-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by HIPEXEC

-

-

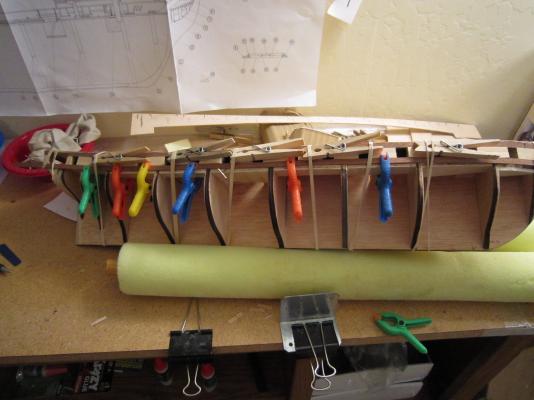

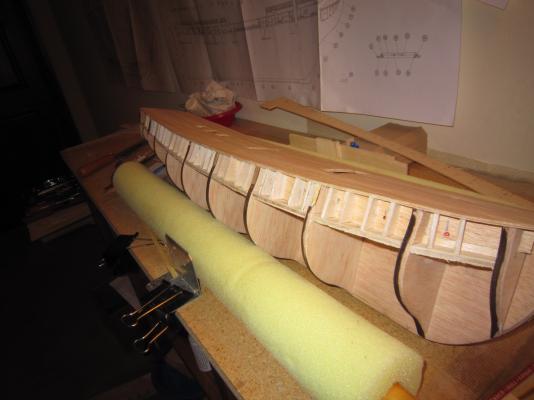

I faced the same dilema with my USS Constituion. The plans called for me to plank the hull then cut the gun ports. I didn't like that since I'm not that good at measuring and cutting and the hull planks are heavy duty and hard to cut.. So, I made frames in the hull for all 30 gunports then I cut the hull planks in my miter box and get nice square cuts. It worked! I'm happy with the false gunports. For me it was easier to measure and make frames. They didn't have to be perfect. The ports wound up be fairly accurately placed. I made a strip of light balsa wood and drew the ports on it from the plans. The I used that to locate each port one at a time. I also made a exact square the size of the port to use as a check before I glued anything in place. Sounds more complicated than it was. I'm sure I didn't save anytime, but I wound up with nice ports.

Hope this helps a little

Rich

hipexec USS Constitution

-

I just tried my new plank bender. It's not magic and it takes the same amount of time to get a bend as my iron did, but the curve is nice and smooth. I'll see what it looks like in the AM when it will be dry.

Rich

-

I planked and varnished my below decks even though I'm not sure anyone will ever see them when they look down the grates. I asked that same question when my plans called for me to plank these hidden decks. I think it was Augie or Sjors who said, "You'll know they're planked even though you can't see them." Well, mine are done. It didn't take that long.

Rich

USS Constitution hipexec

-

The electric plank bender came after I ordered it from ModelExpo on E-Bay. It's a Model Shipways Electric Plank Bender with a curved pattern block. Model Expo is a great place to buy hobby supplies. I'll let you all know how the bender works after I soak a few planks and try it. I built an aluminum clad holder to set the hot bender on while working.

Rich

-

-

-

-

Your planks look excellent! My version has me planking before I mount the stem. I'm not sure how I can get that crisp look you have that way. Oh well, I'll figure it out.

Rich

USS Constitution hipexec

-

-

-

Broke my plank cutter on the 2mm x 6mm Sapelly plank provided in the kit. This stuff is like iron. Doesn't want to bend or cut. I broke down and ordered a electric plank bender. The iron I was using made creases in the planks. I'll have to buy a new plank cutter...more heavy duty than the last one.I'm working on the false gun ports starboard side.

Rich

-

-

Plank number one is defeating me. The kit calls for planking once with 2mm X 6 mm dark Sapelly wood. It's very stiff and subject to cracking and splitting. I soaked the first peices and put them in a jig after using an iron to bend them. They came out near net shape. The plans call for me to pin them temporalrily until the glue sets. Either the pin bends and the pin splits the wood. I'm now soaking new pieces. I will attempt to use guide pins (removable) and rubber bands to hold each plank until the glue sets. Wish me luck.

Rich

-

-

Thanks for that advice, Wes. I didn't do that with my first build.

Rich

-

-

Your wood working is beautiful!

Rich hipexec USS Constitution

-

-

-

I'm spending a lot of time preparing the frames, bow and stern for planking. I don't want to make the same planking mistakes I did framing my Swift. That was my first boat and I had no idea what I was doing. I salvaged the Swift with a lot of filler and sanding. If you look at the Swift closley you see all kinds of of waves and ripples in the planks. I don't want that on this USS Constitution.

Rich

-

-

Yes to both your inquiries. These are for the false cannons and I will definitely try out my deck finish.

Thanks for your imput. It helps.

Rich

-

-

USS Constitution by Hipexec - FINISHED - Constructo - 1:82

in - Kit build logs for subjects built from 1751 - 1800

Posted

I finally finished roughing all the false gun ports! They were my second biggest worry, but they came out fairly square and all lined up. . My first worry is how will I build the upper gun ports? I'll cross that bridge after 50 or 60 more hull planks below the false gun ports.

Rich