-

Posts

2,333 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

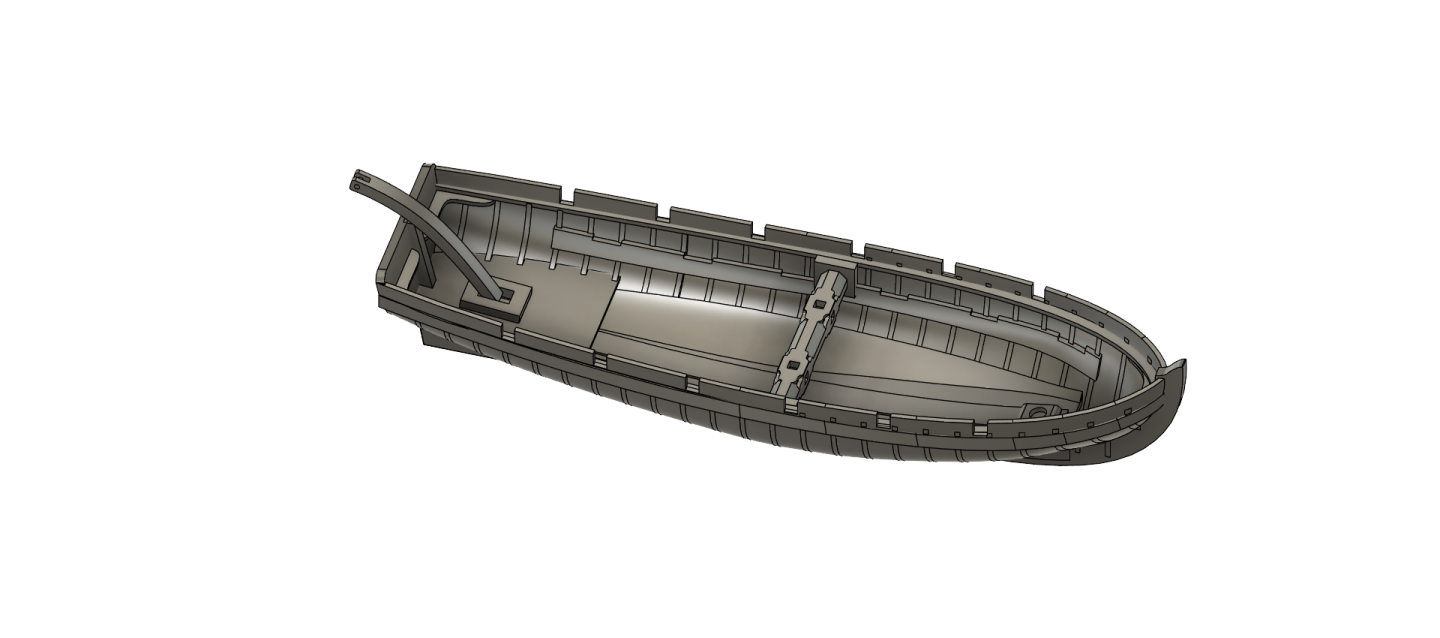

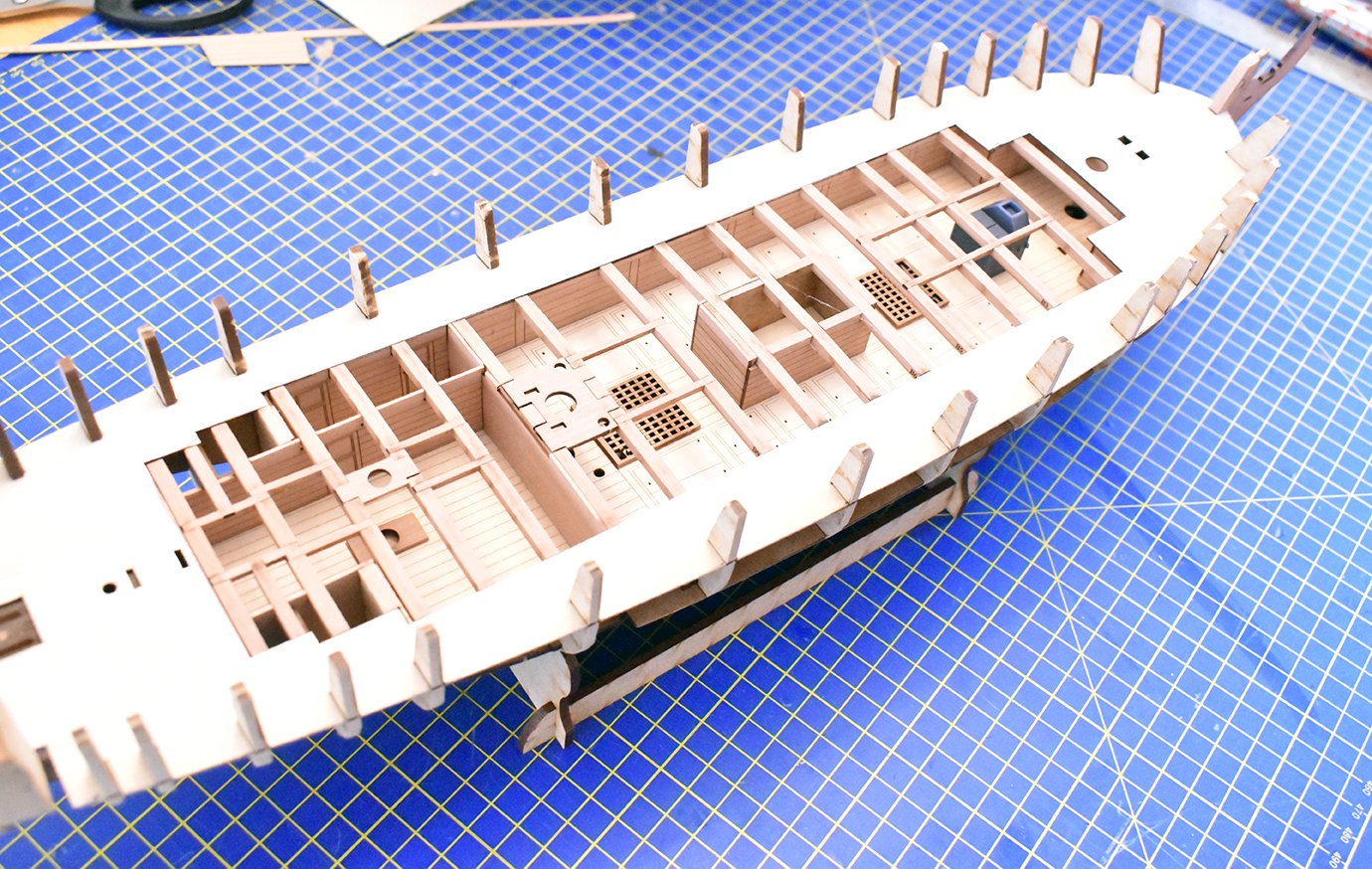

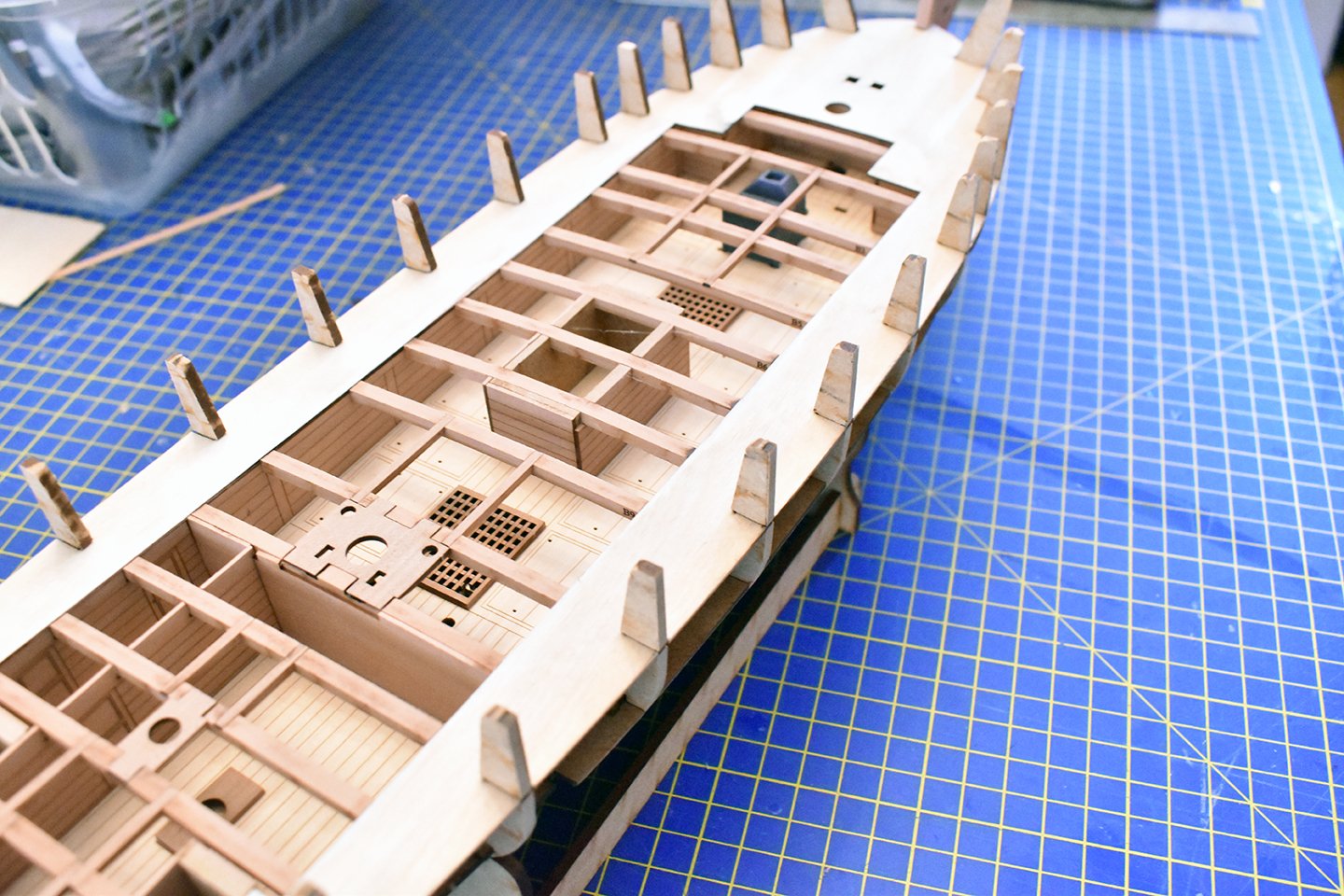

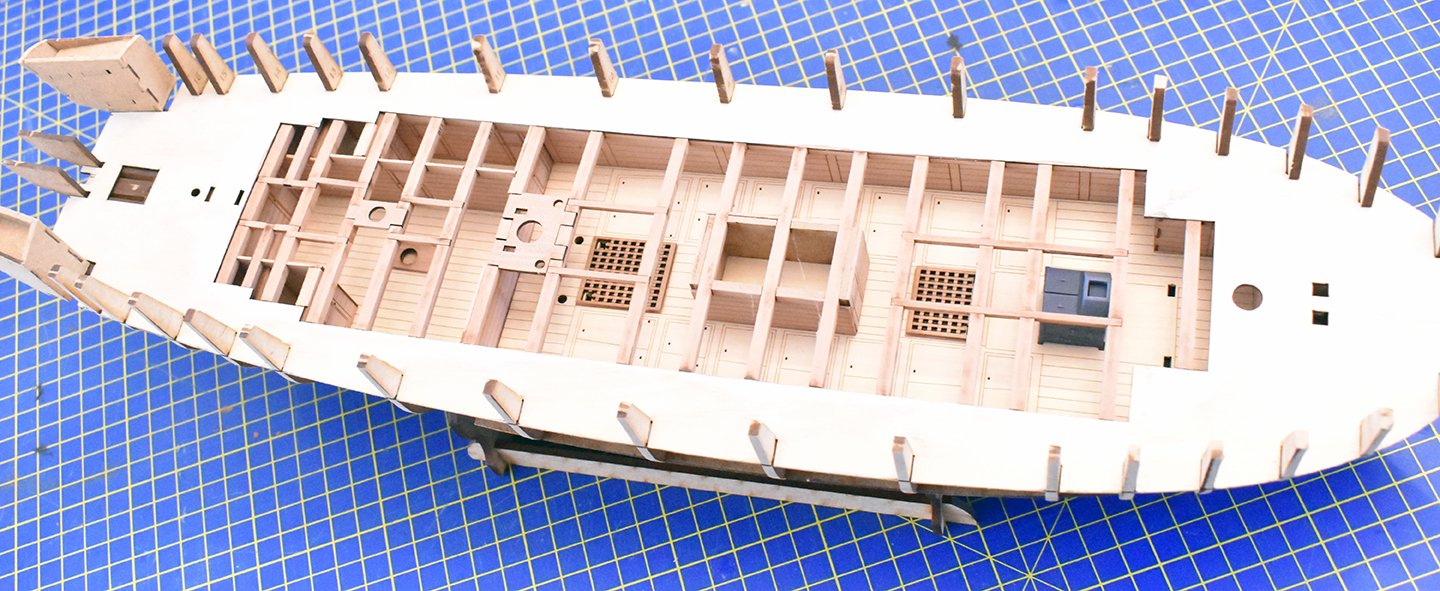

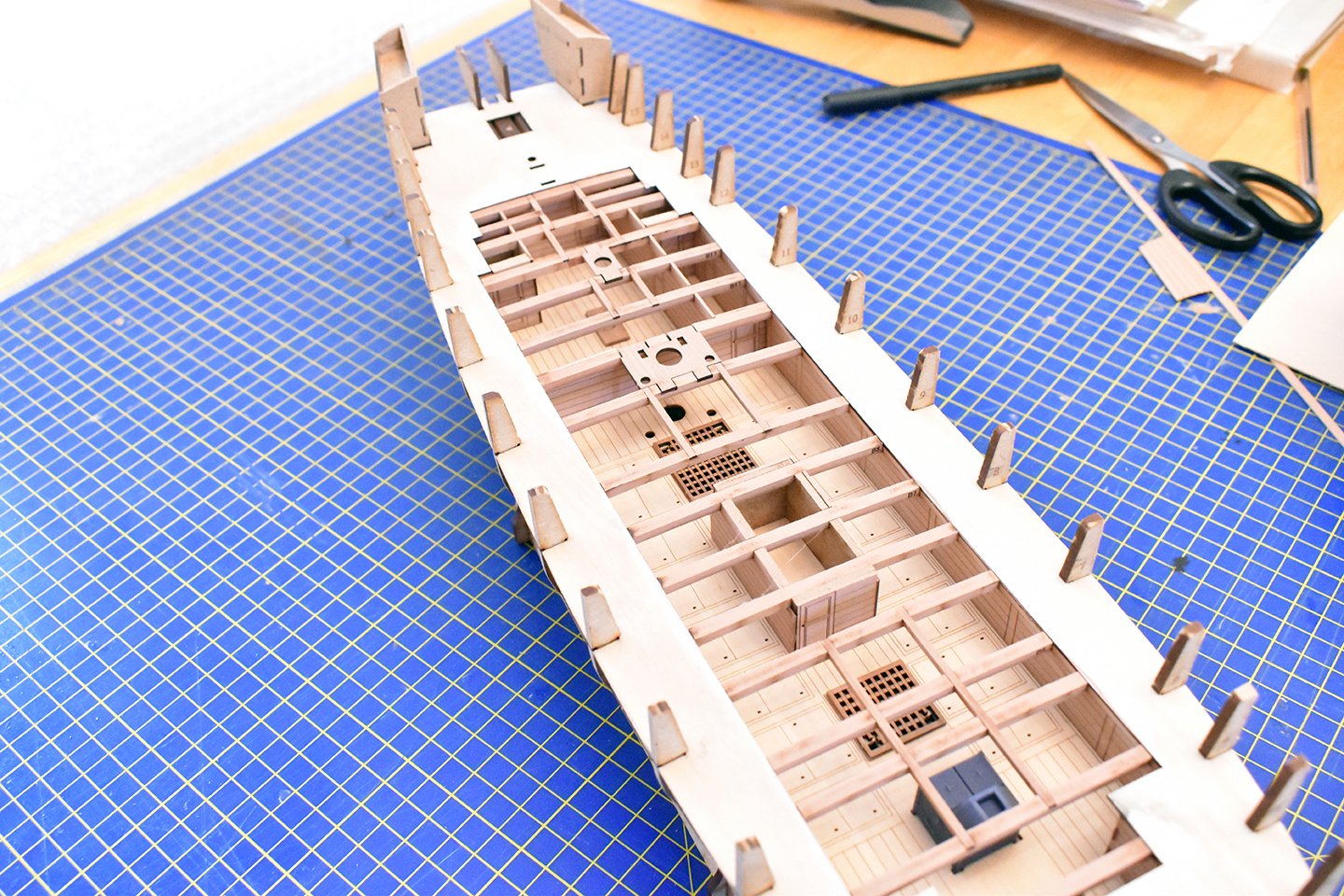

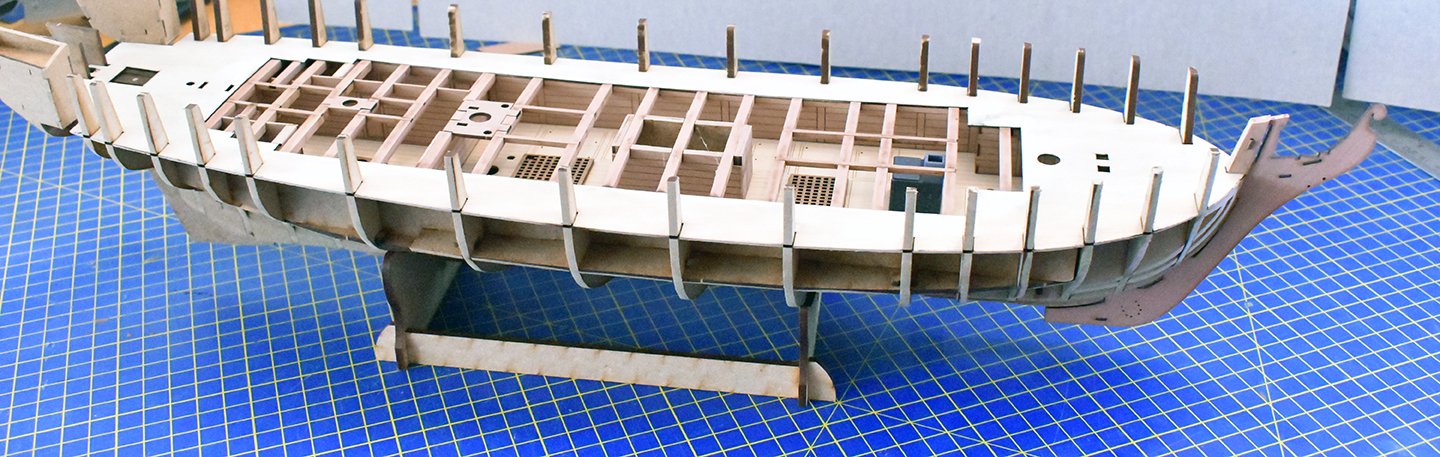

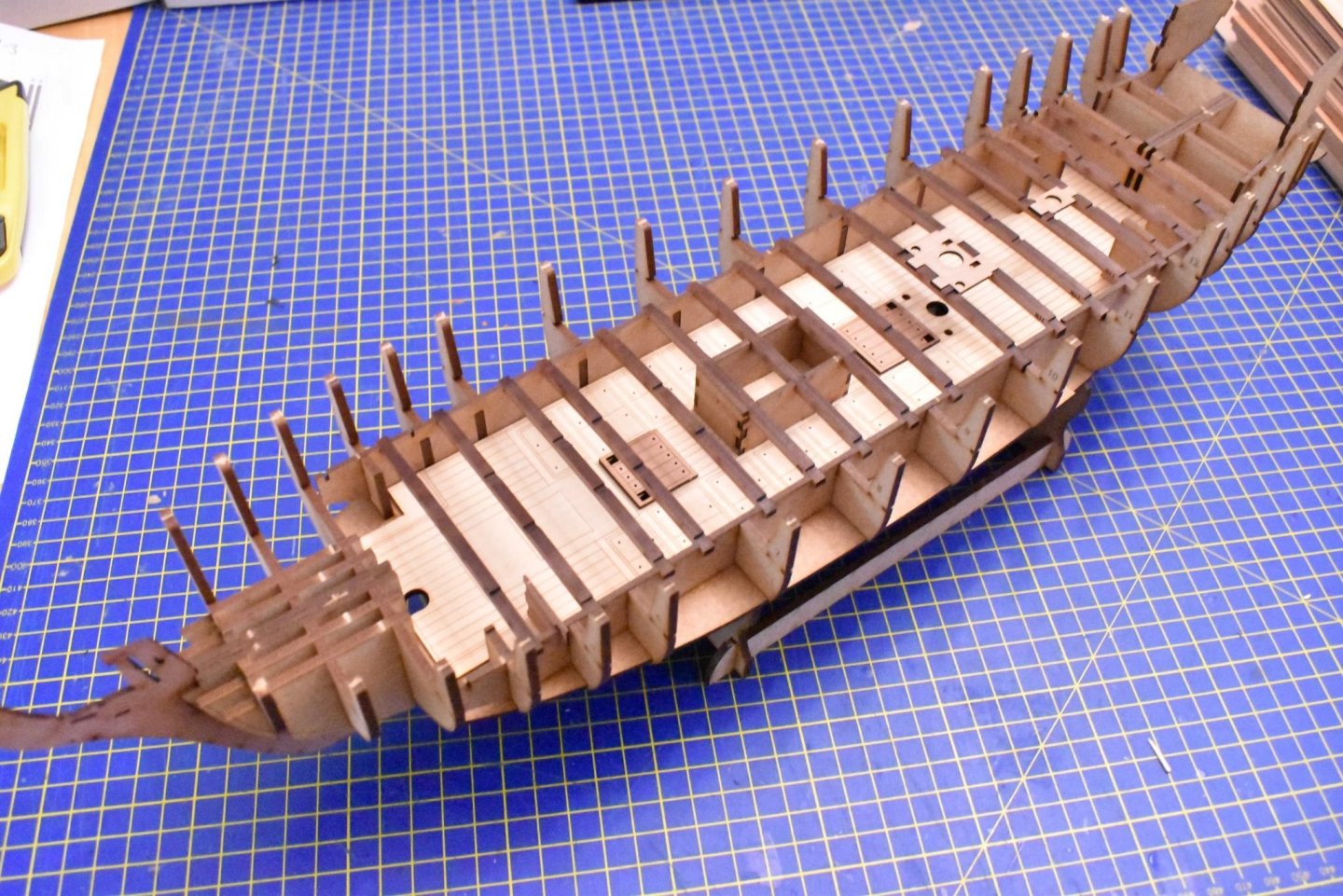

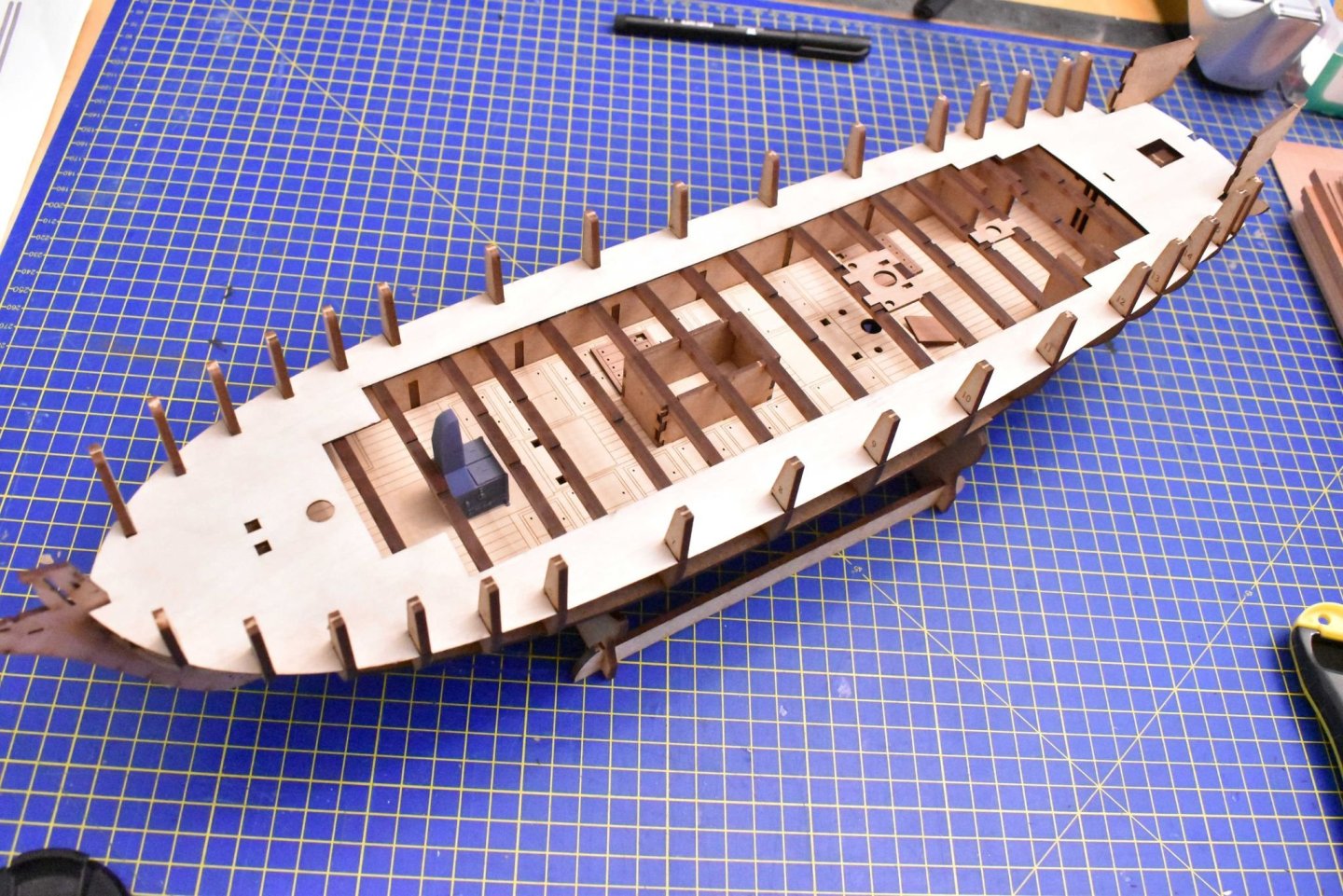

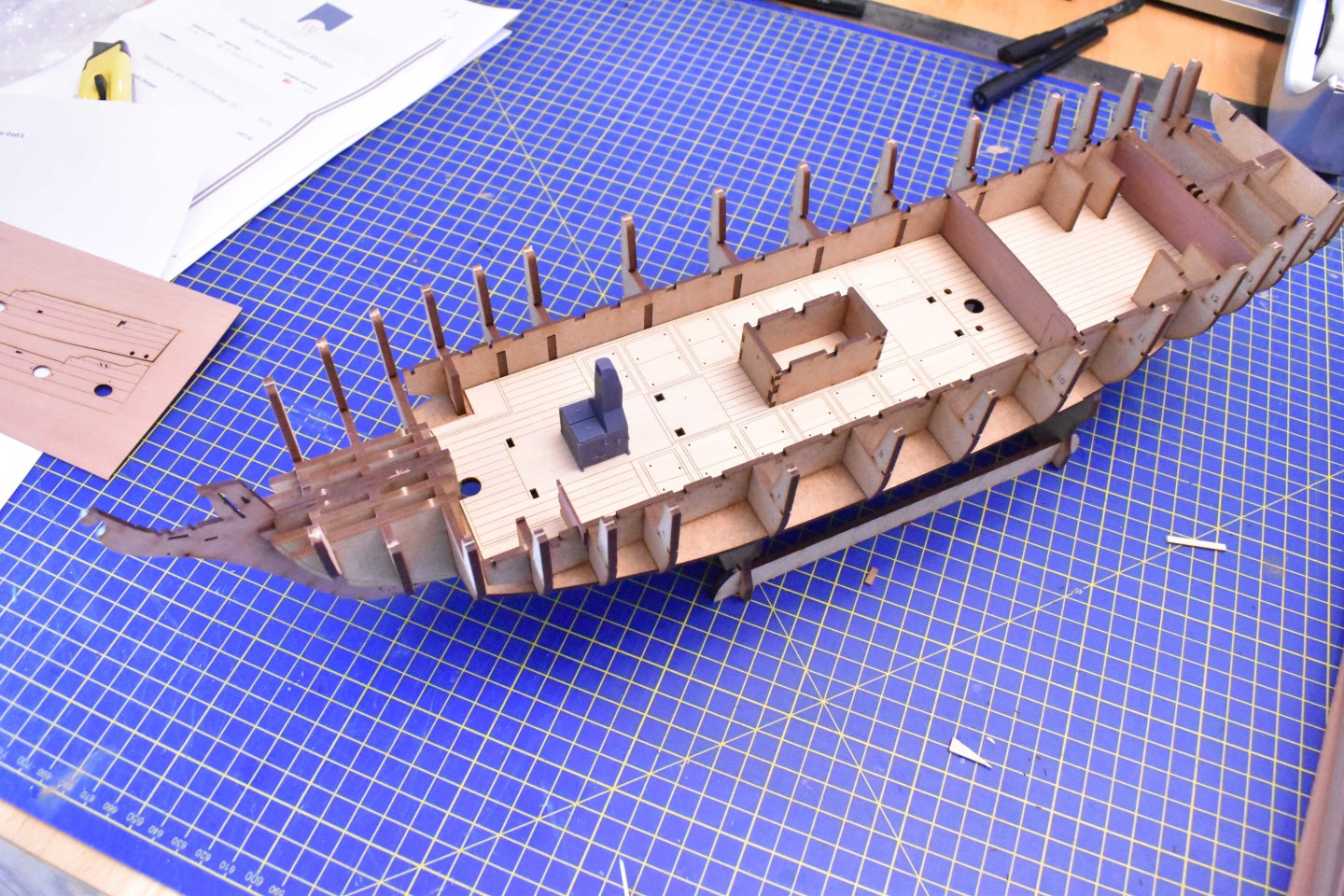

Many innocent sheets of material died to bring you these pictures... This is the fifth hull I have made up, with incremental changes with each new version. I usually just remove and replace the parts I change, but there are many interlocking parts with this one, that I felt more comfortable restarting the whole hull assembly with all updated designs, so that I know all fits as they should. This will not be the final form, however, but am comfortable continuing using the hull form (which is final) to get more information for parts that fit onto it. Hull has been sanded, ready to take gunport bulwark template (which are next to design) (This will be thrown away once all info has been garnered from it...)

-

We are talking 33 years ago! Le Superb was my 3rd ever wood ship kit (Billings Will Everard being the first, followed by Billings Bounty and then Le Superb). I remember building it just fine using the manual, in an age before the internet. I learned from building the Bounty that using other sources for rigging was a given, and I did that with every kit I built (wasn't many, though, after Le Superb it was Sovereign of the Seas and after that, started in the industry)

-

I stand 100% at what I commented on, for the time, the manual was very good. I was really talking about the construction aspect, and the well laid out construction stages. Note I commented on the 'Manual' and NOT 'plans'. At that time, the general quality of both the kit and manual were much better than most. For any modeller worth their salt, rigging plans from this era of kits should be treated with utmost caution. At this time (very early 1990's), it was a given (at least to me) to do your own research for the details, and masts and rig especially - this was half the fun of modelling.

-

16 x 32-Pounder carronades and 2 x 6-Pounder long guns - typical armament for all the 18-gun brigs of this period (1796-1815). Harpy was built for such – and don’t forget, carronades are much lighter than long guns. ETA - Although the larger Dasher and Bermuda Class of flush decked ship sloops, which had a main deck length of 107 foot, 12 foot longer than Harpy, only had (officially) 16 x 24-Pounder carronades..

-

Cruiser Class was only 5 feet longer along the main deck, and 2 foot broader - both classes carried the exact same armament, but Harpy definitely had the more elegant lines. In 64th scale, hardly noticeable, size wise, but I am sure the nicer rake of Harpy will be. The old kits I did were really just keel, bulkheads, main deck, and lots of planking. The new kits have many times more pre cut parts, with planking usually relegated to the lower edges of the main wale down (for the small to medium size kits at least)

-

Always breaking fine drill bitts, they always break at the most inopportune time, too.

- 125 replies

-

- Trial

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I think I have another 2-3 months on designs and building hull to check everything, maybe longer. Those pics are literally the very first cut of the very first designs, and much needs amending. The end result will be a kit of an 18-gun brig with great history in real life, and with partial lower deck detail, including stove, scale spaced deck beams (all pre-cut in pear, and with the correct curves/camber, as usual) - and always trying to make it as painless to assemble as I can, but keeping the detail. I remember doing Snake/Cruiser 25 years ago, that was the last time I did an 18-gun brig. To me, the Diligence Class has more pleasing aesthetics, with a sleeker hull and rake - like a much larger Speedy, but with a much bigger bite* - you can see the natural progression from the Childers and Speedy Class to the Dilligence Class almost 2 decades later, followed by the 'less curvy' Cruiser Class. *Childers/Flirt/Speedy had a single broadside weight of 28 pounds, whereas the later 18 gun brigs like Harpy had a single broadside weight of 262 pounds

-

A little update. I am now out of machined pear block sets for the kits. I cannot buy any more because I sourced these from Russia, which, as mentioned before, a sanctioned country. However, I have been in contact with HiSModel, and have ordered 20 Indy kits worth of machined walnut blocks - although these are costing me a little more than the pear machined blocks I had before, but I figured better to have the option than none at all. I will order sets for the rest of my kits that had this option in due course. (Next will be Sphinx and Duchess)

-

If it were me, I would add only the breech rope.

- 125 replies

-

- Trial

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.