-

Posts

2,331 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

I have tried to made the basic hull assembly as painless as possible. I remember a thread where someone was building a Speedy, and got frustrated because some parts didn't fit as they should. and what happened was the aft deck supports were not pushed all the way home, and then glued that way. This meant a whole new laser cut set for the hull. I now try to design these things to avoid such incidents, hence all the retaining tabs to help lock/secure parts into place. I think I already mentioned this on my thread, but the upper deck planking lines are a rework from original plans for a Cruiser Class, which shows the actual deck planking lines. Not the same class, I know, but designs are only a year apart, and with a little adjustment to the lines (Cruiser Class a little wider at the bow), the planking lines are more or less the same from the contemporary plan.

- 76 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

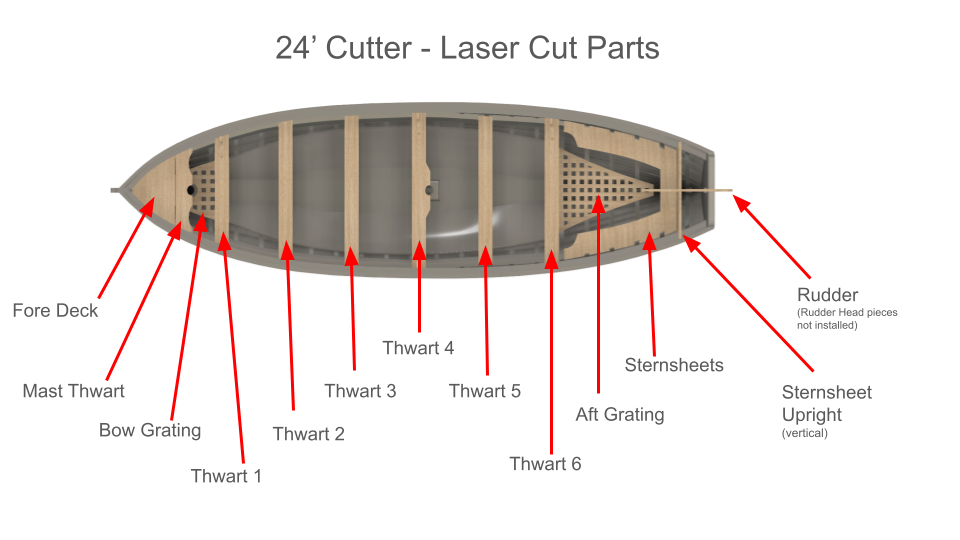

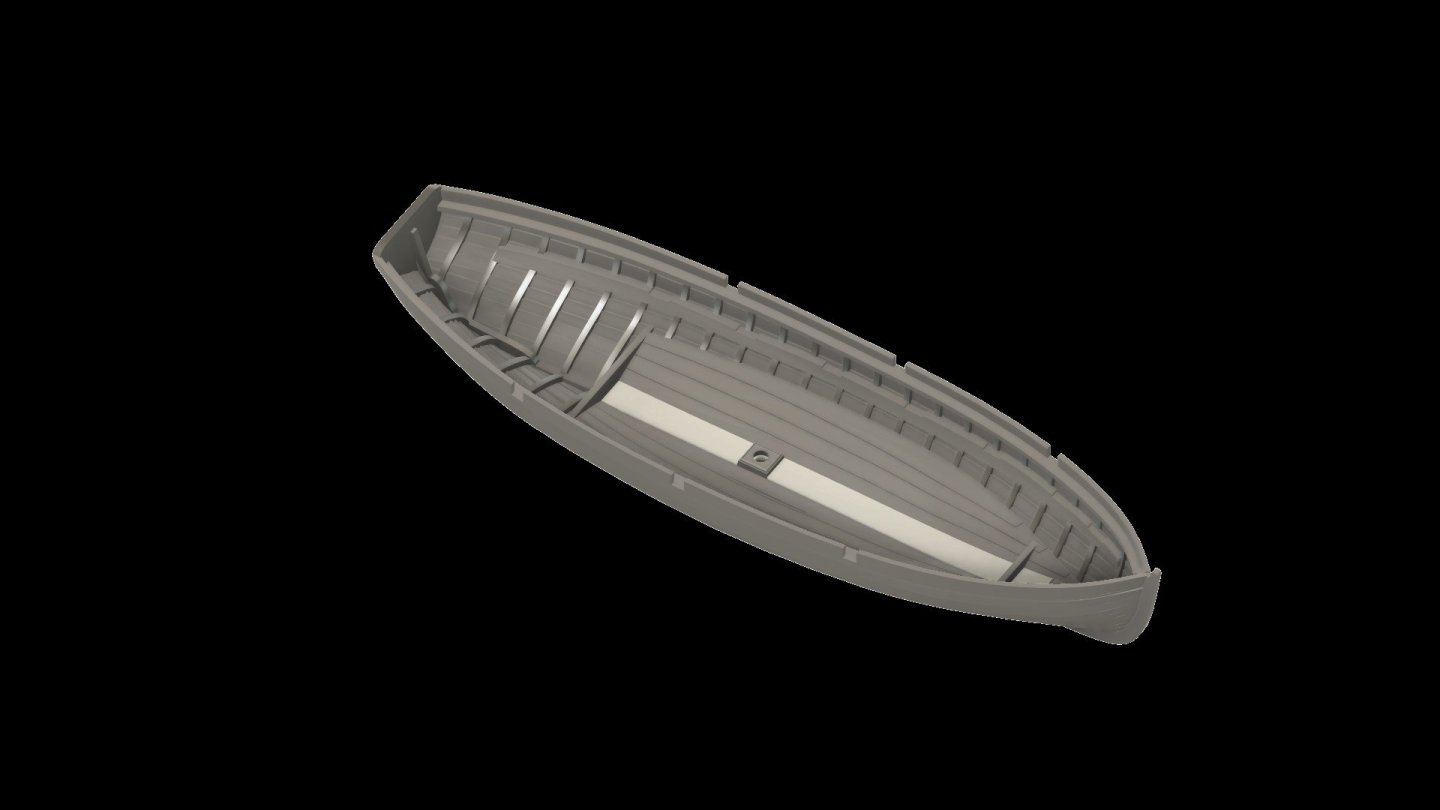

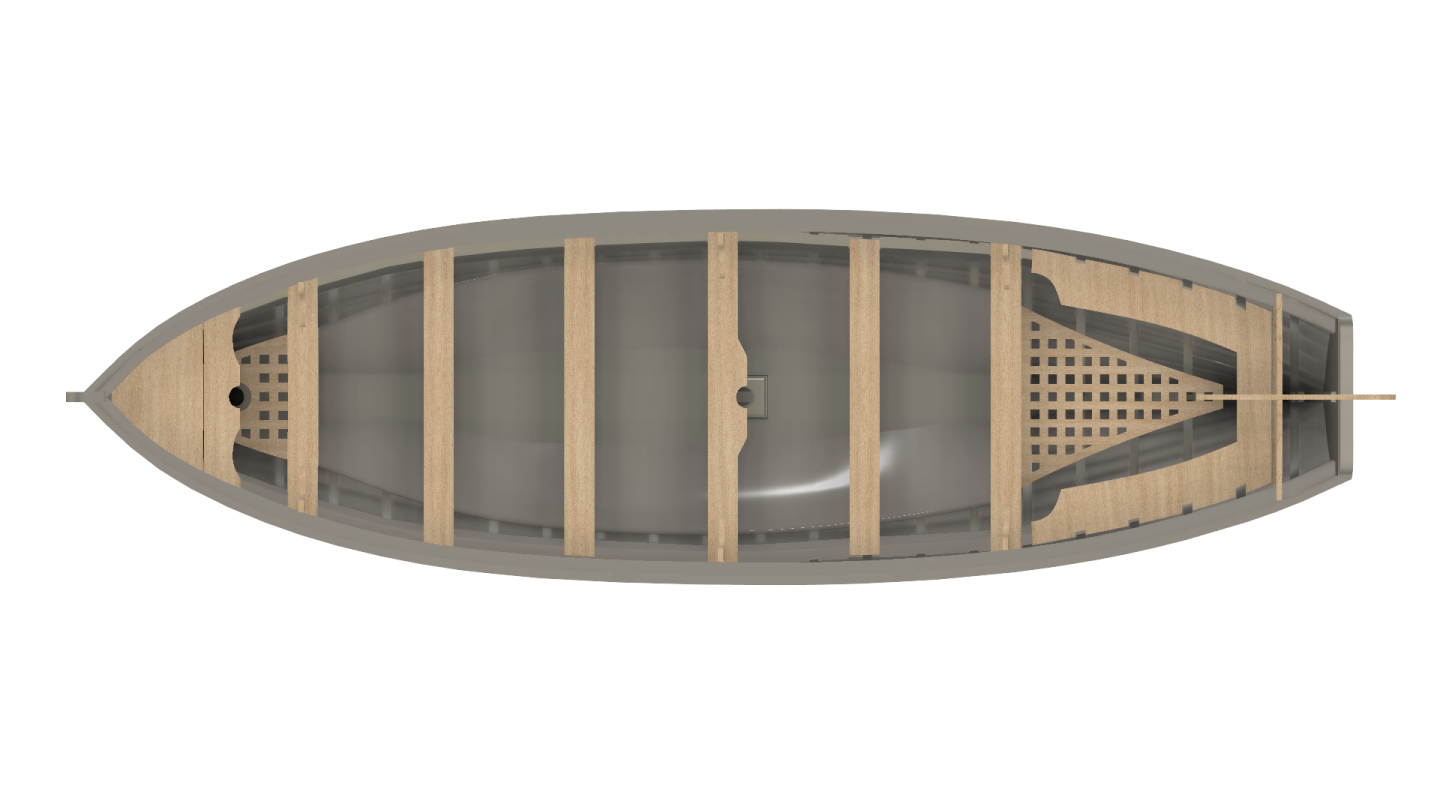

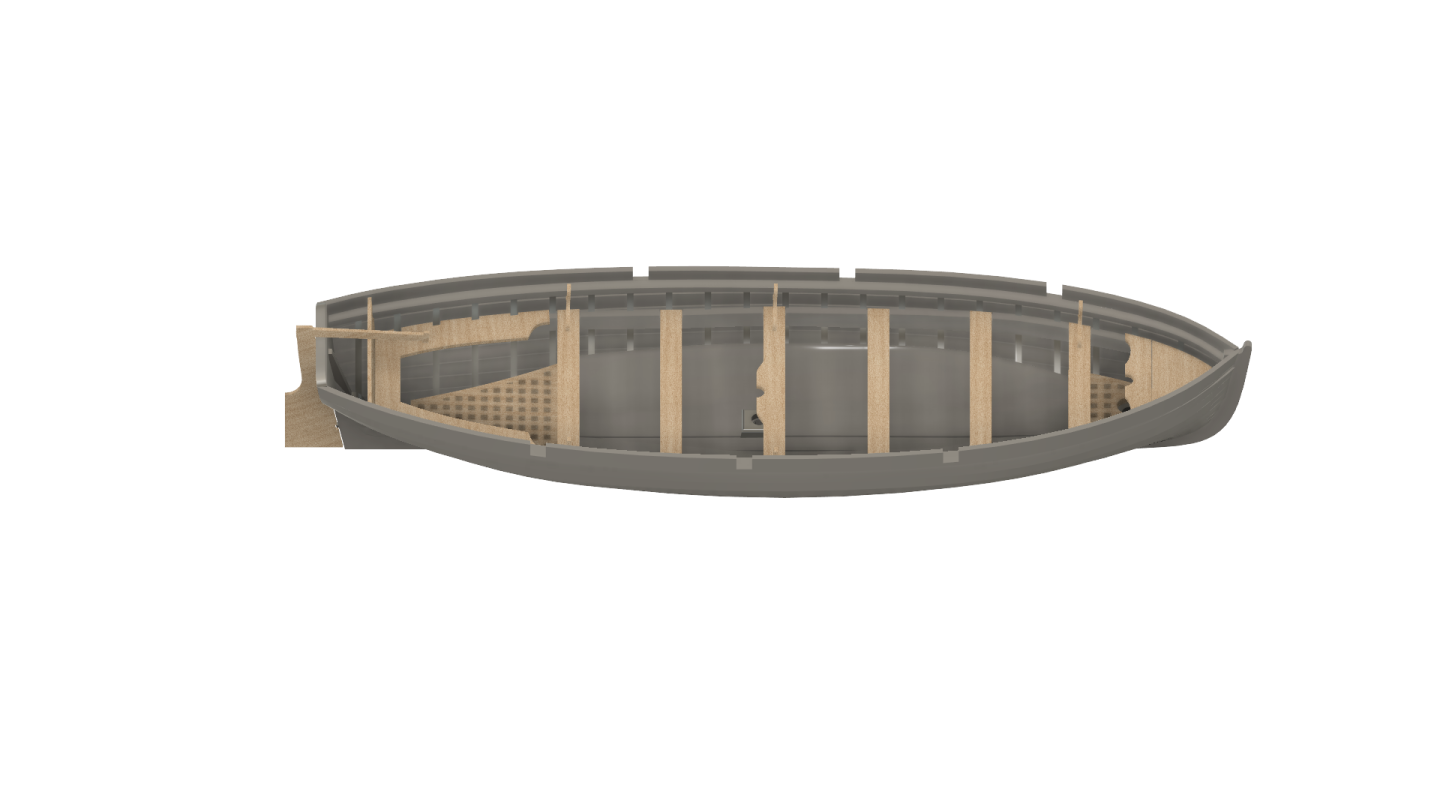

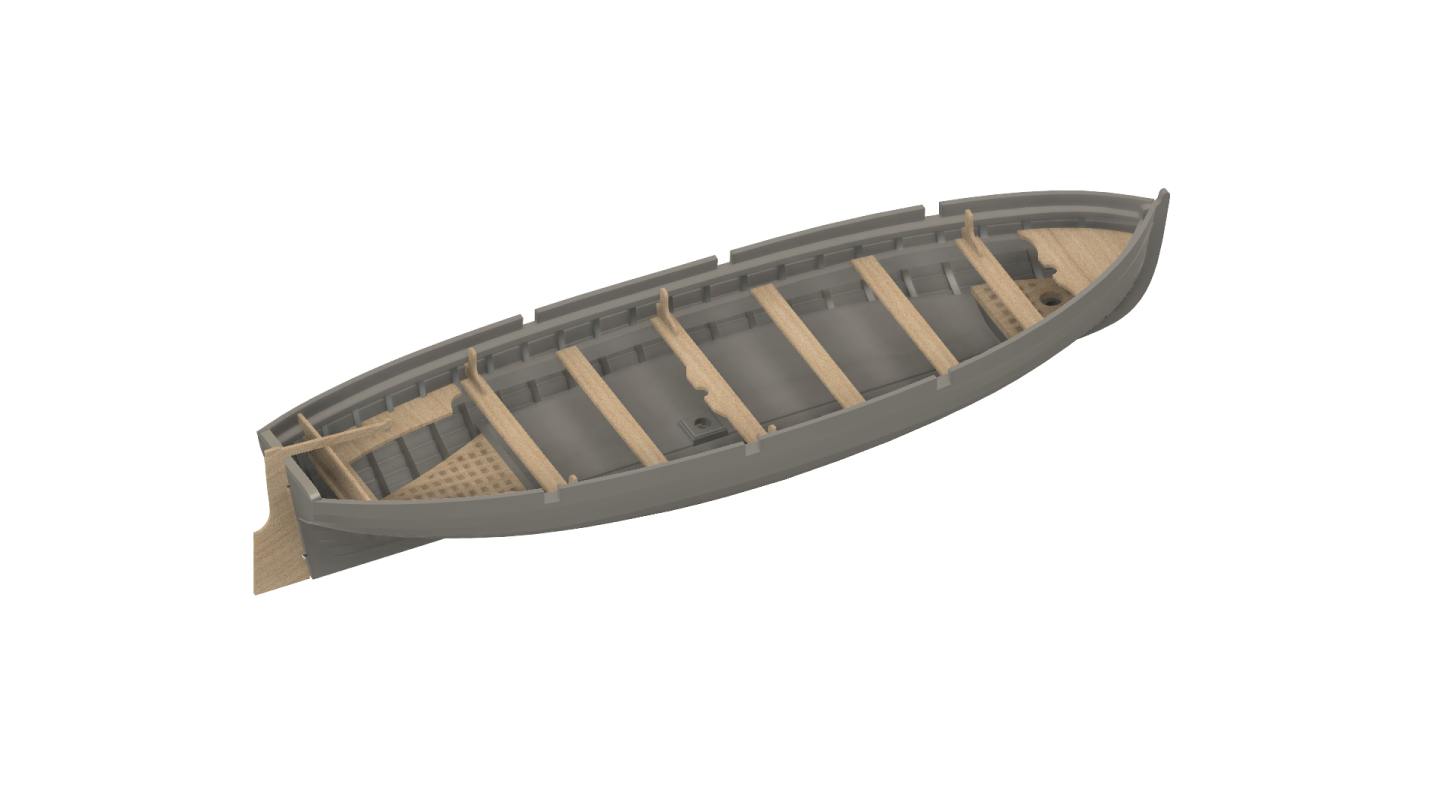

OK, over this weekend, I shall have three scales for the new 3-d printed 24 foot cutter in stock. 1:72nd, 1:64th (of course..) and 1:48th. Each will come with a fully detailed 3-d printed hull with nice clinker planking and a sheet of 0.8mm pear for the laser cut fore and aft floor, seats, knees and oars. 24′ Cutter (full kit – various scales) – VANGUARD MODELS This is not an enlarged file of the 18 foot cutter, but completely new and based off original plans.

-

When nicely planked, I see no reason why the modeller should not just leave the lower hull uncoppered or unpainted.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

I have been asked about 72nd scale versions of the 3-d printed boats. These are now done (well, almost, 18' cutter has about an hour's printing left), so later I shall have a 24 and 26' launch and an 18' cutter available in 72nd scale. Later this week I shall have print and laser cut files for a 24 foot cutter. ETA - Now in stock: 3D-Printed Ship’s Boats – VANGUARD MODELS

-

Brace pendants should be black, my mistake...

- 341 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

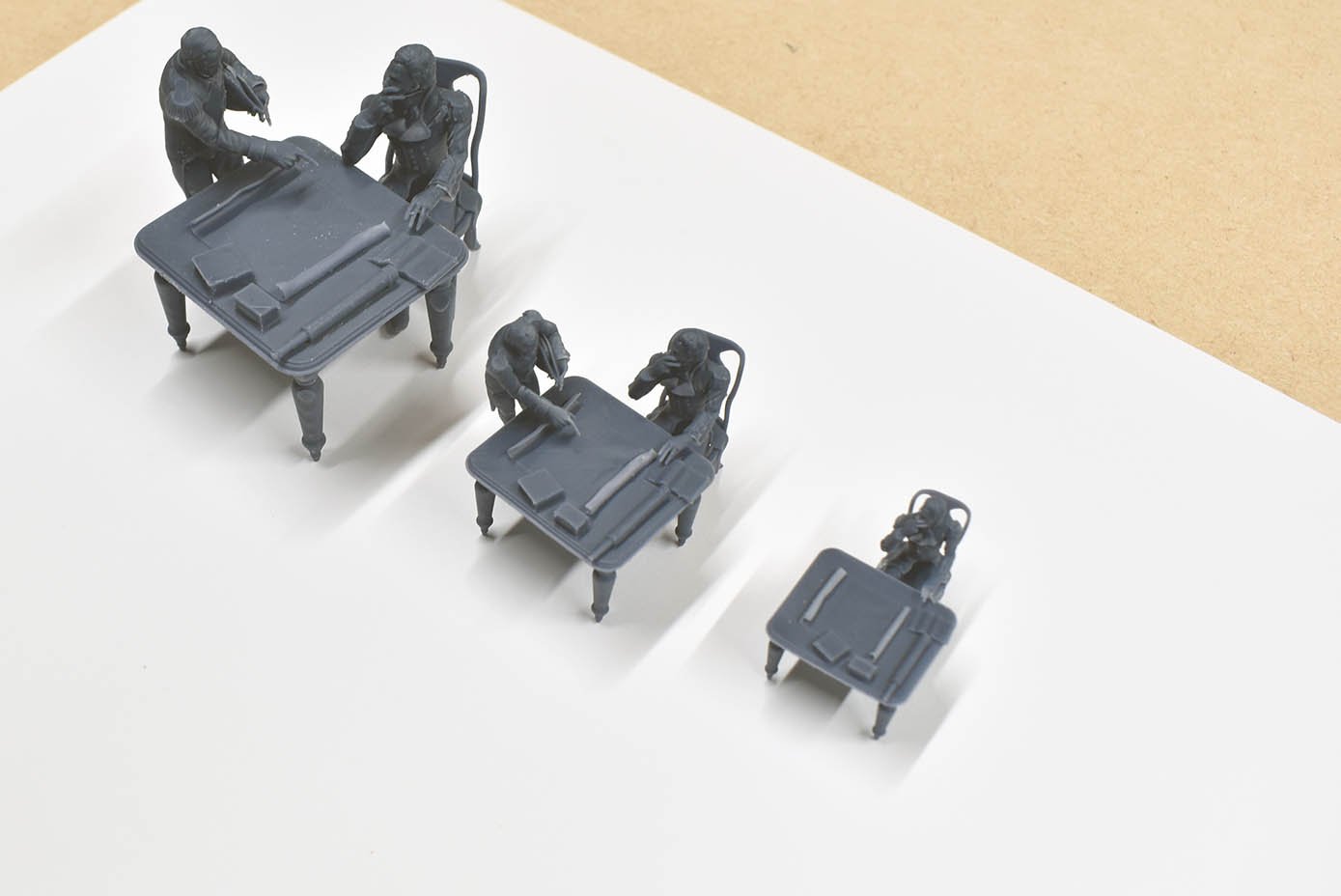

I should get the final files for the figures next week, which I then need to set up on my 'slicing' program. I am thinking the more delicate parts may be better left on their base and supports, to help protect the more delicate parts, and the customer removes the supports. This isn't an issue, as I always use the lightest supports I can get away with to minimise the 'pock-marks' they leave behind. I hope to have the full suite of 3-d printed ships boats before the year's out (so Sphinx and Indy will have an option for all 3-d printed hull boats) - this will be quite a large investment in money, but I think worth it, as even I prefer the 3-d printed hulls, so imagine quite a few customers may, too. Regarding Harpy, I shall be sending Jim the laser cut, PE, 3-d printed parts next week, so you should see a build log of this soon. (I am very much looking forward to seeing what Jim does to this, I love the lines). I still have around 4-5 full working weeks for CAD (plan) work, so still plenty for me to do before even starting preliminaries for kit 18, which I anticipate starting in September. Finaly, I have been told by my PE supplier that copper is back on the menu, but more expensive. So, I will eventually have the PE copper plate option back for kits that have copper bottoms. I will keep them a separate option, as I know some prefer not to copper the bottom, or some even prefer the tape, so do not want to increase the cost of a kit to take into account the expensive PE copper when not everyone will use it - Best to keep it an option.

-

The figure set is being reworked, so should have an update within the next few days. In the meantime, I am busy producing Harpy fittings, laser cutting kits parts for orders and still working on Harpy CAD drawings in between everything else. We have now become so busy that my wife will be working full time for Vanguard Models from September, as it is neither fair or untenable for her to have a full time day job, and then to come home and work again until late putting kits together. My accountant confirmed the validity of this today. Our house is up for sale, as we need a larger premises, but no bites as yet, dammit....

-

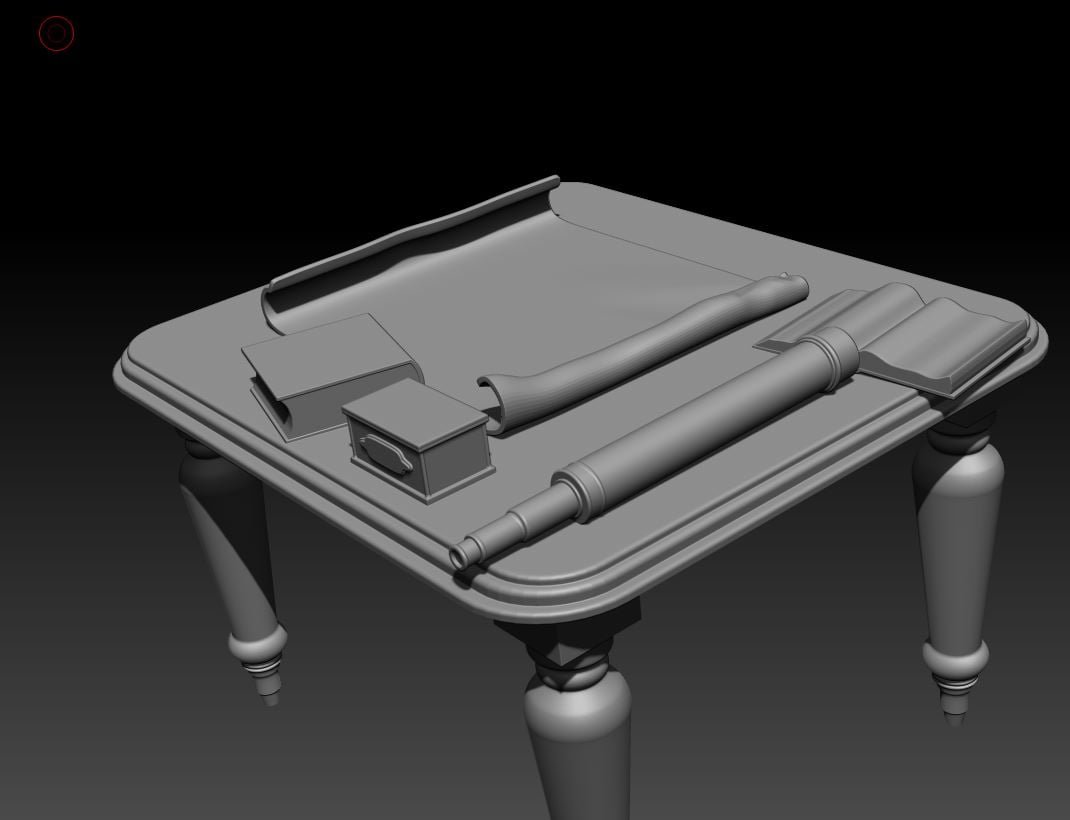

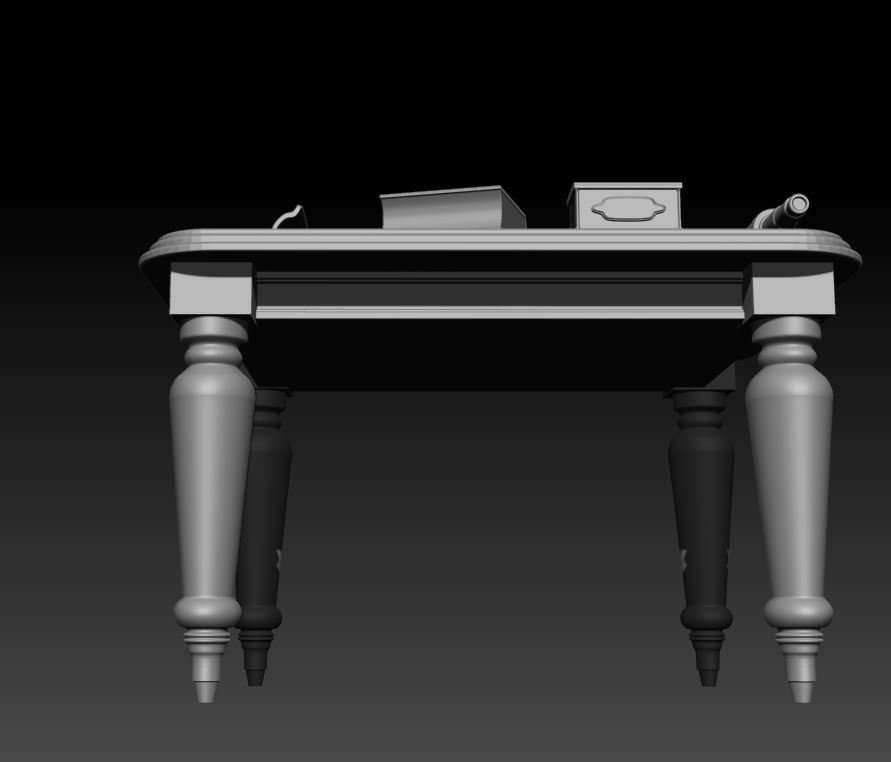

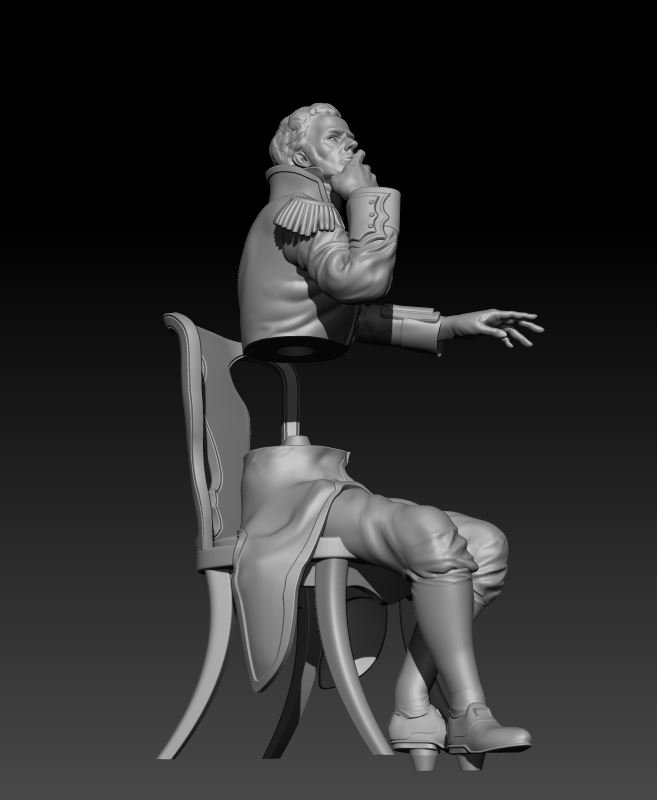

Cheers guys. My problem is that the carver I have used from the start seems to have vanished, I can only think that they may have passed away. He was responsible for all natural and carved decoration, both figures and stern/figurehead 3-d prints. I prefer to stick to just one person or company for each discipline used, that way they know exactly what I want and know what they can do. Problems arise when you have to find a replacement for the previous person or company. To try a new sculptor out, I thought the best thing to do was to give them a figure or two to work on. This is the main reference I suplied, along with another two references for the period clothes, from head to foot. I thought at the time that this would be a very nice addition to my figures range: Now, if something is not right, I will not waste my time producing them (the 3-d prints do take a lot of time) and selling something I am not 100% happy with - even though at my main scale, these details will be barely seen, more so when in their cabin with deck beams obscuring a lot of the view. This was to be a 5-part set and would take a lot of time to produce and post process, so if there are doubts about this set, I have no problem abandoning it and turning my attention to kit design, the one thing I do know well and have complete control over. I will give this carver one more chance to get the problems highlighted sorted - so the fat lady hasn't broken into song quite yet.

-

OK, have asked my sculptor to do something with those hands, and beef up the collars and lapels, as well as chair legs, to help with printing. Just finished first print, only half of the items printed (new printer, so trying again), but I did get a seated and standing figure and table in 48th and 32nd, and the sitting officer and table in 64th.

-

Looks great, you should be proud of that!

- 152 replies

-

- Flirt

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I always do the lower shrouds, then futtock staves, catharpins, futtock shrouds, upper shrouds and upper shroud staves and catharpins. Then ratlines and last of all, topgallant shrouds. I always used to dread rigging, thinking I would spend the same amount of time on that as with the hull. However, I soon learned that rigging is done at a much quicker pace than the hull, which is in reality around 90% of the total time spent on a model. I remember spending over a year (full time) building the Amati Victory hull, yet the rigging took less than 3 weeks from first shroud to final bowline. And that had a lot of shrouds and rats... For the the distance between the deadeyes I think they be at least 5mm, but absolutley no more than 7mm apart for 5mm deadeyes. For 3mm deadeyes, 3-5mm apart.

- 146 replies

-

- Adder

- Vanguard Models

-

(and 1 more)

Tagged with:

-

You are doing a wonderful job, Glenn, well done.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I now have machined block sets back in stock for Indefatigable. They are walnut and look very nice indeed, but do cost me more than the machined pearwood blocks I got from Russia, so are a little more expensive. HMS Indefatigable CNC Machined Walnut Block Set – VANGUARD MODELS I will order sets for the other kits in time.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.