-

Posts

219 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tobias

-

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

-

Hello Siggi, your craftsmanship is exceptionally great, very impressive. Greetings from Bavaria, Tobias.

-

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

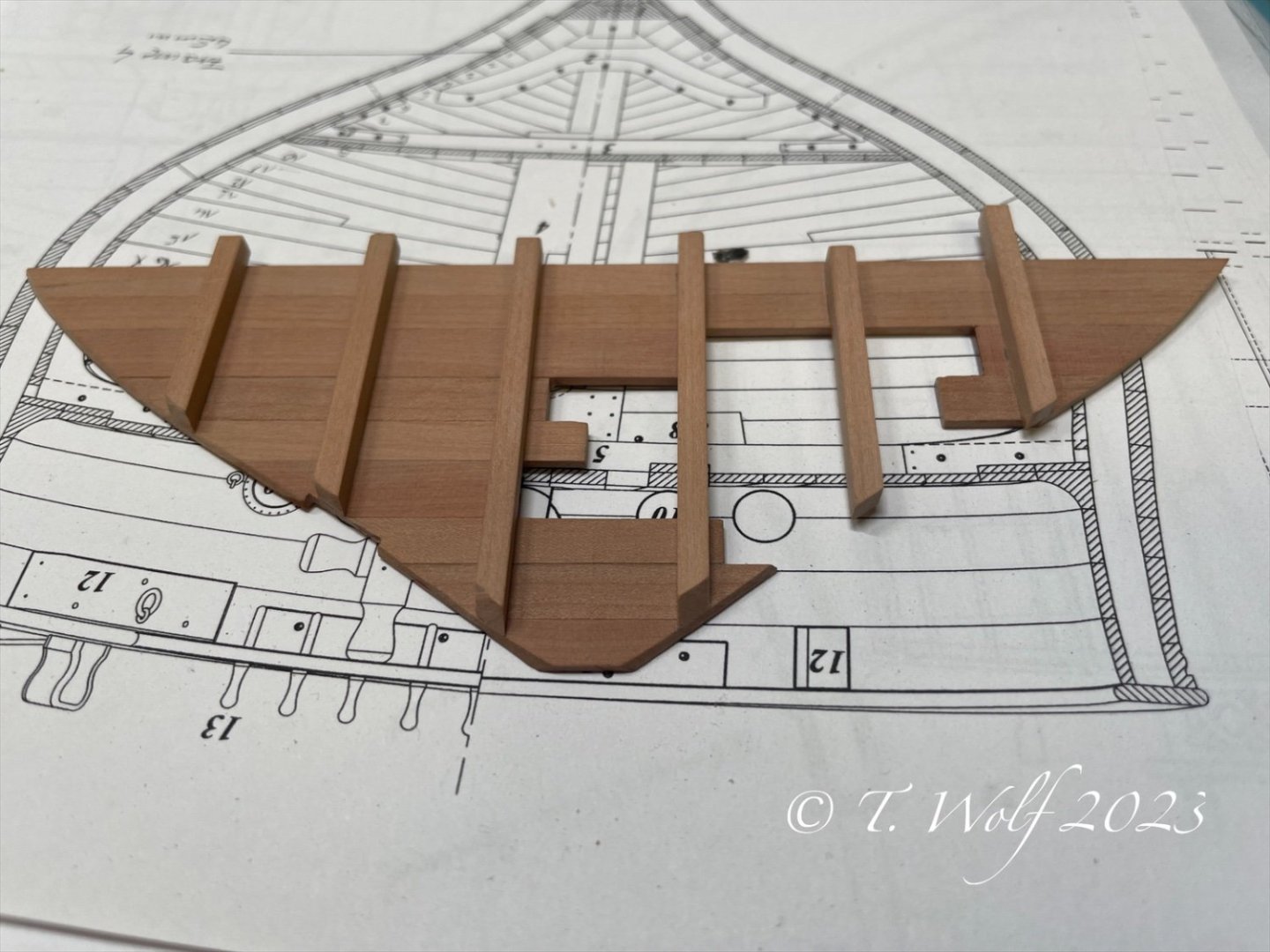

Good evening everyone, here's a little update. I started with the first bulkhead, nothing is glued yet and small adjustments still need to be made. I also started with other parts. -

Good morning Gary, it is a wonderful and absolutely clean work, much to be admired. It took some time to scroll through your log. Sorry if I've just come across this and have to get back to the beginning of your project, did I understand correctly that you drew the plans by hand, i.e. old school with a pencil? That's really impressive, your bookshelf and all the plans in the roles also fascinate me. Absolutely great performance. Greetings Tobias

-

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

Thank you GD, from the German forum I was told Nüsterlöcher - (also: "Nüstergat") holes in the lower frames through which the water can flow to the bilge -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

Hi Mark I mean the recess at the bottom of the frames, unfortunately I do not know the correct name. In this recess is also often a chain installed to loosen larger debris and to ensure that the brackish water can run to the pumps. -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

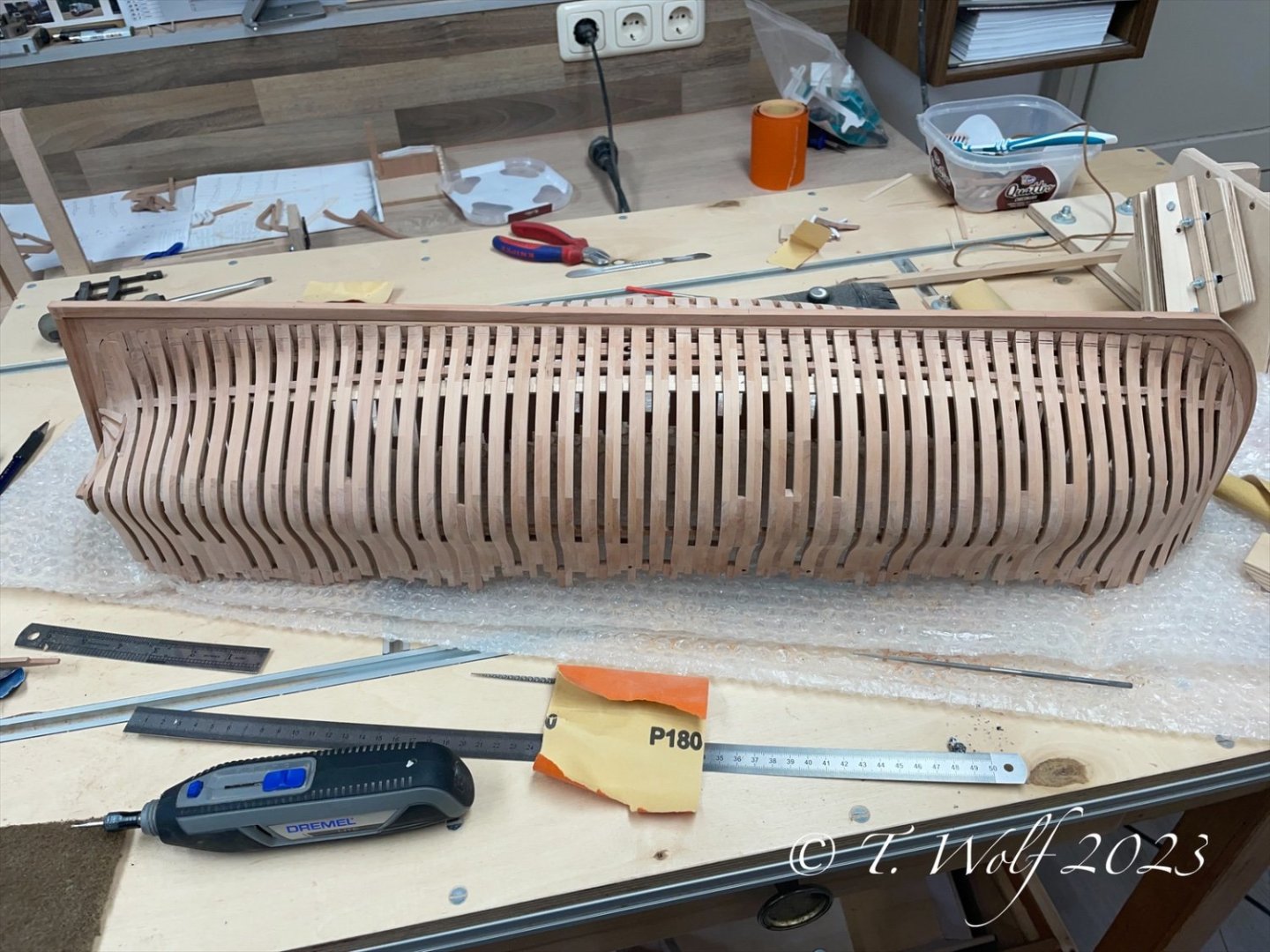

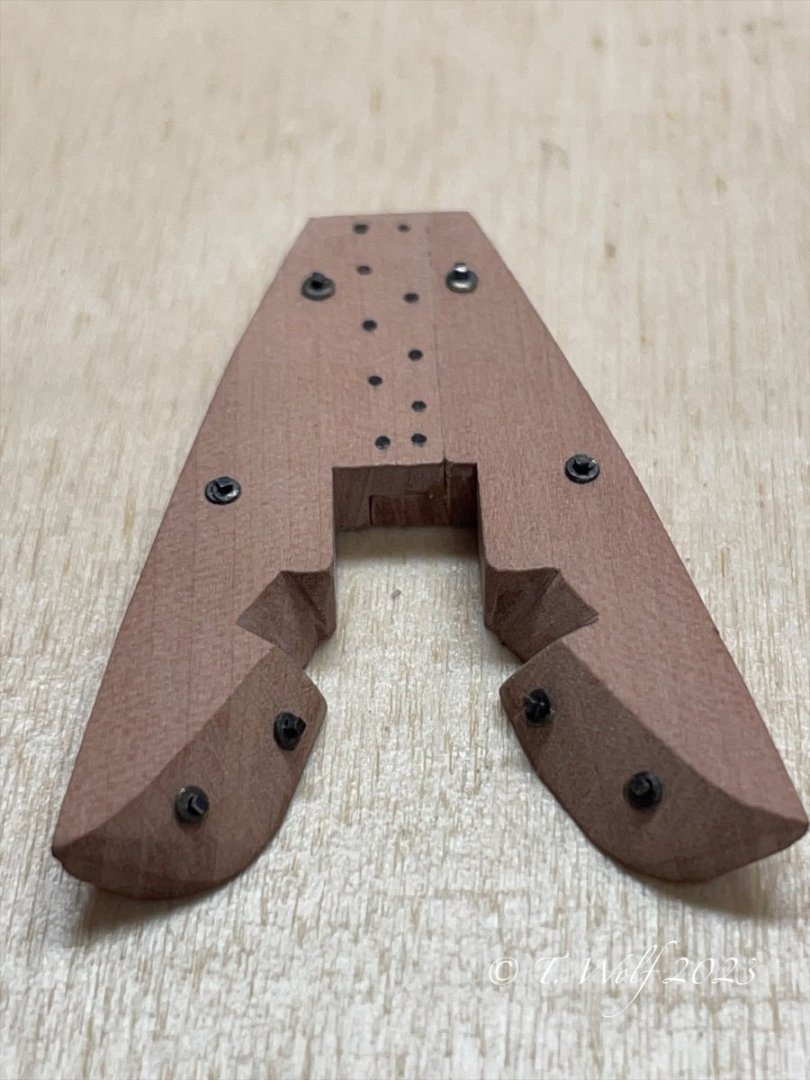

Hello fellow model builders, the last few days have been fine tuning and today I milled the water groove in the frames. Tools used Ruler and pencil for marking, a rasp and a dremel with a round head router. -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

-

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

In the last 2 days I've gotten the hull in shape a bit. The finishing touches are still missing. Thanks for your interest. -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

Hello John, thank you. I came to MSW through Ed Tosti and his amazing Naiad protocol. It's the research that keeps you from just being in one forum. @albert, @No Ideaor you Johann and many others are inspirational for me. I'm also on the road in the French forum to get as much information as possible. Of course you also want to show your model and it's a great feeling when you like it and it's well received. -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

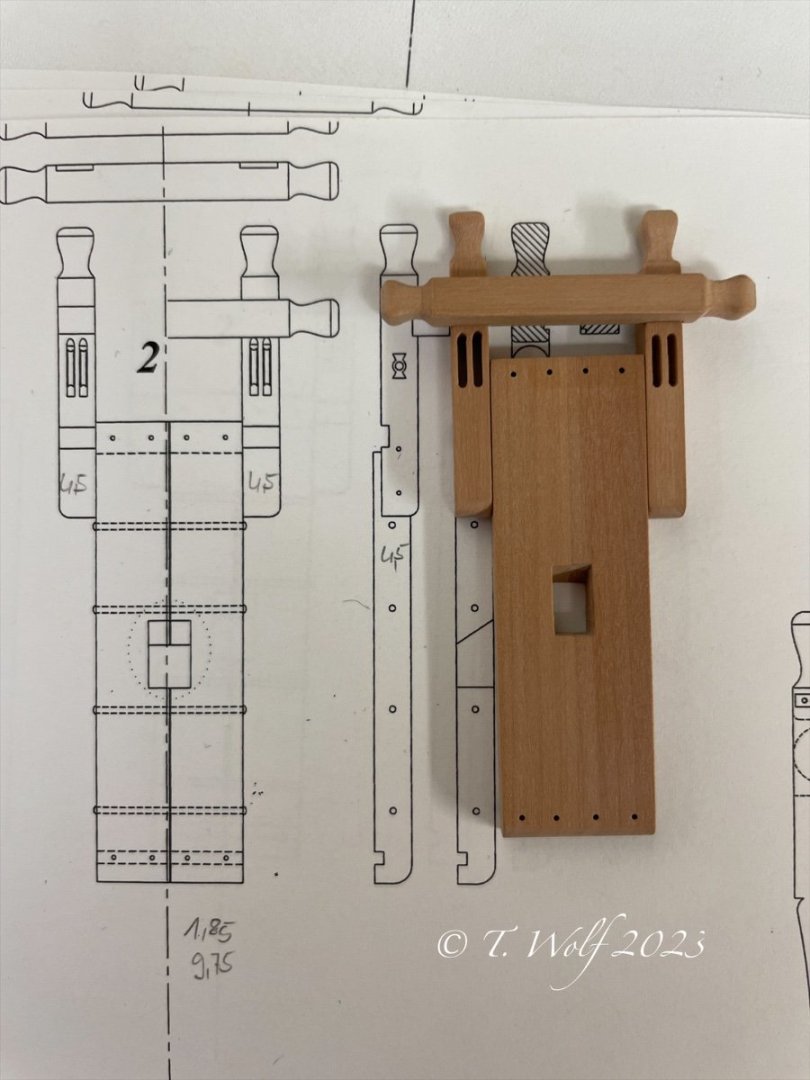

First of all I want to thank you for all the likes and the comments, much appreciated. I had found some time in the last two days to continue building on La Palme. It's a minor update. Thanks again for the encouragement and your feedback. -

HMS ANSON 1781 by albert - 1/48 - 64 guns

Tobias replied to albert's topic in - Build logs for subjects built 1751 - 1800

Hello Albert, I envy your craftsmanship. Naiad has been a dream, I'll stay tuned to see the progress. -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

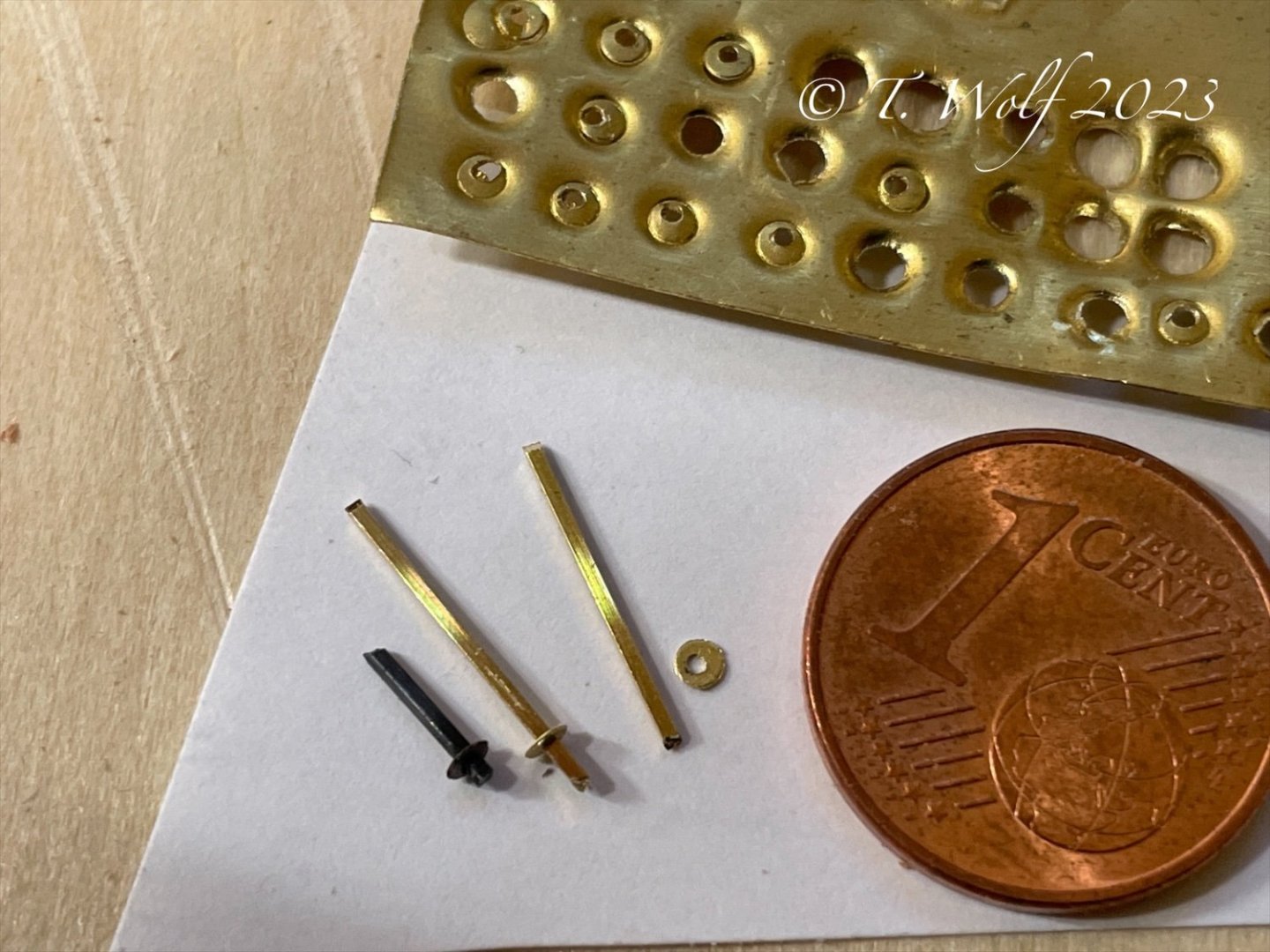

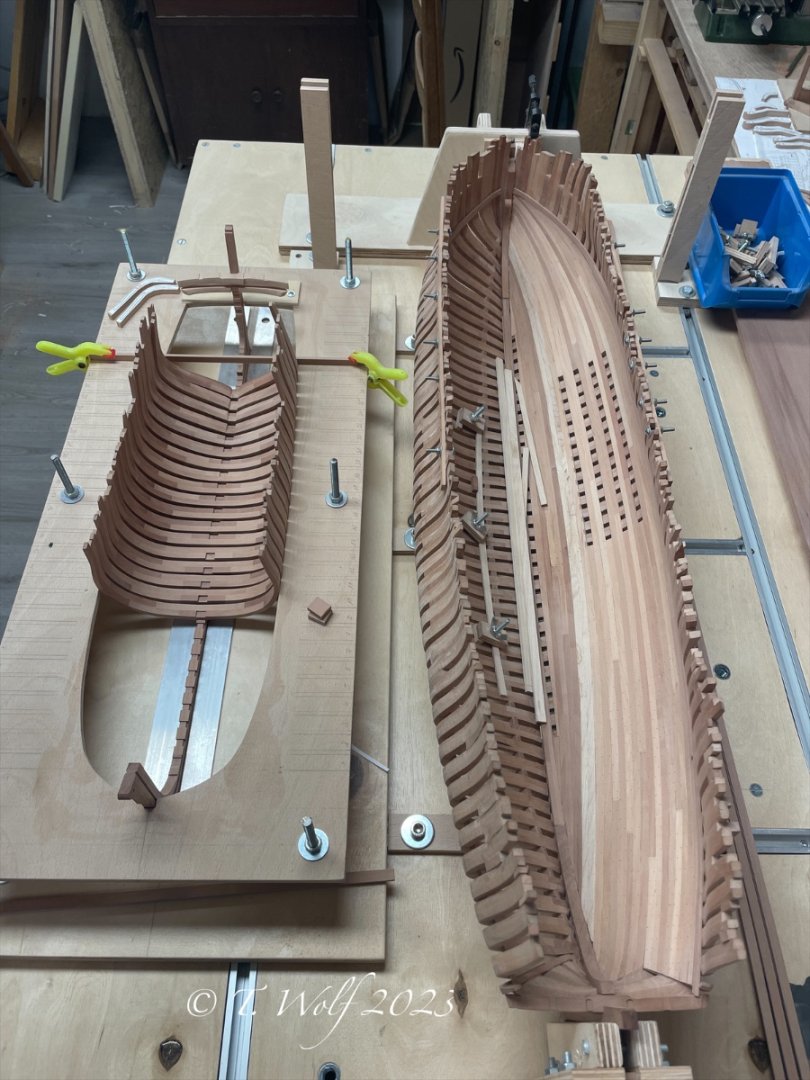

Hello everyone, the nailing is done. In the next few days I will continue on Le Rochefort. Both on a scale of 1:36, here is a picture of both ships together. -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

A little progress 2282 holes have been drilled and approx. 1400 nails have already been set. Now I still have the last frames 32-52 ahead of me. I'm sorry that there aren't too many updates at the moment, but I've started another project as you can see in the picture. Both in 1:36 scale -

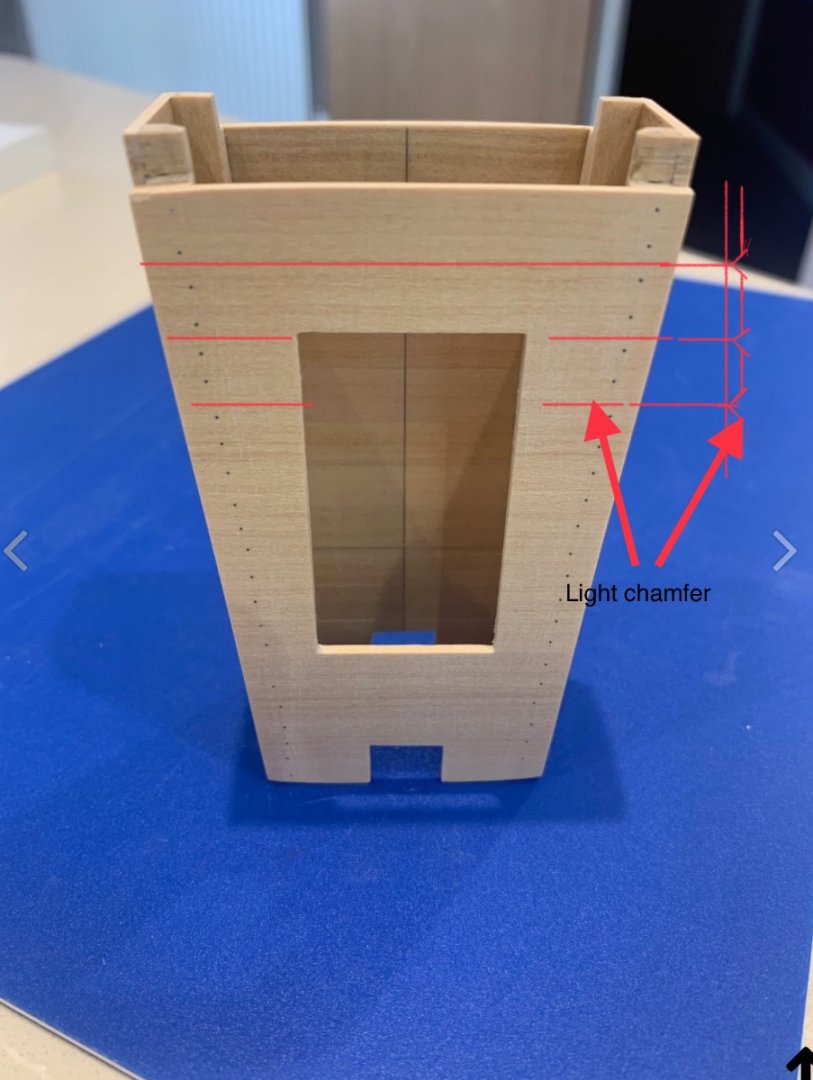

Hi Mark it is once again a fantastic work. Almost a little too perfect, please excuse me I do not want to complain and hope you do not get it wrong. Your precision is so fine that you can't see the individual boards of the pump well and it looks like it is one big area. I know this too well, if I may suggest the following what I have already done in such a case is that I have slightly touched the individual boards to visually highlight the individual boards. Something like this:

-

HMS EURYALUS by Matiz - FINISHED - scale 1:56

Tobias replied to matiz's topic in - Build logs for subjects built 1801 - 1850

Hello Matiz it is always fantastic to see your progress and with what accuracy you work. I have a question, in one of your pictures I saw a milling machine in the background. I can't make out the cross table unfortunately, what brand do you have there and are you happy with it. I also have the Proxxon stand and also use the cutter from AMB. -

La Palme by Tobias - 1:36 - POF

Tobias replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

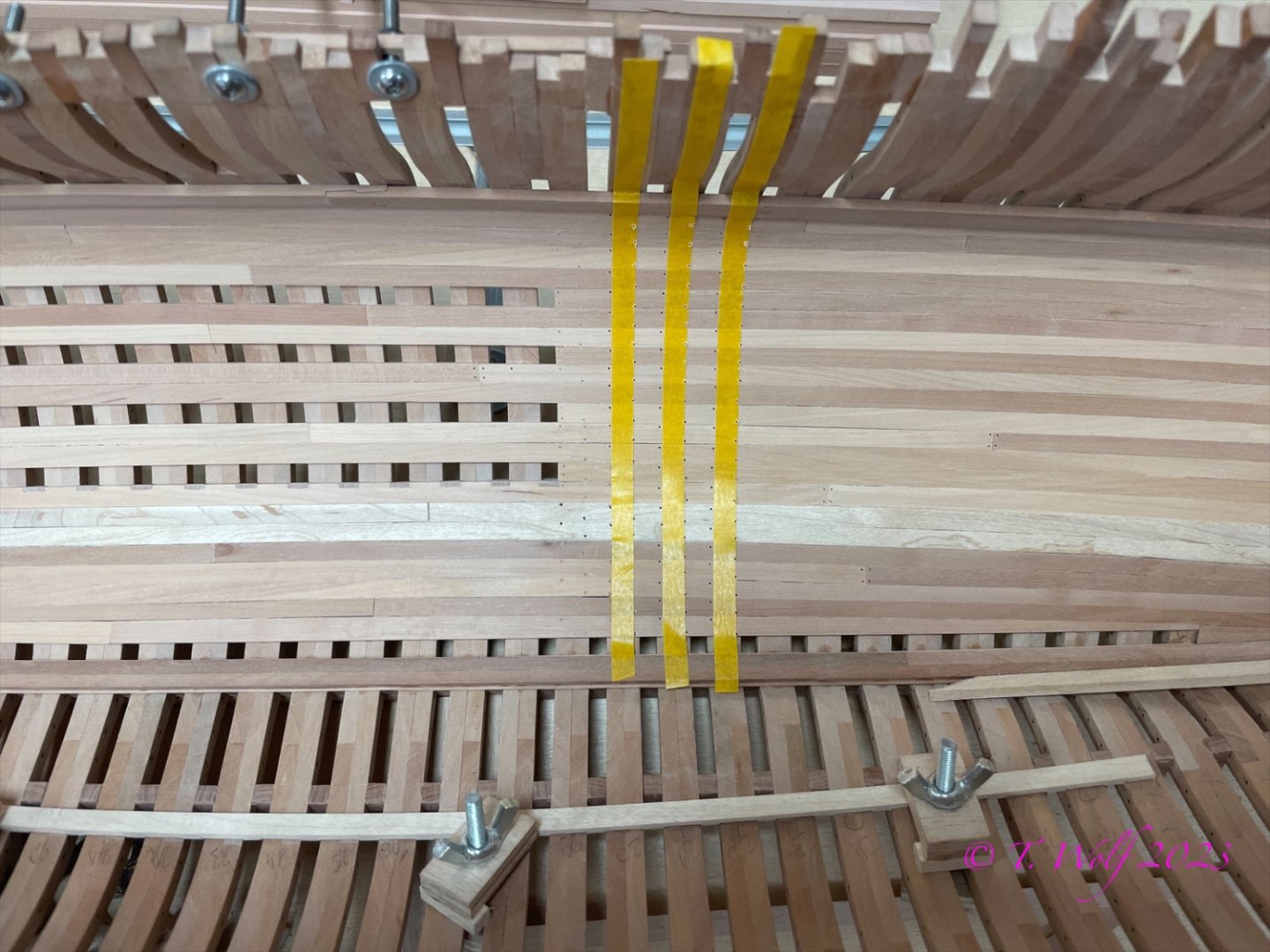

At the moment I come a little less often to La Palme because I have started with Le Rochefort on the side. The first tree nails have found their place. First I wanted to make the nail picture with brass pins, however, I was not sure and have asked precaution at GD. Now it will be tree nails. The first attempt was it with walnut wood this seemed to me but too dark, now I make them in pear and maple. I treated a small area with sanding primer to see how it worked. Sanding primer what is it, It is now used by some Europeans and is nothing more than a colorless primer for wood which gives a very nice Finnish. Apply 1 time and work with steel wool and then apply again and polish with 400 sandpaper. Unfortunately, I have learned from colleagues in America that there is no such thing there. Attached are pictures of the product and the Finnish of a colleague. Image source R. Eschker http://www.eschker-modellbau.de/Home -

Hi Greg you have come a long way since my last visit, great progress that looks excellent.

-

EURYALUS 1803 by Peter6172 - 1:48

Tobias replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

Hello Peter, that's a pity to hear, I only read this paragraph. If you want, I can get in touch with Frank. We ship our items worldwide from Russia to New Zealand - from England to Canada. -

EURYALUS 1803 by Peter6172 - 1:48

Tobias replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

Hello Peter it is sad to hear such news. As far as wood is concerned, a supplier from Germany would be OK for you, he delivers worldwide and he has cherry. That would be the link. https://modellbau-holz.jimdo.com/

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.