-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by HIPEXEC

-

-

-

Well, since I started building my Connie, I've done a lot of wood bending, but I never ran into a more frustrating wood than 2mm x 2mm Ayous. It just won't bend without cracking. No matter how much soaking or how slow I put the bends in, the stuff keeps on splitting. I've salvaged a few pieces that will require a small amount of glue to hide the small cracks, but....what can I say?

I also finished the supports for the bow grate. Constructo calls for me to just glue plain dark planks, but I trimmed them out to more look like the USS Constitution in Boston. Only a small amount of them is seem under the roundhouses, but I'm trying to make it look like the real deal.

- Dimitris71 and WackoWolf

-

2

2

-

- augie, src, Dimitris71 and 5 others

-

8

8

-

-

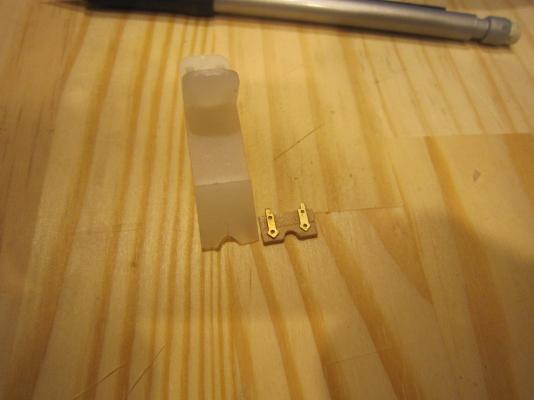

I'll get 5 minute epoxy. 10 seconds had me rushing too much. Since I had to rush I finished all the hinges. Constructo gave not one extra hinge! They did send the 2mm x 2mm Ayous that came today. That stuff does not want to bend! I finally finessed one piece almost to shape. I'll work on it some more tomorrow. I thought I could be more precise with the placement of the hinges, but ? They're close.

-

- Aussie048, src, Elmer Cornish and 1 other

-

4

4

-

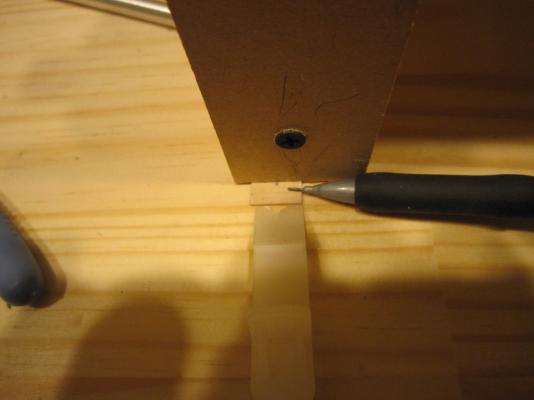

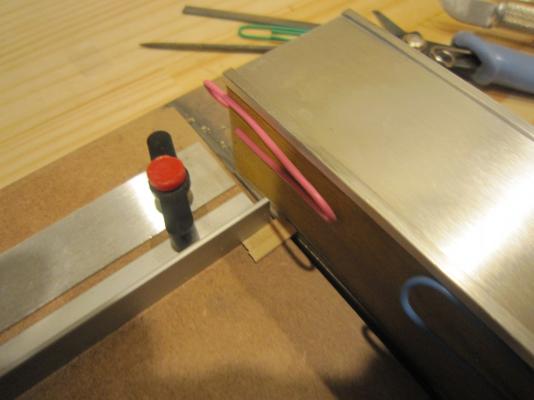

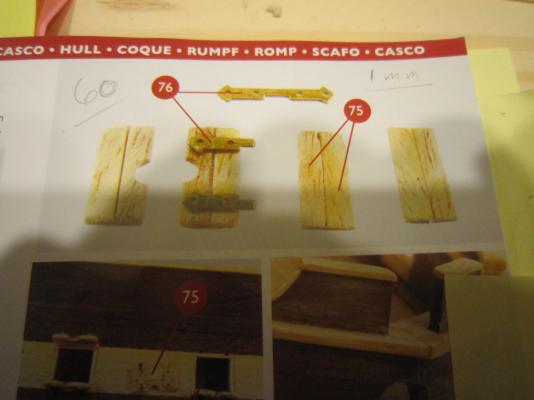

I set up a production line to make the gunport covers. I first precision sanded them square and to size. I made a guage to check the size and mark the center for the gunport which I fled after making a tiny cut with a razor knife. Last, I cleaned off any surface glue left over from gluing the two planks together. I'm not even half way with this part of the process. After this, I have to glue on two hinges on each cover. This is difficult work for me....I can only imagine have much work it would be for the Victory!

- Sjors, Elmer Cornish, Dimitris71 and 3 others

-

6

6

-

Good luck and we'll be watching your build with great interest.

-

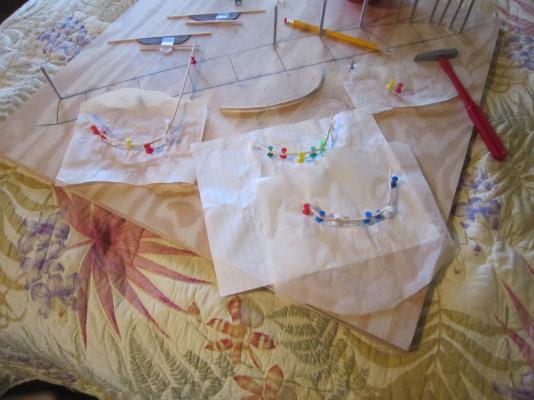

Sam...you were right...it would have been better to glue whole length planks and then cut them to size. Oh well it's done. I finished glued the pre-cut pieces and next I'll precision sand them square and to size. I also made a pattern for the half round cuts I have to make in each lid. Enough for today...I have to give my fat fingers a break.

-

Oh, I almost forgot...more kit bashing...Constructo gave me the exact number of hinges to complete the model and not one hinge more!

-

Good idea, Sam, except I cut up all the small pieces already. Gluing them is not a hard job. gluing on the hinges is tough. I like your template idea.

-

- Aussie048 and Elmer Cornish

-

2

2

-

I'm still trying to figure out how to get standardized results with so many pieces. The wood won't be a problem, but placing those tiny hinges exactly in the same place on 60 hatches will be my challenge.

-

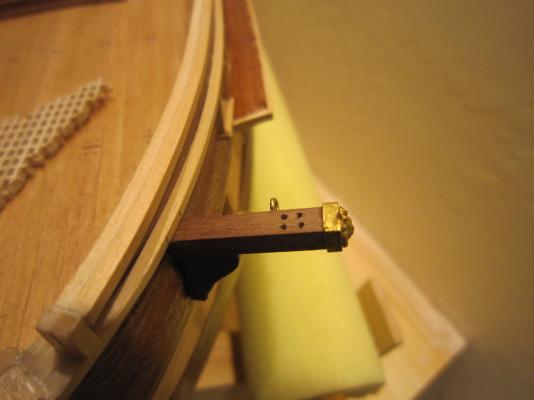

I made a proof of concept gunport door. The concept seems to work just fine. I used regular PVA glue to join the two wooden pieces and then CA glue to attach the hinges. I drilled two 1mm holes in a piece of Sapele hull material and them made a small horizontal slit with a pointy razor knife to align with the flat hinge. It pinned the door to the hull very tightly. When it will be glued it will be very robust. Now I have to figure out an assembly line of jigs so the wood is all the same size and the hinges are cut in equal halves and the hinges get glued onto the wood in the exact same spot over and over all lined up. I have no idea how to do all that, but I'm thinking real hard. Any ideas?

- Aussie048, augie and Elmer Cornish

-

3

3

-

Thanks, Augie. I'm in the process of making one up as a experiment to see how it all goes together and even mounted. Then I'll start the factory. Thanks for the advise.

-

-

- Dimitris71, Aussie048, augie and 1 other

-

4

4

-

- Dimitris71, augie, Aussie048 and 1 other

-

4

4

-

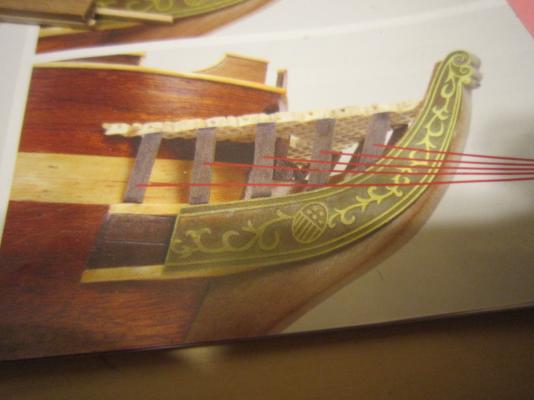

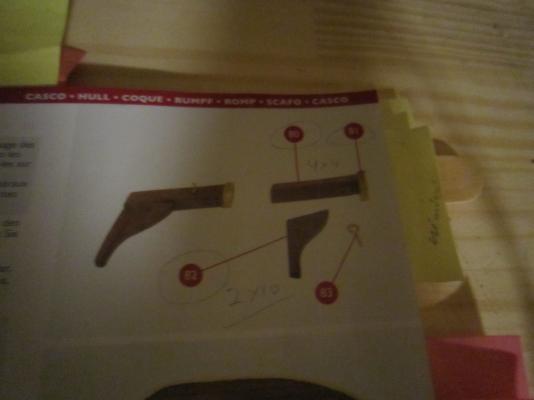

While I'm waiting for the 2mm x 2mm Ayous being mailed from Constructo, I'm trying to construct a pair of bow davits without any dimenisional drawings from Constructo. They only give you a small photo. These things have nine holes to be drilled with no hole dimensions given with no detail as to exactly where they are to be mounted. Sorry to complain, but this small project will wind up taking me two weeks. It shows 2mm brass trim at the end that is driving me crazy trying to bend the stuff exactly to fit. It keeps breaking? I have taped them where they belong since the hull shape is slightly different on each side for a tight fit. I pinned them, but not glued yet until I get all the hole drilled and brass mounted.

There...that felt good to get off my chest!

- Sjors and Elmer Cornish

-

2

2

-

Rich,

I'll be interested in you telling all of us how good the plans and instructions are with a Caldercraft kit.

-

Nice work. I hope you didn't have to cut in all those gunports!

-

Very nice work. Are you adding sails?

-

-

My razor saw worked just fine. Some tiny corner pieces fell off, but I just glued them back on. The bow section is a difficult shape. I put scotch tape over the areas to be sawed and it held everything just fine.

USS Constitution by Hipexec - FINISHED - Constructo - 1:82

in - Kit build logs for subjects built from 1751 - 1800

Posted

I've roughed in the whole bow area. It's not exactly what I was striving to do. I broke more sticks trying to make those bends than I can count. Now I have to jury rig some crooked bends with filler and sanding to make them perfectly curved I don't know how you folks manage such precise bends. It drives me mad....kind of like golf....I know what I want to do...I just can't make my spastic body execute it. Oh well....?.