Joseph Schmidt

-

Posts

9 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Joseph Schmidt

-

-

On 2/24/2023 at 3:01 AM, cog said:

Question: I made a wooden gearshift knob, lacquered it with a car clear aerosol gloss lacquer - multiple layers - but it is getting whitish now - most likely humidity - what can I do about that? Should I use a two component paint, or can it be the wood?

As a wood furniture maker, I've sprayed many hundreds of gallons of Nitrocellulose Lacquer. Sometimes, seemingly for no reason, that whitishness appears. It is frequently moisture related, as lacquer dries very quickly and gets cold in the process, drawing moisture from the air. A quick fix, that nearly always works, is to spray pure lacquer thinner on the project, just enough to wet the surface, allowing the trapped moisture to escape. Sometimes that needs to be done more than once. It has saved many thousand dollar custom executive office furniture pieces for me.. Worth a try.

- druxey, Keith Black, Knocklouder and 4 others

-

7

7

-

I've been using MOLOTOW brand liquid paint markers with a 2mm tip. #703.102 is the liquid chrome.

- mtaylor, Canute, Roger Pellett and 1 other

-

4

4

-

My lightning sailboat I did with wire rope standing rigging. These boats changed over from natural fiber rigging to wire rope standing rigging and synthetic running rigging about the same time as fiberglass hulls were coming in.

The wire was from artwox, 7 strand stainless steel and was finely twisted. I used a single strand from clippings to wrap or serve the end into a simulated eye splice. The mini turnbuckles were also purchased and are functional making it easy to adjust the tension on the shrouds and stays.

- Keith Black, Roger Pellett, bridgman and 1 other

-

4

4

-

- BETAQDAVE, Oldsalt1950, hollowneck and 2 others

-

5

5

-

- hollowneck, mtaylor, Canute and 2 others

-

5

5

-

Heres my block holder. A fly tying vise.

EJ

-

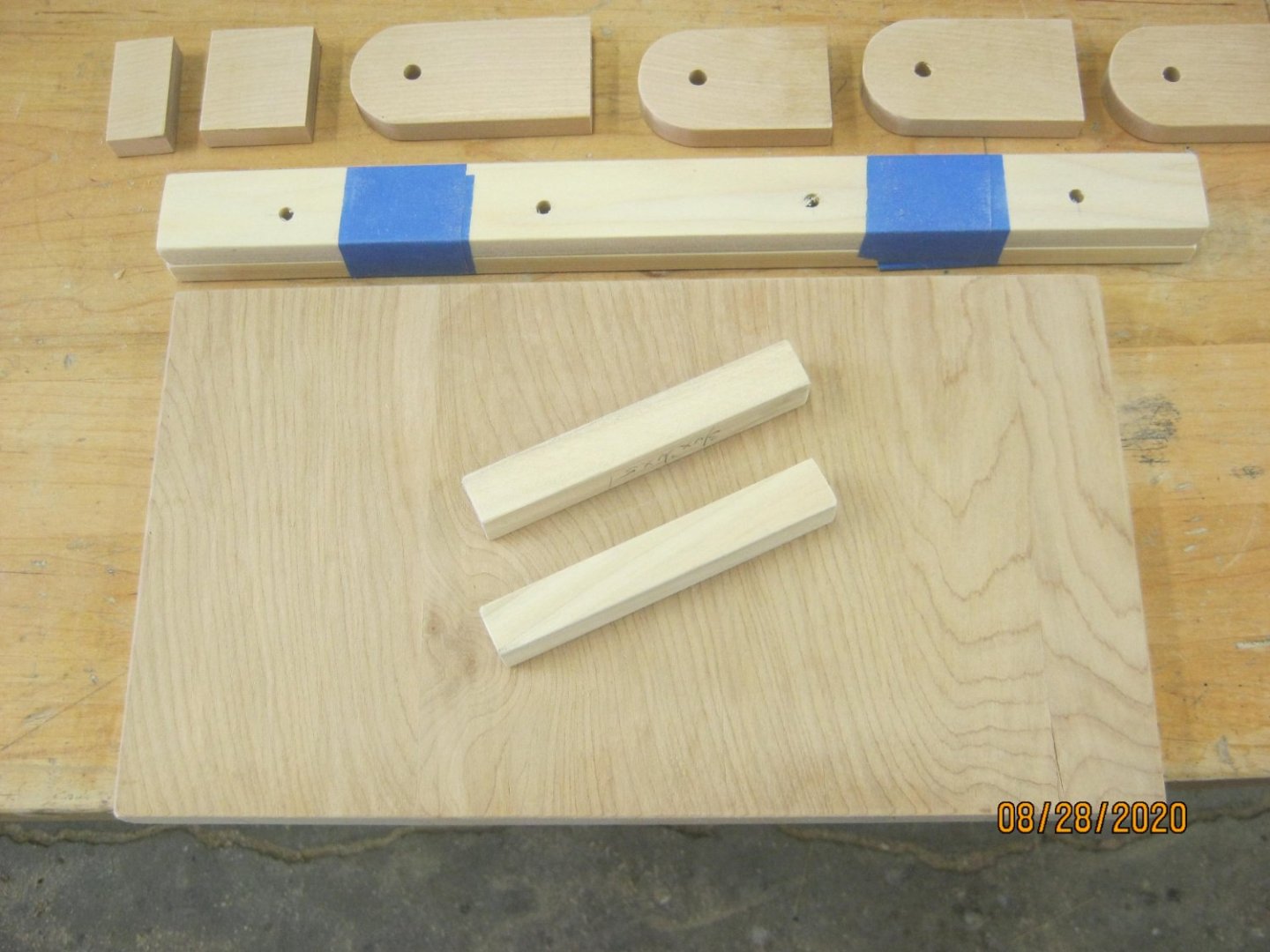

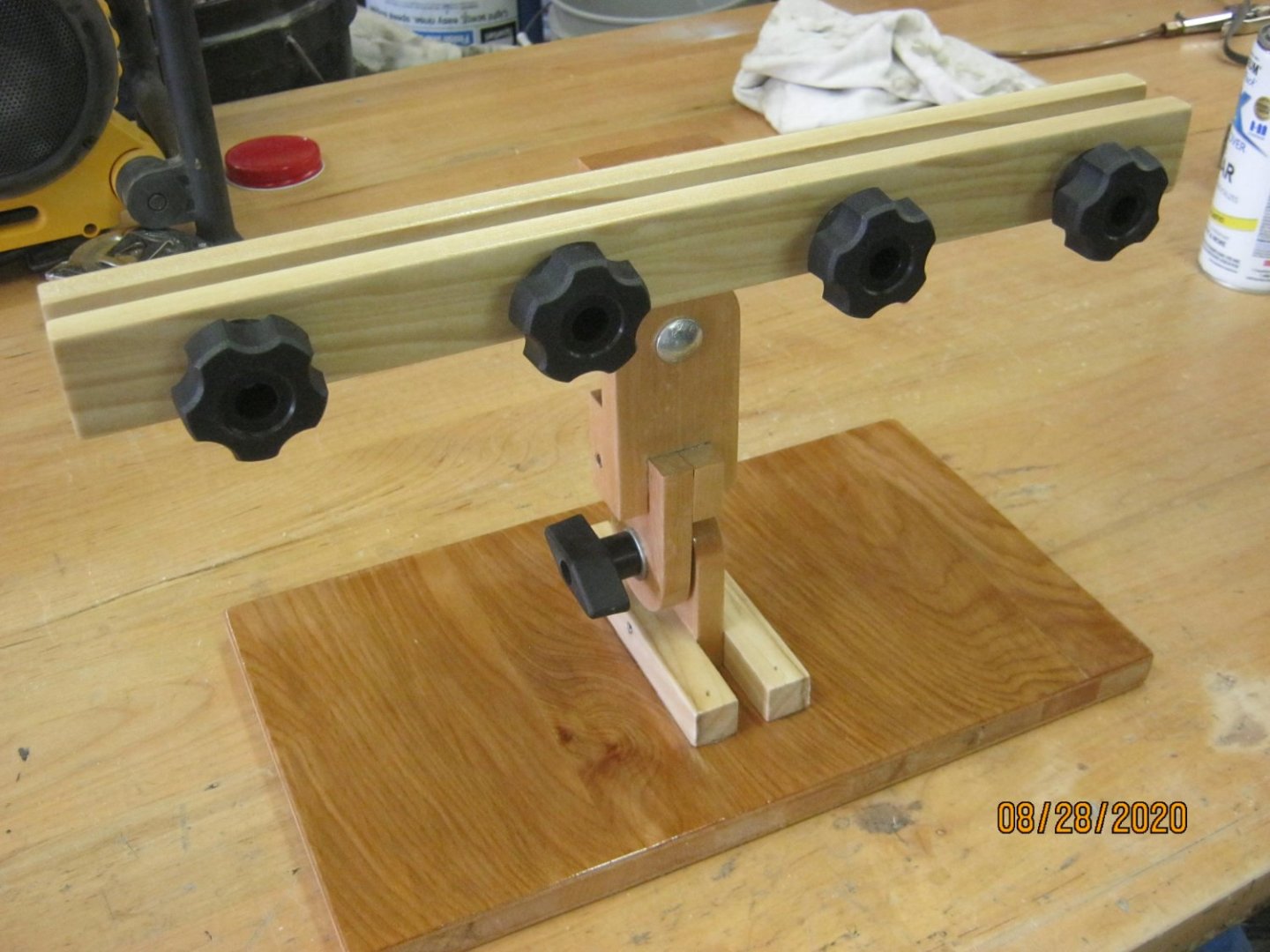

Looks similar to the one I built to fit on my full size wood lathe. Made of junk laying around in the shop except for the drum which I bought. I regularly can make strips as thin as 1/64" on this.

Using the rigid platform of the wood lathe, as well as the 1.5 hp motor to drive it, it works very well. For me the dust is not an issue as this kind of work is done in my wood shop.

EJ

- reklein, Canute, Roger Pellett and 3 others

-

6

6

Mast Cutting

in Masting, rigging and sails

Posted

NEEDS to turn maybe not. Did they? This from a company I worked for that made this lathe.