-

Posts

1,078 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by JacquesCousteau

-

-

Very nice work! The "bite" torn off the roof is an especially excellent detail.

-

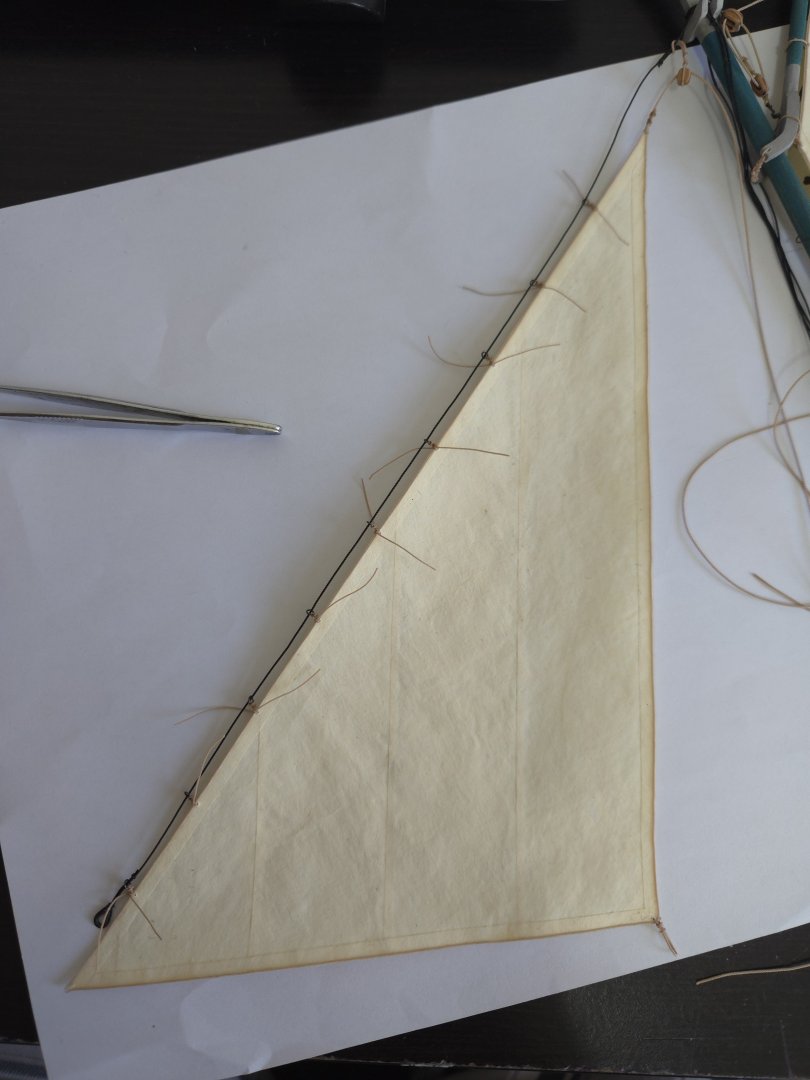

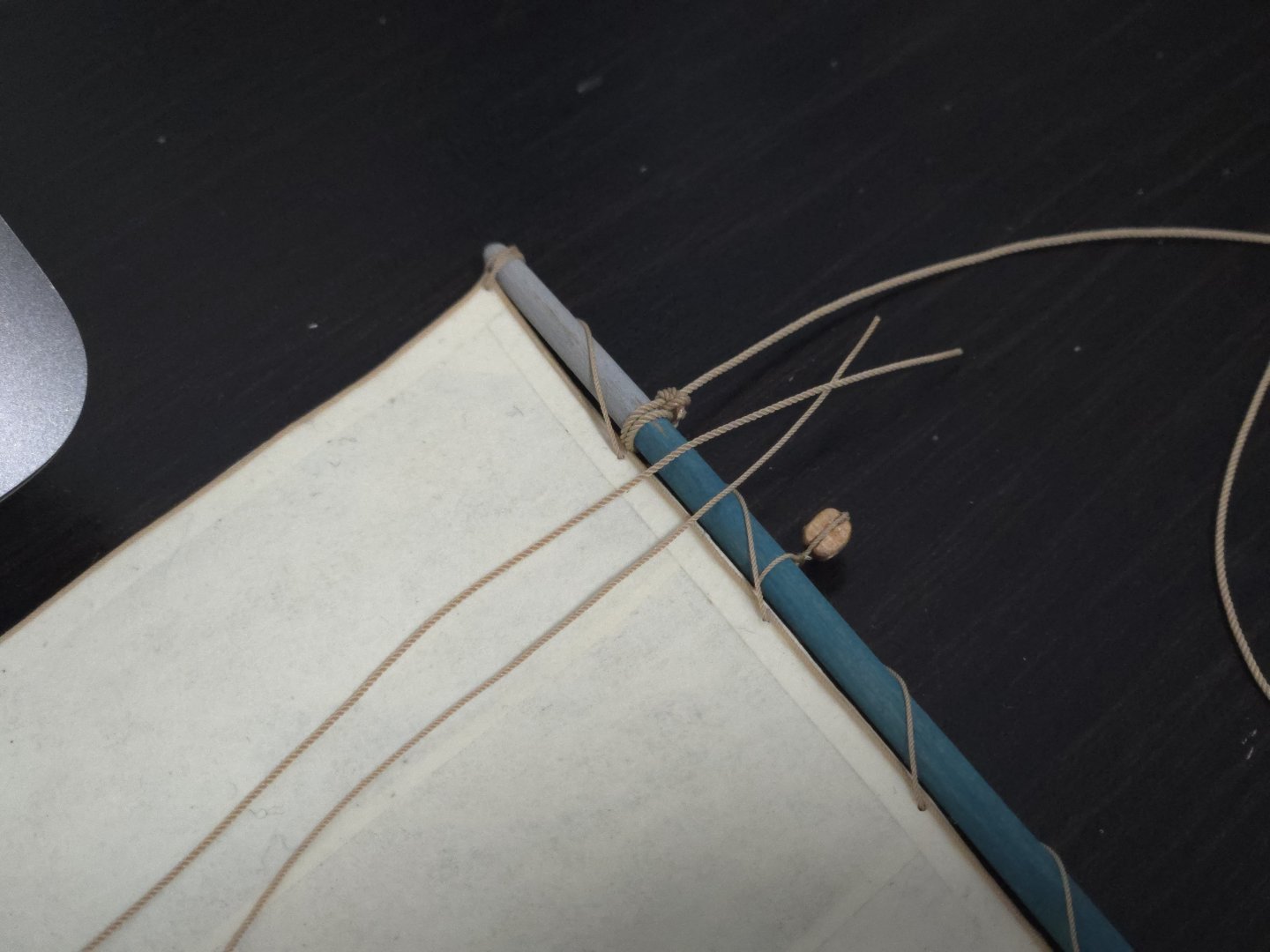

Bending the jib to the forestay was a little tedious but nothing too difficult, just a lot of tiny knots.

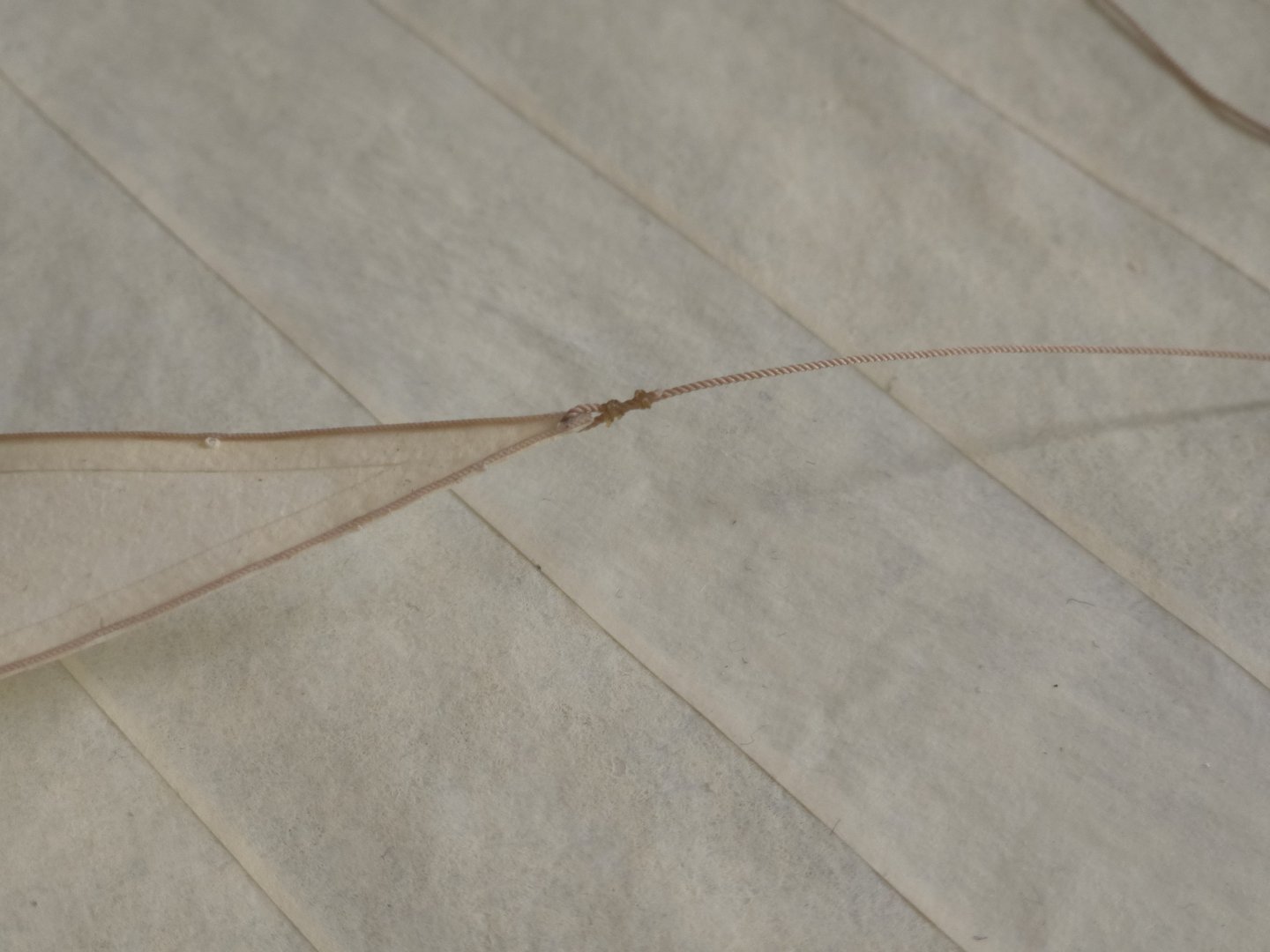

I was lucky that they all turned out all right. After finishing, this was the total amount of .35mm rope that I had left:

After getting as much set up off the hull as possible, it was finally time to step the mast. This was a very exciting step, as I finally got to get a good look at the model with sails in place.

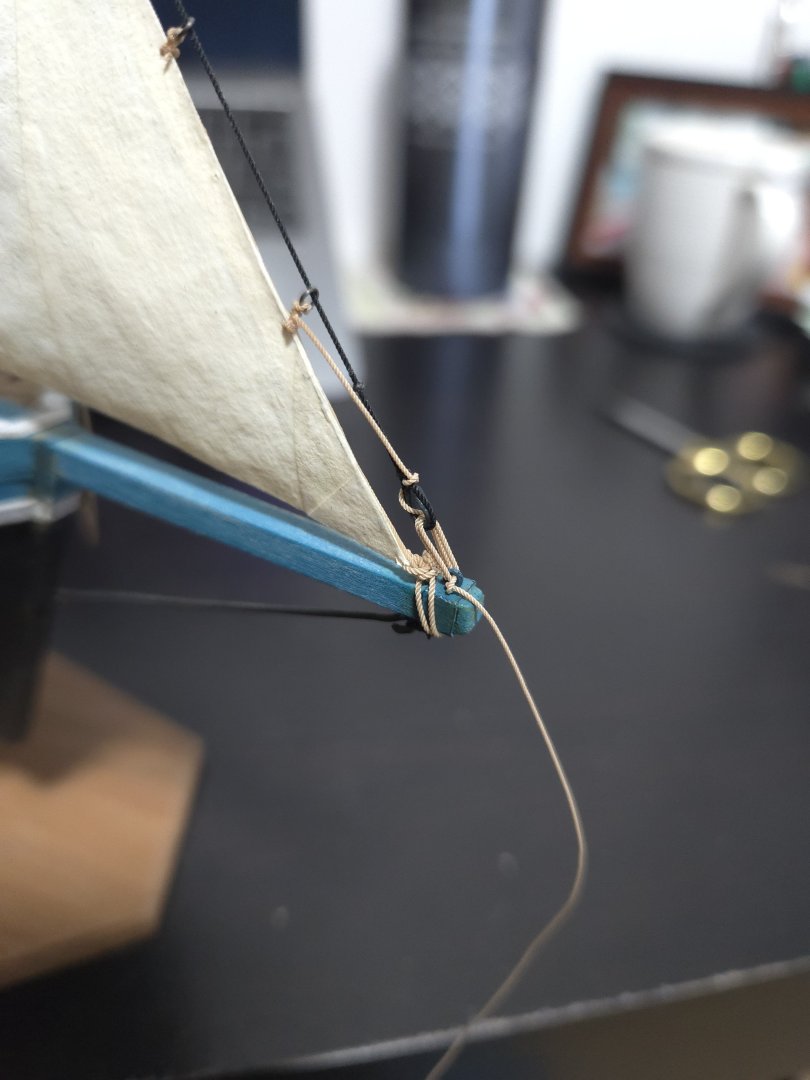

After looking at quite a few photos and other build logs and the like, I did my best representation of the lanyard joining the forestay to the bowsprit. I also tied off the tack of the jib, the rope for which, following photographed examples, wraps around the bowsprit (I threaded it through the lower eyebolt to make doubly sure it would stay in place, although this aspect wasn't very clear in photos). For now the lanyard has been left long, so I can adjust it if I need to.

For the lifts, I ultimately decided to go with the .5mm rope instead of. 45mm. I think it definitely looks better, but I'm still debating whether the mainsheet should be cut off and swapped out for one made of .5mm rope instead of. 6mm, I feel like it might just look a little too bulky. One end of the lifts (which, following photos, are simply tied around the boom, rather than being fixed to a cleat or something) has been left long for now so that I can easily tighten it if the line starts sagging as it stretches.

At the moment, the line is all very long and just loosely piled on the deck. I need to figure out a convincing way to leave it--they definitely didn't use neat coils on these vessels. I also need to tie off the shrouds with lanyards, although this might make more sense to do after finalizing the running rigging so that I have more room to work.

I have to admit that I'm very pleased with how this build is coming along. Thank you very much to everyone who has added a like, left a comment, answered questions, or otherwise offered support on this model.

- Keith Black and KurtH

-

1

1

-

1

1

-

Nice work! While I haven't used much walnut, it's often said to have too pronounced a grain to work very well at scale. Some people seem to get a good finish with it though, it depends on what sort of look you're going for and whether you'll be painting it. In my limited experience, mahogany has the same grain issue and is rather stiff, making it hard to bend and twist. The limewood is probably very similar to what is called basswood in the US, searching the forum under that name will probably generate more results. It's very easy to work with, but is soft and tends to fuzz a bit when sanded.

- FrankWouts and John Murray

-

1

1

-

1

1

-

Thanks, Gary! I'm enjoying trying to make this accurate, even if the sheer variety of ways lanchas were rigged is a bit of a double-edged sword--so many ways to choose from, but at least I have choices.

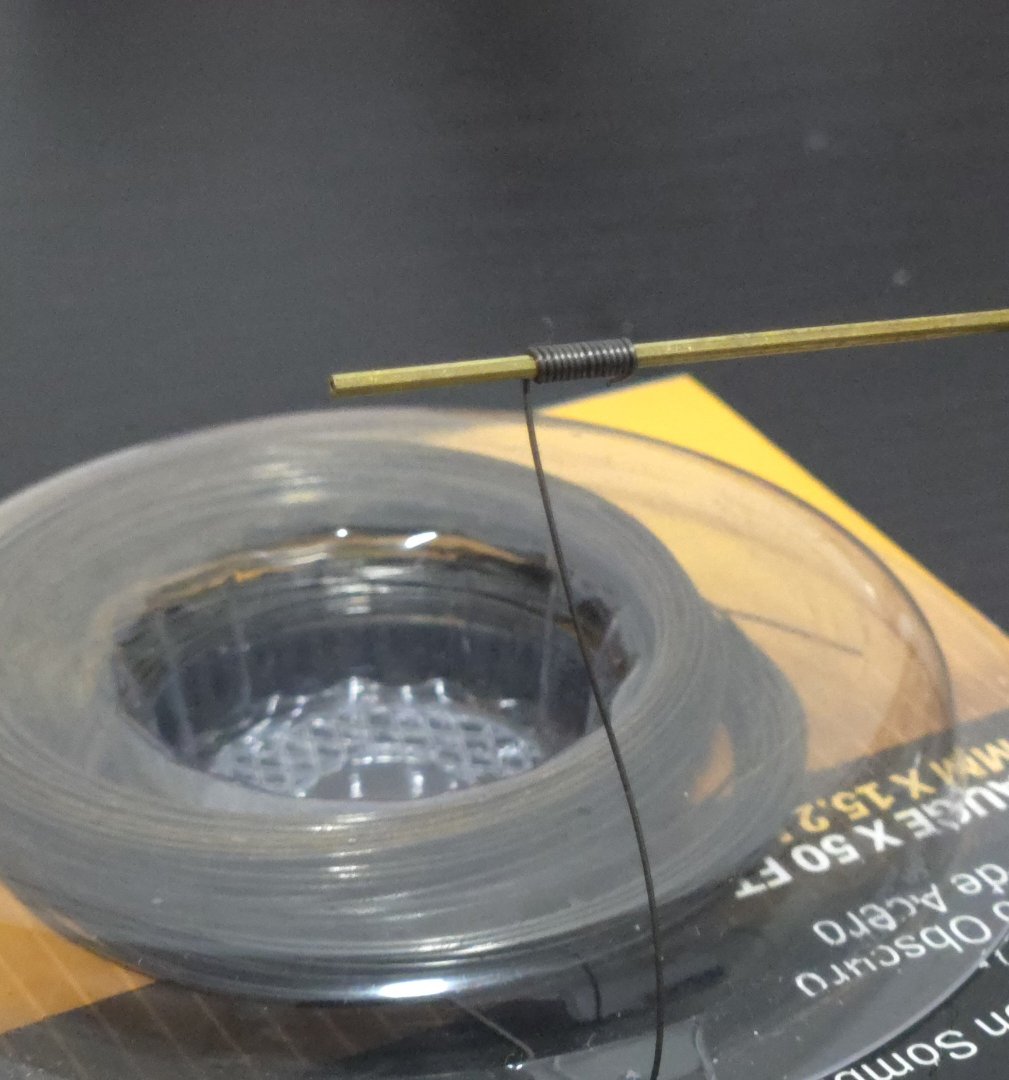

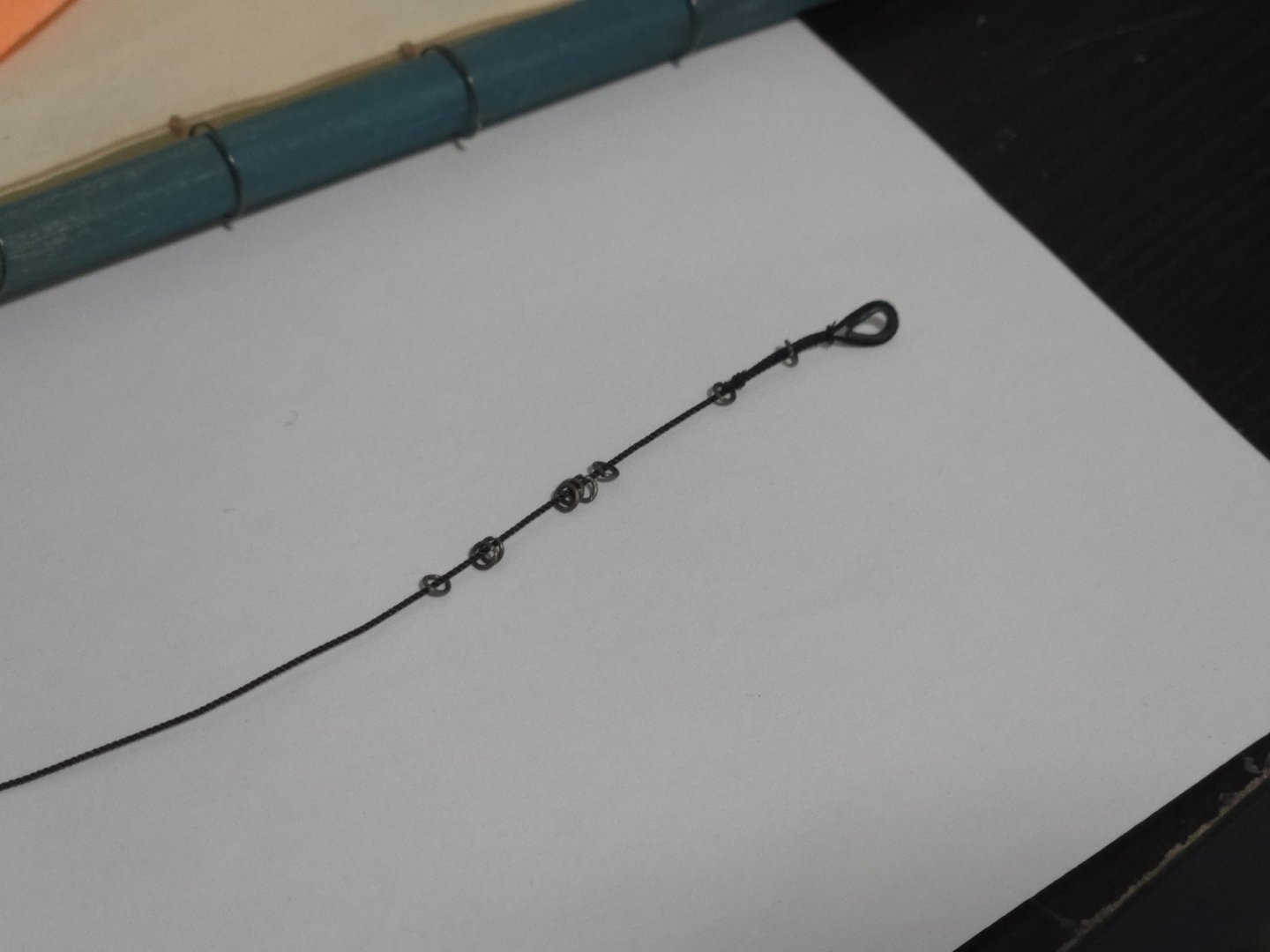

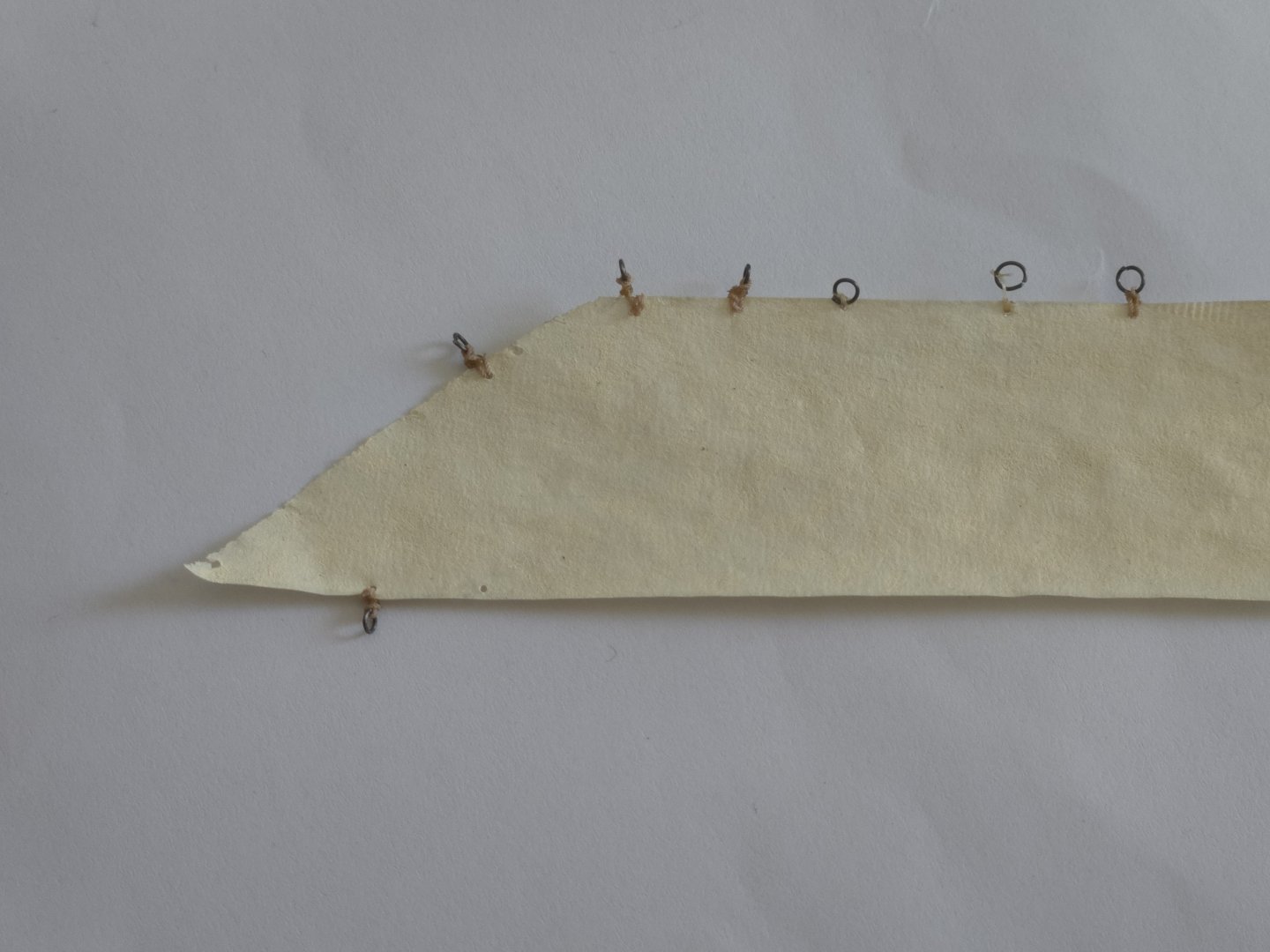

Satisfied with my tests, I made the hanks by wrapping 28-gauge wire around a thin brass tube.

The rings are small enough (2mm across) that I could only cut off one at a time, as my wire clipper was too wide to reach any further. I made some extras in case I lose any, they're pretty tiny.

To get them on the forestay, I placed them in the tip of my hemostats, used a toothpick to open them enough for the stay to fit in, and then, once they were threaded, used finger and tweezer pressure to squeeze them shut, securing with a tiny amount of superglue applied from a toothpick that I whittled into a thin point. Next up I'll need to add the lacings, and then the sail itself.

Before adding the jib, though, I wanted to add the jib halyard, as I thought the seizings, in particular, would be hard to apply once the jib was on the stay.

With that added, I figured that I may as well add the other halyards. I tied off the peak halyard not at the tip of the gaff spare, where many lanchas tied it off, but a little further in, so as not to put too much pressure on the spar extension. While I use half hitches for a lot, I knew I needed a different knot here, and ultimately went with a fisherman's bend, which turned out well with the .5mm rope.

Adding the throat halyard, which had been made earlier in the process, was a simple step. I wasn't sure whether the gaff halyards should both be on the same side of the mast or on different sides, so I watched a documentary on YouTube about a Lancha regatta in the 1980s ("Regata a un ventisquero," Dir. Domingo Garrido, 1983: https://www.youtube.com/watch?v=CDeTRT64kd8 ) and found, arou d 1:48-1:50, that they were on opposite sides. This was helpful for figuring out how the ropes should run through the double blocks.

I'm now having a bit of trouble figuring out how to do the sheet and lifts, though. My impression from photos was that either all the running rigging used the same size rope, or the sheet might use thicker rope and/or the lifts might be thinner. So, to create more visual interest than doing everything with .5mm rope like the halyards, I thought I would do the sheet in .6mm rope, and the lifts in .45mm rope. I attached the sheet with a fisherman's bend again but thought it looked very bulky, and I'm not sure if the .45mm rope for the lifts looks very thin (and makes the bulky knot stand out even more). I'm debating replacing the sheet with. 5mm rope, or using .5mm instead of .45mm for the lifts. In the photo below, the sheet in .6mm rope is at top, then there's .5mm rope, then .45mm (while the lacing is .35mm).

- KurtH, Glen McGuire, Paul Le Wol and 2 others

-

5

5

-

Looks like an interesting project, hope you're able to get back to making sawdust soon! I'm curious what source you're using for Oneida being built in New York City, as I was under the impression it was built on Lake Ontario.

-

-

Amazing work, it's incredible how much that looks like metal!

- Jack12477, FriedClams and Keith Black

-

2

2

-

1

1

-

-

6 hours ago, Thukydides said:

Great progress jaques. The sails are looking really nice.

Thanks!

A little more testing, and I think I have the jib hanks figured out. I can get the rings down to an inner diameter of about 1/16-inch, which is still probably slightly oversized but any smaller and I'd have a very hard time working with them (it's already hard enough even just to get my metal cutters into the ring to cut them). I also switched to using the same method I used on the mast hoops to lace them to the sail, entailing first attaching the rope to the ring and then tying on the sail. This holds the ring perpendicular to the sail instead of parallel. It took a few practice runs to get it right, as seen below:

The three tries at top right were either a little bulky, or, in the case of the one on the corner, I added a little too much super glue to the initial knot and the rope became too stiff to be run through the eyelet properly, instead holding the ring too far out from the edge of the sail. The test at bottom left is where it finally came together.

All of these tests, except for the early ones that used only fly-tying thread, used the cut-off bits of .35mm rope from the gaff robands and mast hoop lacing. These were tiny scraps, about 1 inch long, making it very hard to tie the knots. For the final version, I think I can go with lengths of rope about 1.75 inches long, which should be much easier to work with, without quite using all of my available. 35mm rope, as I'd like to keep a little as backup in case something needs to be redone. I think the hanks would probably look better with .25mm rope, but I don't have any, so these will have to do.

- Thukydides, FriedClams, Paul Le Wol and 3 others

-

6

6

-

I've done a little bit of testing for the hanks. I made some small rings with 28-gauge wire and tried a few methods of attaching them. Below, there are three samples.

The center one was the first I made, using fly-tying thread that I looped and tied through the sail eyelet a few times before tying on the ring. It didn't turn out very well, with the final knot barely holding on thanks only to superglue. The left example also uses fly-tying thread, but this time I only passed it through the eyelet once before looping it through the ring, and then going back through the eyelet a bit before tying it off. It turned out better, but 1) I need more distance between the ring and the sail, and 2) the thread snagged on who knows what and created a tangled bunch of fibers. I find this happens fairly often when I try to use fly-tying thread. Finally, the one on the right used a bit of the .35mm rope, secured with a couple knots and a lashing with the fly-tying thread. I think this one turned out best, although it was also the most complex to make.

That said, my sense is that the metal ring is still too big. You can compare what the current size would look like on the jib, below (I tucked the test behind the jib), with some photographic examples that generally show quite small hanks.

Source: https://www.bibliotecanacionaldigital.gob.cl/bnd/629/w3-article-320749.html

Source: https://www.carlosvairo.com/galeria-puerto-montt-lanchas-chilotas

Source: https://www.memoriasdelsigloxx.cl/601/w3-article-86076.html

I'm not sure if the best solution is to keep going the way I've been going, but to make the rings a bit smaller, or to use black rope to represent the hanks instead, as it would produce a smaller hank.

- wefalck, Bryan Woods, KurtH and 4 others

-

7

7

-

-

Continuing on the sail, I first laced it to the mast hoops, securing all the knots with a dab of superglue. The photo below is from before trimming the loose ends.

Next, the robands on the gaff. I was initially going to just loop the rope through the eyelet in the sail and then directly around the gaff, as below.

But, looking at photos, I decided it would look more accurate to first do a half hitch through the eyelet around the boltrope, and then around the gaff, as below. Subtle, but worth it.

As with the mast hoops, I first tied off everything around the sail before attaching the gaff spar.

The throat took some thought, as I wasn't sure whether it should be attached to the gaff or the mast, and once I decided the former, it wasn't clear how to tie it off, as it's located at the gaff jaws. After a bit of searching, I noticed in the photo below that there was a thin rope running around the gaff jaws.

Source: https://www.flickr.com/photos/luchinmardones/5232587713/in/photostream/lightbox/

After seeing it in a few other photos, I now think that the throat was simply tied off around the jaws on many lanchas, so I did that, as seen below.

To make the robands, I used the same "fake splice" as I've used for stropping blocks: tie a half hitch, secure with a bit of glue, and trim the ends tightly.

A quick check, with the gaff temporarily held at the right angle with scrap thread and wire, to make sure none of the angles are wrong.

For the boom, I ultimately decided to go with the continuous loop instead of robands. While it at first looks like the continuous loop uses more rope, that doesn't take into account that each roband needs excess rope that gets trimmed after tying the knot. Handling it as a continuous loop was much easier than doing separate robands. That said, while I've seen a number of photos with a continuous loop lacing on the boom, none of them show that on the gaff spar, so this is accurate.

Finally, the photo below shows that, unlike the rest of the mast where hoops were used, the tack was held in place with a wrapping of rope.

Source: https://www.carlosvairo.com/galeria-puerto-montt-lanchas-chilotas

This was a pretty straightforward matter to represent.

With that, the gaff sail itself is finished! Next up, I need to figure out how to properly represent the hanks on the jib, and add the running rigging. At this point, I have about 1.5 feet of the .35mm rigging left, hopefully I won't need much for the jib.

- FriedClams, Bryan Woods, Thukydides and 6 others

-

9

9

-

That's unfortunate. Plywood does have a tendency to delaminate when soaked. If you can trace the shape of the bulwarks onto thin wood, like basswood (walnut might work too, if you already ordered it, but it will be harder to bend), you might be able to redo the bulwarks. You also might want to look at build logs for kits from Vanguard Models, I believe that company uses plywood for the bulwarks too.

-

Thanks, @Glen McGuire! I agree, I think the second option looks less bulky.

Thanks, @wefalck, it's good to know that robands and continuous lacing can be mixed. While it would make a lot of sense to leave the foot of the gaff sail loose, photos show it was attached. Below, the looped continuous lacing is very clearly shown:

Source: https://www.carlosvairo.com/galeria-puerto-montt-lanchas-chilotas

Of course, that photo's from the early 1980s, so I wanted to check earlier photos as well. The photo below is from 1940 and shows what look to me like robands:

Source: https://www.bibliotecanacionaldigital.gob.cl/bnd/629/w3-article-613541.html

At this point, I'm leaning toward robands on both gaff and boom, as I think it might use less of my dwindling supply of .35mm rope.

-

Thanks, all! Yes, Wefalck's bark technique is really excellent. If anyone gives it a try, my main advice is to not judge it until it's dry, as it looks odd and fuzzy when the paint is still wet but really sharpens up once it dries.

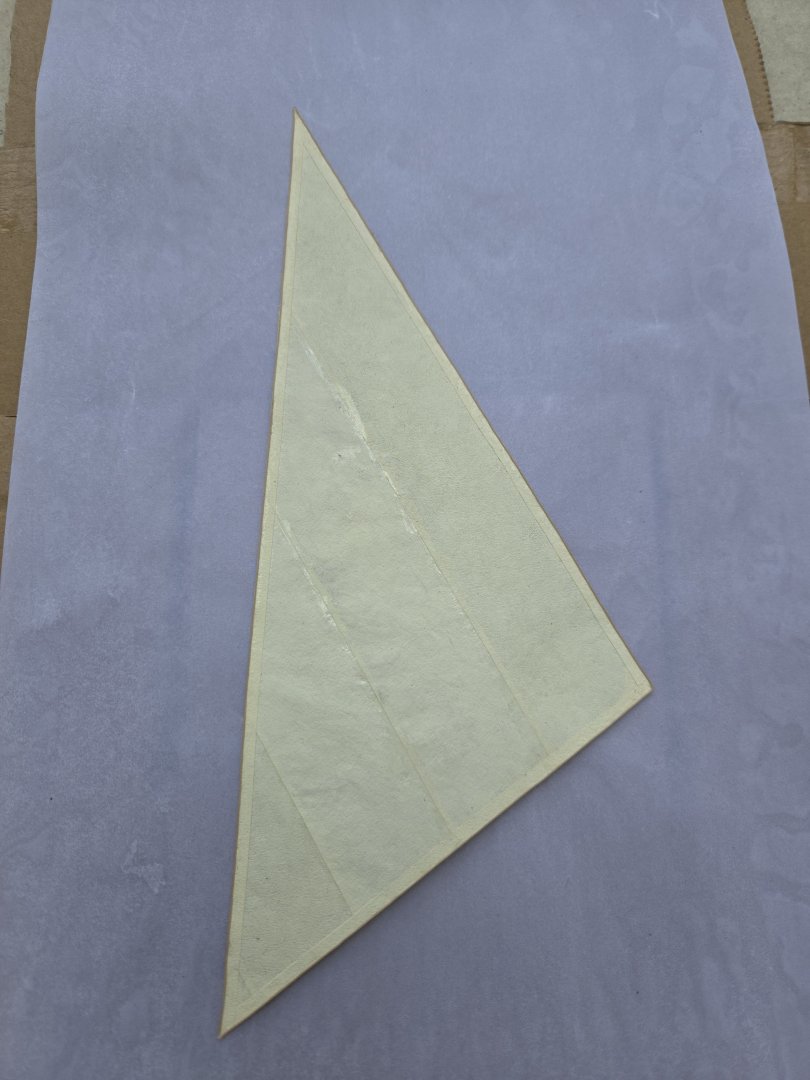

I've continued to advance on the sails. I added the bolt rope to the gaff sail and, taking advantage of a brief break in the clouds, applied the transparent spray. I then measured and drilled holes where needed to attach the various bits of rigging.

I also added a loop of rope to the clew of the jib, as photos showed that the jib sheet ran through a loop here.

Next, it was time to start actually attaching the sails. After looking at several photos, I decided that thin wire mast hoops would be the most realistic-looking option. I made them out of 28-gauge wire, wrapped around a length of dowel. The dowel was a little oversized, so I trimmed a bit off the ends before gluing them shut with superglue.

Next, lacing the mast hoops to the sail. A lot of other build logs show people adding the mast hoops directly to the sail and then sliding the whole thing onto the mast, which which would definitely be easier, but with everything already on my mast, this option wouldn't work for me. I drew inspiration from diagrams in John Leather’s The Gaff Rig Handbook and examples in a lot of build logs to figure out how best to loop it. I experimented with using fly tying thread, but found it a bit too thin and tricky to work with as strands kept coming off it when threading it. Instead, I went with. 35mm rope. Initially, after looping it through itself around the hoop and running it through the eyelet twice (once from each side), I tied a simple knot on each side with the remaining thread, as shown below:

I had a hard time getting it tight on each side, though, and was worried that it was a bit bulky. So I retried by just tying the loose ends off to each other.

I'm still deciding whether the first or second option looks best--feel free to weigh in! Both are simplifications from actual practice, but completely following how it was actually done would result in a very bulky knot here. While I decide, I've been attaching the lacing to the mast hoops.

Finally, I'm trying to figure out how to attach the sail to the gaff spar and boom. It's a bit tricky. I've seen some photos where the boom very clearly has a continuous rope lacing, and others where the gaff spar very clearly uses robands. So both options seem to have been used. But would a single boat combine both methods--e.g., continuous on the boom and robands on the gaff--or would it make more sense to be consistent?

- wefalck, Glen McGuire, Keith Black and 6 others

-

9

9

-

Incredible work! Especially making the shiplap planks, they look great!

- Keith Black, druxey and No Idea

-

2

2

-

1

1

-

-

Nice work, looks like you're off to an excellent start! The weathered deck looks good.

One word of advice for future builds: planking one side at a time can sometimes cause the hull to twist, so it's generally advised to plank both sides simultaneously.

-

Very nice work, the model’s really coming along well!

-

Excellent work! Did you use a tiny needle to thread it, or just stiffen the end of the string with super glue?

-

Thanks, all! I'll give wax paper a try next time instead of plastic.

Some minor progress to report. First, I remade the jib halyard block's stropping and the loop around the forestay. It's much shorter now, which is more accurate to photos and will allow the jib to fit properly. After fitting it, I tensioned everything with thread and applied a bit of watered-down white glue so that it would properly hold the tight fold into the eye of the forestay.

I also worked more on the jib. The bolt rope is made of .35mm rope from Ropes of Scale, glued in place with more Aleene's Fabric Fusion.

As can be seen above, a lot of the seams had shiny glue residue. To get rid of this, I took advantage of a brief bit of sun--Mexico City is quite rainy these days--to apply a matte transparent spray. A couple of coats on each side later, and the residue is practically invisible. The spray also adds a bit of strength and resistance to the sail, which is a nice bonus.

Next, I need to do the same to the gaff sail, and add the running rigging. I also need to work out how best to make the hanks (to hold the jib to the forestay) and mast hoops. According to Vairo, by the 1980s these were usually made of wire. I think I'll do some tests with 28-gauge galvanized wire and with thin black rope.

- FriedClams, KurtH, Paul Le Wol and 5 others

-

8

8

-

On 6/22/2025 at 10:20 AM, SardonicMeow said:

However, I did find that Lewis was arrested for the incident described below. (Washington Times, 19 January 1898).

Quite a bleak story! Who knows how many other cases were never brought to the authorities' attention. I wonder if the sailors ever tried to unionize? Although the seasonal nature of the work might have been a barrier.

Excellent progress on the build, too. The hull really looks great! Wonderful lines.

-

Great work! Details like the extra planking really help bring the hull to life.

- FriedClams, Keith Black, yvesvidal and 2 others

-

4

4

-

1

1

-

It's great to see the model coming together! And very interesting research, too. That German-language newspaper is really something, I wonder what happened after the captain was questioned?

Lancha Chilota by JacquesCousteau – Scale 1:32 – Chilean Coasting Sloop

in - Build logs for subjects built 1901 - Present Day

Posted

Thanks, Keith! It's nice to see it all coming together.

I figured that I may as well go ahead and add the shroud lanyards. So far they're not glued in place and I've left some excess, so I can adjust if necessary. Figuring out how to properly do the lanyards was a little tricky, given that these aren't deadeyes, just thimbles and hooks.

I've also loosely coiled the rope ends, also without glue, mainly to tidy up the deck a bit. The miniature rope doesn't naturally lay in a pile the same way the real rope does, so I'll need to figure out a better way to pile it up and glue it in place.

I also did decide to replace the sheet with .5mm rope, down from the original .6mm. I think it looks more natural running through the 4mm block, and the knot is a lot less bulky.