-

Posts

57 -

Joined

-

Last visited

About Deacon

- Birthday November 19

Contact Methods

-

Website URL

https://www.instagram.com/whiskyworkbench/

Profile Information

-

Gender

Male

-

Location

Poole, Ontario, Canada

-

Interests

Modelmaking, Antique Clock restoration and repair, 3D CGI Artist & Animator.

Recent Profile Visitors

-

etubino reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

etubino reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

etubino reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

etubino reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

dafi reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

dafi reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

dafi reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

dafi reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

dafi reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

dafi reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

dvm27 reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

dvm27 reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

Thanks Greg. It's a little of both. The starboard side is a bit narrower but it is also accentuated by the camera angle. As you can see, the original printing on the plywood was less than accurate. The frames are 3/16" T. plywood, so the grain you're seeing is only the outside layer. And yes, they are delicate. Plywood is approx. 45 years old, but is generally in good condition. The deck beams will be Maple, primarily because it is readily available here, economical, and should prove to be much stronger than the kit's original plywood beams, adding strength and rigidity to the frames. Working with a vintage kit like this presents a lot of challenges and makes one appreciate the materials and technology of modern day kits.

-

dvm27 reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

dvm27 reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

Finally a bit of an update. Bulk of scroll saw work completed on the frames. What's left to cut are the half-lap joints on the hanging knees for the deck beams. Decided to cut and mill all the deck beams from solid timber. Presently building a pivoting table for the scroll saw which will allow me to cut the beams to a consistent radius and depth. Radius of the beams does increase slightly as you move up through the decks, but at 1:98 scale, the change is so small it would be unnoticeable, so all beams will be cut to the same radius. Once the curved beams are cut, I'll mill the grooves for deck stringers and the half-lap joints on the beams, then cut the half-lap joints on the frames to fit the beams. After that, the frames can be permanently installed to the keel and stringer, then beam and decking installation can begin from the lowest deck and progress up through the five decks... a ways to go before that can happen.

-

Twokidsnosleep reacted to a post in a topic:

Hello from Canada’s west coast

Twokidsnosleep reacted to a post in a topic:

Hello from Canada’s west coast

-

Prowler901 reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

Prowler901 reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

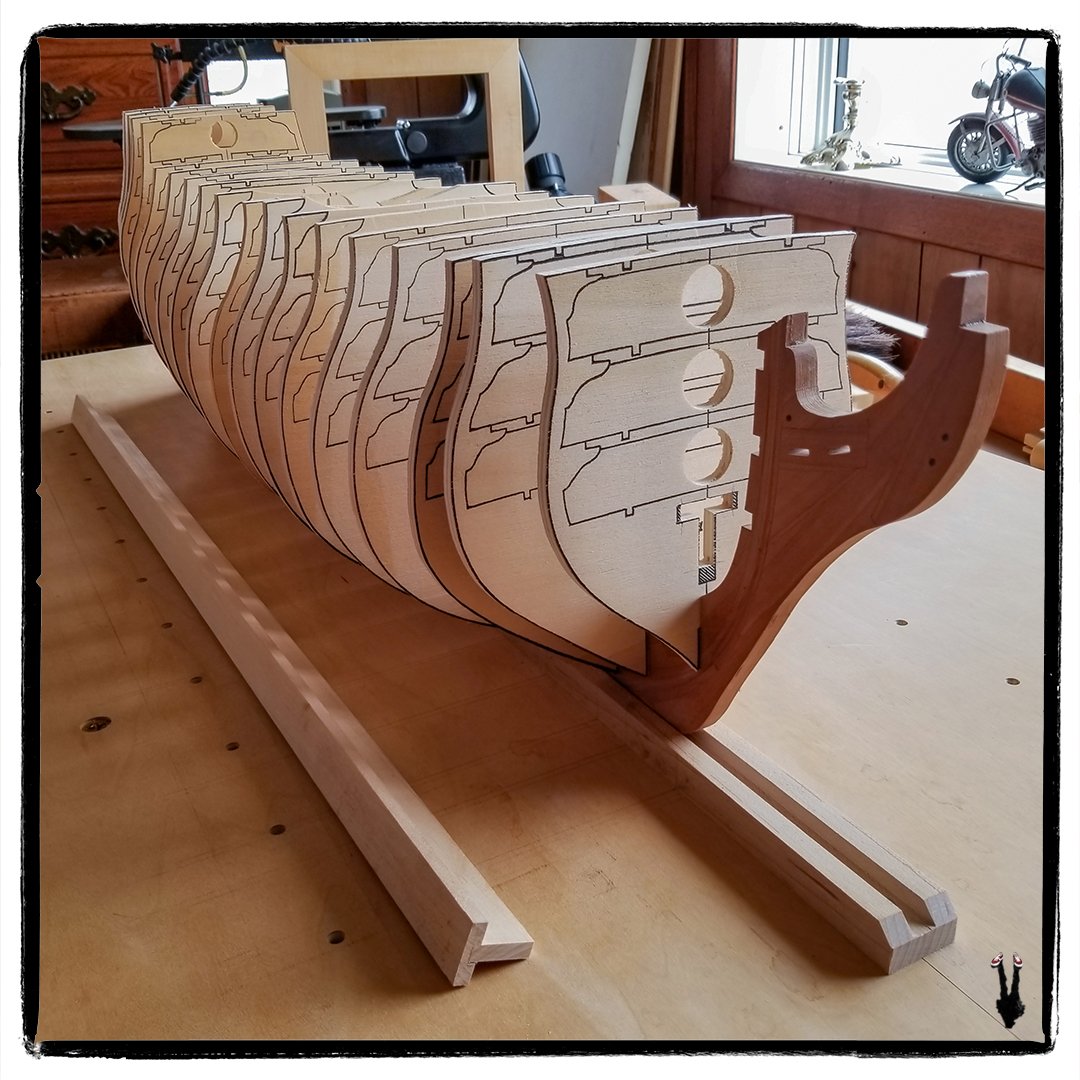

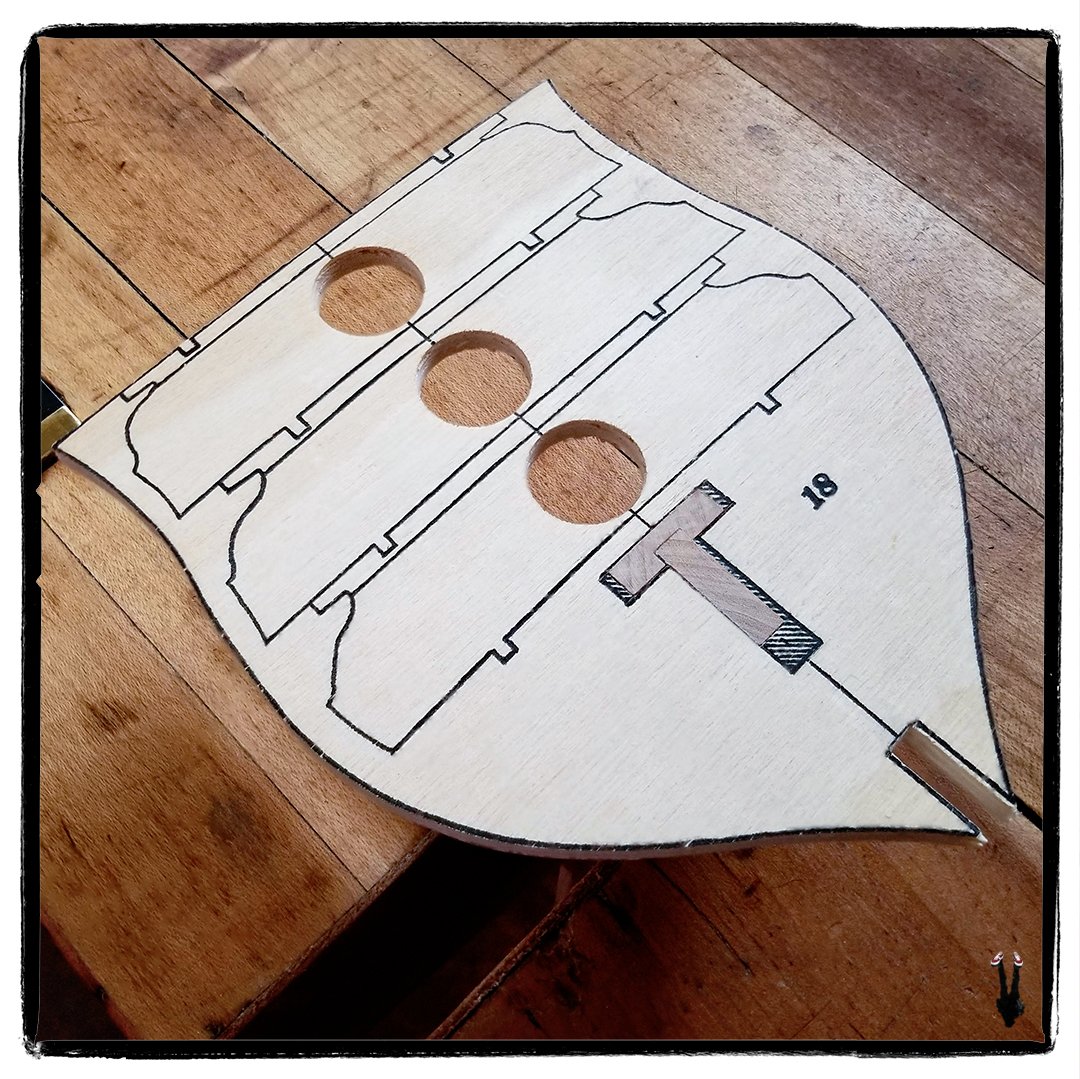

After milling and paring out the T-slots in all the frames, I did a test assembly of the frames, T-stringer, and keel. Be a bit of a tricky process when it comes to glue-up, but as it is, it's a strong, rigid assembly without the glue. Next step is to finish flattening a couple of warped frames, then cut out the waste areas between the deck beams on all of the frames.

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

GrandpaPhil reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

Finally have an update on the Victory project. The past several months have been something of a challenge. A long-standing CG watch animation project, put on hold during the pandemic, came back to life after the watchmaker was granted a patent on his new escapement design, so I am spending most of my time in the animation studio working on that. In addition I recently completed a program of radiation treatments (succesfully as far as we know at this time) which took a great deal of time and energy. Now that treatments are finished, I've been able to make some time for the workbench while work progresses on the watch animation, which will continue to take most of my time for the next few months. It certainly feels good to be back at the workbench, I've missed it. I've cut out all of the frames on the scroll saw and milled/pared the slots in the frames where they attach to the keel. Photo shows them lined up temporarily on the keel on the build board. The holes in the frames were bored with a Forstner bit as access holes for cutting out the waste material in the deck regions. The large hole makes it easier to set up cutting angles in the scroll saw. In the foreground is the "T" reinforcement stringer that runs the length of the hull from the furthest forward frame to the aft-most frame. Currently I'm milling openings in the lower portion of the frames to accept the "T" stringer. The photo shows the milling setup. I made an MDF sacrificial table onto which I scribed a centre line with the mill, then milled a small slot along that centre line to accept a piece of scrap keel stock as a locator. The frame is slid into place on the keel locator, then centre line alignment confirmed before clamping the frame to the table and milling the "T" slots. In this way the "T" slots are aligned accurately with the keel slots. After milling, I square up the ends of the slots with a small chisel. I'm referencing off the frame centre line for all milling operations, as the printed cut-out lines are less than accurate on most of the frames. That is particularly obvious in this photo which shows the forward frame in position on the "T" stringer. The printed cut lines are considerably off centre. I also reduced slightly the overall size of the stringer by truing up the stock supplied in the kit and assembling the stringer with a machined rabbet in the top piece for added accuracy and strength. That's it for now. Once all the "T" slots are milled, it will be time to cut out the waste material in the deck areas with the scroll saw and hand-held jewellers saw. I'm considering replacing the plywood deck beams with machined solid timber pieces for greater accuracy. Not sure yet, will depend on how the cutting goes.

-

Thank you Bill. Which Aeropiccola kit are you building? All the solid wood in the Mantua kit is usable. The plywood though is a little sketchy in some areas, so my plan is to replace all the visible plywood with solid timber which adds a great deal more work but should result in a better finished product.

-

Deacon reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

Deacon reacted to a post in a topic:

HMS Victory by Deacon - Mantua 776 - 1:98

-

After months of intermittent work on the keel, attention can now be turned to the Victory frames. First photo shows the full keel assembly with the solid timber keel, sternpost and bow timbers married to the modified Mantua plywood keel. Second photo is a detail shot of the forward section showing the Boxwood treenails used to reinforce the solid timber keel to plywood joint. There are also three brass "treenails" (not visible) reinforcing the joint between the bow timbers and the plywood. These pins come in from the top of the plywood keel and pass into the bow timbers. Near the upper right of the photo you can see one of the two threaded brass inserts in the keel which provide the option of mounting the hull to machined support pillars as opposed to a cradle.

-

Deacon reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

Deacon reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

-

It's been a long time since I've posted an update on this project. Took July off from the model bench to build a vendor display (in Maple and Purpleheart) for my sister's embroidery business. Because of its size, that project took over the entire workshop. Our two remaining Ash trees were felled last month, so I've been spending a lot of time flailing about with a chainsaw, schlepping logs, and splitting firewood... it never ends. Concerning the Victory, the solid wood Bow Timbers are now glued up to the modified Mantua plywood keel and the joint has been cut in the solid wood Keel/Sternpost assembly, ready to be glued and treenailed in place.

-

Welcome aboard Abbot. This a great and helpful community regardless of what medium you model in. I expect your first hand knowledge of the U.S. Navy and your research into its history will prove of value to modelers in that discipline.

-

Beautiful workmanship... well done indeed!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome to MSW DeHammer. Looking forward to watching your progress on the Bluenose, our iconic Canadian ship!

-

Just finished milling the frame slots in the original Mantua plywood keel. Bottoms of the slots were squared up with chisels. The screw holes in the plywood keel were used to mount it to the sacrificial MDF table in the milling machine. Photo shows all the major components for the keel. Now it's time to cut down the plywood keel to accommodate and join the scratchbuilt solid-timber keel, sternpost, and bow timber assembly.

-

Welcome to the forum Scott, from Ontario...

-

Truly beautiful work... well done!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Deacon reacted to a post in a topic:

HMS Victory by BikerMart - Caldercraft - 1:72

Deacon reacted to a post in a topic:

HMS Victory by BikerMart - Caldercraft - 1:72

-

Deacon started following SeaWatch Books

-

Very sorry to read of the loss of your son Keith. We're not supposed to outlive our children, it's against the laws of nature. The death of any loved one leaves us adrift. It's through the support of family and our extended family that we can get back on course and continue as our loved one would wish us to.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.