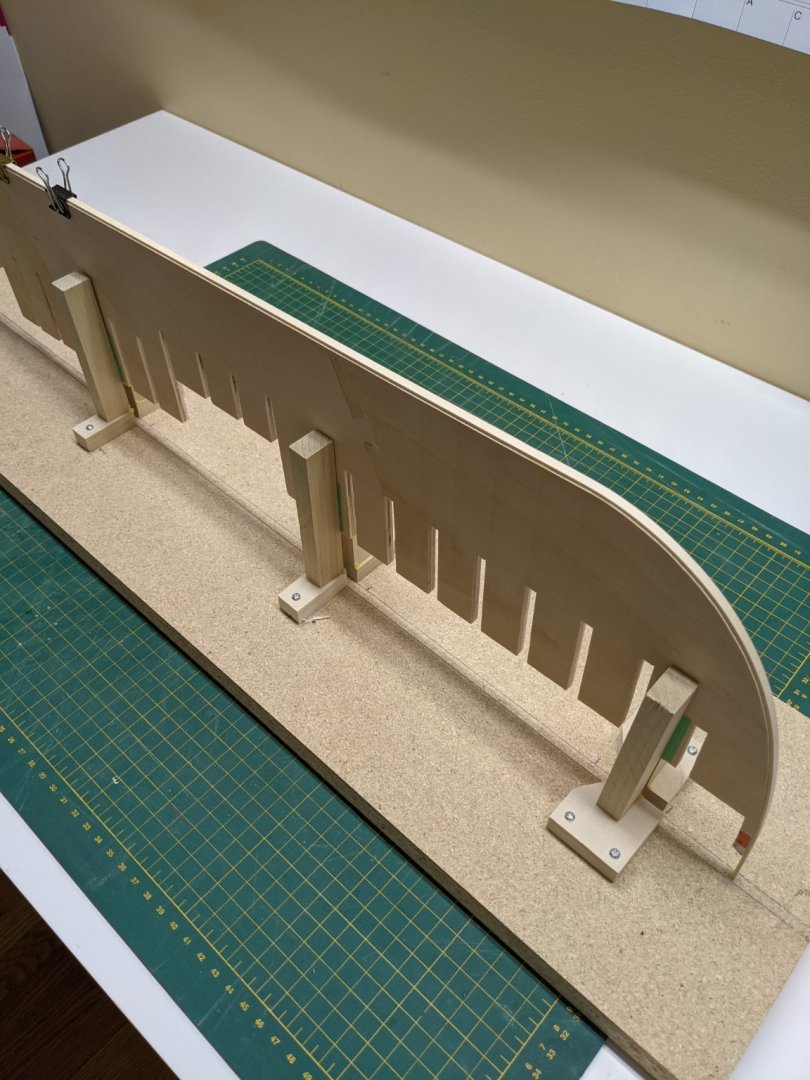

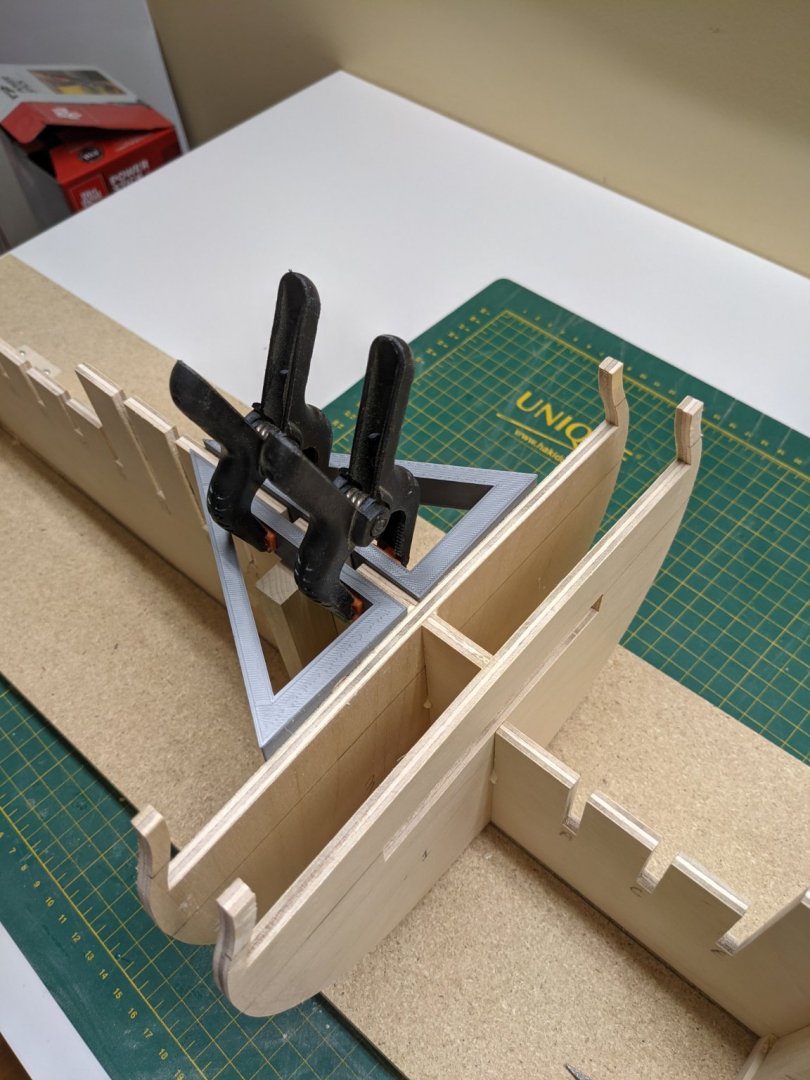

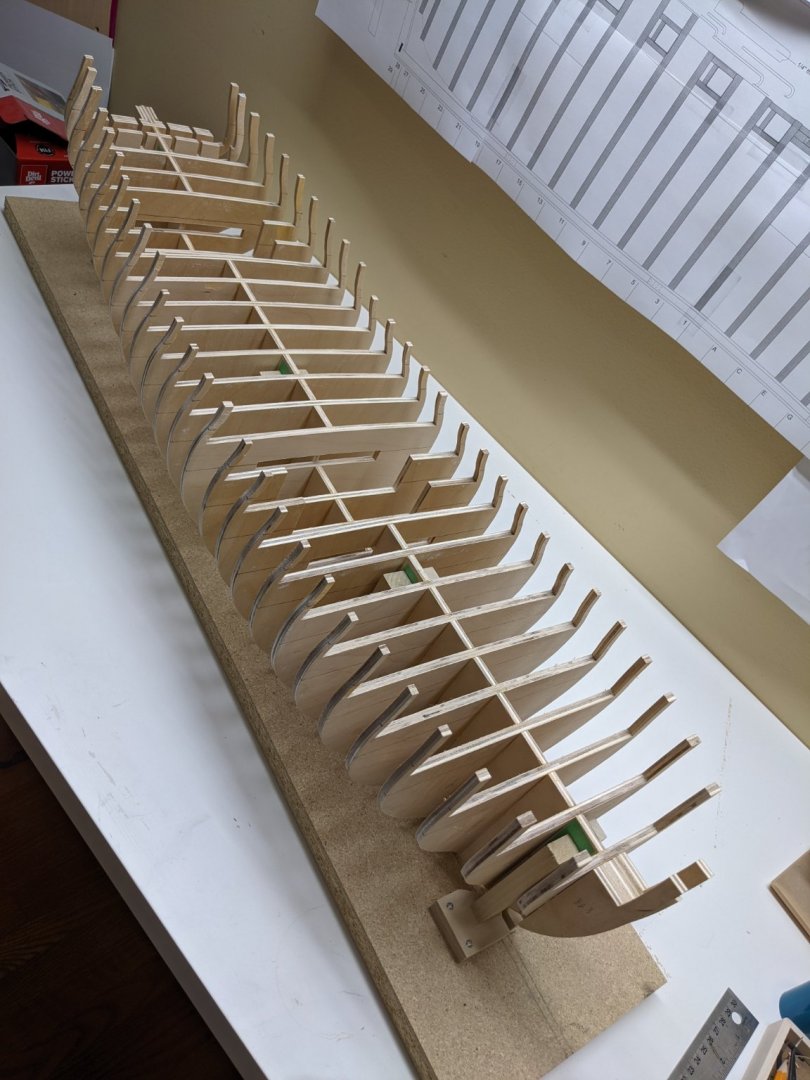

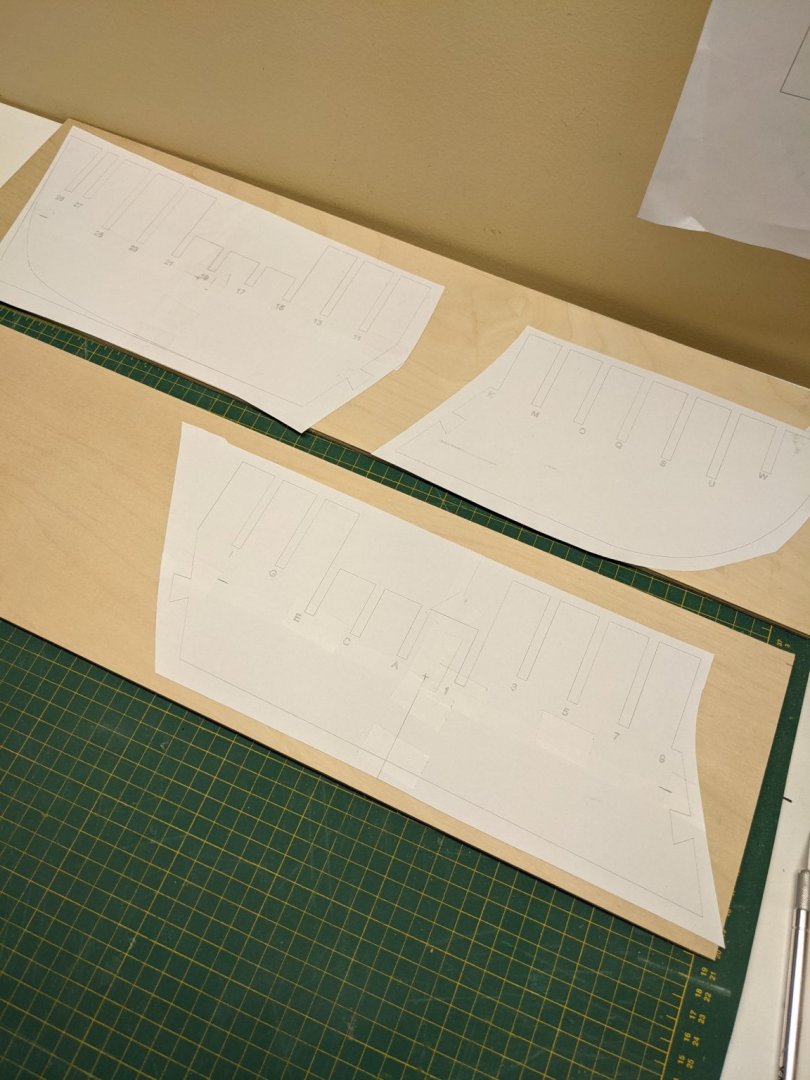

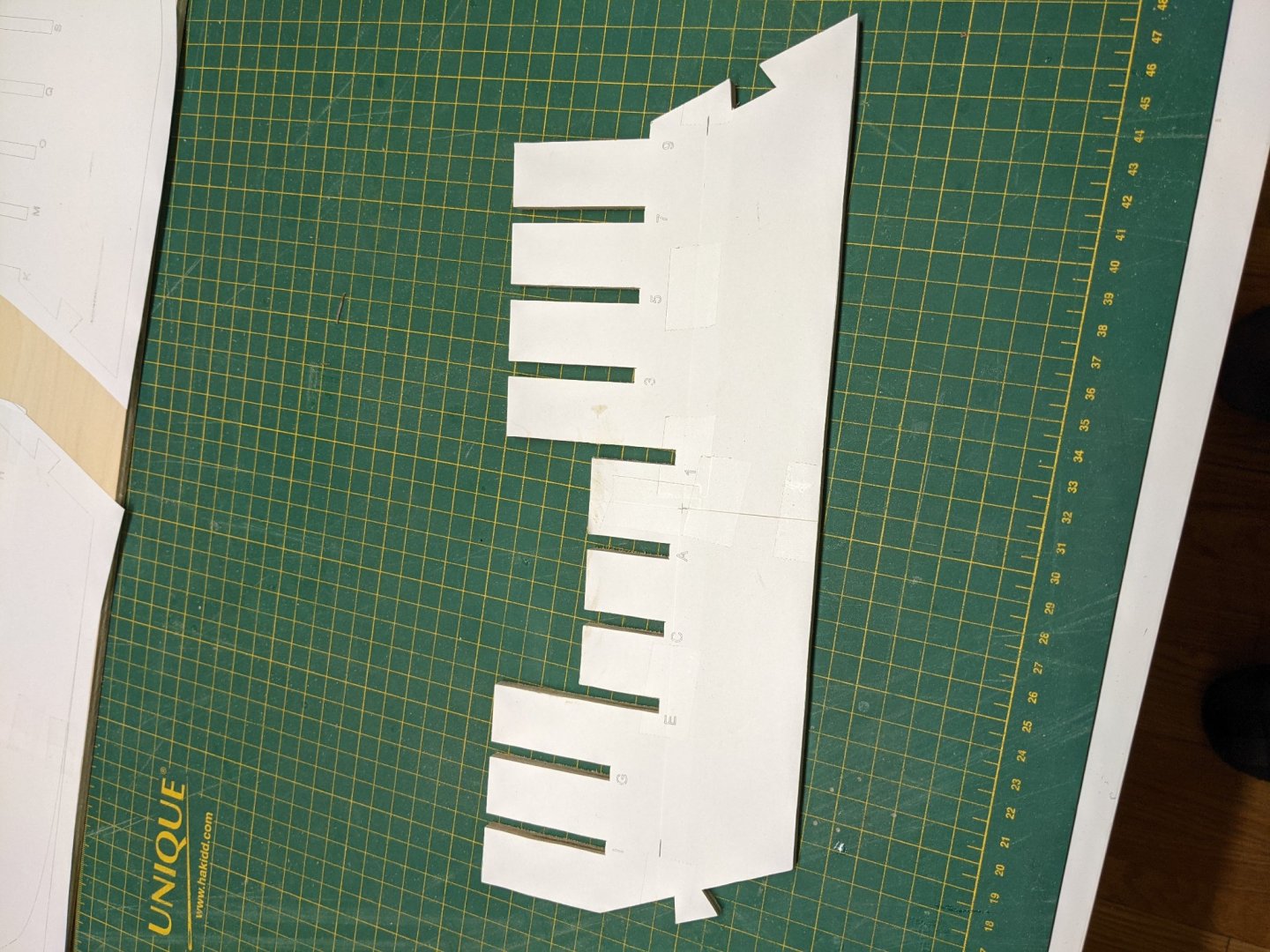

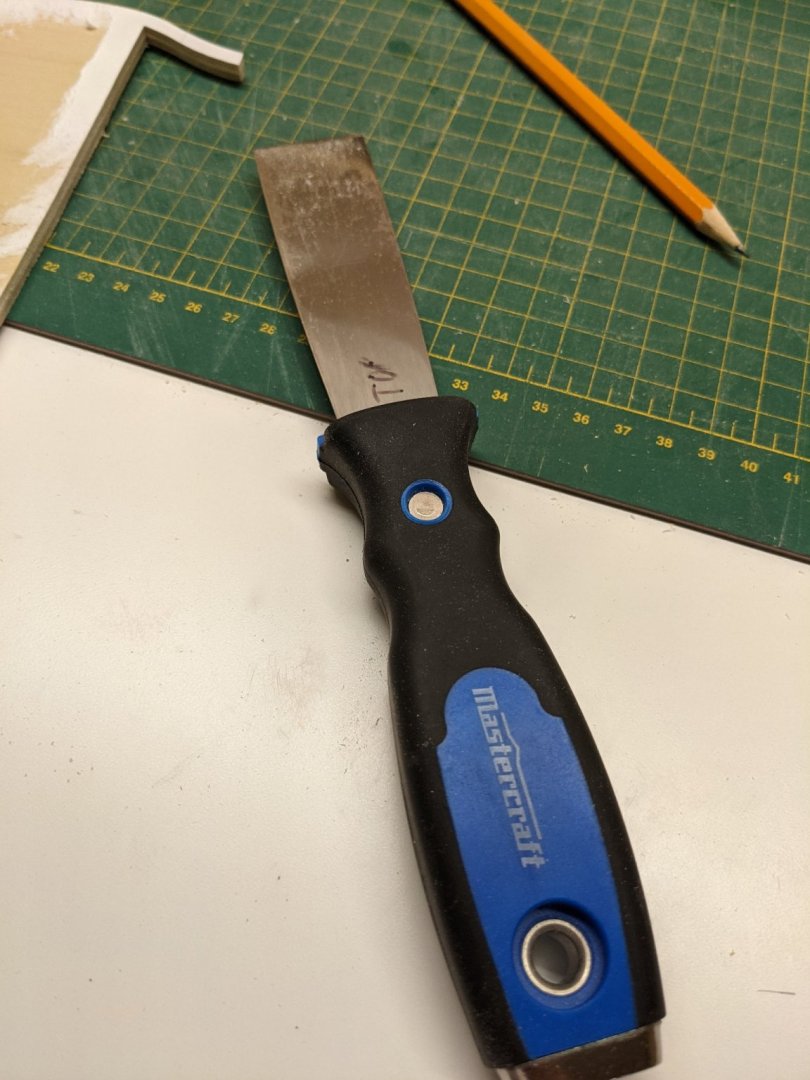

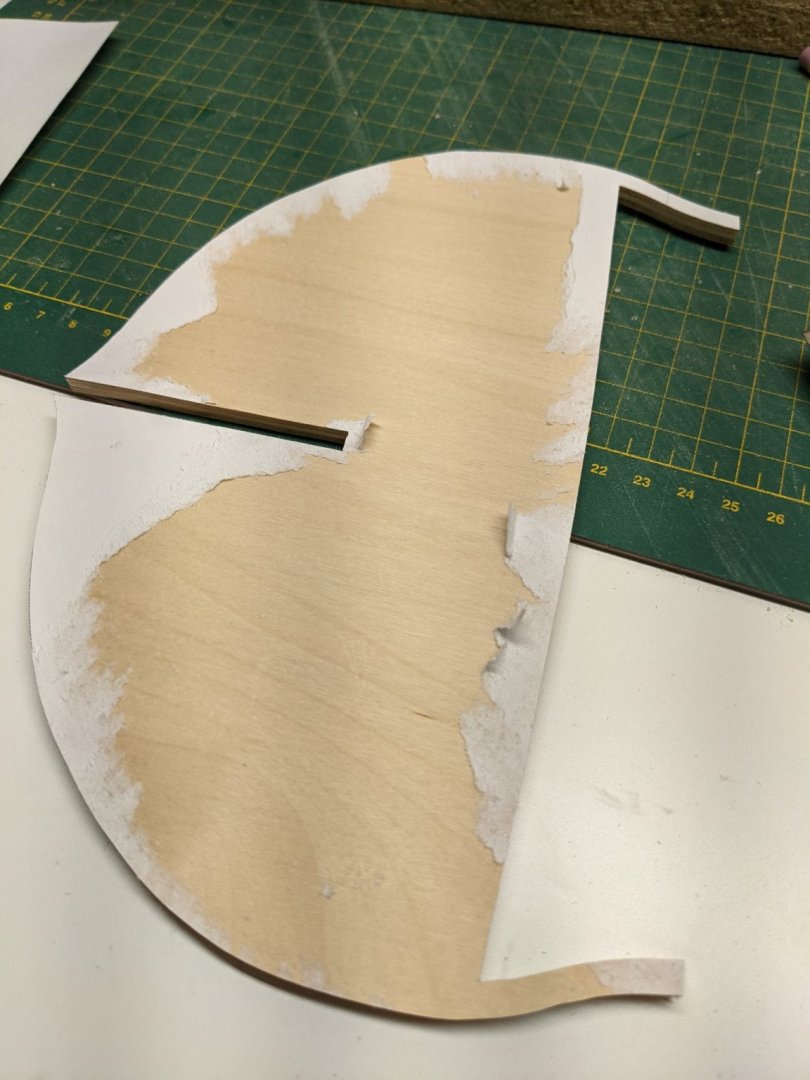

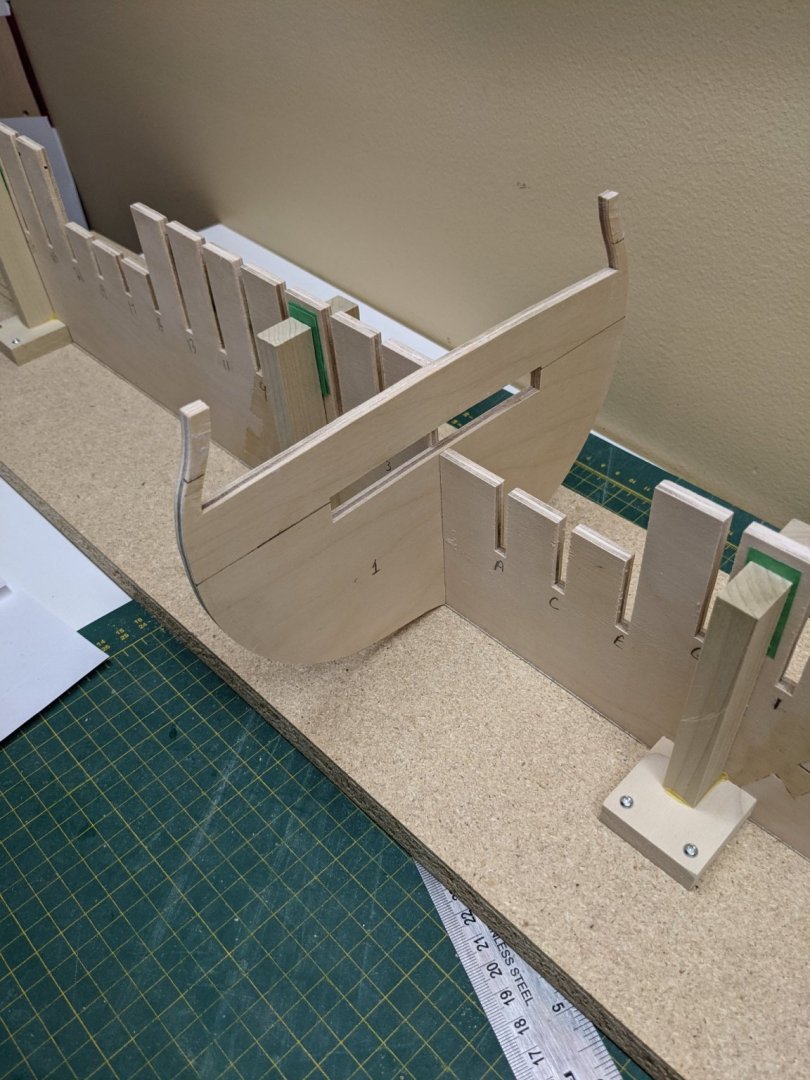

Posting the start of my build log for the Winchelsea. This is going to take quite a while to build as it is huge and complicated with many parts to make. I am going to attempt to scratch build as much as I can as a challenge to myself. I started cutting out the bulkheads and false keel with my scroll saw and it can be done but you have to use sharp blades and work slowly. You WILL break blades and I found that when they get dull you are not far off from breaking. These are the blades I used. They give a very smooth cut. I am using 1/4 inch birch plywood sourced locally and printed out the parts to cut and then used a glue stick to the wood. Then carefully and slow cut with the thin blades right on the line as best as possible. I found sitting with my saw on a desk works best as it ends up being chest high and you can follow the lines easier than standing which is hard on the old back. I did cut the false keel in three pieces as this will keep any warping between pieces to a minimum. Once the pieces are cut I have a sharp scraper and just peeled and scraped the glued on paper off. This scrapper has been sharpened with 800 grit sandpaper so it is very sharp. While I was at the lumber store I also picked up a 3/4 inch MDF used for stair treading as my work base. It is nice and straight. I also made up some squaring pieces for assembly and did have to modify the bases a bit later as they are too large and interfere with the bulkheads. Here is have the false keel pieces glued up and held straight. It was a lot of cutting and if you do it slow not much sanding. Once that was all set I mounted my squares on the build board. There is a very slight warp at the top of one of the pieces which release when it was cut but I am aware of it and will make sure there is no warp built in. Next up is the process of cutting each bulkhead and laying them in place. You know there are a lot of them right? I still haven't decided on Yellow Cedar or Cherry for the most of the build yet. Hope you can follow along and offer suggestions or even an attaboy which helps with motivation as my new 3d printer keeps pulling me away from my projects

-

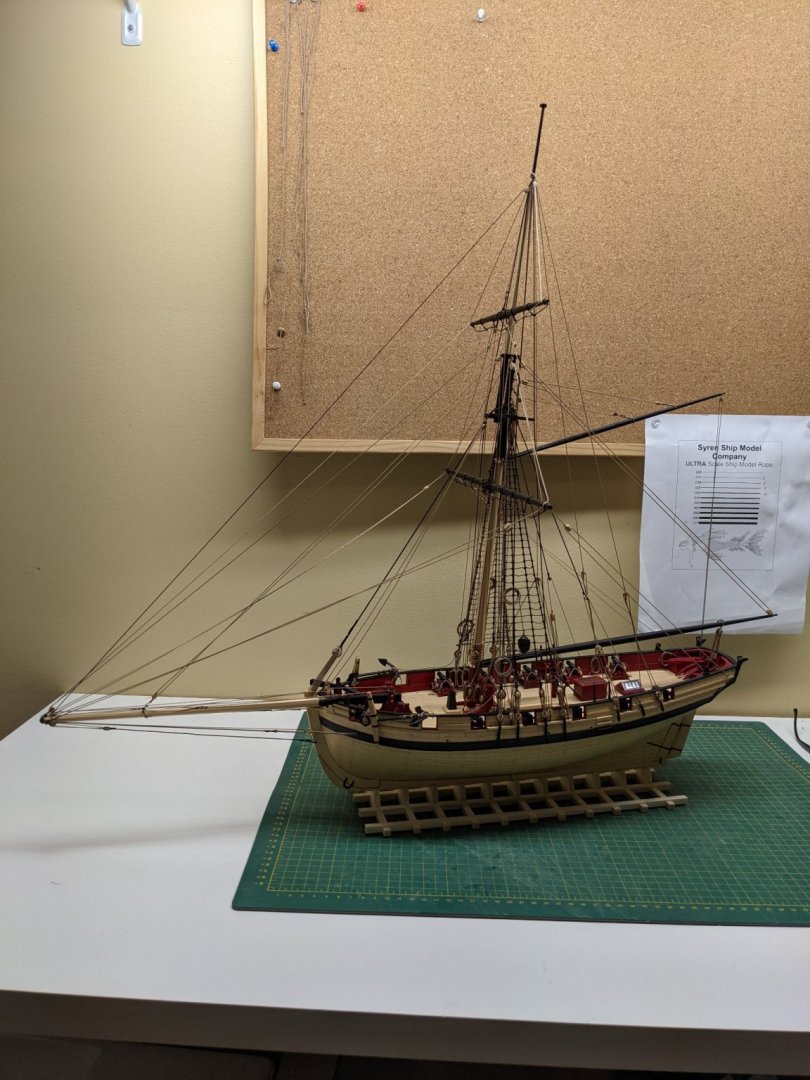

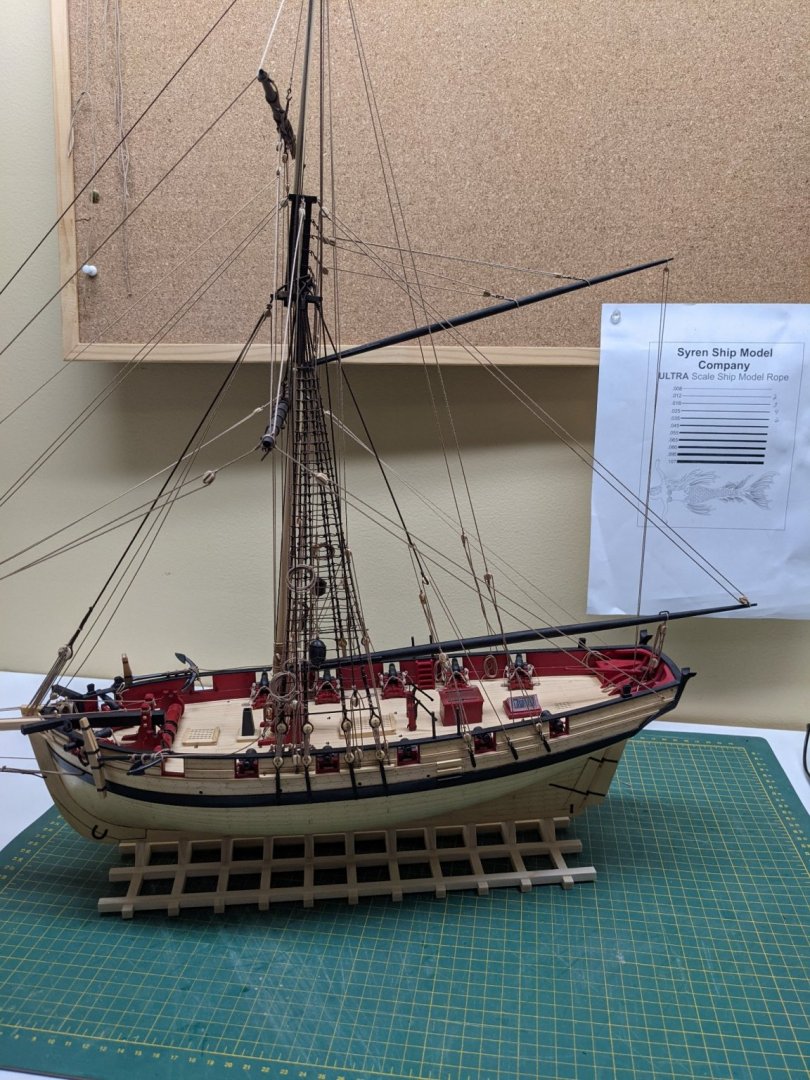

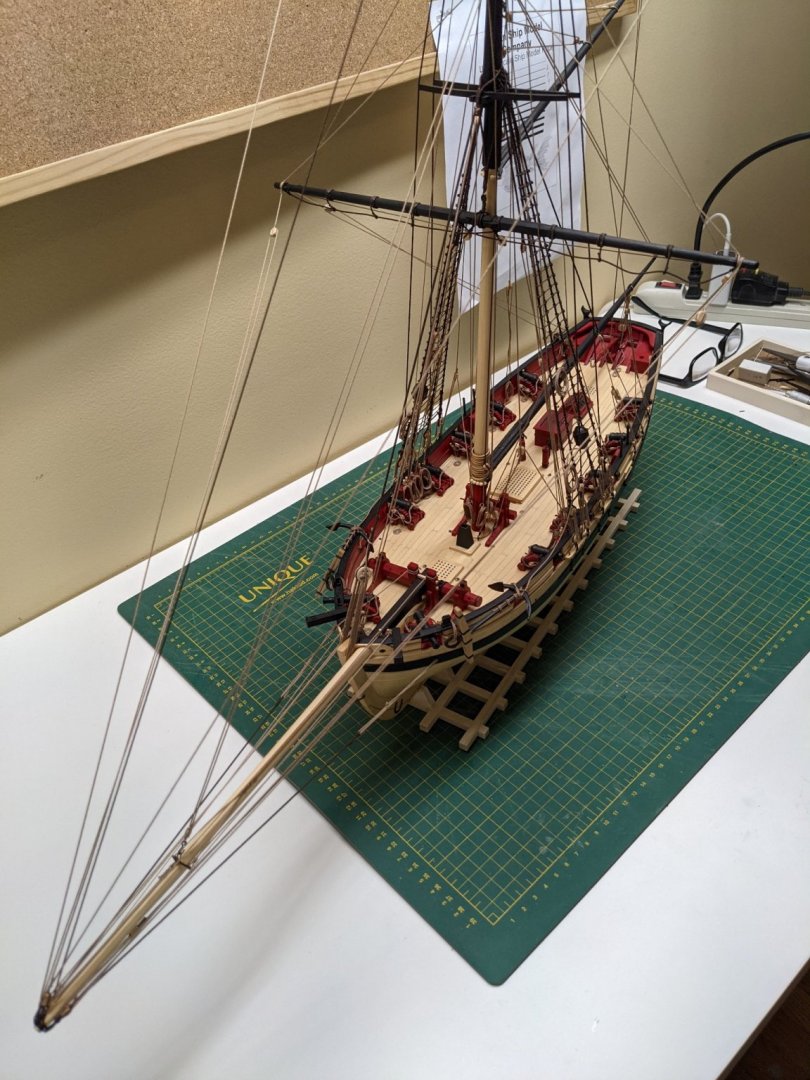

Wow you guys are awesome and I really love the comments! I do spend a lot of my free time building as it is my hobby hence the fairly quick build. (I need to slow down) My next project is the Winchelsea. I have the plans and do have a plan in mind. I will be cutting most of my parts myself as I really enjoy working with wood. That will be a slow project and it is HUGE!

-

-

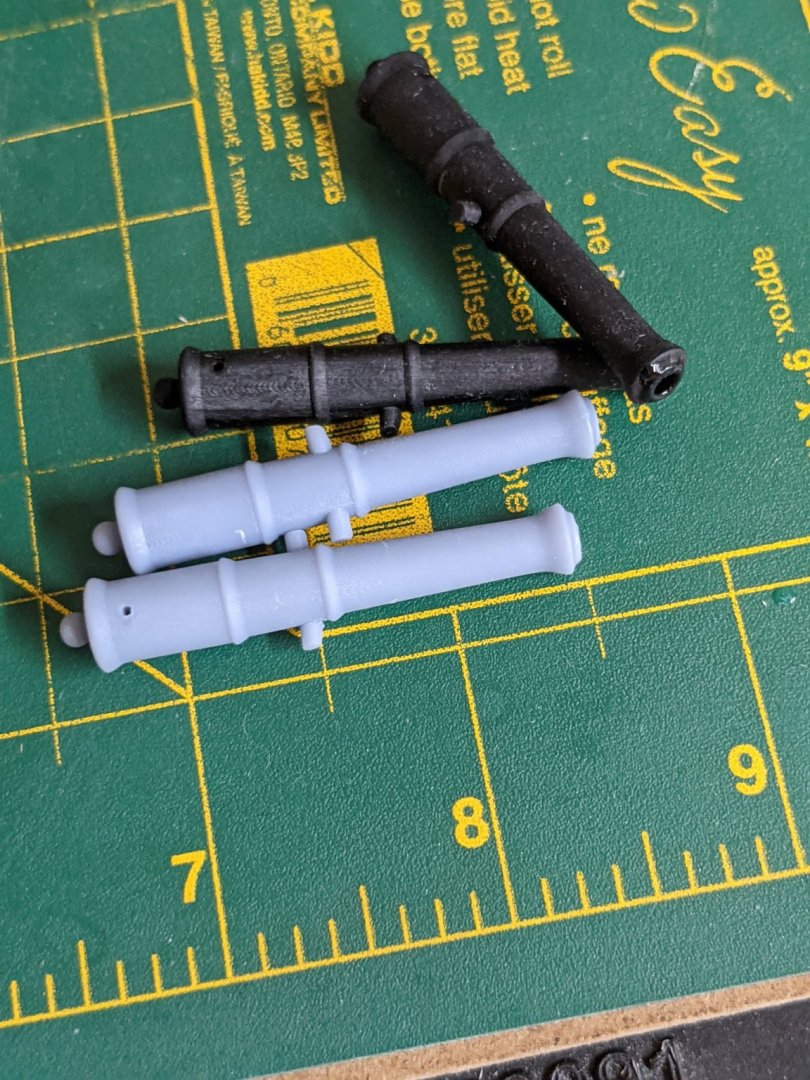

This is such a small print and I have a lot of supports on the bottom so I have no failures with this print. Let me try printing it with the muzzle flat on the plate like this as see how it works.

-

-

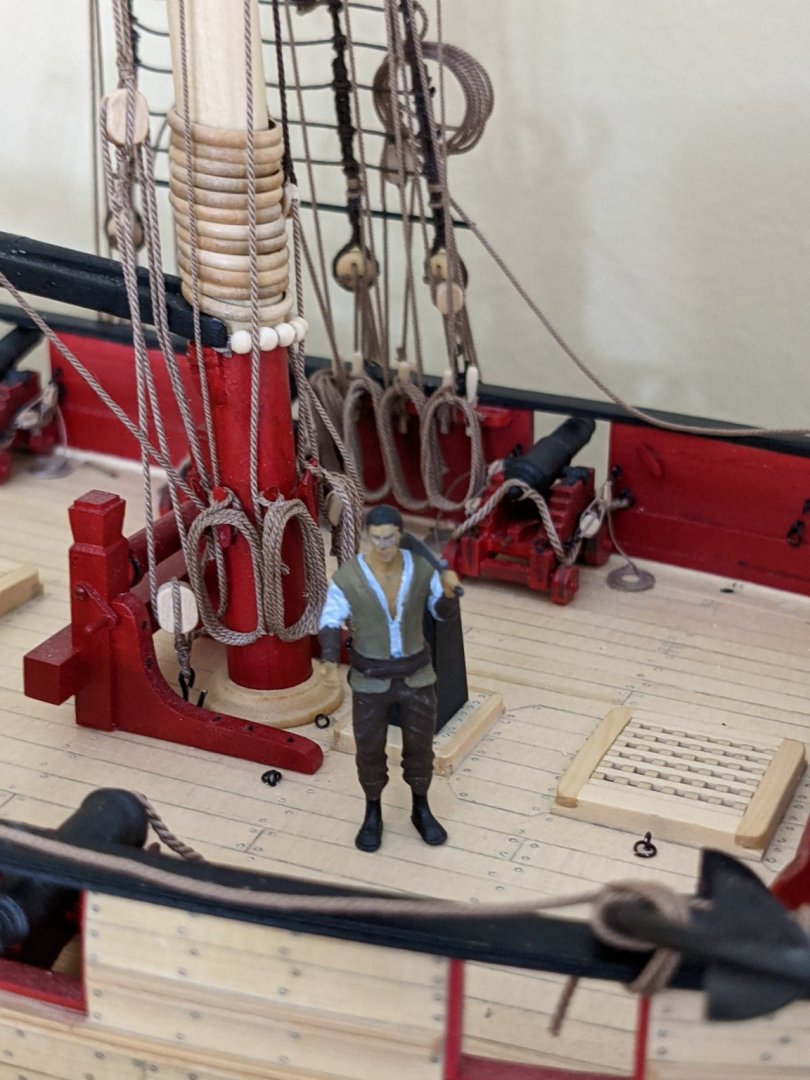

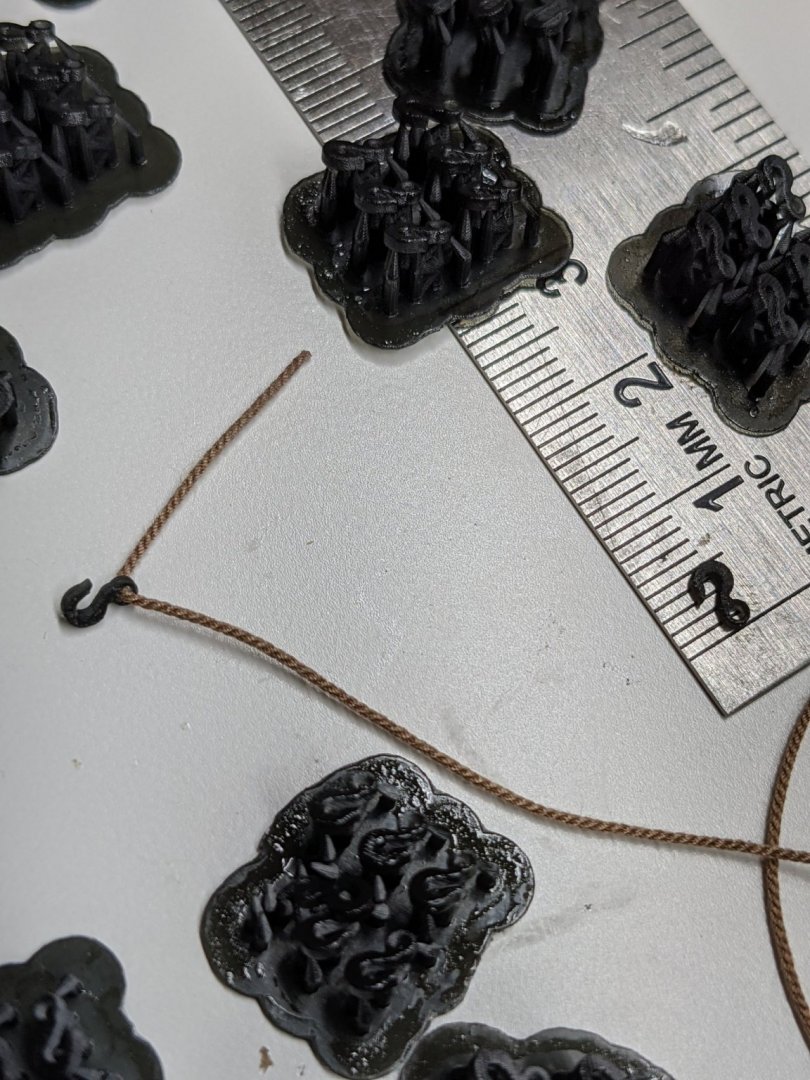

You are correct on this. Here is the difference between the same print of some canons. The black is water washable and the grey is regular resin. Also the water washable just seems softer than the standard resin and the detail is less. Something the black I have is good for is small detail parts. Here are some hooks I drew up and printed. I tested the strength and they are mighty strong. I left them on the supports to cure and they come off easy and I don't loose them

-

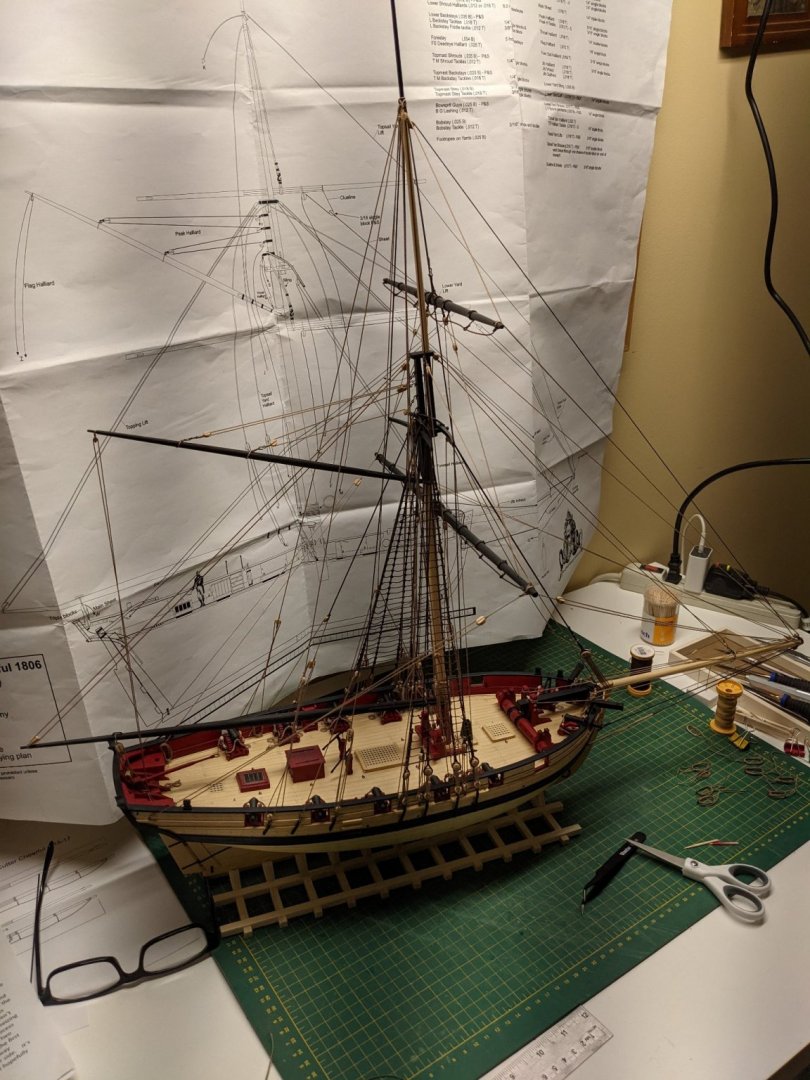

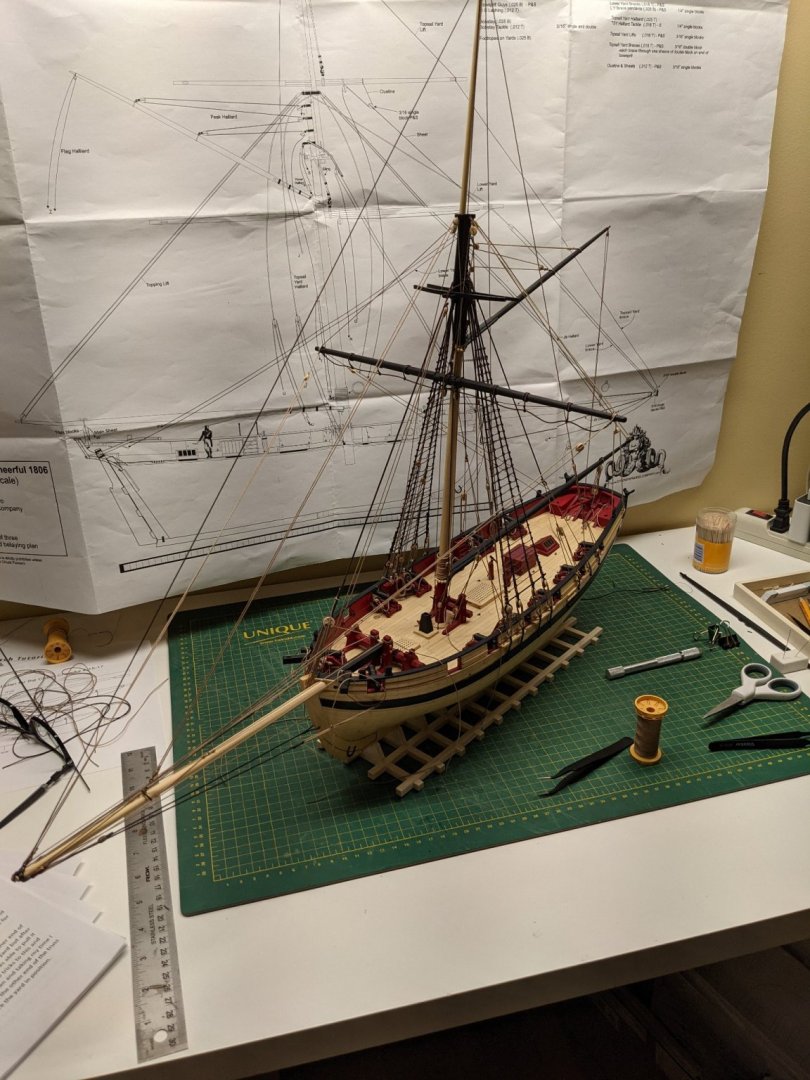

Thanks Chuck. Yes it is huge now and I have to be very mindful when I am working on it to not snag myself in all the rigging. Thanks Glen. I am going to be happy/sad to be finished and have not completely decided on my next project. It is a decision between the Triton cross section or the Winchelsea. Today I am leaning towards the Winnie but will be cutting my own bulkheads if I do it.

-

I am pretty happy with the detail you can get with the resin printer. This is with the Elegoo black water washable resin. The finish is dull and I have purchased some Anycubic standard grey resin to try. I am still in an early learning stage and find that Lychee Slicer is a lot more user friendly so I will stick with that. Here is a few things I have learned: Do not use paper towels on the FEP as they will scratch it. Run a vat clean and removing the piece of cured resin is the best way to clean up after a print failure and might not be a bad idea between prints. To do a plate level on the Mars 2 use two pieces of paper and home it with the bolts loose. Then slowly snug them down back and forth then remove one sheet to check and you are done. The spring is quite strong in the build plate. Make sure you get the build plate back on all the way when you remove it. More supports are better than less to avoid failures.

-

Brodak in the US has silkspan also. light and medium https://brodak.com/silkspan-lite-white-only-2-sheets.html

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

(1)(1)(1)(2).thumb.jpg.792ad774561d3d4f35888704cde27a8e.jpg)