-

Posts

693 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NavyShooter

-

Gotcha. There was a hobby boat show at the old Museum of Science and Tech once upon a time that I was thinking about, but I guess not. All good, and hopefully she turns out well after the refit! NS

- 235 replies

-

That's some cool history there - in 1977 I was 4 years old. I wonder if I ever saw that ship in person when I lived in Ottawa...I recall being involved with the RC Boat group that met at the Canoe Club in the 89-91 time-frame as a kid.

- 235 replies

-

BZ! This is a beautiful build! Your work with the photo-etch is fascinating to me. That stuff honestly scares me! The crew is only 5mm tall...wow....well done! NS

- 97 replies

-

- Enterprise

- Tamiya

-

(and 2 more)

Tagged with:

-

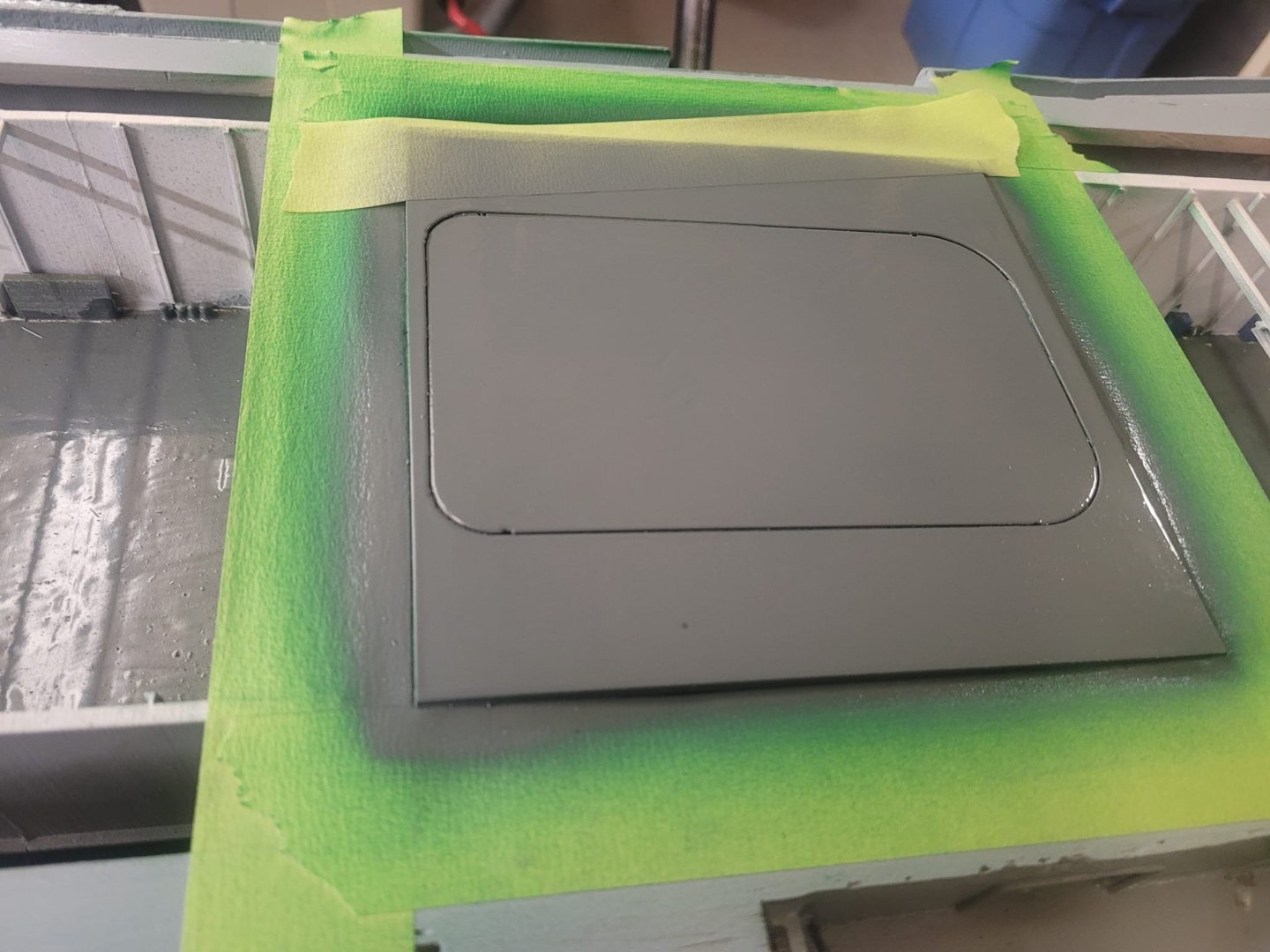

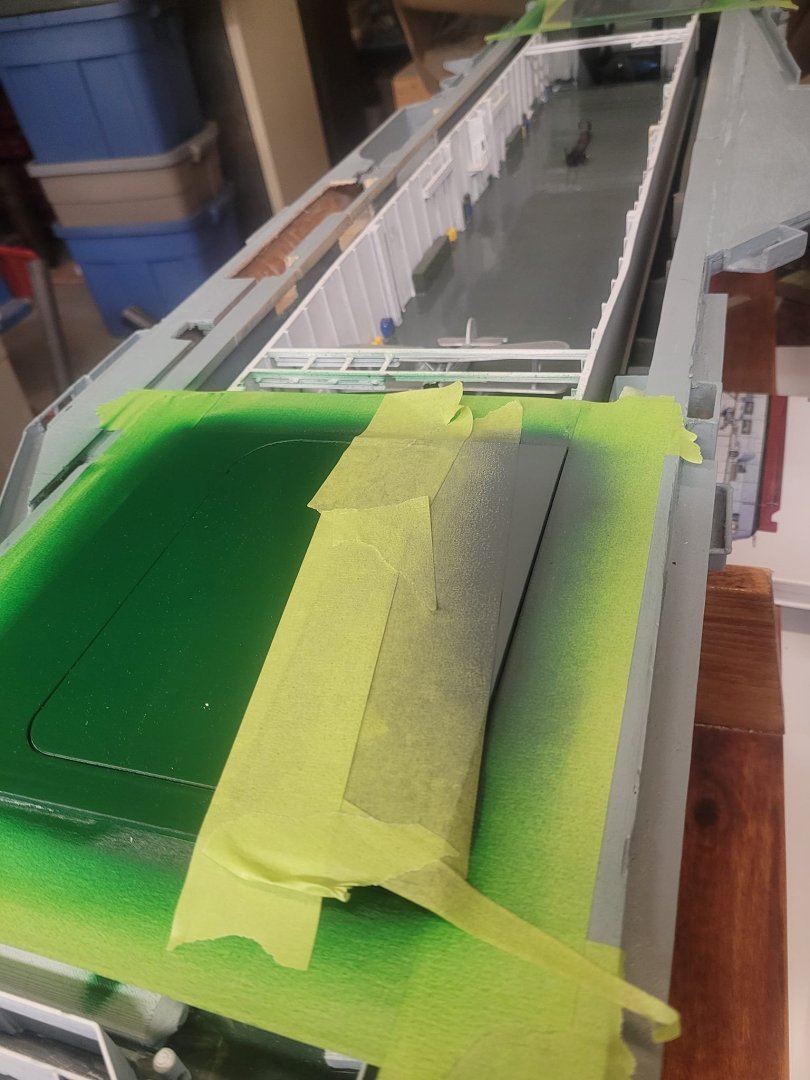

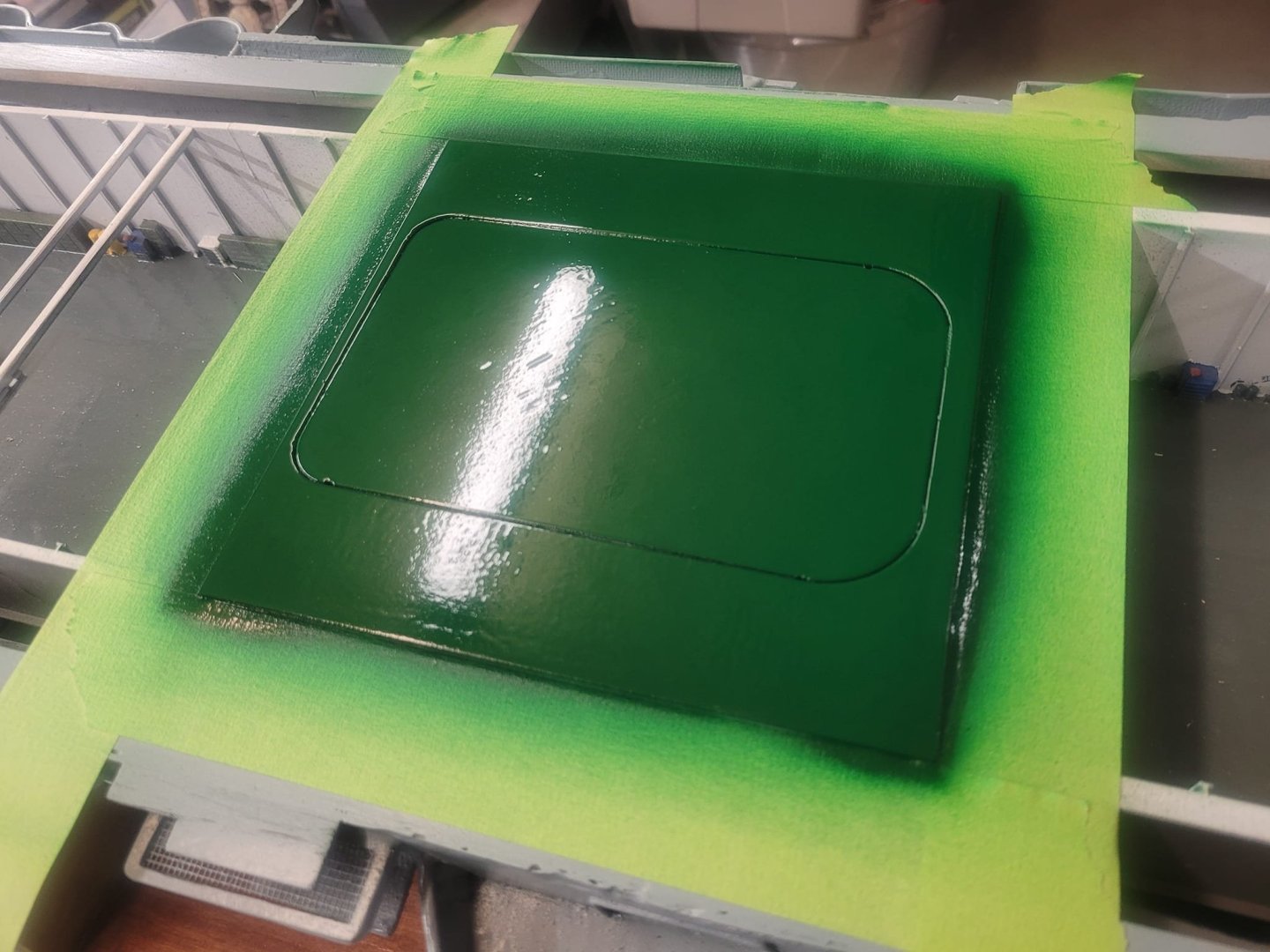

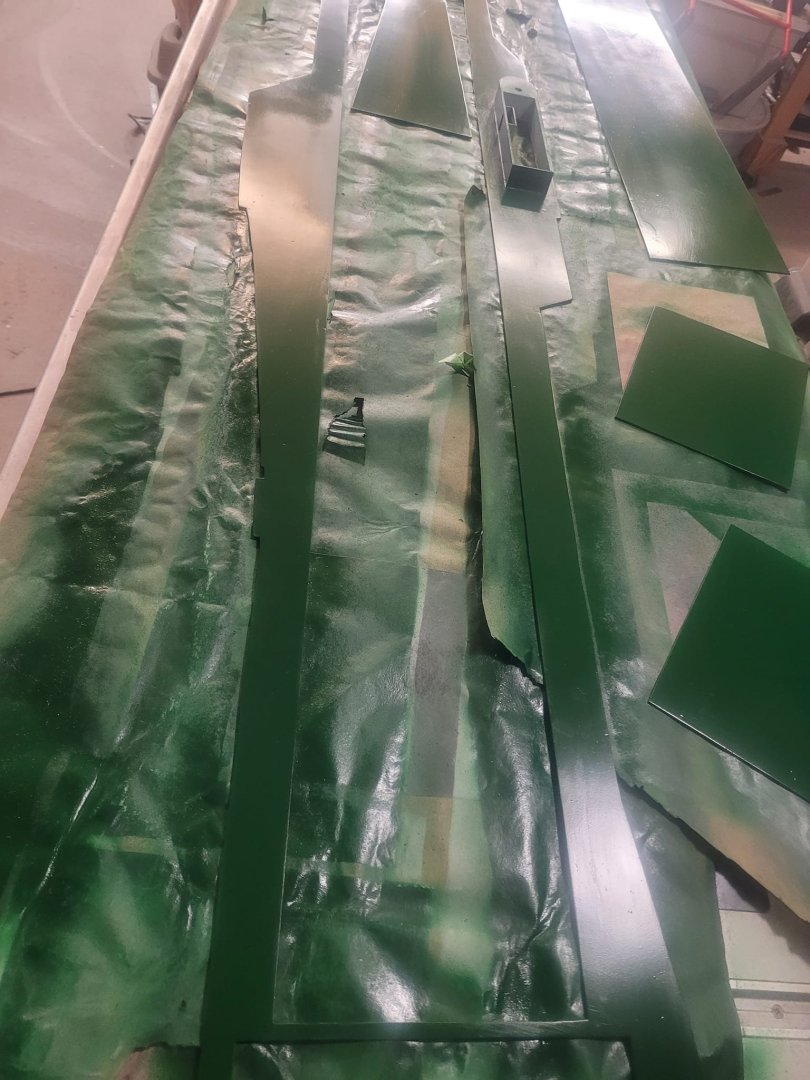

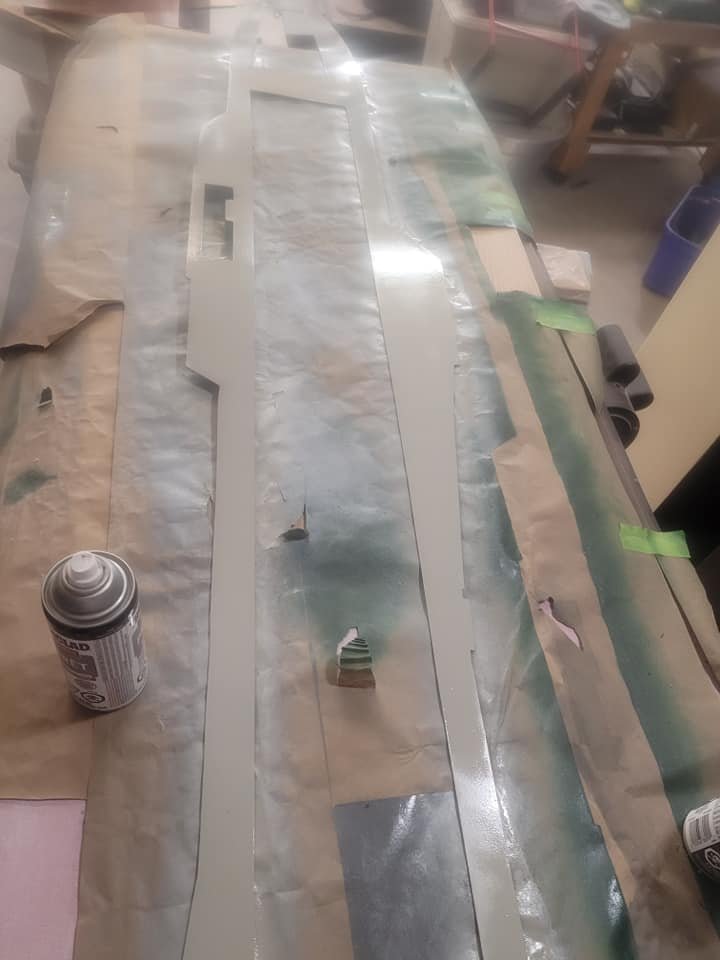

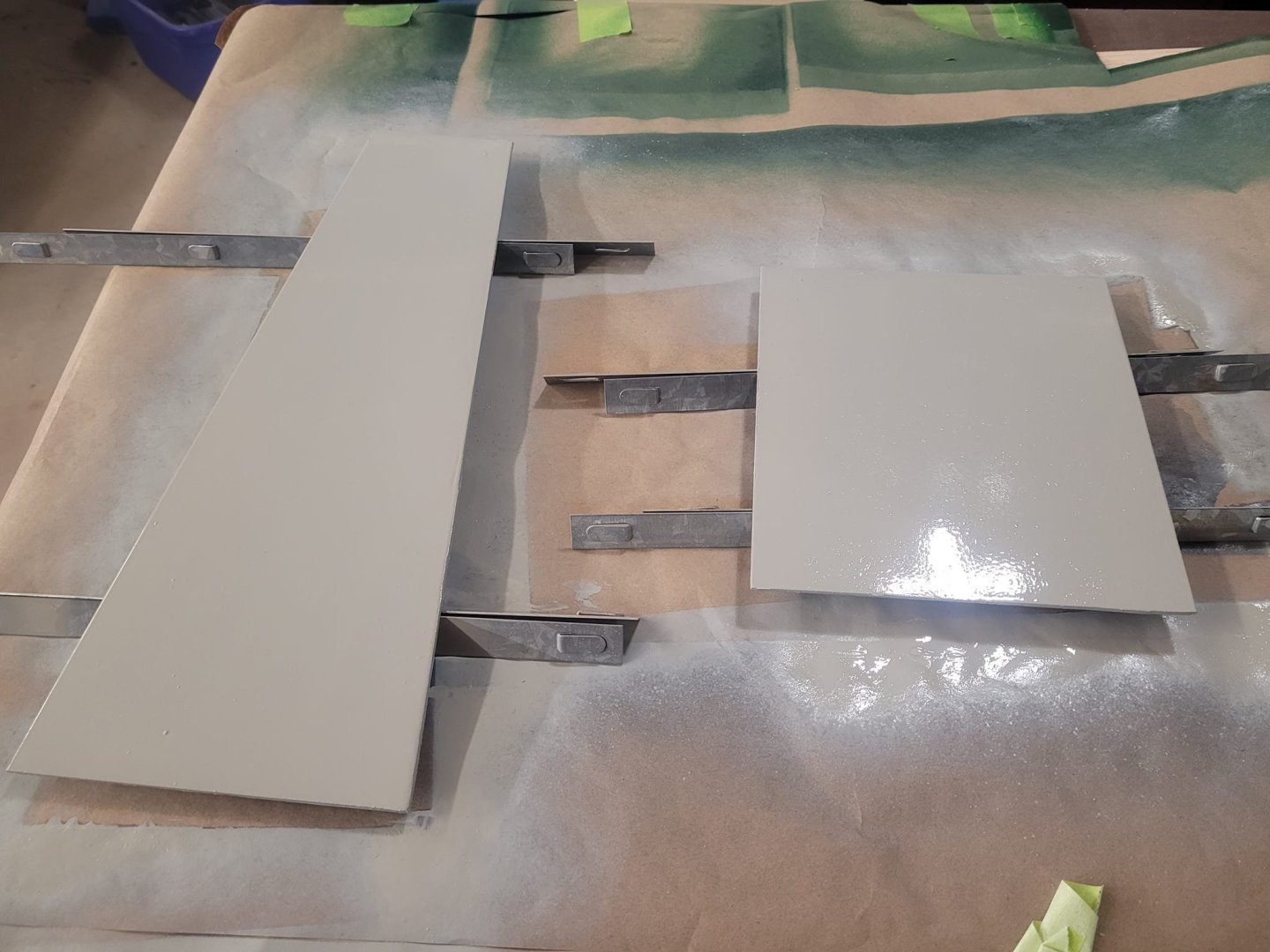

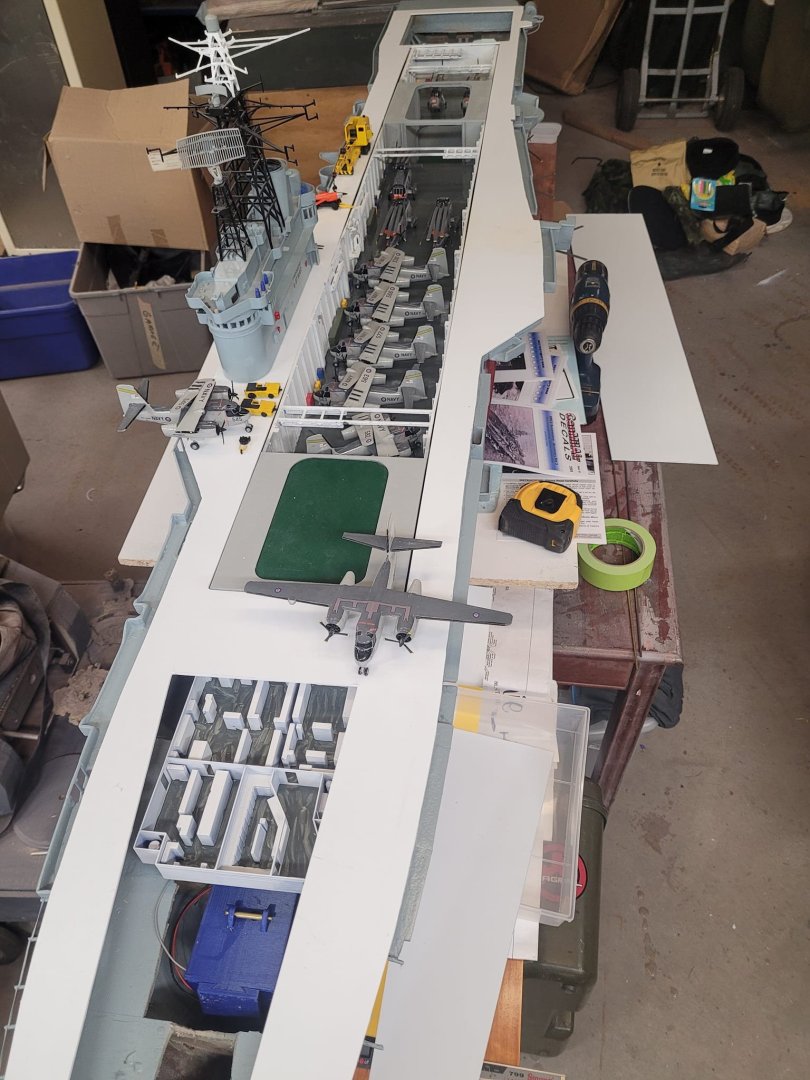

So, something I noted is that the last time I was futzing about with the flight deck paint a couple of years ago, I had a problem with paint bubbling...and I had to strip it (I used a belt sander on the plywood that time.) I recall that I used the same type of paint both times. So. This time around, I'm going to try a different brand. We'll see how it goes.

-

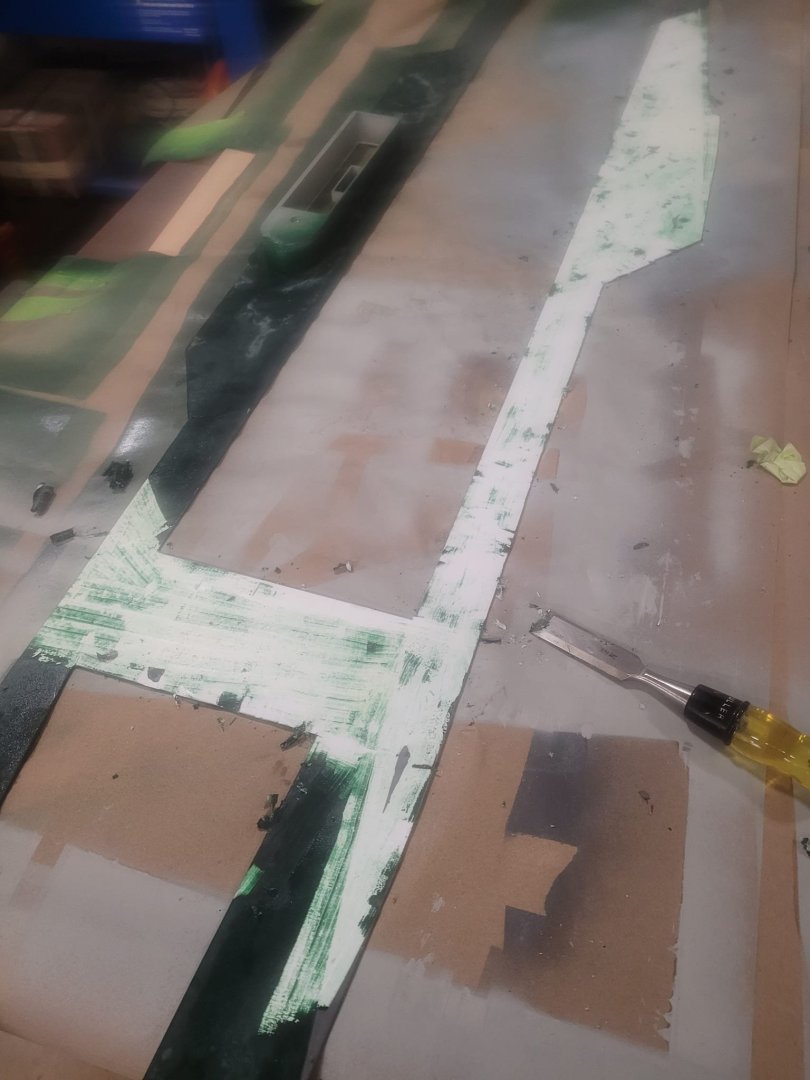

And. The verdict is - I'm an idiot. I rushed the paint job in adding the gray, and didn't wait long enough between coats. The tape stuck to the deck and left behind glue all the way along the green, and the gray paint bubbled in multiple spots. I'm going to have to strip and re-do. Damn damn and triple damn. I'm mad at myself tonight.

-

Following as well - I have an interest in RCN Ships!

- 5 replies

-

- Harry DeWolf

- AOPS

-

(and 1 more)

Tagged with:

-

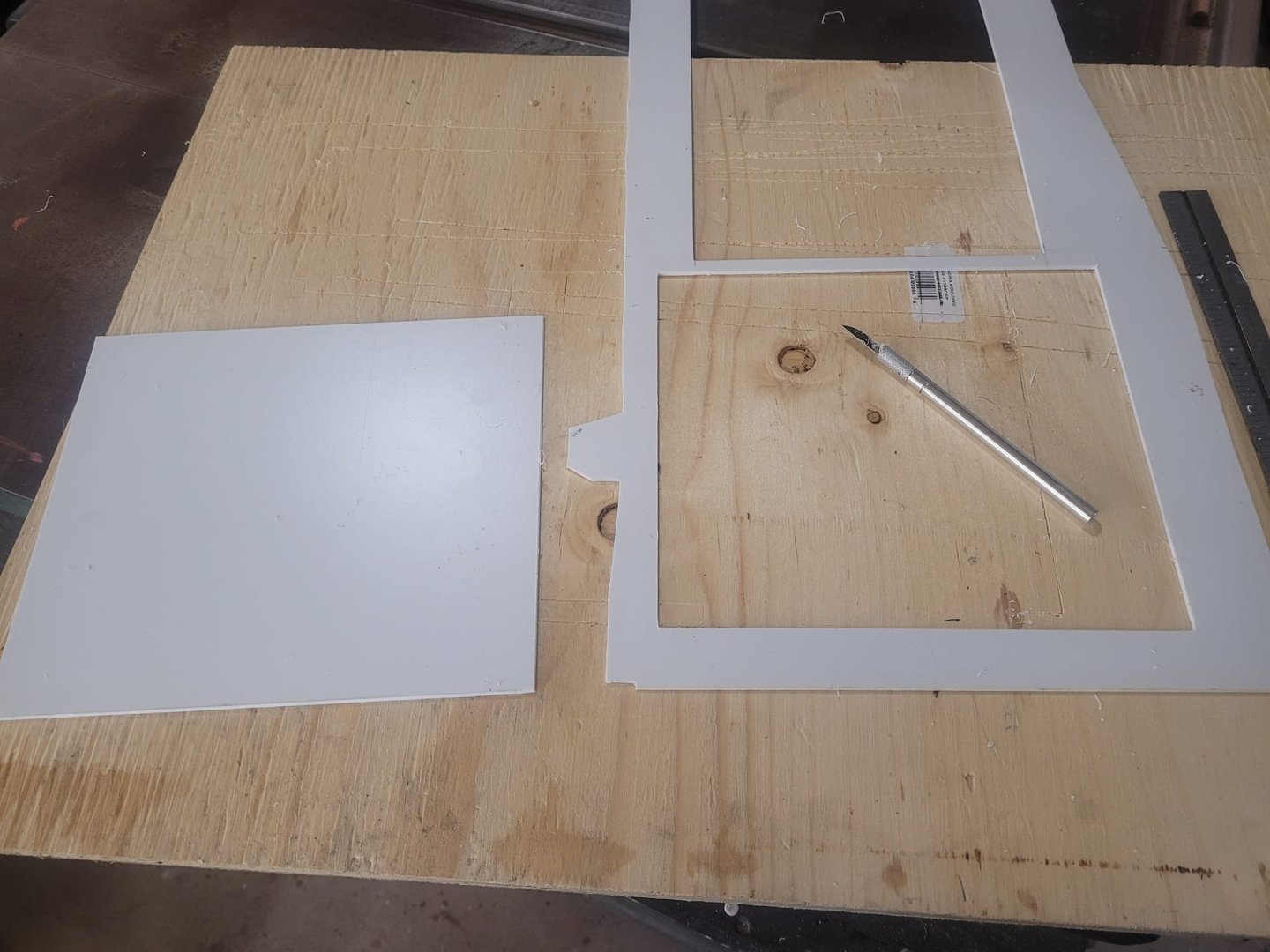

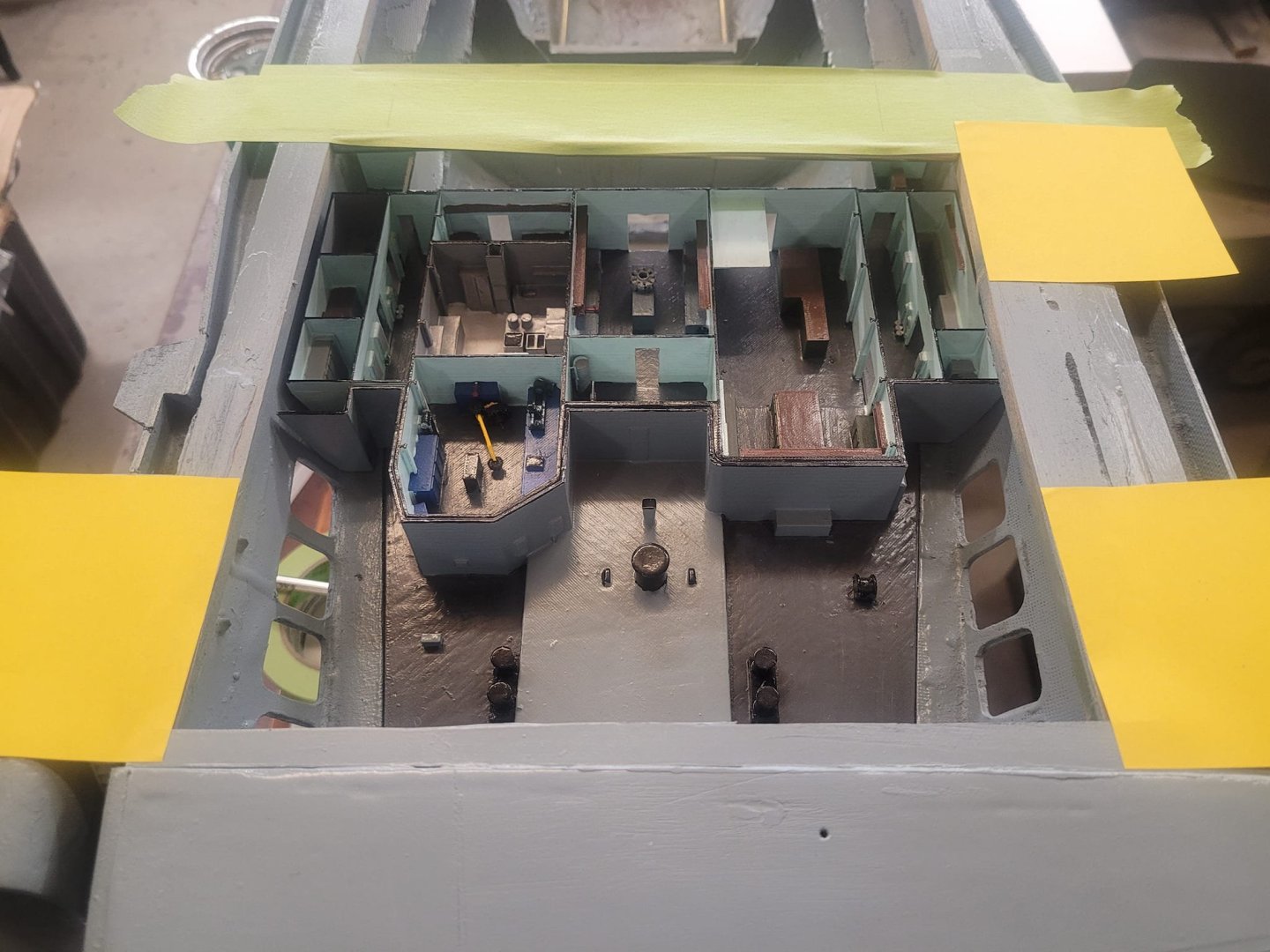

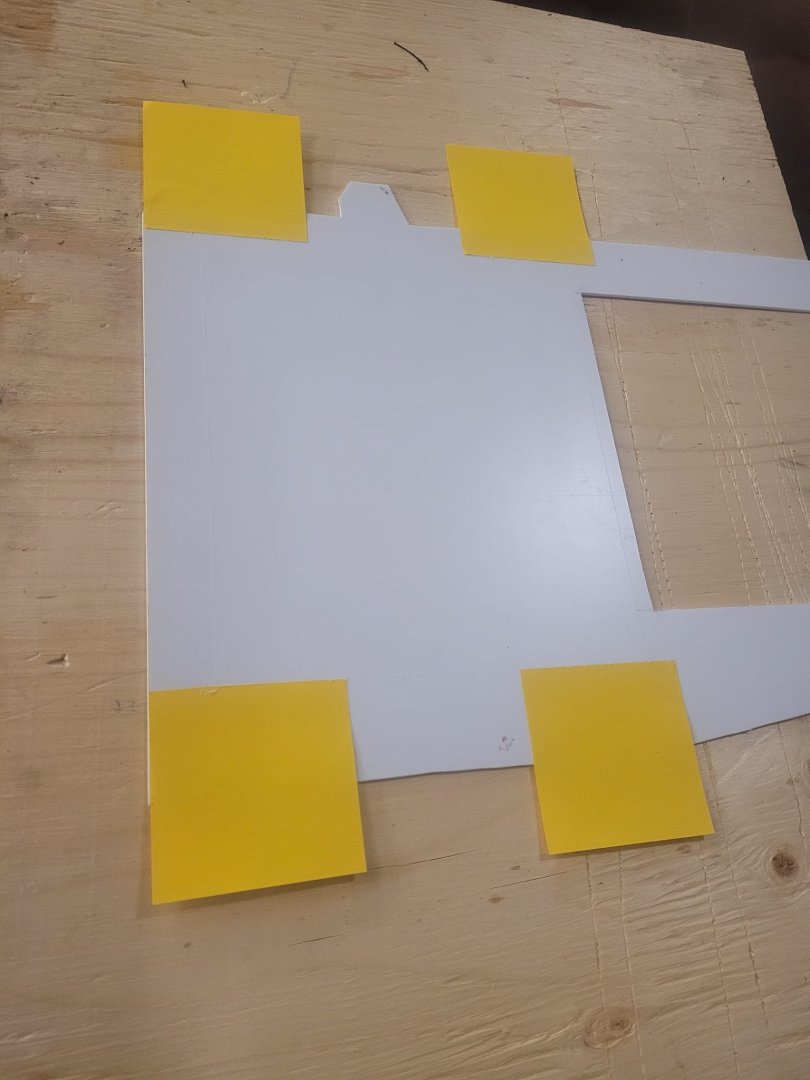

So this afternoon I had a few minutes to invest in working on the Bonnie. I've got the large opening in the flight deck for the hangar module done, now it' s a question of having access to the rest of the interior bits I need to get to. So, here's the entry hole for the rudder post/servo area cut out. It's also the space where I put in the workshop spaces that I 3D printed - so - I have to be able to remove them through this hole. It all fits and works. Observe the use of the post-it notes to setup the edges of the hole for cutting - I put the post it notes on the hull to line up where I wanted the edge to be on the flight deck, and then instead of measuring/transferring the hole dimensionally, I simply put a post-it note over top of the lower one, aligning the edges perfectly. If it looks stupid, but it works...is it really stupid?

-

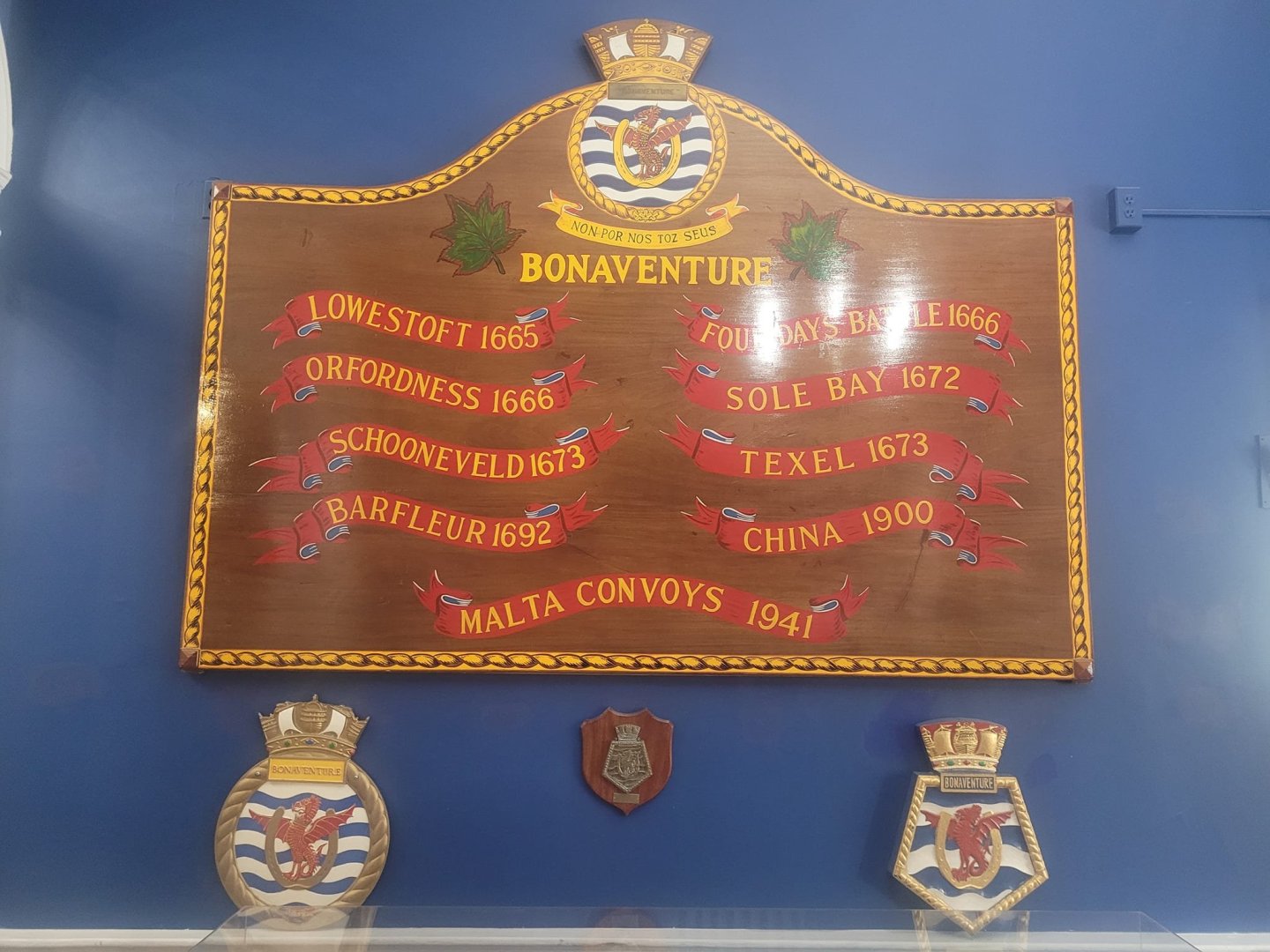

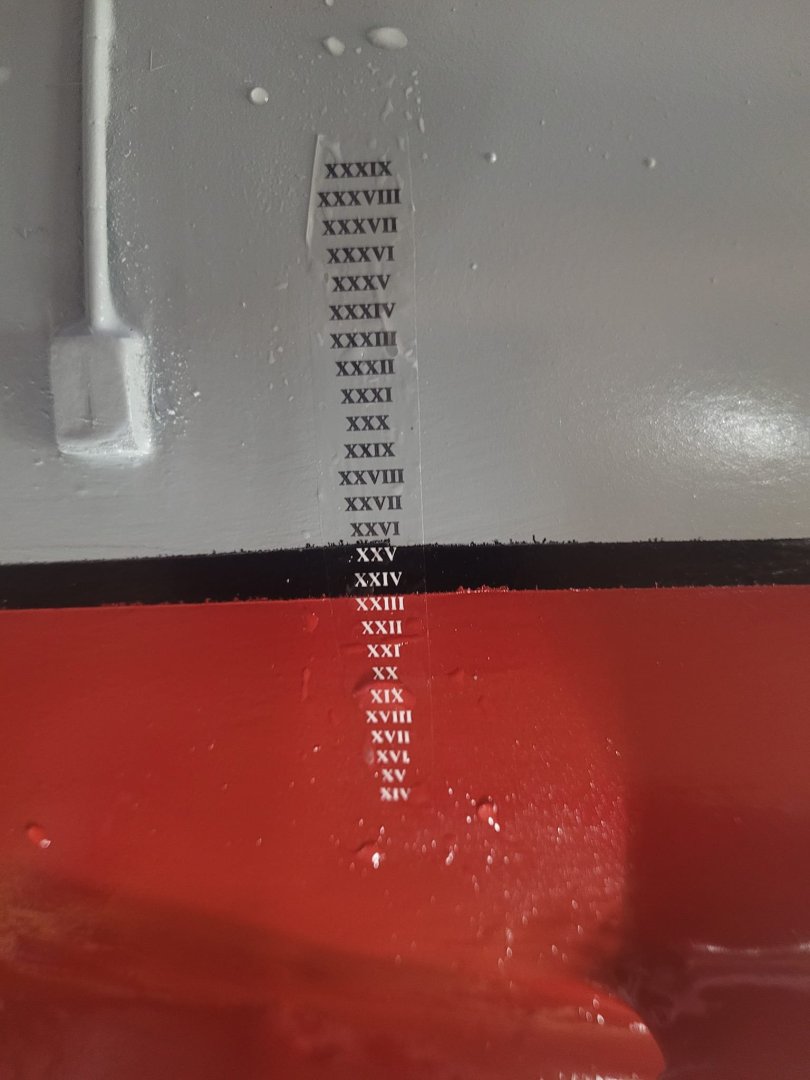

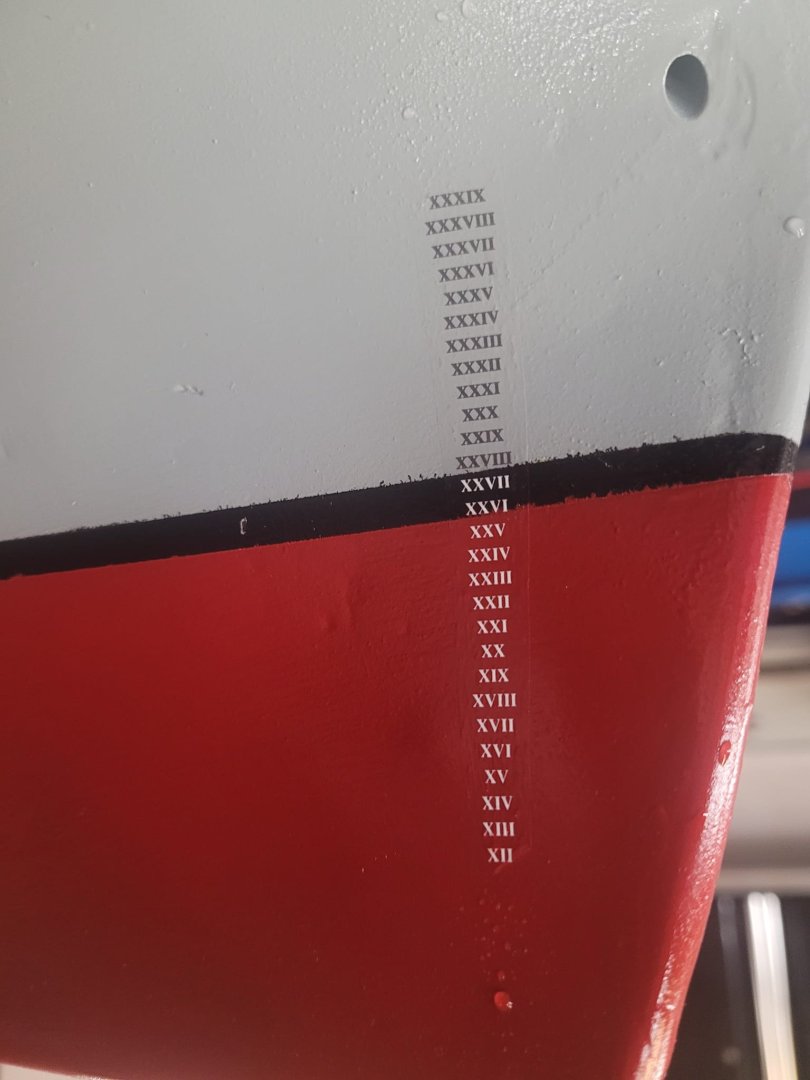

A couple of weeks ago, I came across a gent who has a display setup honouring the sailors from the Bonnie (and other veterans) in a local mall, so on Monday, I'm dropping off a 'mini' air-det to him, with one each Tracker, Banshee, Sea King and Horse. There is a glass cover for the display box, so they'll be protected (which is a good thing.) Also, the hull has now dried a bit, so I've decided to put the draft markings on. I'm quite pleased with how that looks. Let that dry for a few days and I'll add a few layers of clear coat sealant on it to protect them.

-

Tonight I was out in the garage puttering away at a few things - I masked up the boot topping, and shot the keel with the first layer of red. I'll let it dry a bit and shoot it again on the weekend probably. I was also puttering away with some electronic bits - once the keel is done and dusted, I'll be able to flip the hull over and start working on the guts...but wanted to get some work done tonight on some of the 'extra' channels on the receiver. I was puttering away at the Anchor Chain hoist system tonight. It's a bit finicky.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.