Jared

NRG Member-

Posts

305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jared

-

Over the weekend I made significant progress on the Bowsprit, Jib Boom and Dolphin Striker. The work on the Bowsprit and Jib Boom was fairly easy. The paint scheme is as per James Buttersworth's Flying Fish painting. The various holes for the ring bolts and other rigging components are difficult to see but have been completed.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Spent all day today building the dolphin striker. This tiny part turned out to be one of the most challenging pieces to date. All of the small metal fittings on the dolphin striker were made by bending thin blackened copper wire. For the lower metal band I used adhesive copper tape. The lower fitting was made from a single piece of wire. On another note, I mentioned that I discovered the other day that I was missing one size of wooden blocks. I contacted Model Expo and soon after I received a reply that the missing blocks were on the way. What fantastic customer service!!

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

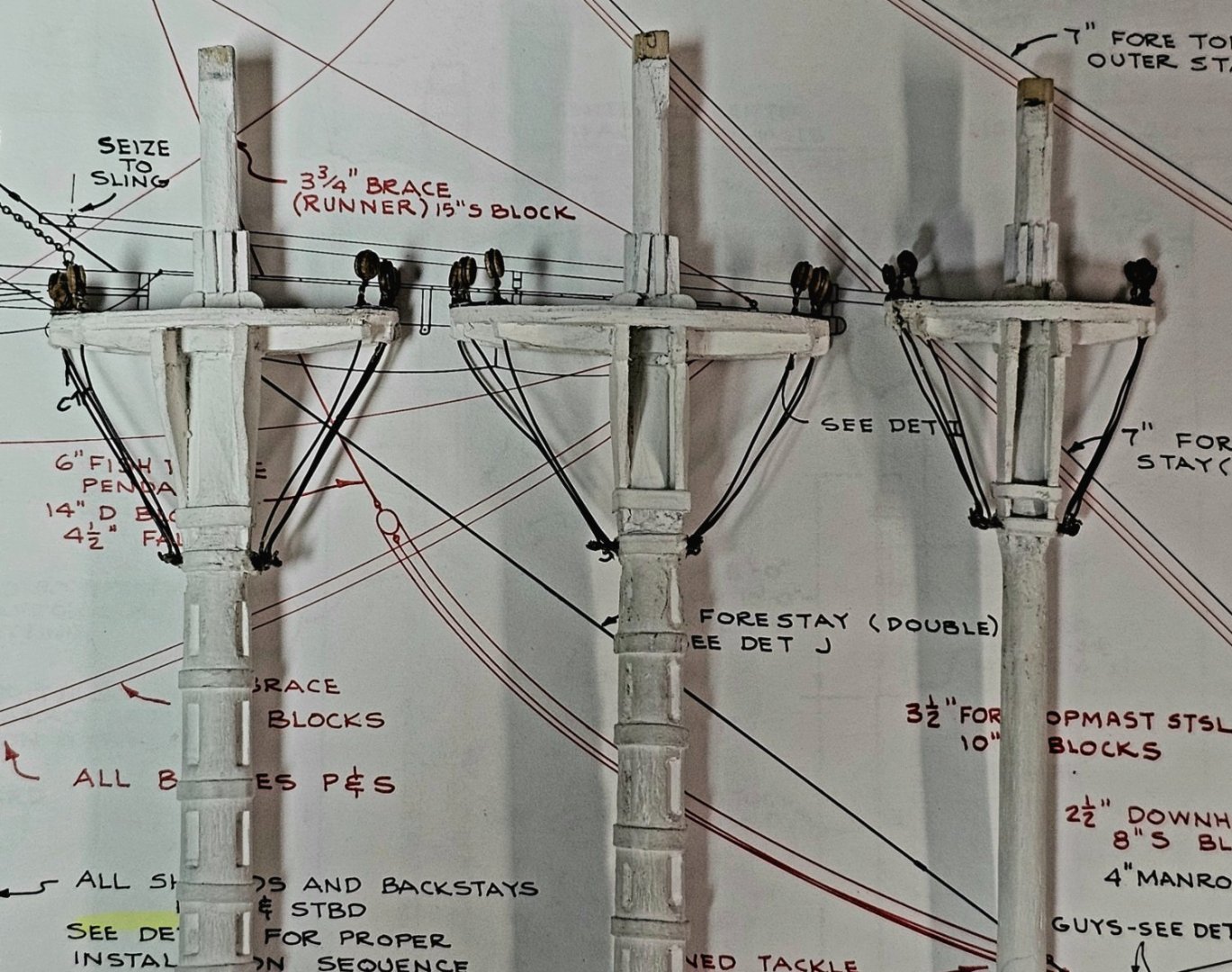

Quick update. The spreaders on the 3 topmasts. I was hoping to start adding the blocks to the masts, but discovered on size of blocks was missing from my kit. While I await the missing parts from Model Expo, I will work on the bowsprit and jib-boom. I implemented your suggestion George to strengthen the spreaders with copper strip on the main topmast and mizzen topmast spreaders. I added copper strip where I could on the already completed spreader on the fore topmast as doing otherwise would have required a complete rebuild of the structure. Adding the cleats to the 2 new spreaders went much better than what I encountered on the fore topmast. Put it down to learning from experience and using finer tweezers.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thanks George for this great suggestion. I was very concerned about them breaking or bending when attaching the rigging.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Since the last update I have begun working on the the topmasts & bowsprit. These have been loosely mounted on the ship. In the past few days I have built the top on the fore topmast (see photo). I will be painting the top white. The trickiest thing about building top was the fabricating and mounting the cleats on the spreader. I had to try different types of wood incl. multilayer strips before I finally found something I could cut without the tiny wood pieces falling apart.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Like your phage George. What did you study in grad school? I am a bacteriologist.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I wish you a soeedy recovery George. Covid is on a surge now, even for those fully vaccinated many times. 3 family members living in 3 different cities have had it in the last month.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thanks George and Rick for your quick, helpful responses. It will certainly be much easier adjusting the rigging made with the thread/cord rather than with stiffer wire.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Forgive my ignorance about the standing rigging on the Flying Fish. From the drawings and instruction book, it looks like the standing rigging is to be made from dark thread, meant to simulate tarred hemp. UNDERHILL states in his book on clipper ship masting & rigging that "By the beginning of our period ( i.e.clipper period) wire had to a large extent superseded hemp for all forms of standing rigging". Should I be making the standIng rigging from blackened brass wire? Thanks.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

My ship has also been on hyatius for various reasons. Best to take your time and work on it when you are in the right frame of mind. I look forward to seeing your progress!

- 34 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Have now completed the futtock shrouds on the lower main mast and mizzen mast. The work on these went much easier and faster than those on the foremast. Put it down to experience 😀. Much easier to do once you have worked it all out. Nowhere as difficult as what I implied earlier.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Today's activities were reworking the front of the tops thanks per the information ClipperFan provided above based on the Glory of the Seas. This was a simple fix. (See first Photo below). I then tackled the futtocks shrouds on the foremast, which might have been simple if I were an orthodontist, which I am not. The brass wire I started working with turned out to be too thick and stiff to work with. After completing 2 of the shrouds I switched to a thinner brass wire and the work proceed much better. All of the brass was blackened before assembly.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Back to the cutting board to fix the front side of the top. As to the lubberholes, I am going to leave them as is, as it will require a complete rebuild of the under top supports. The cross tree design under the Glory's tops are very different from what the FF plans show. Thanks for posting the Glory images.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thanks for sharing your wealth of knowledge ClipperFan. The photos are very helpful.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Interesting photos for sure. I do worry about how small the lubber holes are on the FF model. The cap bases in the kit are all supplied laser cut so that set the sizes of the lubber holes. I won't be surprised if I have to enlarge them later to accommodate all the rigging, especially on the mizzen mast.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

To err is human! In reading through the chapter on masts and spars of wooden vessels (Chap. III in Underhill referenced earlier), I discovered several errors in the construction of the tops on my lower masts. These are highlighted in the first two photos below. These mostly resulted from my lack of close enough attention and understanding of the fine details of the model plans, many of which are less than obvious. I failed to notice that the thickness of cheeks should taper off towards the heel and that the cheeks fit flush with the mast in stops cut into the the port and starboard sides and "dressed down to make a flat seating and stop for the cheeks" (Underhill pg. 65). Underhill goes on to state that the joint between the cheek and stop is covered by the futtock band, not above it the way shown in the kit plans. In my efforts to scratch build the iron plates on the top platforms, I didn't pay enough attention to where I drilled to holes in the plate - which should have line up with the cross trees so the futtock shrouds are correctly placed. They did not. And finally, something I cannot find in the Flying Fish plans is any reference to cross member spacers which sit between the the fore ends of the trestle trees to confine the fore side of the topmast heel (as illustrated by the drawings from books by Underhill and Mastini, in photo 1 below). I point these out for the benefit of any builder of the kit who is following my log, so that they don't fall into the same holes. Photos 3 and 4 show the reworked lower masts on my model as they now stand (to be further sanded and painted).

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

A quick update. Finally got around to securing the the 3 ship' boats on the cabin top. This was my introduction to the coming rigging on the Flying Fish and to the difficulties in securing ropes in such small spaces (see Photo below). As I now contemplate the final construction of the lower masts with the futtocks shrouds and attaching various blocks and eye bolts, and look ahead at the complex rigging diagrams on the plans, I have come to appreciate George's advice that the construction of the masts has to be planned well ahead to ensure that all the holes are predrilled and fittings for the rigging attached before the masts are fully assembled and secured to the deck. In truth, the rigging diagrams at first sight seem rather overwhelming to me. My previous model build was a whaler (Charles Morgan), whose rigging plans are far less complex than that of a clipper ship. I have therefore decided to pause for a bit and refresh my understanding of ship's rigging, before proceeding any further. This week I started reading my way through Harold Underhill's classic book "Masting & Rigging the Clipper Ship & Ocean Carrier", which is a masterful resource. My plan at this stage is to complete my Flying Fish with the standing rigging and some of the key running rigging, but not to put sails on her.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thanks Mike. Yours look like they would anchor very well with lots of surface area for the glue to grip. For mine I used long nose pliers that I ground down to make the tip end thinner. All of the wire bending was by hand. It's tricky at first to get consistency but with practice it is achieved. I think your method would be much better with thinner wire. Thanks.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

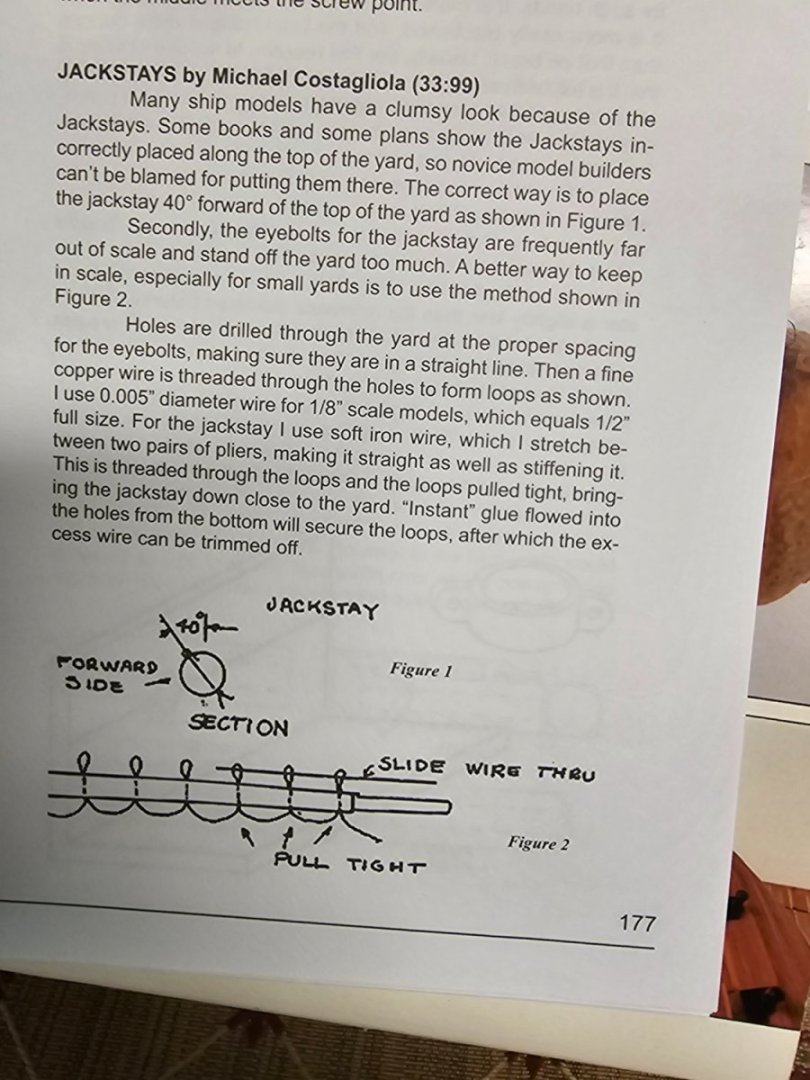

Thanks as always for your recommendations George. As to making eyebolts & jackstays from thinner wire, I found a very interesting technique described by Michael Costangliola on page 177 of Ship Modeler's shop notes II that is worth looking into. See accompanying photo.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I tackled the spencer jackstays on the lower main and fore masts this week, which I had been putting off for some time due to unwarranted fears of getting them right. The smallest eyebolts in the kit seemed too large to use here so I decided to make my own using the 0.22 ga. brass wire in the kit. They were then blackened and glued into small holes I drilled into the aft side of the masts. A blackened straightened section of wire was then fed through the loops and secured in a few spots with glue. See attached photos. Overall the construction was much easier than what I had feared.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

We are all in the same boat on this for sure. Every piece presents challenges and more than 1 try to get right.

- 345 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Re: "By the way, if anyone knows how to embed a more proper two column view - I'd love to know - otherwise I'll just copy/paste this sorta messy version." I use PowerPoint to create mine then do a screen capture to produce a Jpg. file to post.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.