-

Posts

693 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NavyShooter

-

Free CAD program

NavyShooter replied to Frank Burroughs's topic in CAD and 3D Modelling/Drafting Plans with Software

Currently installing FreeCAD... -

Free CAD program

NavyShooter replied to Frank Burroughs's topic in CAD and 3D Modelling/Drafting Plans with Software

One of the key things that 3D printing and CAD bring to the table is the ability to generate what is effectively a 'kit' from a set of plans for a ship that no company will ever produce a model of for you to build. Usually we call that scratch-building. The thing about doing it with 3D CAD though is that you can generate a model...and another model, and another...just by clicking print again. So, you can build yourself a fleet - or you can offer the model for others to build so they can have a model of your favorite ship as well. I have a plan in mind to help the local museum - I am working to do a 3D design of a ship they have in their collection, and I'm hoping to get the design workable for print in a couple of variations. First as a highly detailed model that is a great replica of the ship that I can produce in a suitable scale for floating in a pond myself as RC. Second, as a lower detail model, smaller in size, that can be fairly easily assembled by students doing a summer camp or March break program at the museum. My hope is to have that 'March break camp' something that the model club can contribute to, and do a presentation with the campers about 3D design, and then have each of them design an 'accessory' for their ship - something like a bollard, an anchor, a funnel, or whatever, using TinkerCAD, and we then print that item for them by the end of the week for them to assemble it onto their individual model boat. That's my concept. I'll see how that works out. -

Free CAD program

NavyShooter replied to Frank Burroughs's topic in CAD and 3D Modelling/Drafting Plans with Software

I've used TinkerCAD for simple projects - I started with firefighting lockers, then deck landing lights, flight deck tractors, then a crane truck. When I wanted to move up to designing a new island for the Bonnie, I moved to a program called Design Spark Mechanical (DSM) which has a free version as well. I've had some success with it, and for 'straight line' items like a hangar deck, a radar mast, that kind of thing, it seems to work well. Trying to loft a ships hull in it has been challenging, and not very successful for me (so far.) I'm interested in the DELFT Ship Free program, and will look into that. I'll note, all the aircraft are downloaded files, everything else here (hull and deck excluded) are my own designs in TinkerCAD and DSM. If you're just starting out, I'll suggest going with something simply like TinkerCAD, and start with a simple project like making bollards or lockers. Once you get the basics of the design, you have to consider how it will be printed. Understanding printing mechanics (how many wall layers will there be, is a single 0.4mm line better than a pair of 0.2mm lines...etc) and how you slice and support things is important as well. I am 6 years deep into 3D printing, and it's fun, and challenging. Getting good quality results off your printer requires a good design, a good model that's designed to be printed, a good printer, and good post-printing finishing. -

As I wait for the hangar modules to print, I'm getting in some 3D design time. I was originally going to have a folding articulated accommodation ladder, but realize that this will exceed the limits of what I can do with my FDM printer, so I went back to basics, got some dimensions, and produced a swappable folded, or setup accommodation ladder. When the Elevators are done printing, and the anchor module, I'll be able to kick a couple of these out to test them out.

-

As I await the printer before I do anything further with the flight deck, I decided to have a look at the anchor system. Here's the 'anchor module' that I've designed. This will be about a 9 hour print. You can see at the top the 'ears' which will hold a 3mm brass rod that'll act as a spool for the chain to run across. Below that is the winch deck, and below that at the bottom is the cable well, and there's a solid 'bar' in the cable well to tie the end of the anchor cable around so that it isn't lost by running out all the way. We'll see how version 1 works...

-

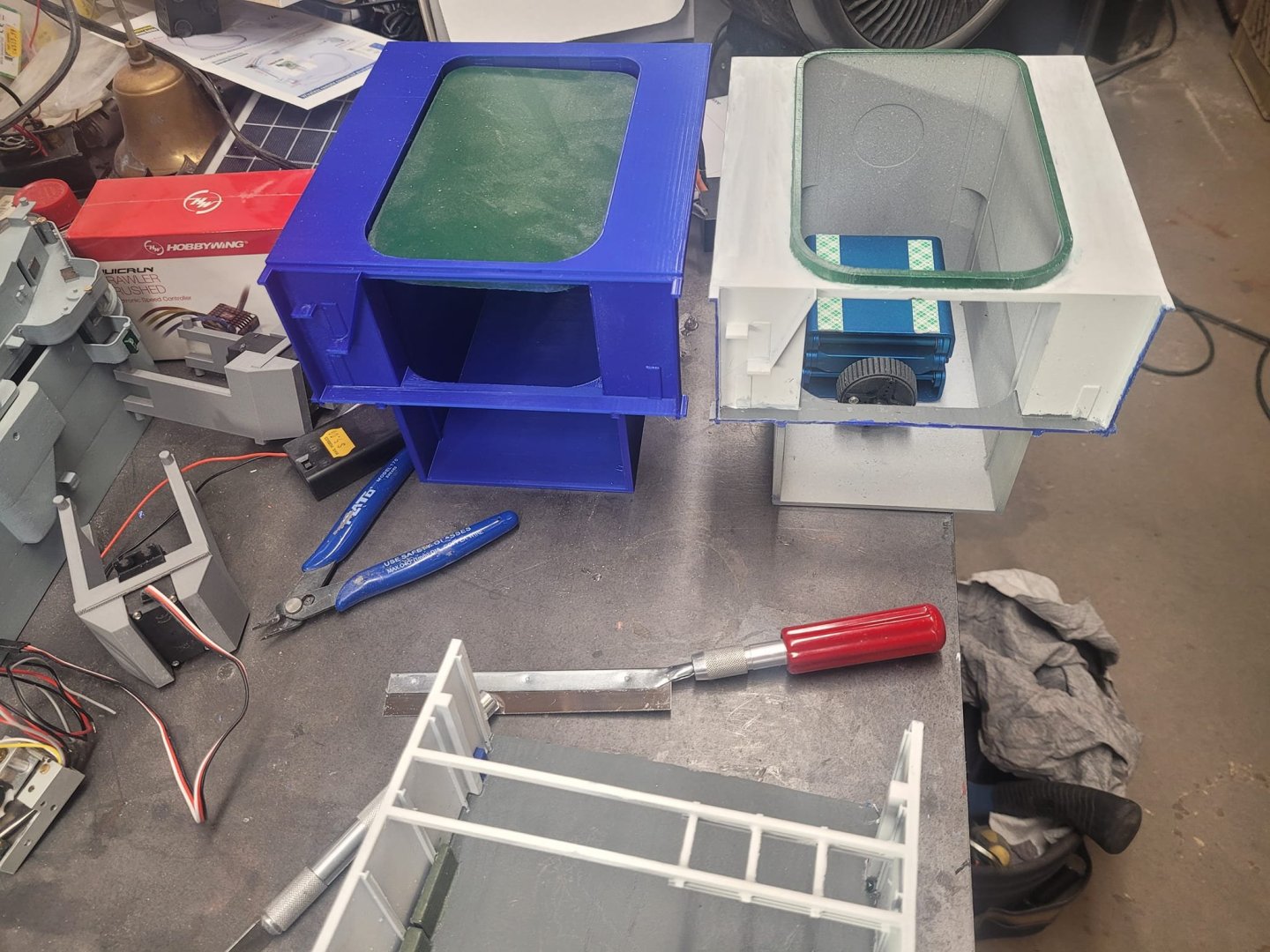

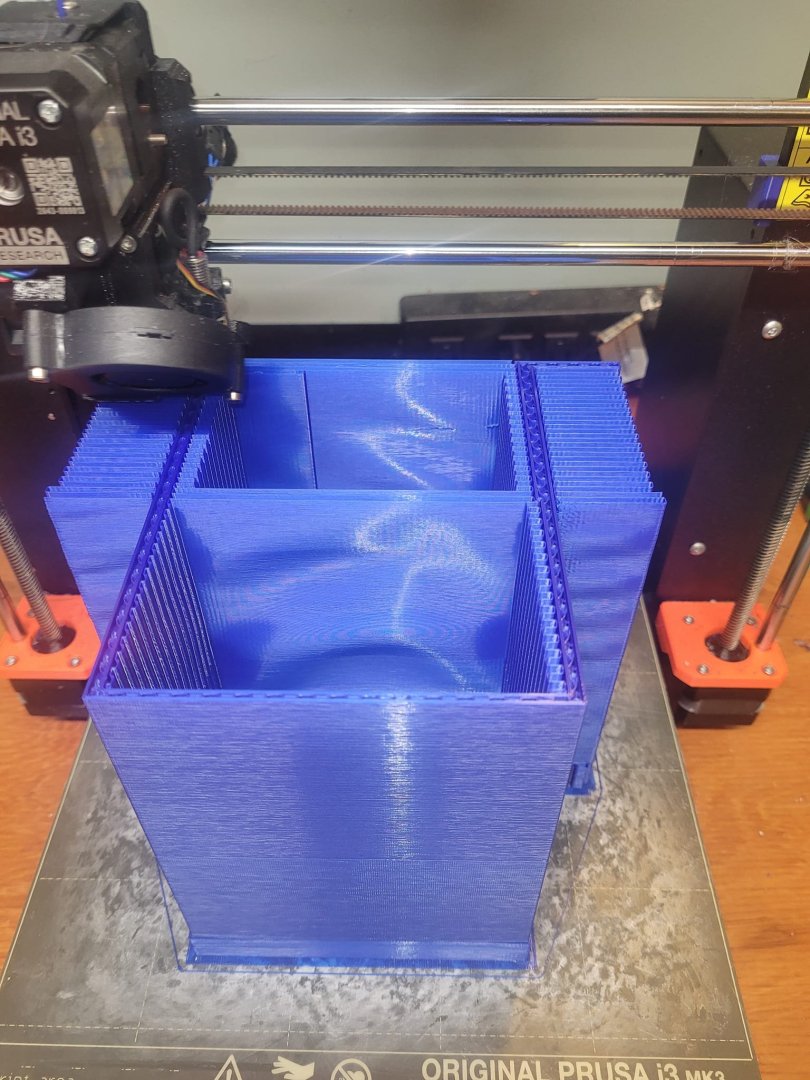

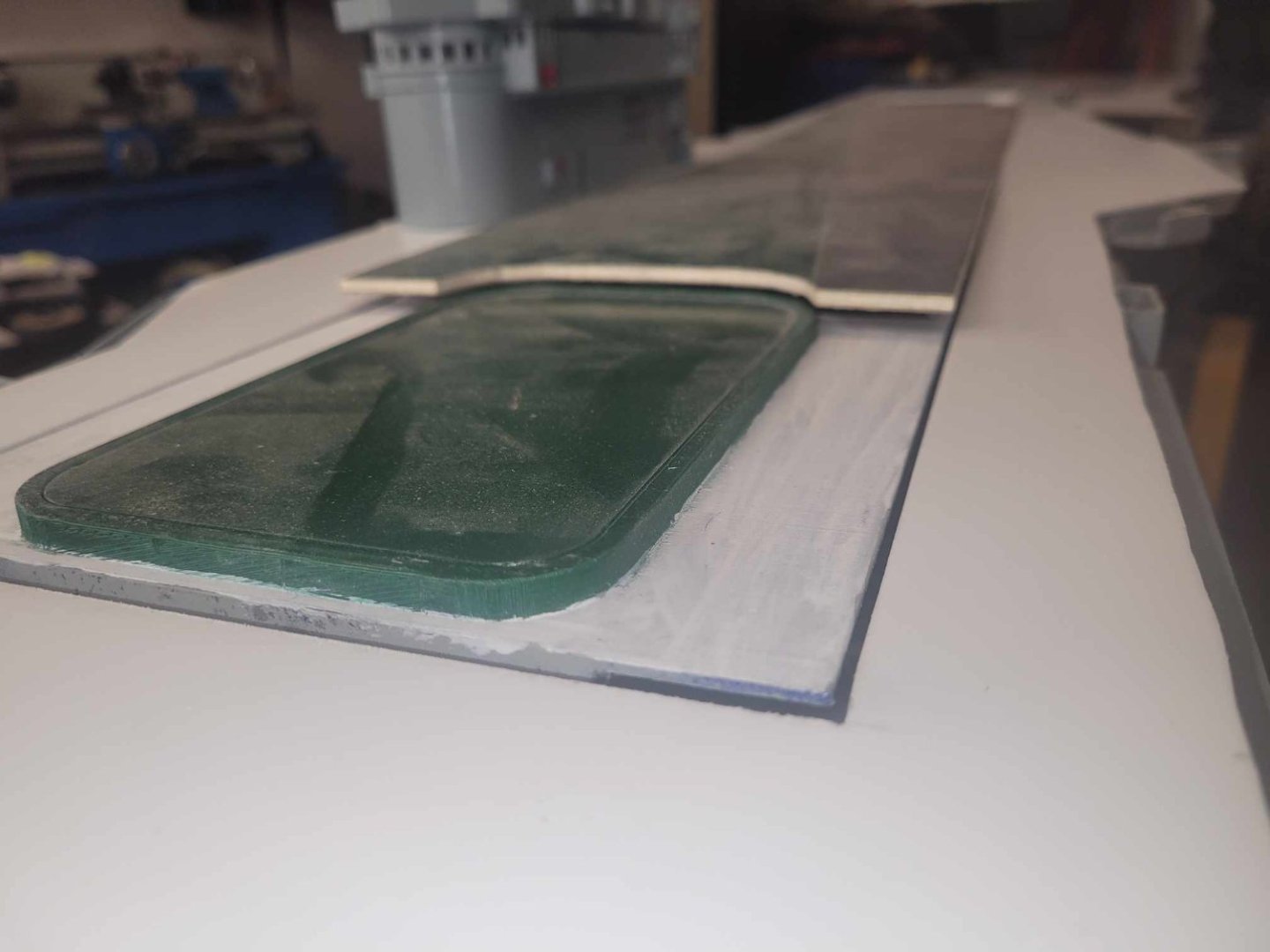

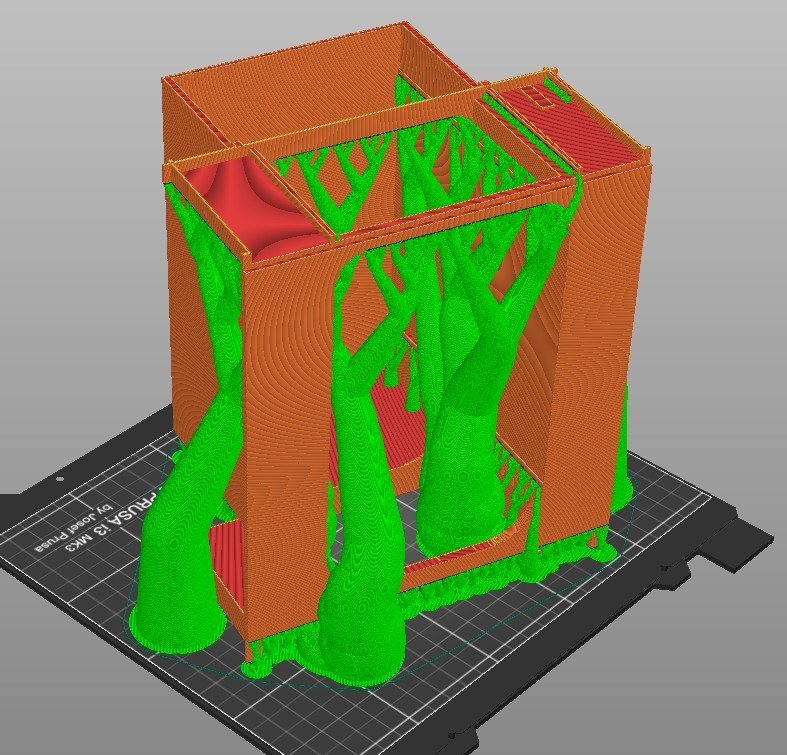

Some careful measuring, scribing, and cutting this afternoon, and I've got the hangar deck cut-out done, and the hangar deck insert fits almost perfectly. That said, I realized that the design I made originally was factored around the 6mm thick wooden flight deck, so the top of each of the elevators actually projects 6mm up above the white 'pad' around it. That is....less than desirable. It means that I have to either do cut-outs around the elevators, or, re-print the elevator modules. So. I'm about to start re-printing the forward and after elevator modules. Again. Version 5 now...?

-

And here we go with the flight deck. 2mm sheet styrene. Flipped the ship up to get a rough profile, cut out with a set of tin-snips, then clamped in place and started trimming. Got about half done - taking a break for lunch and I'll see if I can get this finished up this afternoon. I was thinking this would take a LOT more time than it is. Still need to sand it, but I'm generally pleased with how it's cutting. A sharp/new blade is making quick work of things!

-

That is the plan! Follow the MSMG on the F-Book place and you'll get updates on when we plan to launch her! In other news, I've been testing my LED flashing light circuit, and based on my test results, a standard 9V battery lasts about 4 days of continuous flashing. I tried with a NiMH battery pack, gave it a full charge, then hooked it up to a solar panel circuit and it lasted about a week - so...I'm guessing that the flashing light circuit (which was designed for Model Railroad use) makes use of a lot more power than I thought it would. Which is odd for a simple circuit with just one LED light. So. Does anyone have any suggestions for a long lasting flashing light LED circuit setup I could use? A cheap LED flasher from amazon or something that I could simply add extra batteries to? I could buy a 20 pack of 9V batteries from Costco and rig them up in parallel, letting them run for about a month and a half...but that seems...inefficient.

-

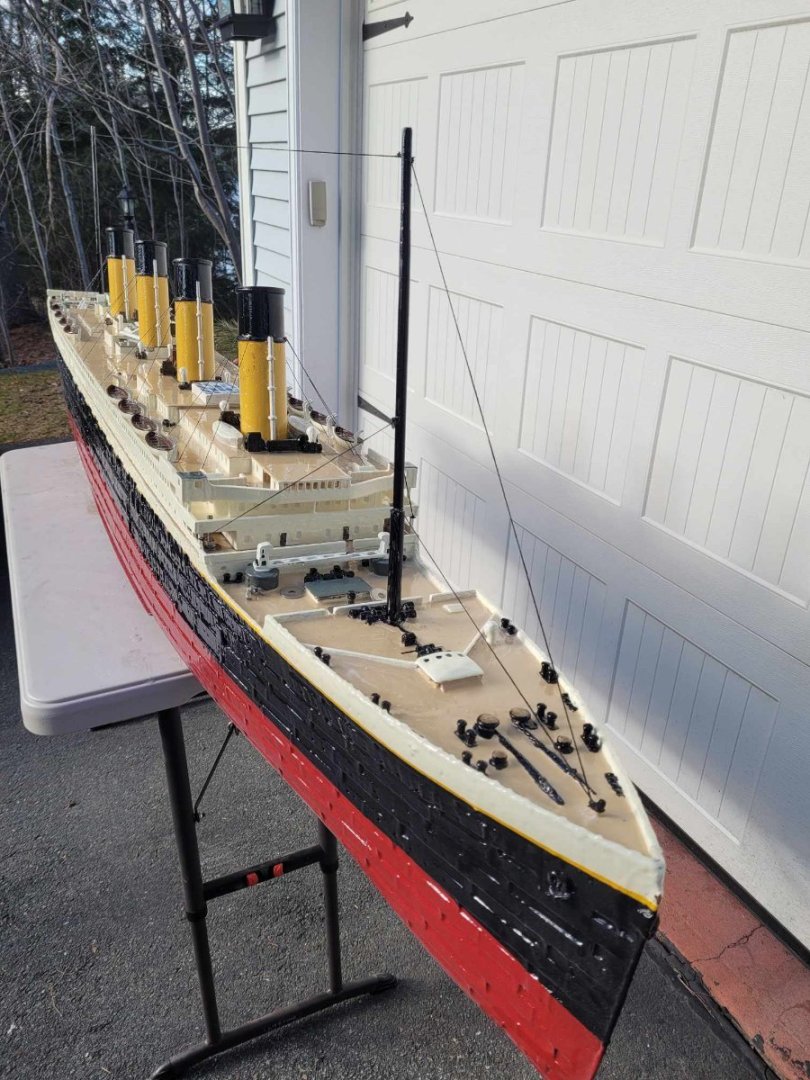

I brought the model into the Guild meeting this morning, and we had some good discussion about the ship. Here's the ballast and leak test from this afternoon. I was concerned about the model going in the lake and going from being warm to being cold (lake is only recently un-frozen) and potentially having cracks in some of the layers - and then I realized that after driving home with her in the bed of the truck that, well, she was already cold...so...off to the lake with some steel plates, and in she went. 20 minutes or so in the lake, some bouncing up and down to test her out, and she seems to hold up well. Most important bit is that there was no water ingress - looks like things are well sealed. Next step will be the 'unofficial' test launch in the near future where I'll put her in the lake here for a couple of weeks to test the ship in a longer term float before we put her into the Public Gardens pond. I will note, I'm updating this site more often than the Guild's official f-book page, so you guys are getting the news before the rest of the world!

-

@Ian_Grant that's something I was told about - and is something we will look at in the fall when she comes out of the pond. The guy who was actually supposed to do the build will be back by then, and he'll be taking her home through the winter to affect any repairs and refitting required. (He's an actual fan of the Titanic - I'm not - I just inherited the work when he went away for a year on a contract.) I am fairly certain that he's going to want to add extra details, correct some colour selections I made, and that sort of thing. He's welcome to do that, and I'll suggest that he add that layer of UV coating on top. We'll see how the ship lasts this summer.

-

I was asked elsewhere about costs and time...well, you can see the timeline for this build in this thread. Basically just over 4 months from start to finish. Here's the blurb about costs that I shared elsewhere: The plastic for printing was $470 - ish. The lead shot for ballast was $60 The fiberglass resin for sealing was $120 The paint was $150 (several cans of spray plus several pots of various colours of other paint) The epoxy outer layer was $200 - West Systems Epoxy is NOT cheap. The Stainless Steel Hardware (bolts/nuts/washers) was about $50. The Aluminum strengthening strips were about $60 (inner and outer) The Aluminum masts were about $10. The Line for the rigging was $25 That all adds up to about $1150 or so, give or take a bit. I bought the printer (used) specifically for this job (and the St Thomas model I did as a test print.) then sold the printer again, so using it for 3 months cost me about $150. Print time was about 6 weeks. Some modules took 50+ hours to print, there were 18 modules in the hull, and 8 more for the superstructure. The lifeboats and Davits were all individually printed too.

-

OK, I got the masts painted this evening (hopefully they're supposed to be black...?) and I got the last of the rigging complete. I'll see about getting her out of the garage tomorrow if things are nice out and getting a few pictures. All that's left is: - LED Flashing SOS System - Float Test - Ballast installation - Foam installation - Launch.

-

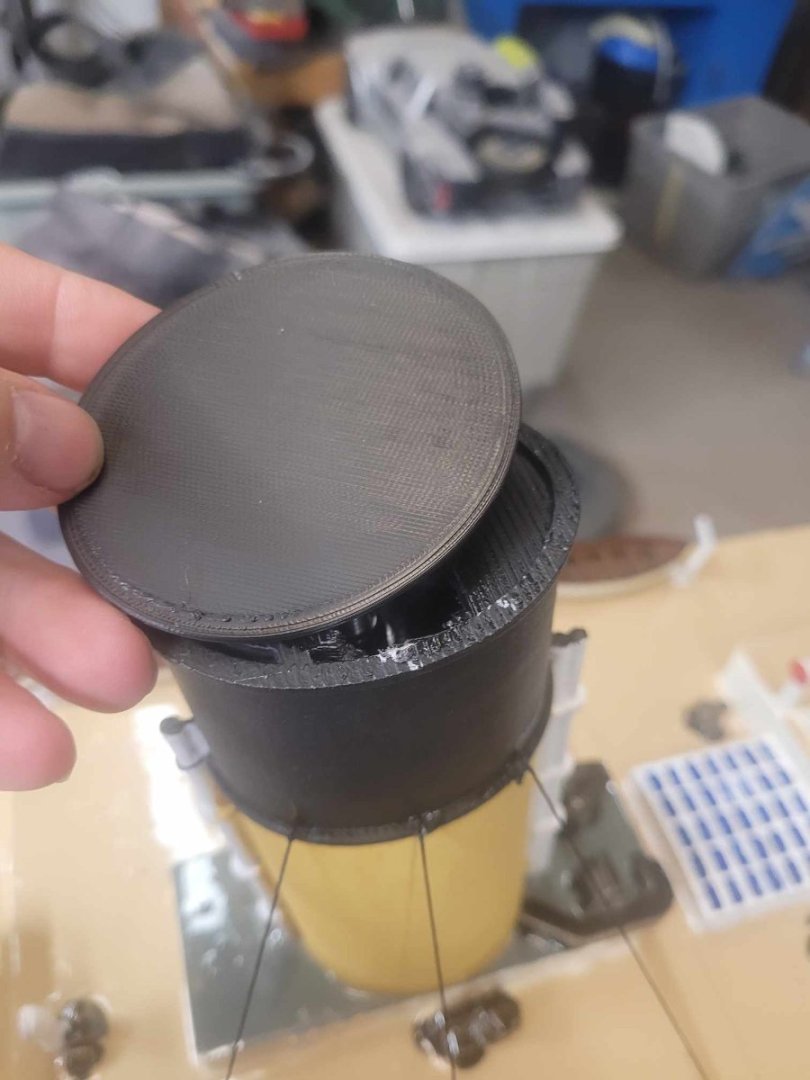

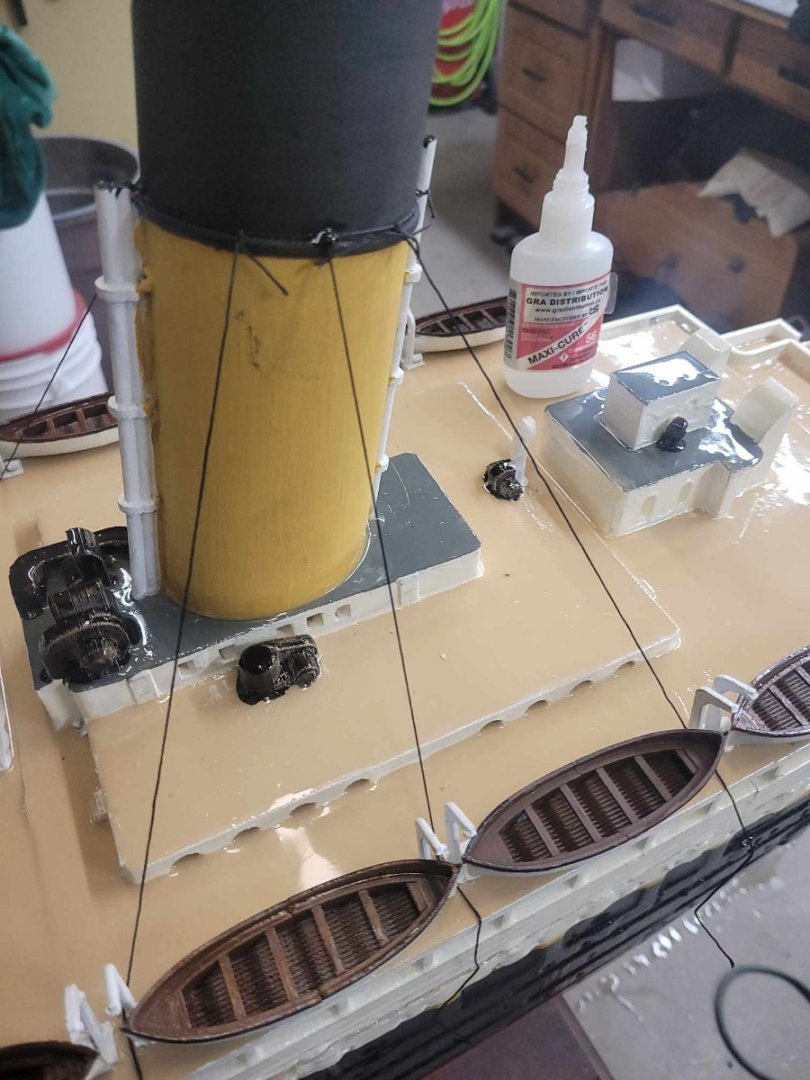

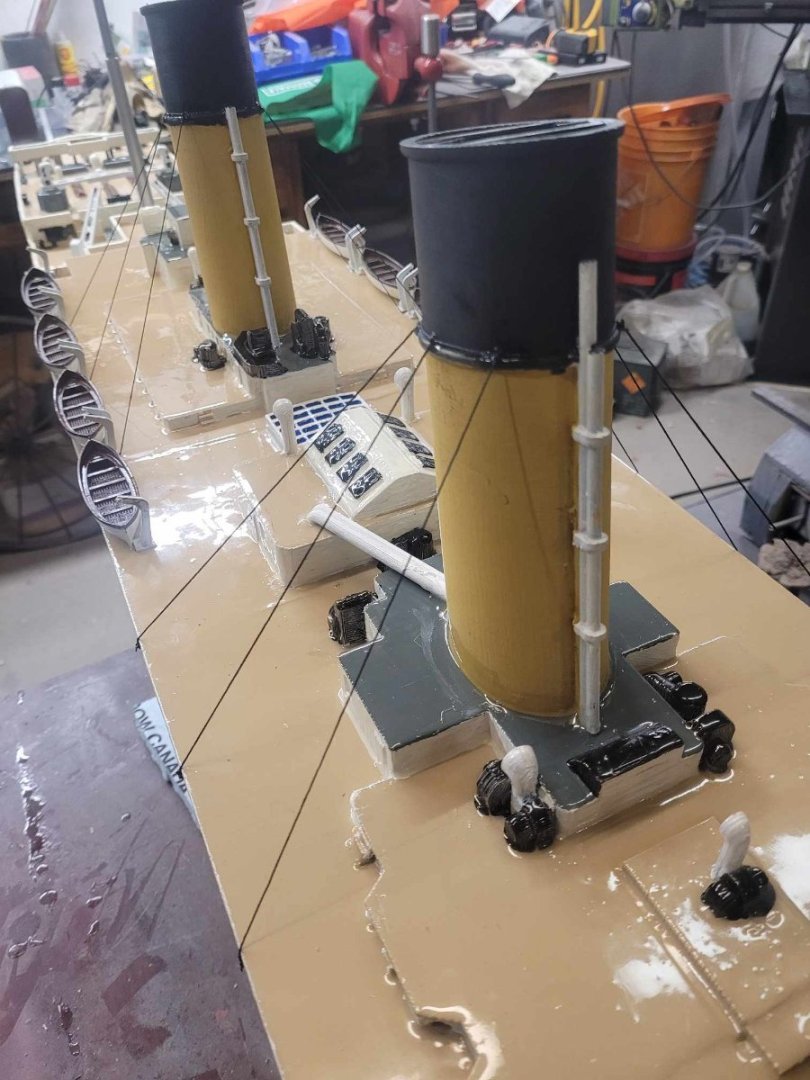

A couple hours of work tonight, and we have everything except the LED light system and the main mast rigging complete. I 3D printed the funnel caps and glued them on. This is hopefully the last layer of epoxy put on. Note - I filled the lifeboats with epoxy so that they wouldn't fill with water when she's in the pond. There were a few bubbles visible, so I took a trick I saw in a 'night shift' video and used a bit of flame to clear them away. Basically - she's ready for launch at this point. I need to get some outdoor photos on a nice day though I think. Here's tonight's work:

-

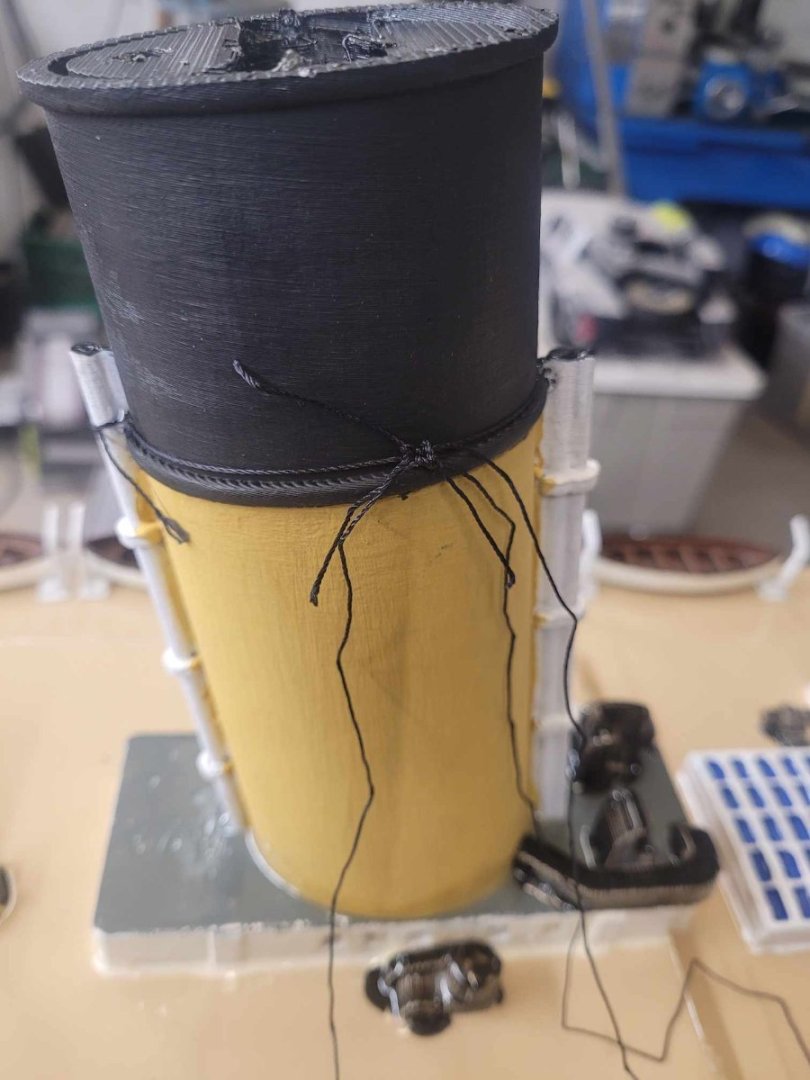

I spent tonight doing the 'minimalist' rigging that I planned to do. Put a string around the funnel band, tied lines to that, then glued the lines down to the deck. There will be a layer of epoxy added over all of this, so the lines will STAY PUT quite nicely. The 'to do' list is now getting quite short.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.