-

Posts

698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NavyShooter

-

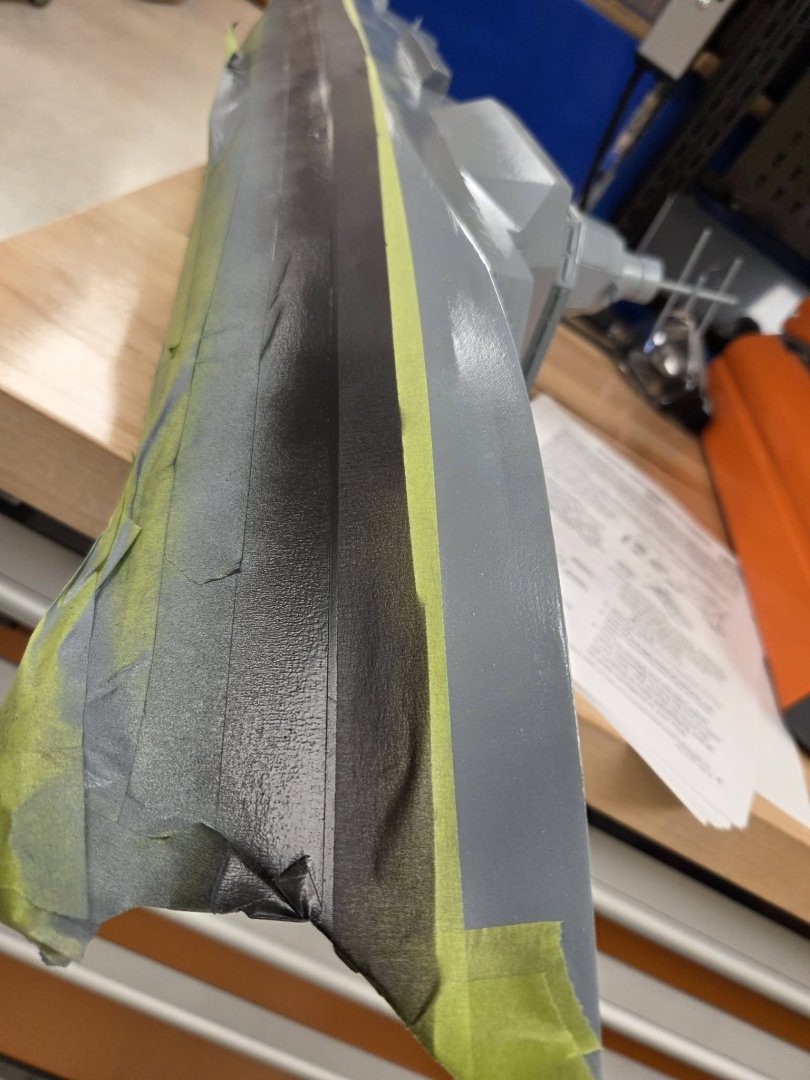

Hull #2 got a layer of blue today...then some minor putty addition, some sanding, and a final layer of blue to set over the weekend. Next week will see me getting the ship's side Gray done on the uppers, painting the 'non-skid' parts, then detailing. This one's probably going to be done by the end of next week. NS

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

Today she got another shot of putty which dried quickly and got sanded, finished the sanding with some 180 grit - good enough for this one. At end of today, she's gray primed, and almost ready for some blue on the hull. I need to print and add the prop shafts in the morning then I'll be able to paint.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

Well, hull #1 was presented to my unit's CO yesterday - she was quite pleased with the Fraser. Moving along with V2, she got a dose of putty, then some sanding yesterday morning.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

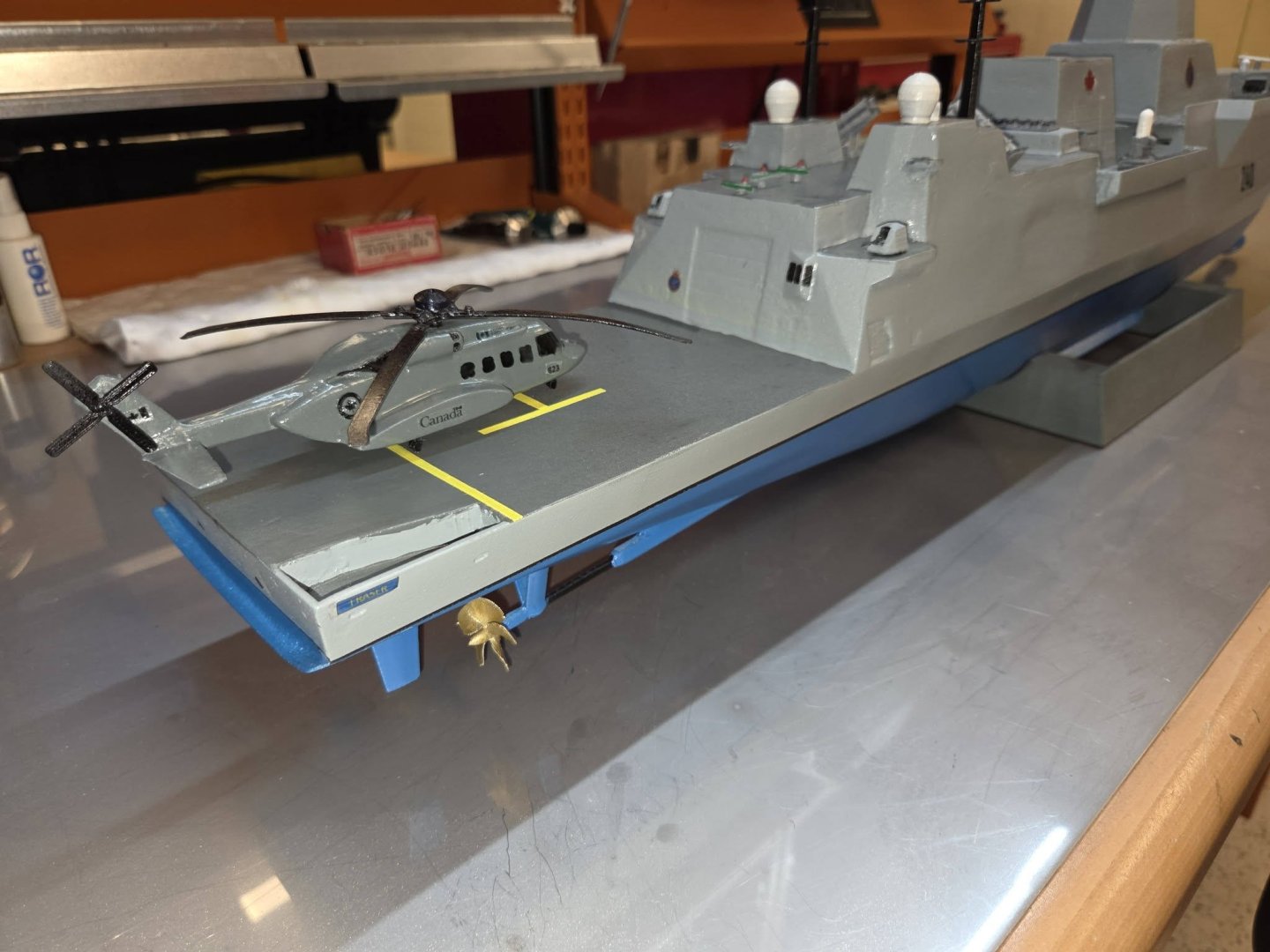

And here we are, HMCS Fraser DDH 240 is complete. Decals are applied and clear-coated. I'm generally pleased with how she looks - hull #2 will be better - second coat of putty was just applied. Hull #2 will also have a more accurate weapons loadout - I've made a model of both the SEA RAM launcher and the NSM, so CIWS and Harpoon will disappear on the next version.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

Alrighty, Calling V1 complete - it's headed for the CO's office first thing next week. She will hopefully appreciate it. My hope is also that other leadership around the base will see it and will go "HEY, I WANT ONE TOO" and my day job will get busier making these....I figure I can put out about 1/month of this quality. More detail will take longer. V2 got a layer of putty today and will dry over the weekend.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

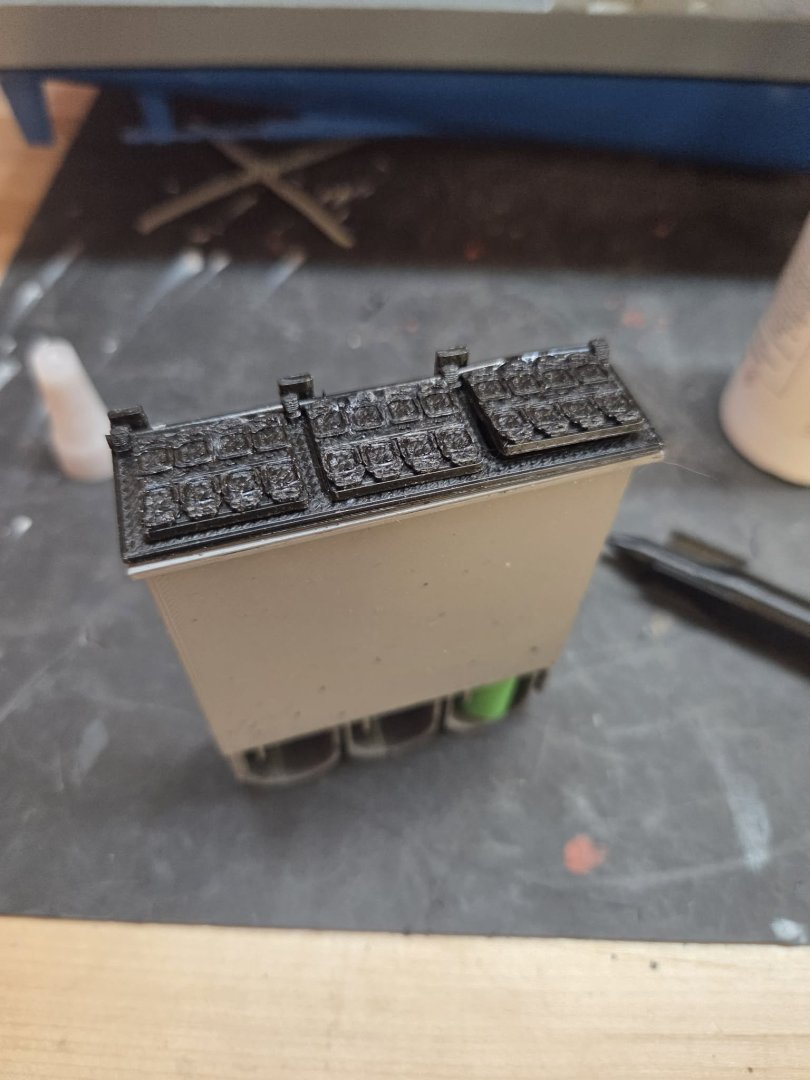

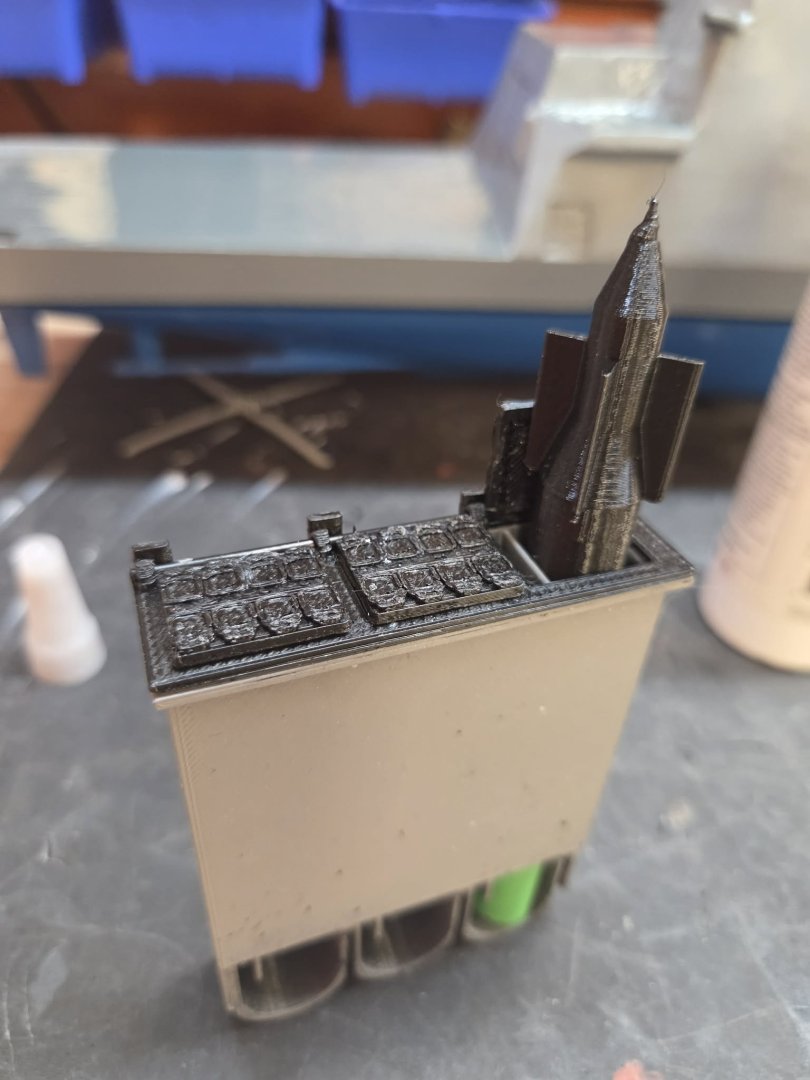

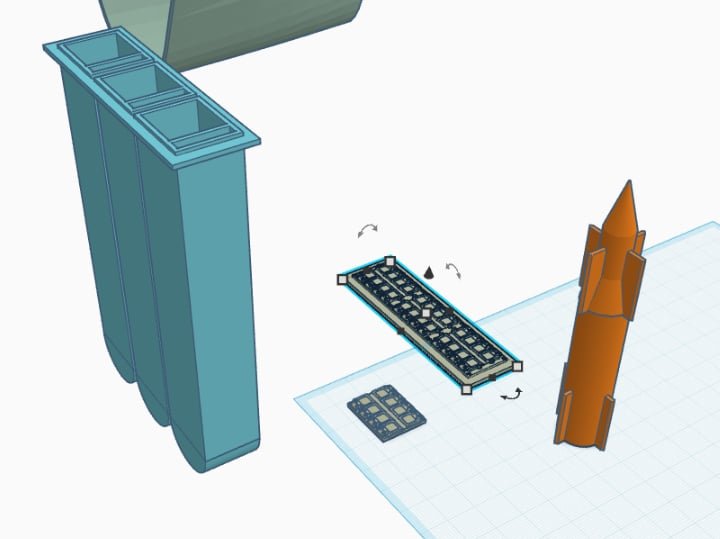

David, Visible in one of the images is the brass plate I glued in place in the bottom of the launch tube (J-tube) to see if it'll work for me as a heat deflector. Intent is to have the module effectively disposable after firing so that I won't have to worry about burn through. I'm going to be testing this a bunch before firing from the ship. Good news is that with 3D printing, I can do rapid prototyping and adjust files to match the reality of needing more strength/etc. I also have, through work, access to some 'fancy' filaments that will take more heat than just PLA or PETG, so that may end up a path I follow. NS

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

Yes Ian, that's the Bondo stuff - I have tried the acetone/brush method as well, but didn't apply it with this model. I might try that with the 2nd hull. The amount of putty needed meant that I thought I'd need a lot more than just brushing it on would provide. As for the missiles - working on test-firings. I found a model rocket calculator program online to run some pre-launch numbers for me: https://www.translatorscafe.com/unit...-max-altitude/ It lets you calculate based on known info and known engine performance stats, how well the rocket will perform. Based on what I plugged in, the rocket I've designed will fly a maximum of 6 meters up - if it actually stabilizes out of the tube (unlikely) so it'll go up a max of about 20 feet or so - which is actually acceptable to me. 🙂 Firing from the ship in the pond will be planned to happen beyond that 'theoretical' effective range. The rockets cost about $0.18 each to print - so I'm not worried about recovering them much. The igniters almost cost as much as the motors....

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

Welcome aboard!

-

So, the VLS plan is on hold for a couple of weeks until I get some new model rocket ignitors in hand that I ordered tonight. The Estes 2 wire ones are too finnicky to be consistent. I've found one that looks like it'll work better - I guess we'll see in about 2 weeks. NS

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

I understand that the 'newest version' may actually have RIM-114 missiles in the 21 packs instead of CIWS. The armament mix is still a bit in flux - I hear that the 5" gun is changing as well from Leonardo to the USN version due to AEGIS integration simplification issues. (Adding a non-US 5" gun would require an adapter in the middle between AEGIS and the gun interface - all of which would require testing/certification that Canada is trying to avoid. Getting the US 5" gun that's already certified with AEGIS is a low risk solution.)

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

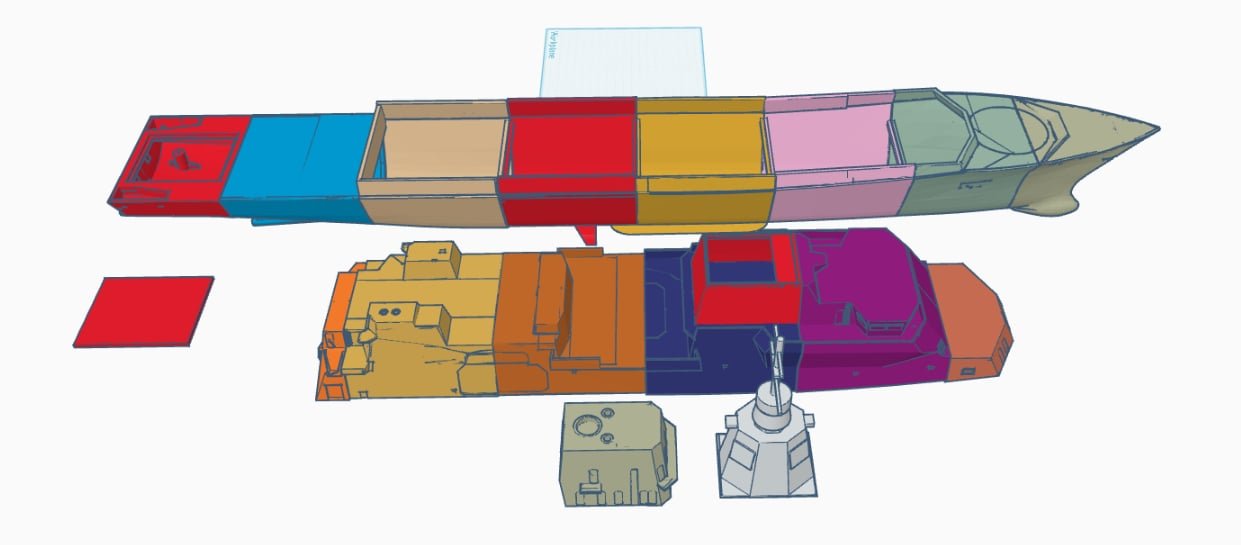

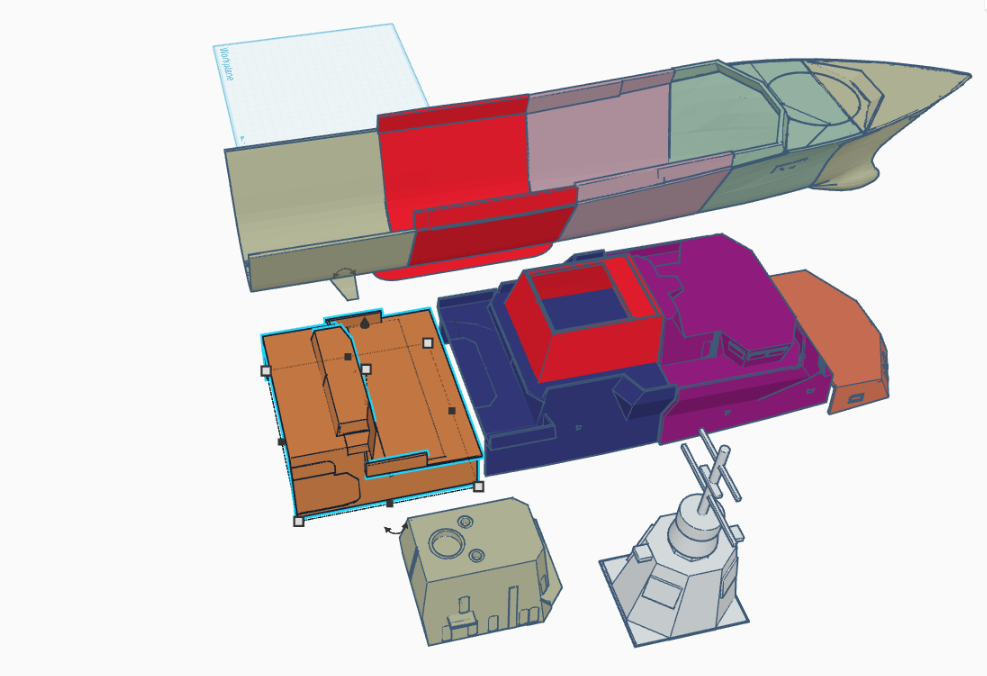

So, the first one of the builds is almost complete - I've got some of the detail bits added on as of this afternoon, and painted a nice "H" on the flight deck along with a rear limit line. It's not perfect, but hey, it's looking OK. I'm going to be presenting it to the CO of the unit next week once I get the last bits done. Speaking of last bits, I decided to do up a Naval Strike Missile launch tube set in CAD tonight and have shared it on makerworld as of a few minutes ago (still showing as 'pending' though) in case you feel the need to download and print a set of Kongsberg NSM's for any of your projects. Oh, and I spent a few minutes today gluing together the hull of RCD #2 - this one is now much thicker, and should be able to be sanded before I add the many layers of putty to pretty things up. Pictures below... How many River Class am I going to end up making? Probably at least 4. I've got the one headed to the CO, I'm going to do the black one up for display at my office, then I'm working towards an R/C one, and hey, why not do one more up to sail in the Public Gardens too? We'll see....

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

Of note, this build thread is now going to actually encompass 3 hulls - maybe more. Hull 1 is the one already pictured....she got a second coat on the decks today, and tomorrow will get details glued on...and some touch-up paint added to bridge windows and such. Hull 2 is the improved static file set that I've just finished printing and will start assembly of tomorrow. I'm going to try some spray on putty stuff that someone suggested (seems like stucco - I'll see if it works.) Hull 3 will be the R/C version that will incorporate the VLS - hope you're all patient enough to wait for that one. I've not yet finished that file set. Good news though - once the files for the RC Version are done, and I've posted a completed picture/video of the build to credit the original designer, he has agreed that I can share the files with people here that might wish to make their own Type 26.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

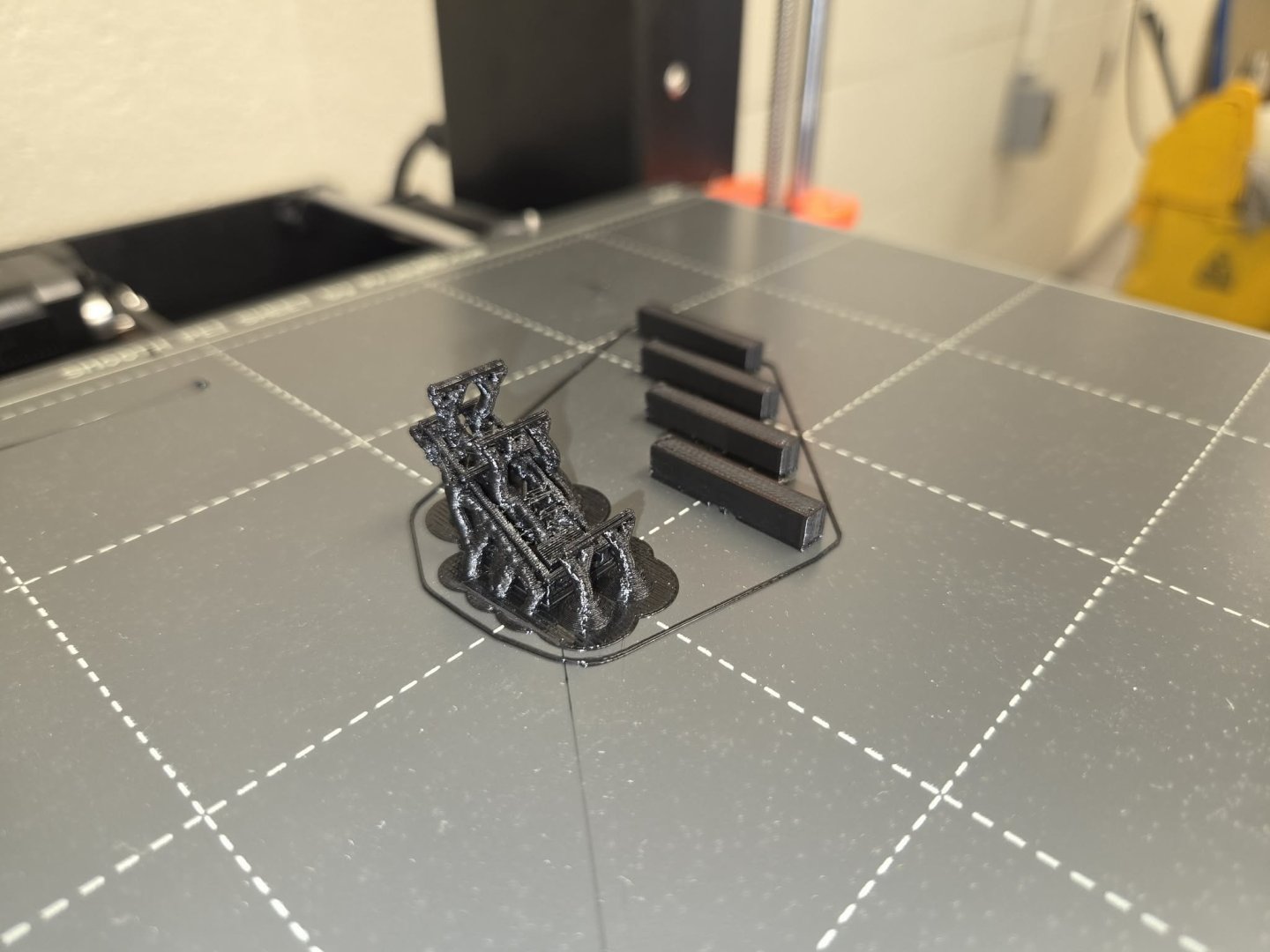

OK, the really really good thing about 3D printing is that it's very quick to shift from 1 version to the next in the prototyping stage. V3 got glued up today with brass inserts in the bottom of the J-Tubes, and I tested the 'doors' (flaps really) Here's some pictures. Each 8 cell 'pack' of the MK41 is a single tube in this scale. Version 4 is now heading to the printer once we get power back after the ice storm tonight - I needed a bit more space for the wiring channels and there were a couple of fit issues I had to solve. I'm trying to keep it simple so I can use them as effectively disposable launch tubes, but if I can re-use, I will try.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

And...a few more hours of CAD work down the trace, and here's the 95% solution that I'm going to try printing I think. And...if I'm going to have a Type 26 that's got a VLS system, I'd best have a functional VLS to go with it.... Sizing it to take 3 cells with a 14.5mm rocket body to accept a 1/2A Estes 13mm rocket. We'll see if/how this works out.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

I've decided to try and make a version with a removable upper deck/superstructure and access through the flight deck to the rudders/steering system. That will make it suitable for RC - I'll see how this turns out. It'll still need a bunch of sanding and smoothing, but perhaps it'll run.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

Looking great! Can you share more details on the spray putty please? I suspect this is something I need in my life! 🙂

-

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

-

It's a pretty good feeling to peel back the tape and see a mostly crisp line. There is a bit of touch-up to do, but that's looking alright.

- 61 replies

-

- Type 26

- City Class

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.