willz

Members-

Posts

98 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by willz

-

-

fixing the broken bits is all part of the fun, and the experience makes sure you never make the same mistake

- 144 replies

-

- corsair

- bermuda boat

-

(and 1 more)

Tagged with:

-

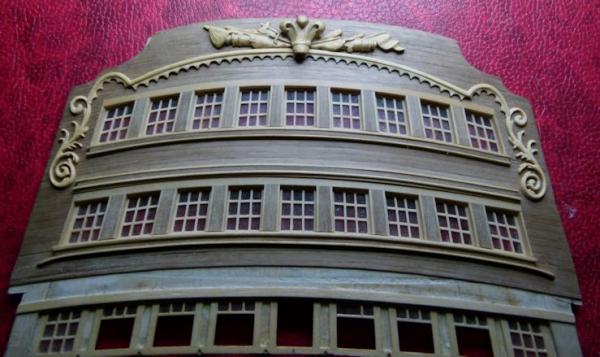

checked out your stern shihawk and its looks fine, commercial parts are nearly always a let down but you have cleaned them up super, as for the carving you must use the correct material, I purchased some boxwood and like you had a go, took a couple of attempts to get the hang of it and although not perfect they look ok, here`s my version of the right hand strong man and the view through a macro lens shows all the errors but when looking with the naked eye he`s acceptable.

-

-

there was never a door for the entry port, simply because the was never an entry port. i cant find one single painting or photo before she was restored in dry dock with one. if anyone can find a painting or photo of victory with a entry port pre dry dock please post it

-

mckays book shows the entry port without a door, and as she is now in dry dock there is no door. having said that i have only ever seen the entry port on the victory in dry dock, every single photo and painting previous to this shows her without an entry port ?? but thats a whole new ball game !!

- 413 replies

-

looking good so far, as for the door, there isn`t one, just a opening with a lining.

- 413 replies

-

Thanks all for your kind coments, small update, finished the first planking of the hull, cut out all the gun ports inserted the linings and filled in all the gashy bits on the ports side, the quarter galley doors have had the linings inserted and left slightly proud so as to let the second planking butt up and then be sanded flush, all prep work finished on this side, started work on the starboard side but still lots of work to do ,cheers William

-

-

thanks for the comments, appreciated. Time to tackle the sheild, complex piece, so will be semi abstract

-

-

small update, both the small guys are finished for the time being, more work will be needed when fitting them

-

-

had a go at carving one of the small guys on the figurehead, quite pleased with myself even though it looks nothing like the real thing except for the stance, the right arm rests on the figurehead crown and will be carved to fit at that stage, (if I ever get there) !

-

not quite finished yet, rear seat backrest and rudder to do

-

-

hi David, all my plans are from the book The 100-gun ship Victory by John Mckay. cheers

-

hi Wayne, yes the laser was very helpful, with it being a scratch build, i cut the rib slots slightly wider than the false keel to give me some side to side movement, then with the keel plumb inserted the ribs keeping the centre line of the rib in the middle of the keel and then setting the line on the top strap to the laser, putting in a top strap with a centre line makes sure its bang on, also the top strap gives the ribs much more strength for fairing, planking e.t.c., when the time comes the top strap will be removed. cheers

-

hi Anja, no, didn`t use any filler blocks and already started the planking, although i curved the planks round the bow when fitting i noticed that they later tended to lose the curve and judder round the bow, oh well we live and learn, cheers

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.