-

Posts

395 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JacquesCousteau

-

Very nicely done, it looks excellent! I like the contrast between the natural wood and the paint job.

- 11 replies

-

- Skiff

- Midwest Products

-

(and 1 more)

Tagged with:

-

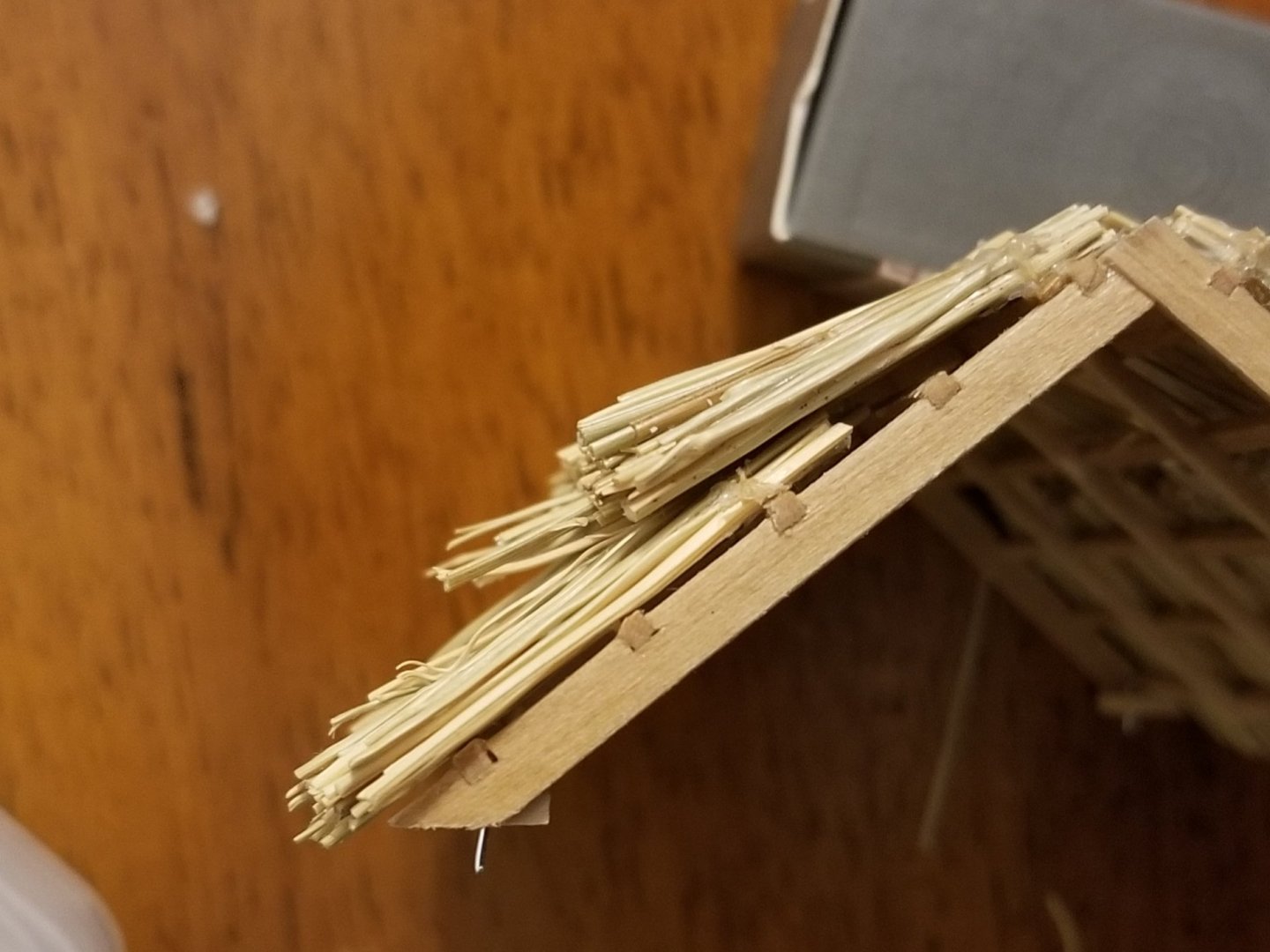

Thanks! Between cutting away some of the upper layer straws and poking new ones into the gap between layers, I think it's turned out in a way that I can accept. The rancho isn't glued in place yet, just held by the pins. Next, I'll need to add some protective/stiffening varnish, especially over the new additions. Then I'll be working out the cloth covering that runs along the top.

- 163 replies

-

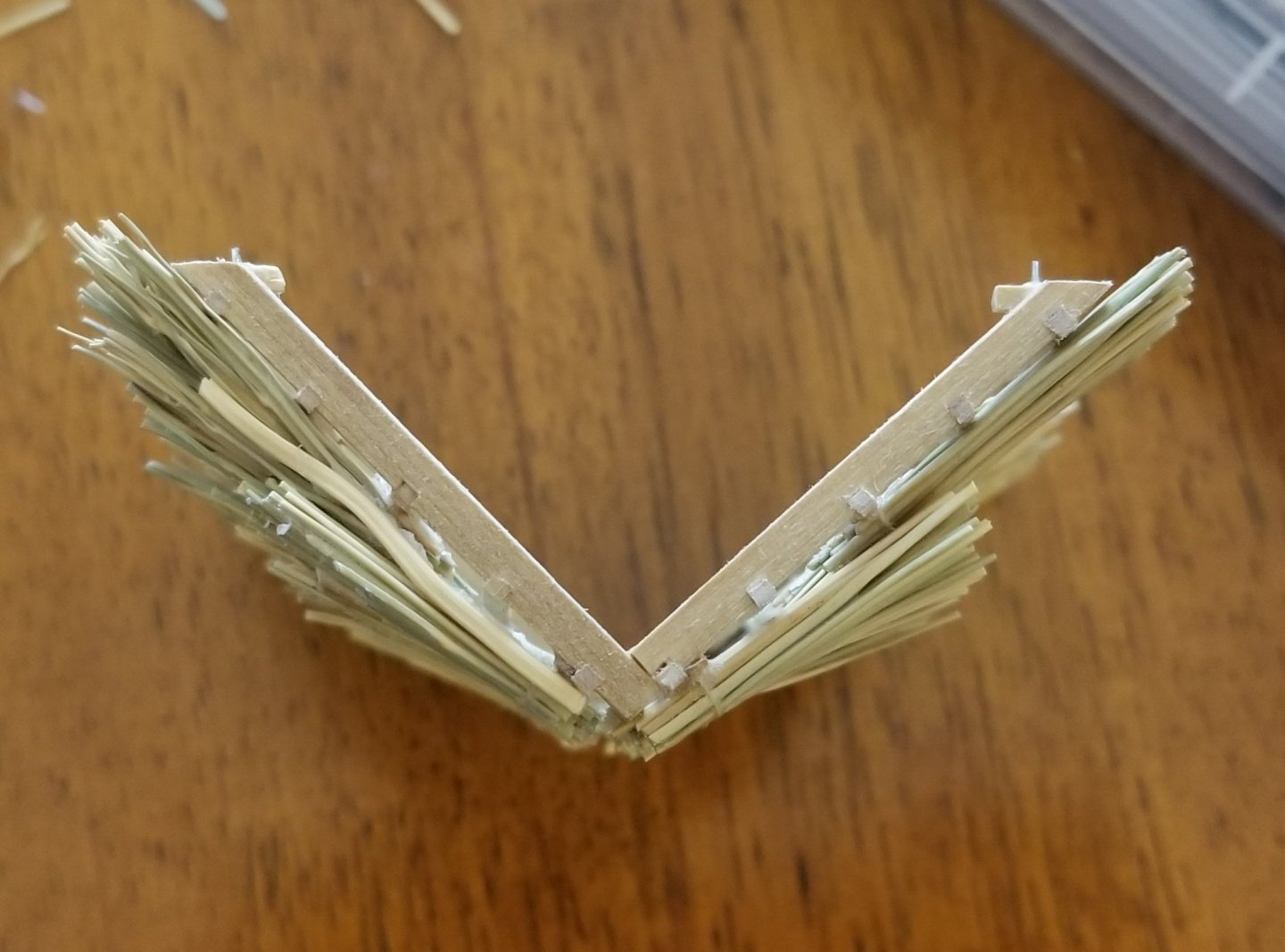

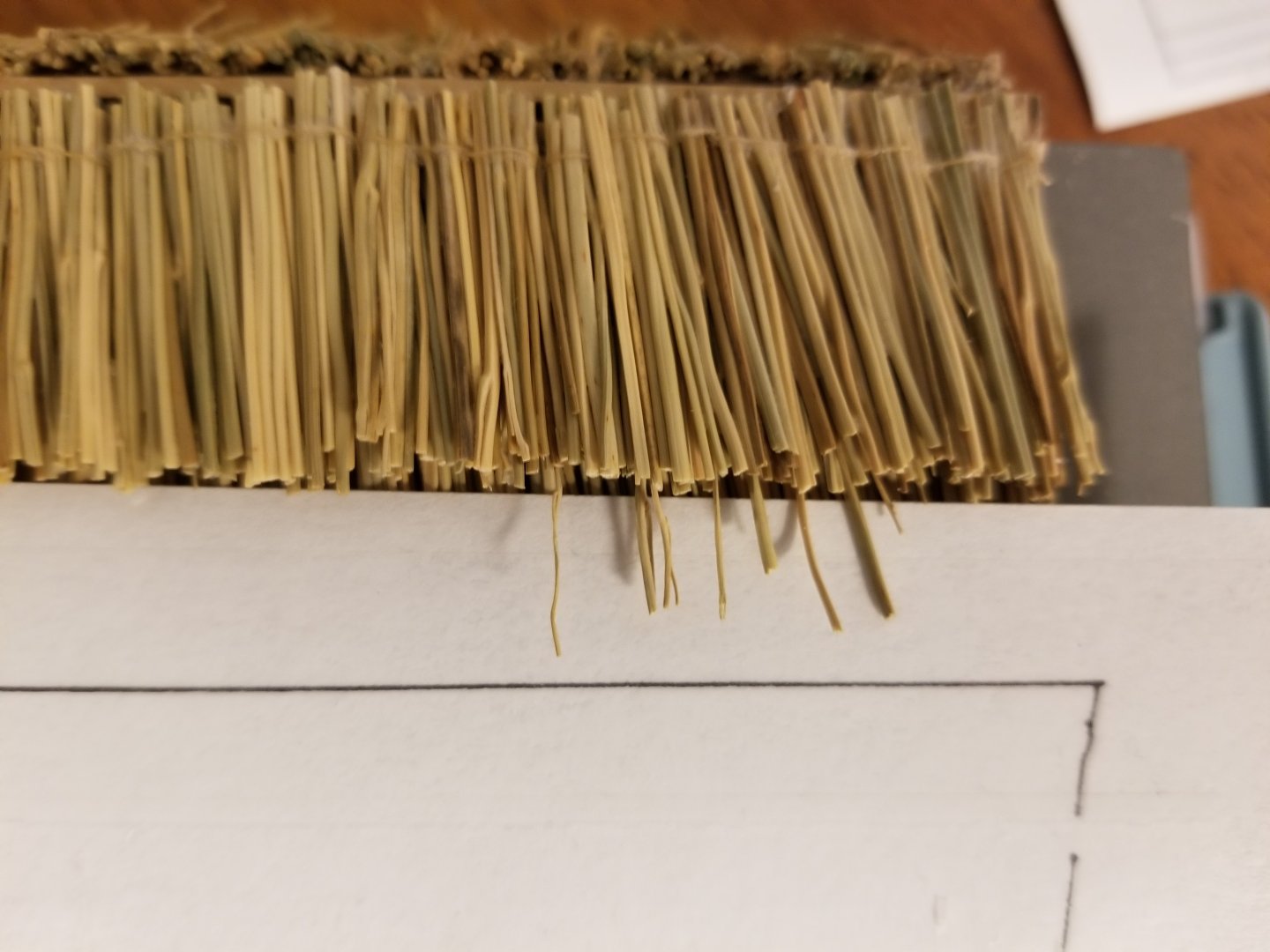

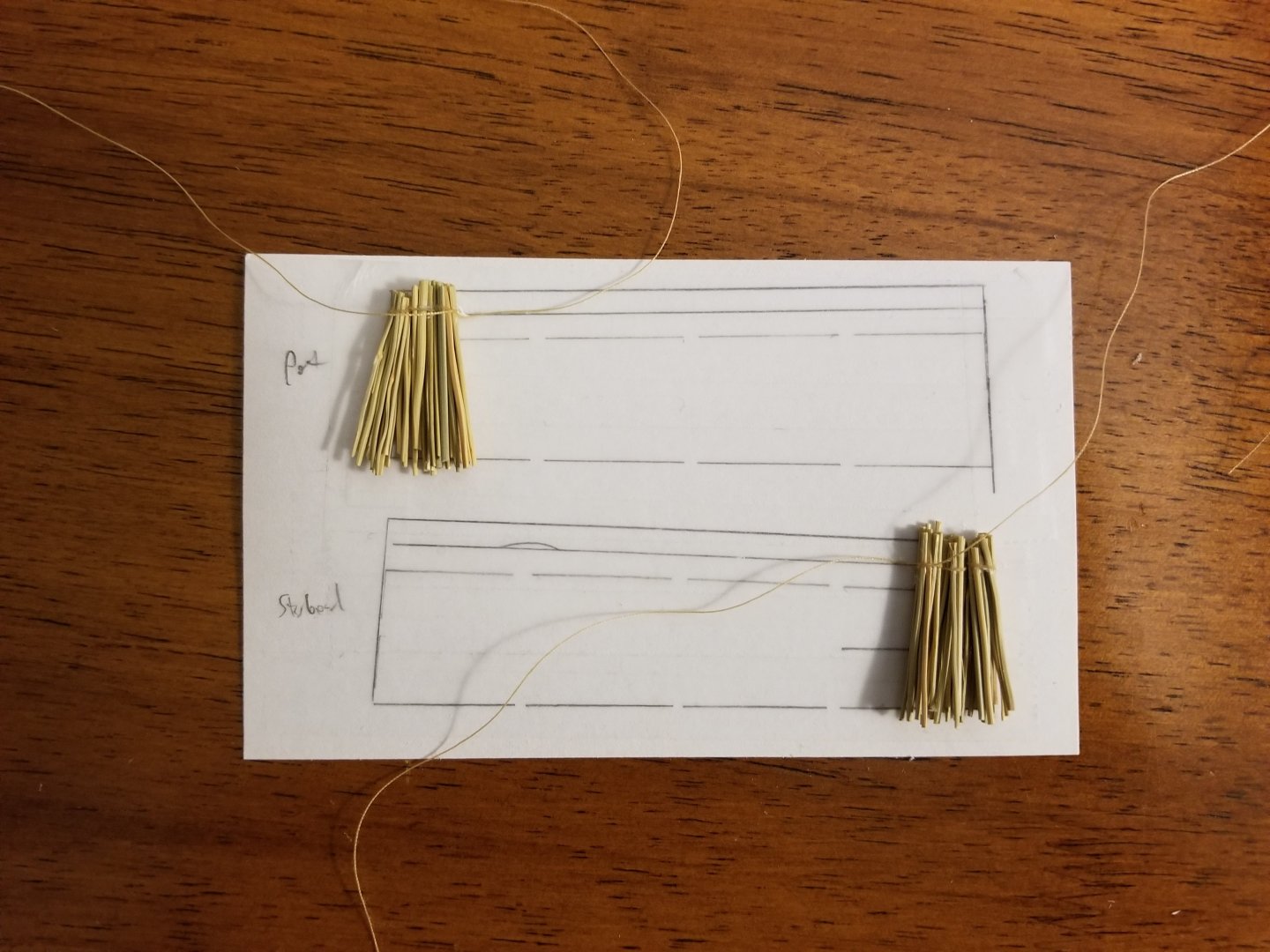

Thanks for the suggestions! @Glen McGuire Unfortunately each layer is pretty solid in itself due to all the varnish, but I have been able to pick out a few here and there to disrupt the solidity of the edge of the layer. I've also been busy inserting new pieces one at a time into the gap on one side. It's not perfect, but I think it's looking a lot better. As with any bad haircut, letting it grow out makes the problem less noticeable. As can be seen, the difference between the two sides is most apparent when viewed head on. I may try to cut back a few more from the top layer, add a few more to the gap, and perhaps add a few shorter pieces above the top layer. It'll be a bit on the shaggy side, but that seems accurate for at least some canoas, based on the photos record.

- 163 replies

-

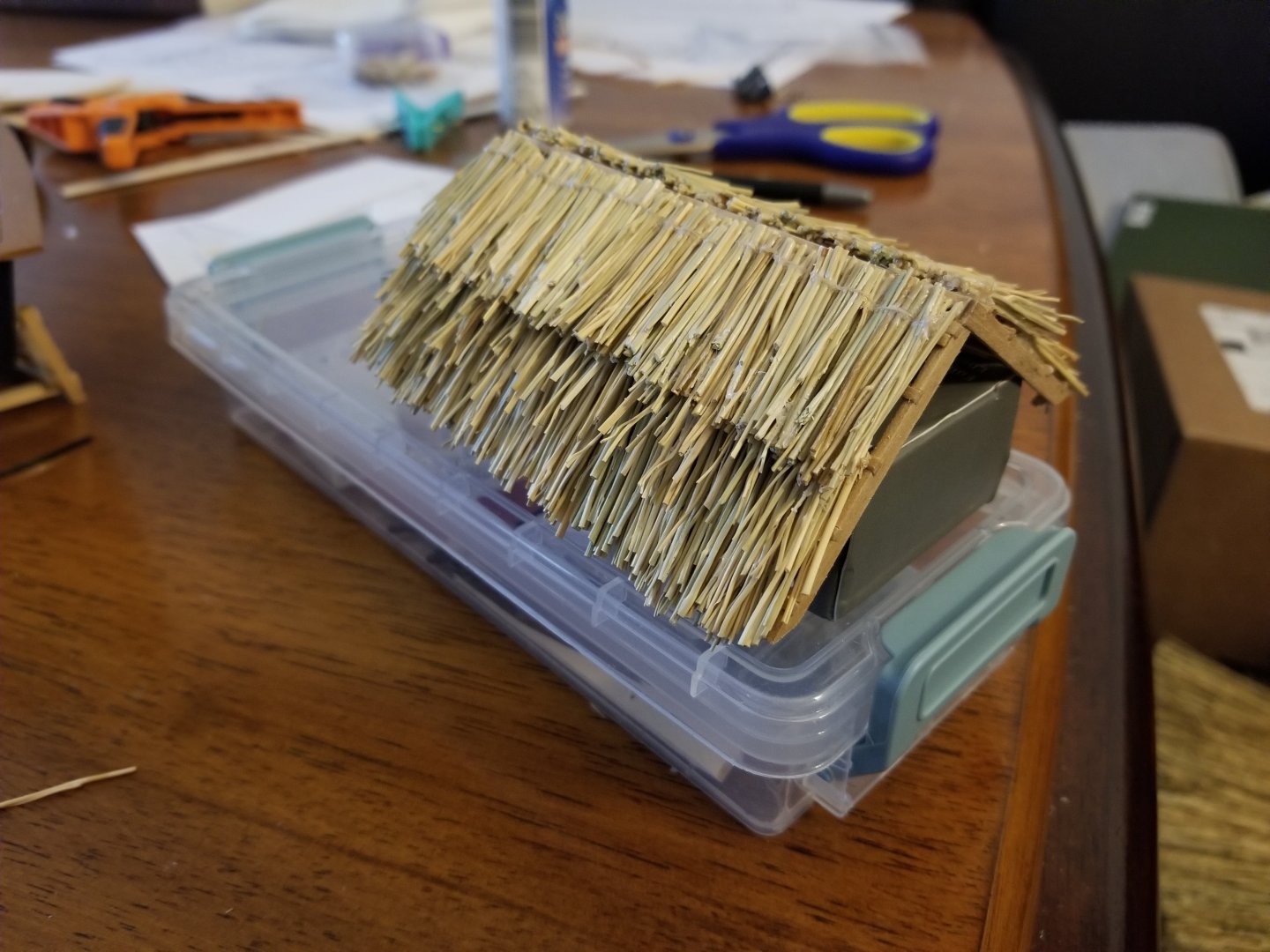

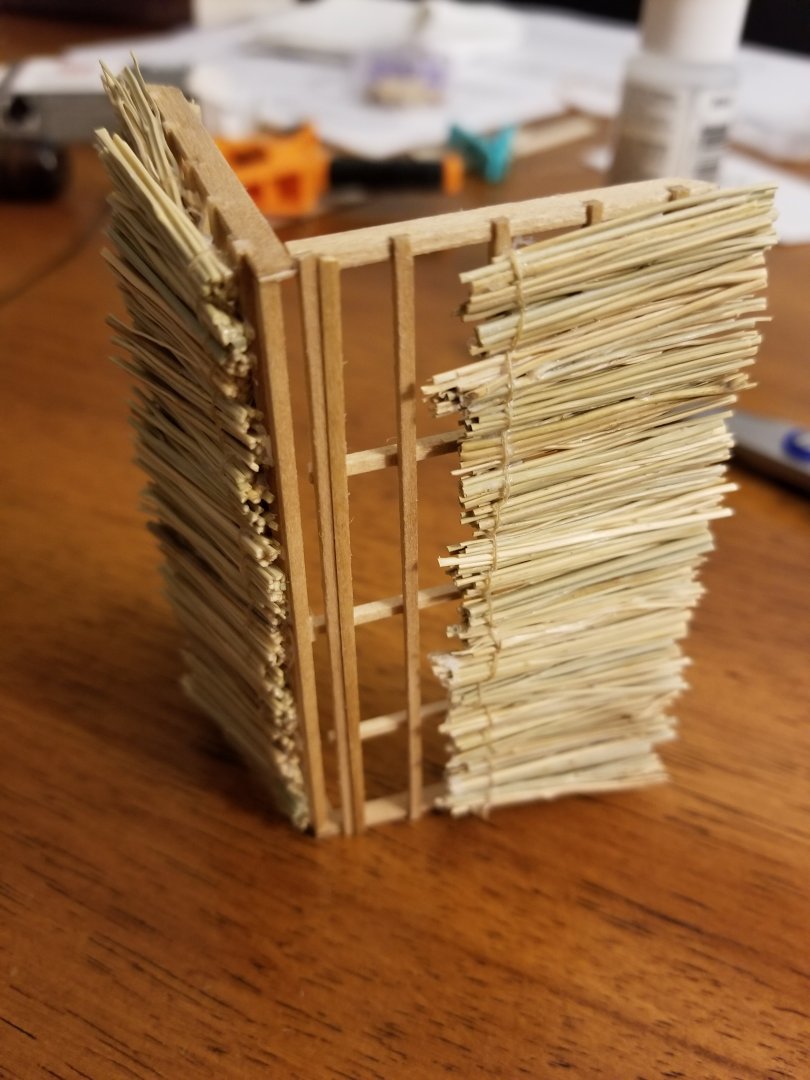

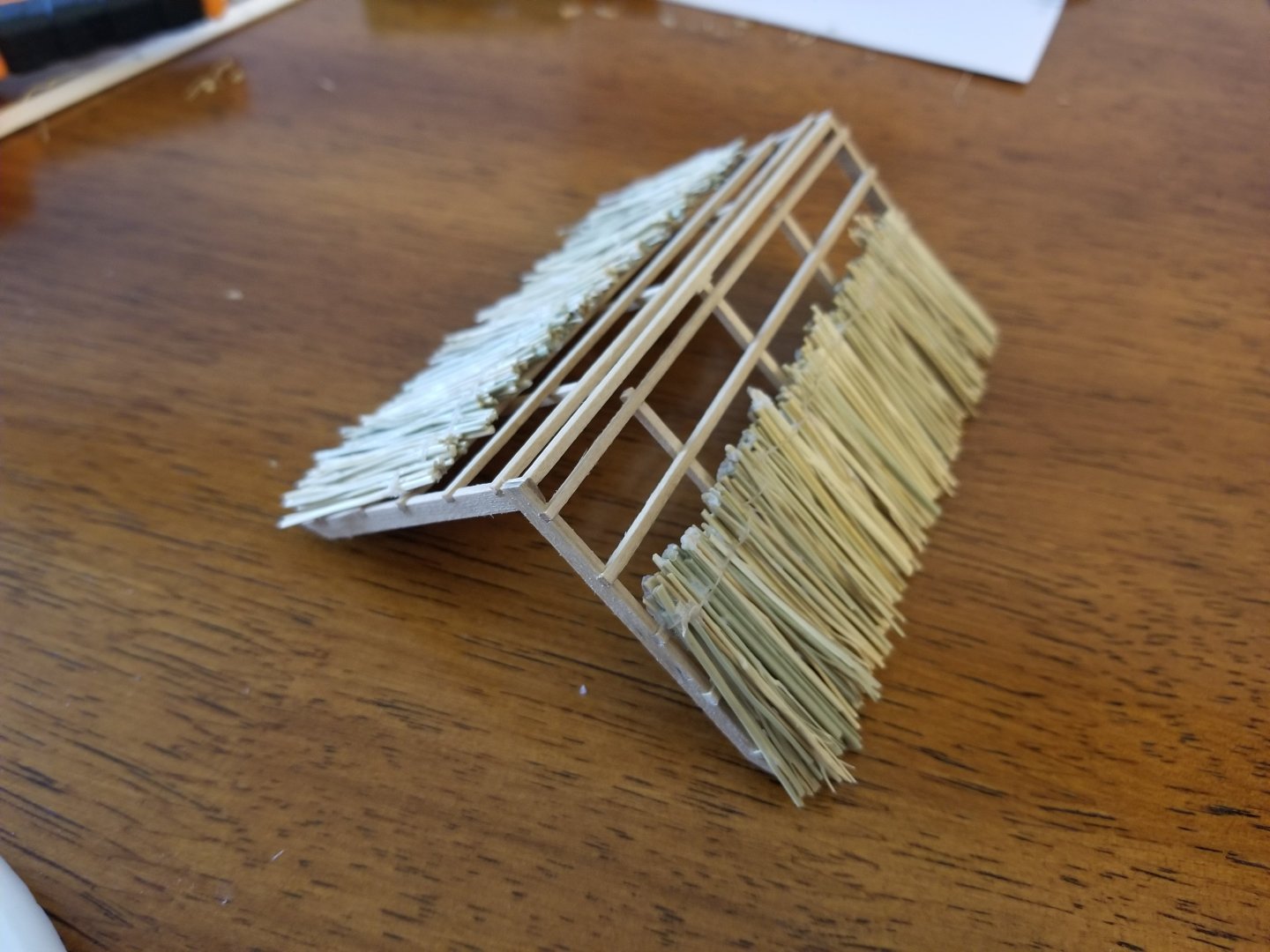

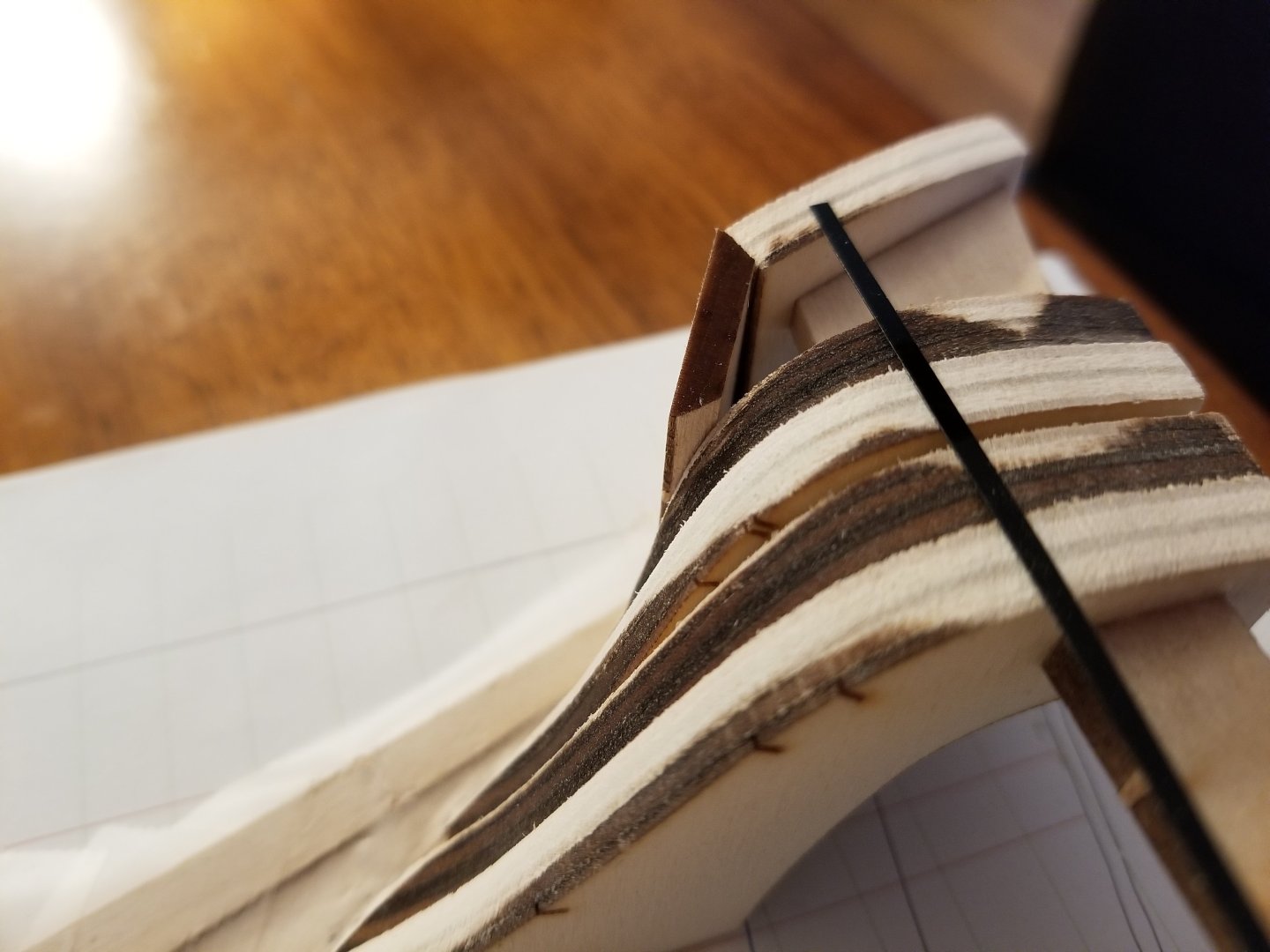

@Harvey Golden Thanks! I may look into a base board. The stand is just stained basswood, so it wouldn't be hard to match, although I would probably have to pre-treat the board so the stain comes out evenly. Well, I finally got the upper layers of the thatching on. The results are.... a bit mixed, I think. As can be seen, I ended up doubling the upper support crosspiece so there would be more of a gluing surface to work with. The very top will be covered with some cloth, which seems to be what was done on the actual vessels if I'm interpreting the photos correctly. While I avoided the unnaturally straight edge I unintentionally gave my first attempt, I'm not totally happy with this one. As can be seen, the layers are each very thick. This wasn't a problem on my first attempt, as the layers were much thinner, but on this one it's very noticeable. While photos make it clear that plenty of actual canoas did have layered thatching, it never seemed to stick up so much like this. From some angles, and from a distance, I don't think it looks bad. But from others, it looks like a bad haircut. So, I'm a bit torn about how to proceed. As I see it, I have a few options: 1) I could redo it with just a single layer so that I don't have to worry about any overlap, but that seems daunting. I've already spent months working on the rancho, and while I'm not on any timeline for completion, I would like to actually finish the build at some point, and I especially would like to be able to move on from the rancho into more interesting parts of the build. 2. I could redo it with a simple wood rancho. It would be a lot easier and faster, but I have to admit that I think it would be visually less interesting. 3. Leave it as it is, accept that I've done a lot on this already and have learned some lessons about considering how parts will come together while scratch-building, and hope that I one day come to love it, bad haircut and all. 4. Continue with it, but see if I can lesson the jarring transition between layers by sticking some additional individual pieces of straw into the gap, as I've started testing (without glue) below. I think I'll try option 4 for at least a bit to see how it turns out. I don't think it's going to make the haircut look worse, at least.

- 163 replies

-

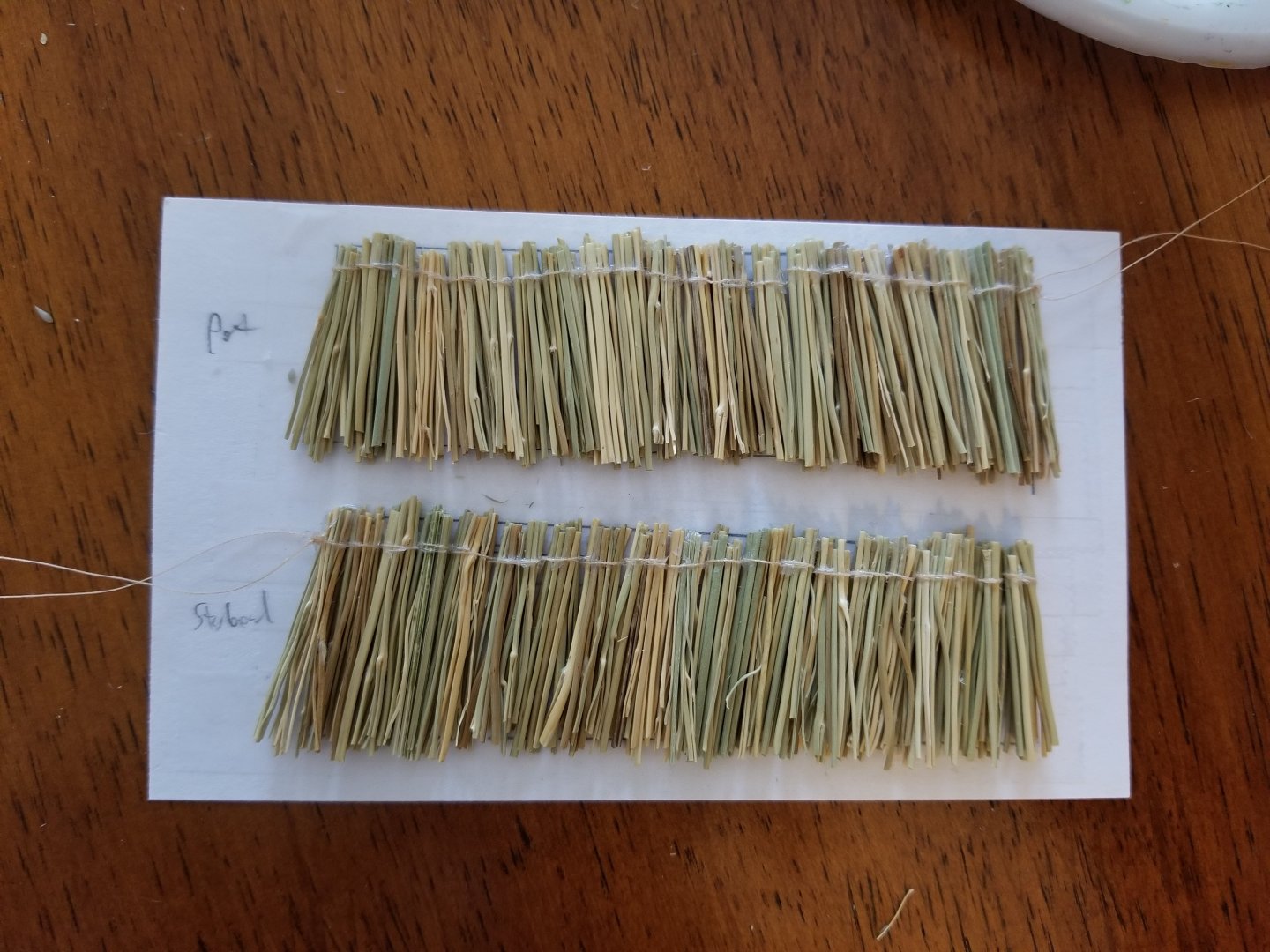

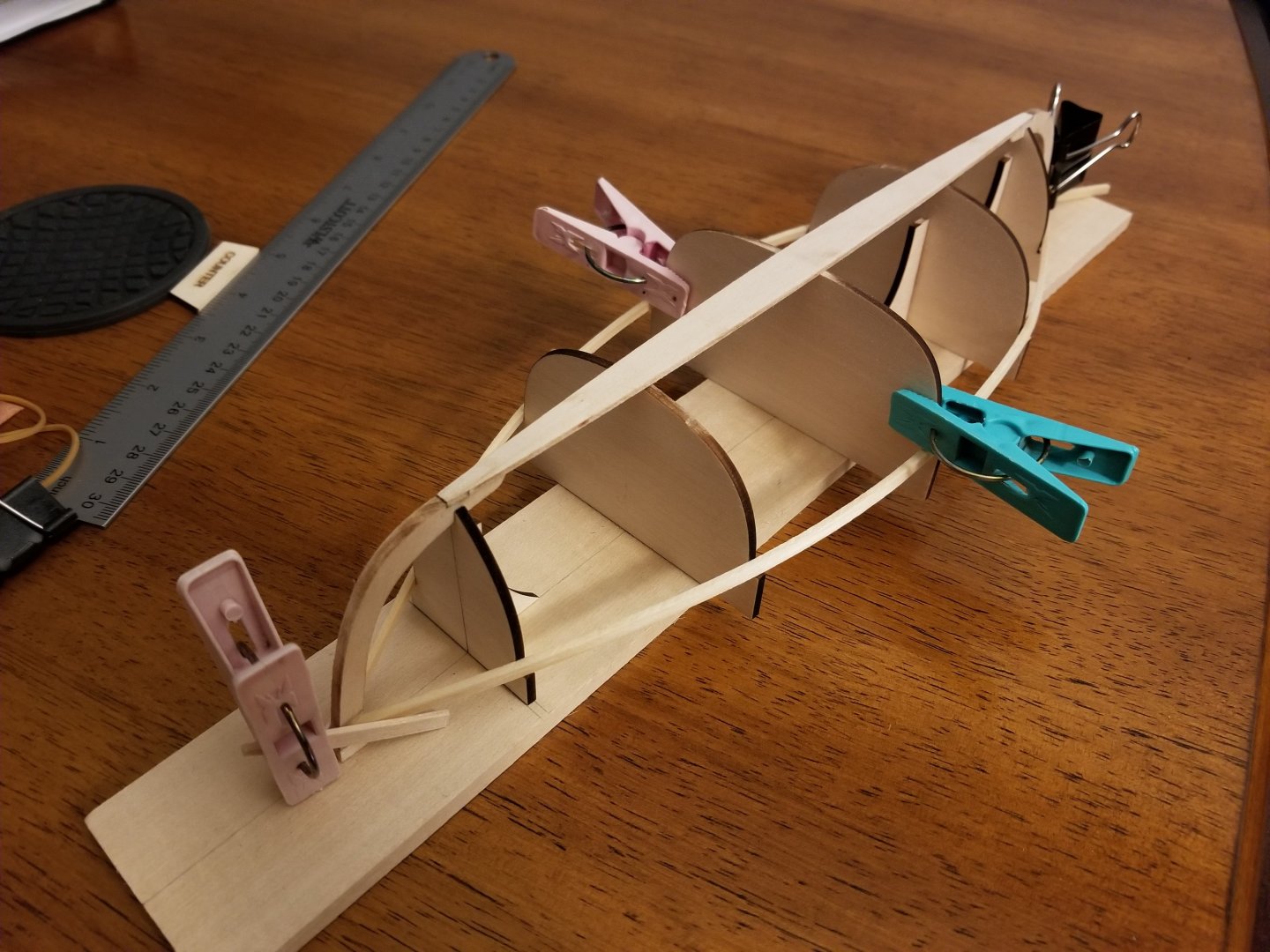

I finally had a peaceful weekend and was able to advance! First, I finished the base. I'm not crazy about it, as I think I made it slightly too long, and I feel like the color stands out too much. I may paint it black, or make a new one to a different design later. But for now, at least the model has a proper stand. I also finally made some progress on the rancho! First, I superglued bits of wire into the holes I drilled in the base of the rancho supports. I think I need a new superglue, as the stuff I got is extremely tacky and seems to stick poorly. Meanwhile, I was progressing bit by bit on the upper layer of thatching. As can be seen, I improved a lot at keeping the string more or less in line. Unlike the lower layer, where I added varnish after each bunch of thatching, for the upper layer I used a generous helping of glue from the string to the top as I went (it will be covered later) and have only added the varnish now at the end. Once that dries, it will be time to remove the thatching from the backing (index card laminated in tape so the glue doesn't really stick). I also glued the lower layers in place on the rancho, using a lot of coffee stir sticks and scrap to clamp. The lower layer is now on pretty solidly. I'm looking forward to finally being done with the thatching, it's taken far longer than I had hoped. If something goes catastrophically wrong at this point, I'll probably just make a wooden rancho, which would be less interesting but equally accurate at far, far easier to make.

- 163 replies

-

Sorry to hear that you're going through a tough time, hope your dog is back in good health soon. The rigging looks great. Does the Syren rope need to be glued before it's cut? I know some ropes will unwind otherwise.

- 64 replies

-

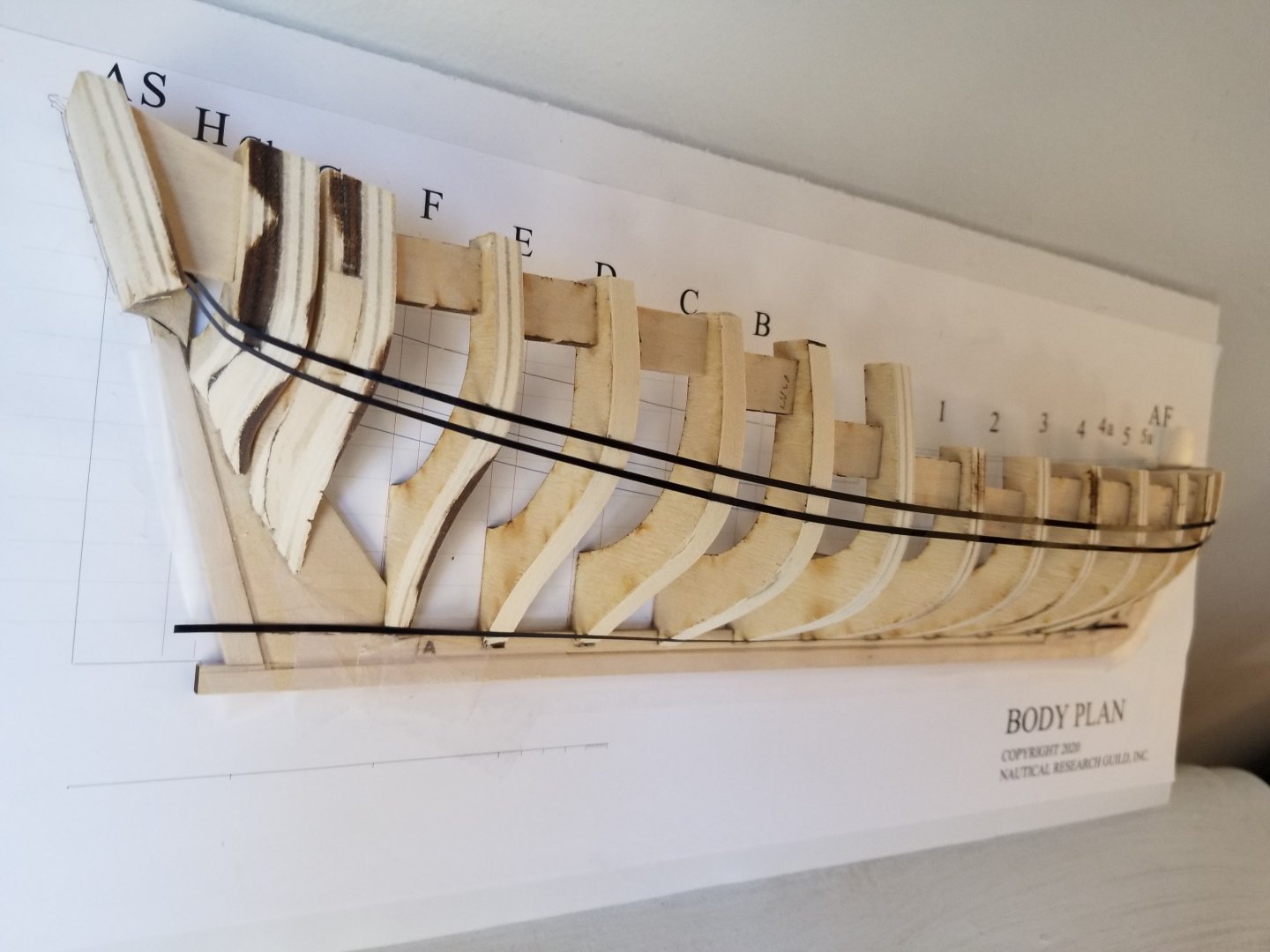

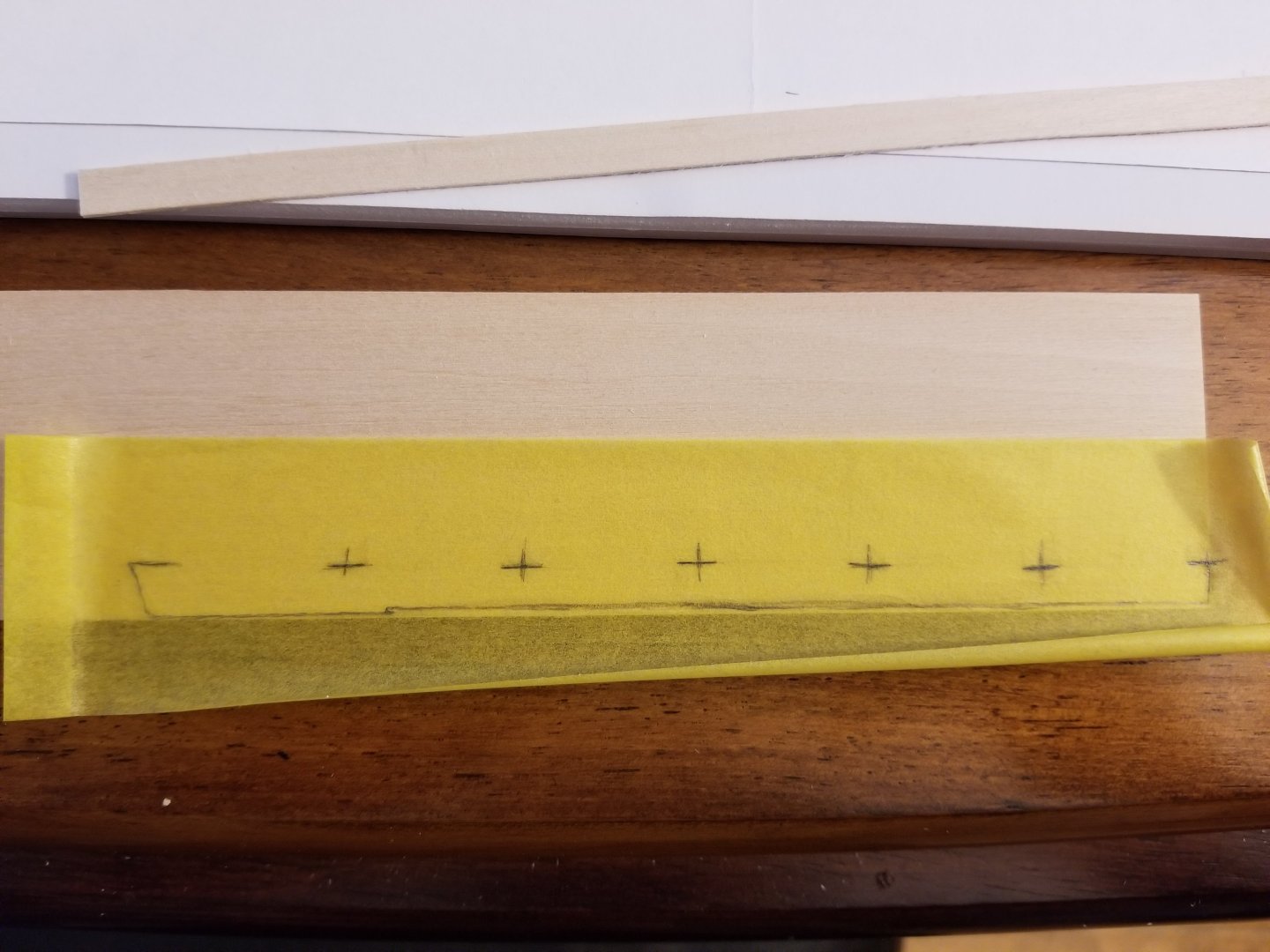

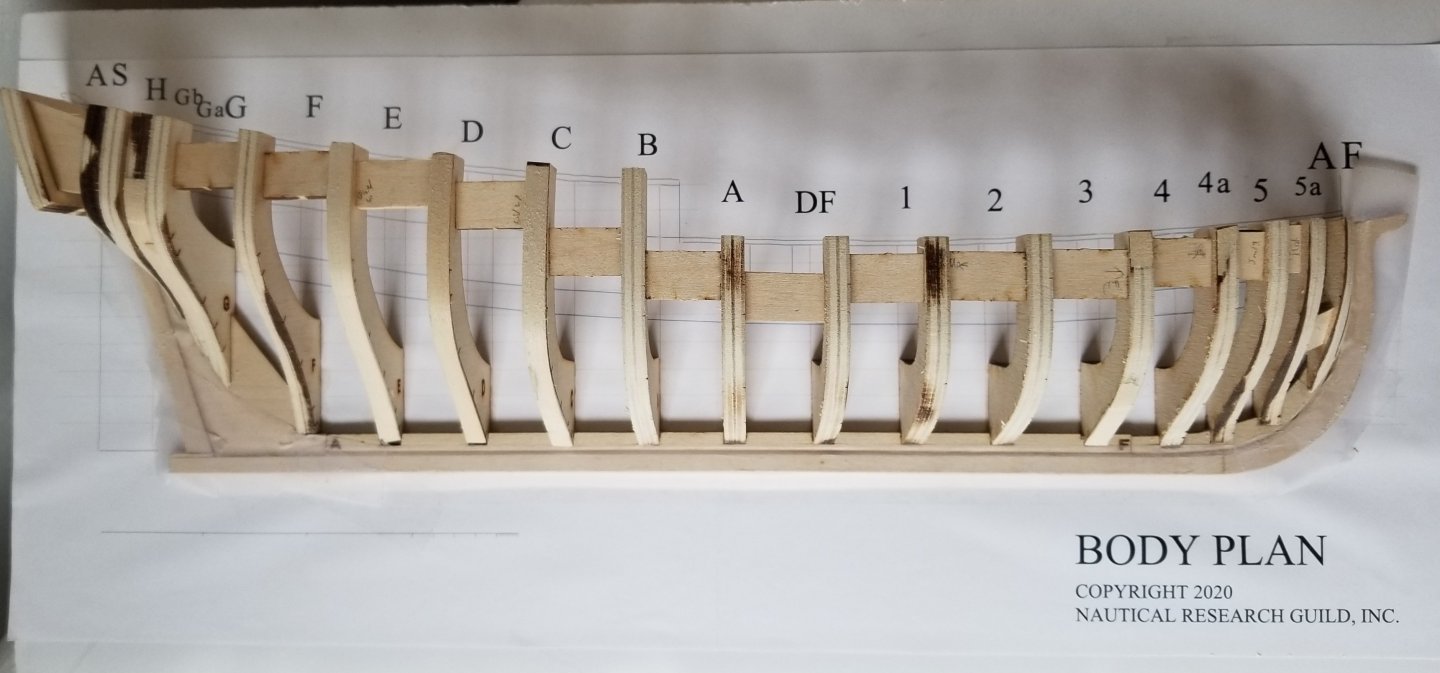

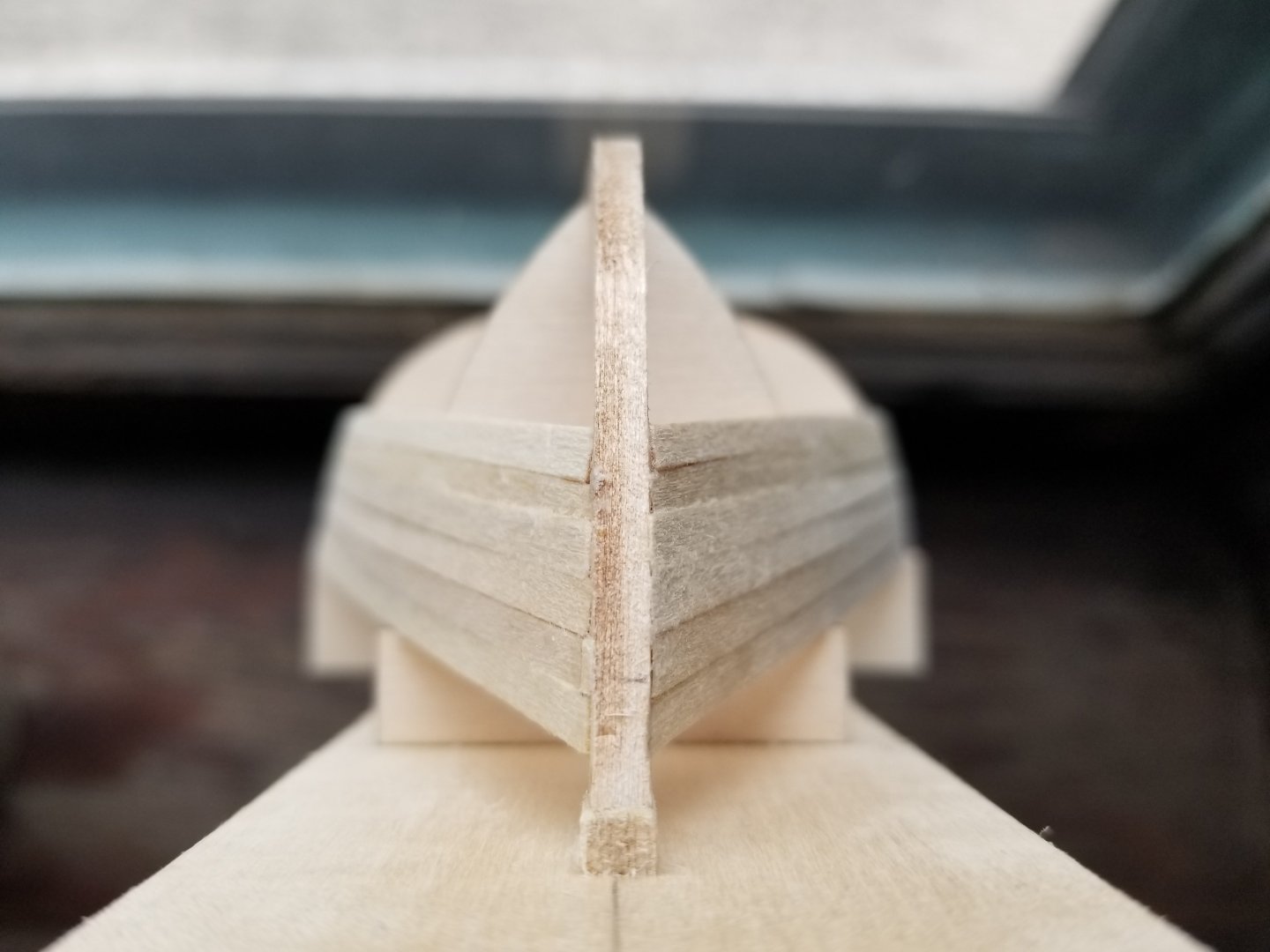

The garboard strake is on! I marked out the wale and the location of the garboard's top edge with chart tape. It needed a little adjustment after these photos, but not much. Then I removed the tape that was protecting the stem and keel. In the future I should use actual masking tape, scotch tape didn't do a great job of withstanding accidentally sanding and tended to rip rather than to come off in one piece. I marked out the garboard strake, starting with the aft plank, on tamiya masking tape as per the instructions. The sawtooth aft was a bit exaggerated, and the plank took some sanding to finalize the shape. Although the instructions don't say to soak the plank to bend it, I did it anyway to reduce the stresses of twisting it so much. Then I glued it in place, and repeated the process for the fore plank. As can be seen, the aft plank turned out ok. The rabbet was perhaps a hair too shallow. As for the fore plank, I think it's low enough at the bow to avoid the "smiley-face" problem. It also didn't sit well at the bow rabbet, as it approached it at a shallow angle. I'm debating whether to try to remove it to sand down the inner side of the rabbet or something so that it sits better. Overall, though, I'm excited to finally be making planks. Fairing the hull took a lot longer than I had anticipated.

- 23 replies

-

- half hull planking project

- half hull

-

(and 1 more)

Tagged with:

-

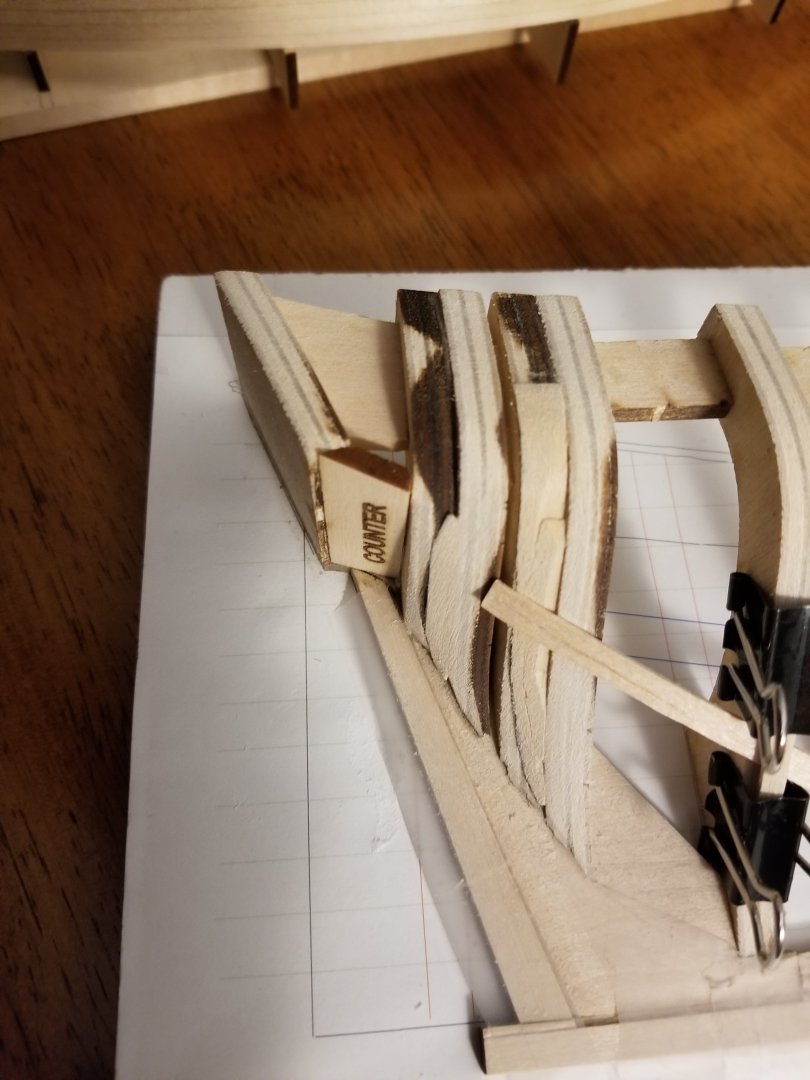

Forgot to mention: I've also reshaped the counter. As far as I can tell, something like this should work. Although now I should probably fair the aft edge of the H frame a bit more....

- 23 replies

-

- half hull planking project

- half hull

-

(and 1 more)

Tagged with:

-

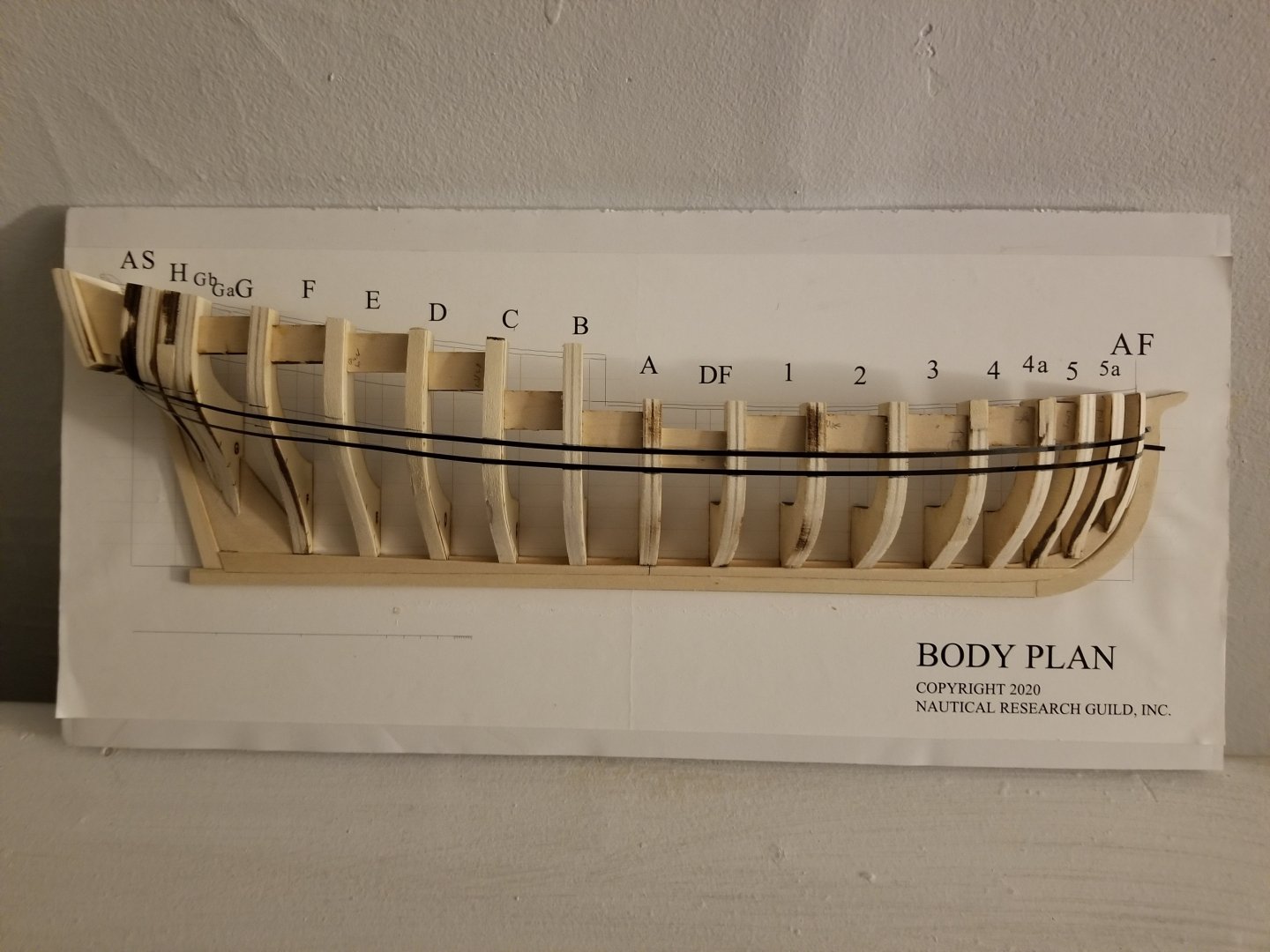

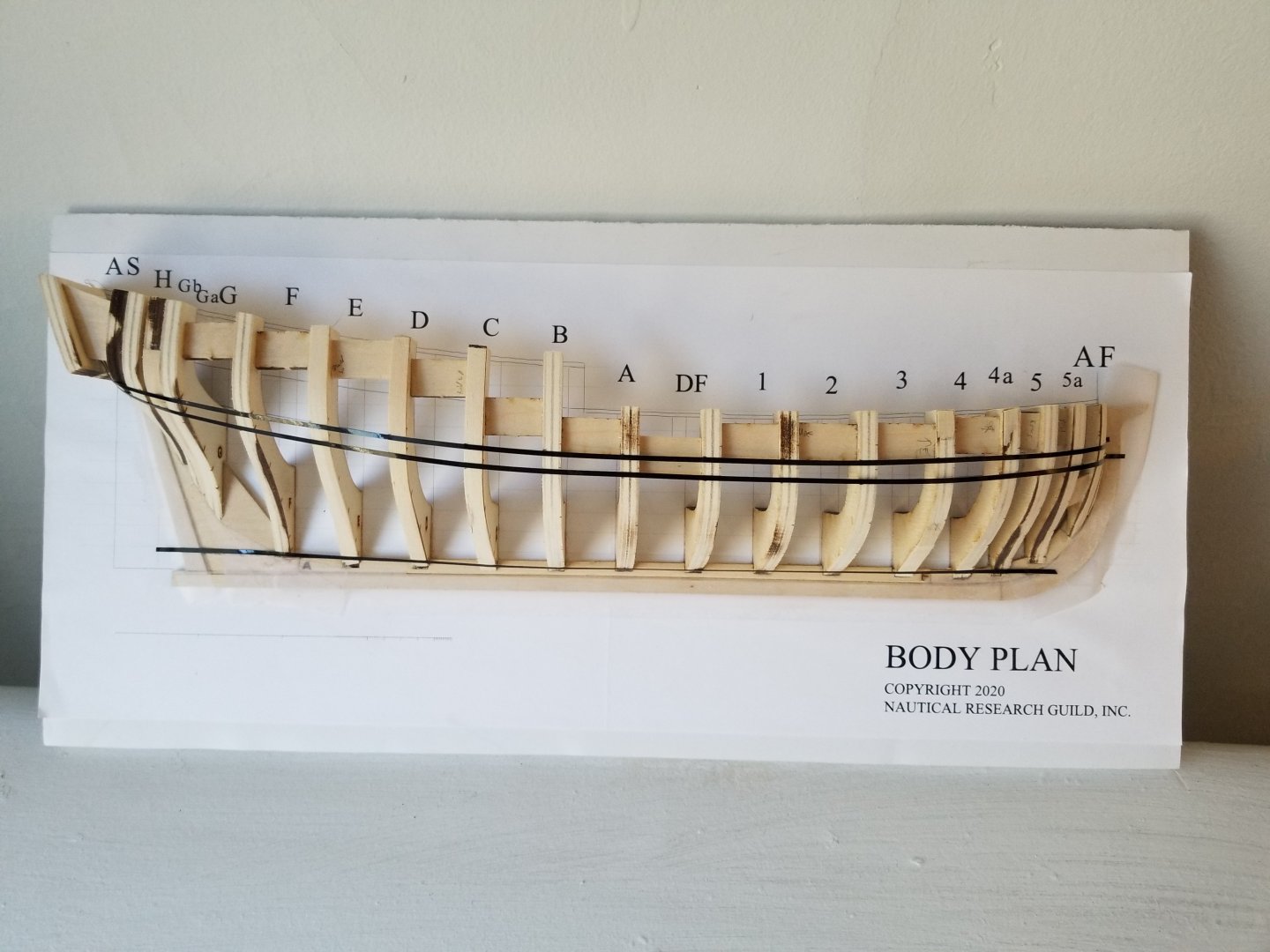

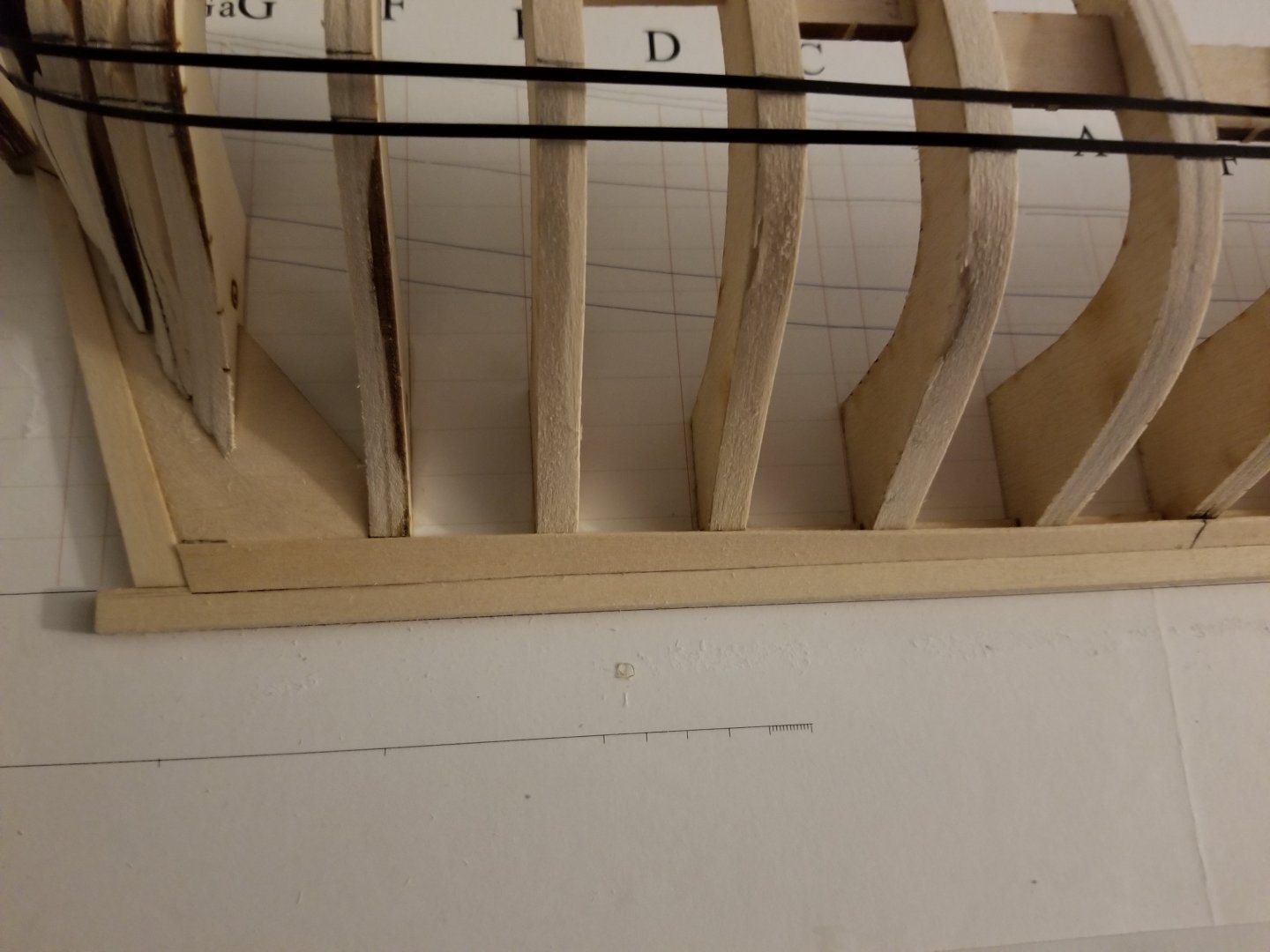

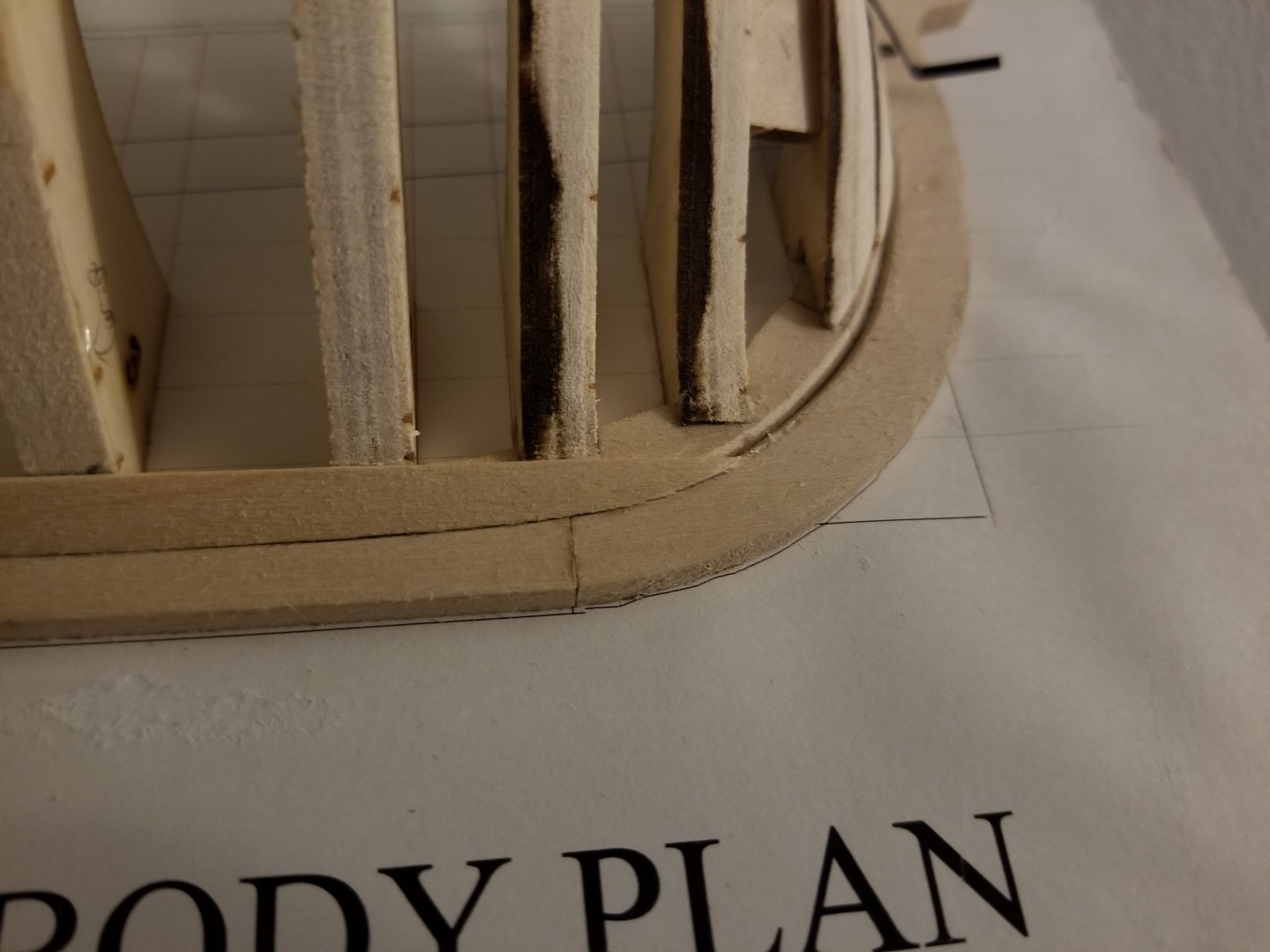

I think it's finally faired, but I'm still not totally sure on the stern. As can be seen, the bow now takes a smooth curve: I've faired the stern more and I think it's looking better, but I still have to admit that I have a hard time understanding what it should look like. This, for instance, would be for a strake that ends against the counter, near the wale. I'm not sure if it's still bending too much upward at the stern. There's still a bit of a bend like that further down for planks that would end at the rabbet, as well: Do I still need to take more off? At this point I've sanded so much that I'm worried about taking too much off, but I still can't figure out if this is fair or not. Any advice would be appreciated!

- 23 replies

-

- half hull planking project

- half hull

-

(and 1 more)

Tagged with:

-

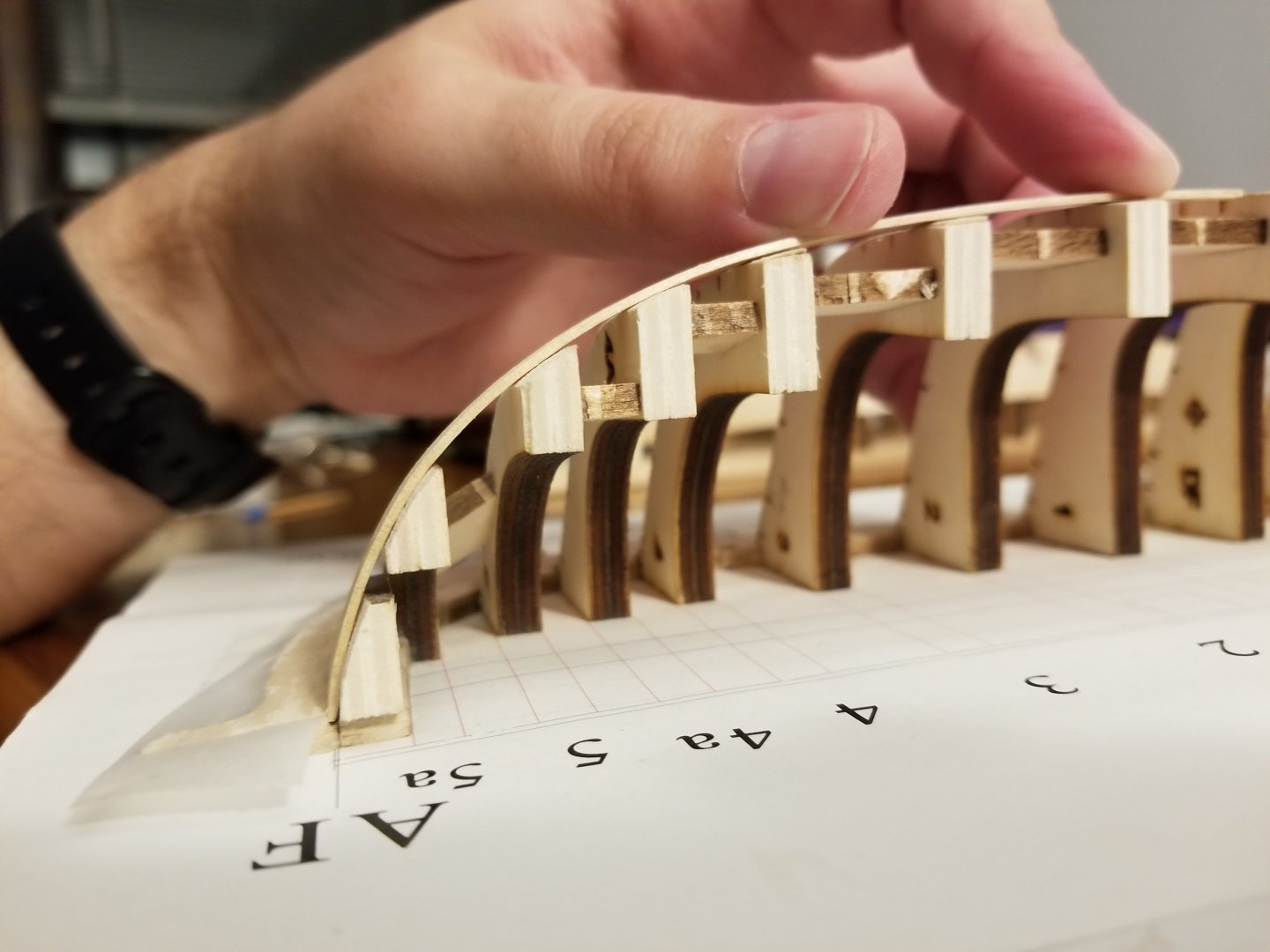

I think I'm nearly there with fairing? Toward the bow, adding some fillers on frames 3 and 4 was useful. Testing with a coffee stir-stick batten seems to suggest that I need to do just a little more on the lower part of the 5a and 5b frames right at the bow. At the stern, I ended up carving some filler pieces (as it was a very complicated curve) to fill some of the major gaps around frames. As can be seen, there's now a lot more surface area for the planking here. However, I'm not sure if I need to fair this area significantly more? I'm having a hard time visualizing how the planks will transition into the rabbet. It seems like a very complex series of curves in all directions in this area, and I'm having a hard time visualizing it from photos elsewhere.(Test with coffee stir stick below.)

- 23 replies

-

- half hull planking project

- half hull

-

(and 1 more)

Tagged with:

-

As can be seen, I was able to correct the unevenness at one of the stems by paying more attention to shaping the planks. Although one plank is wider at the stem than its pair on the other side of the hull, this discrepancy shouldn't be noticeable once the hull is sanded and painted. As I continue, I'll pay more attention to making sure the planks are an even width as I taper them. I recently got a mini plane, and I'm looking forward to using it to taper the planks.

-

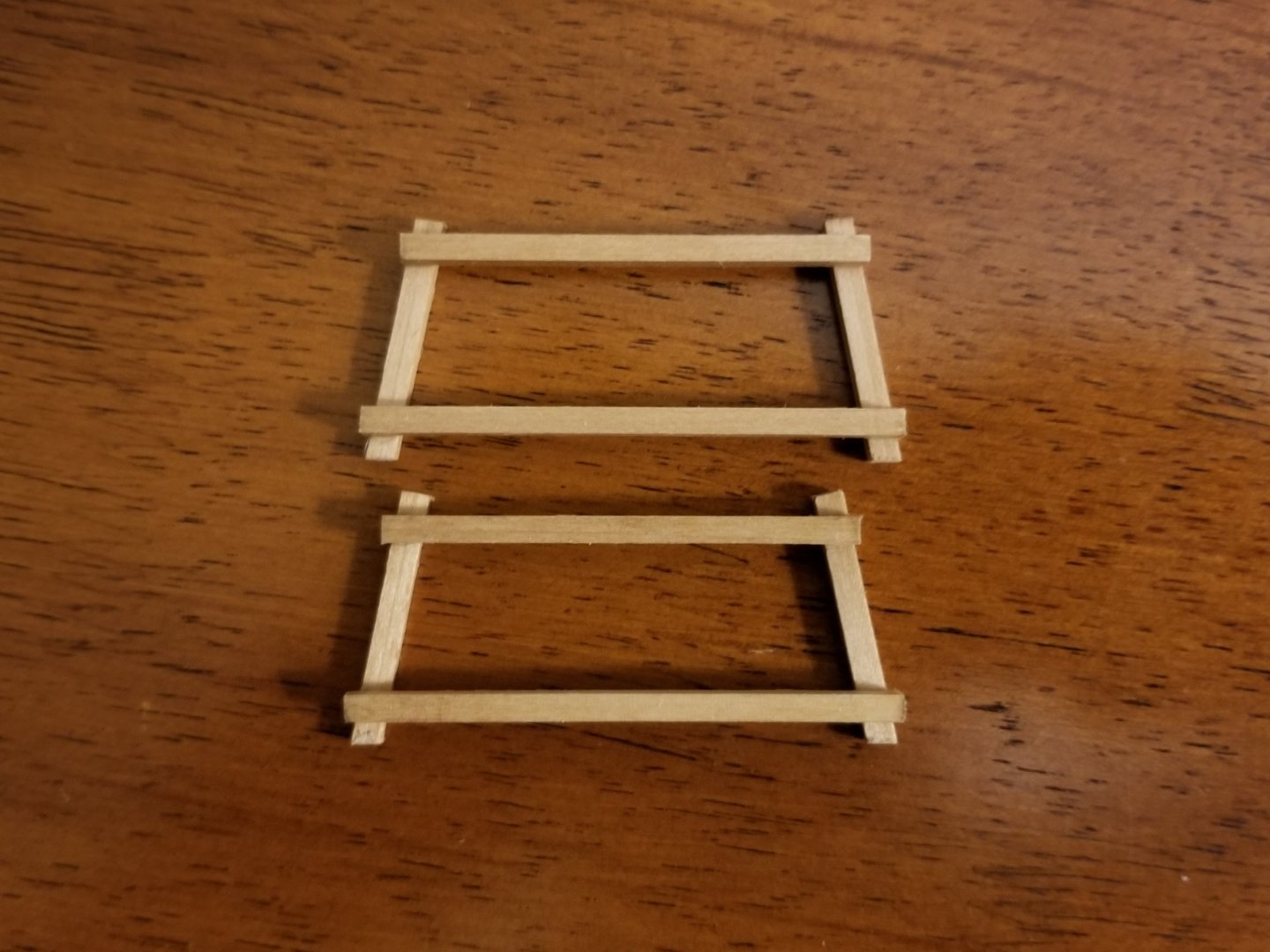

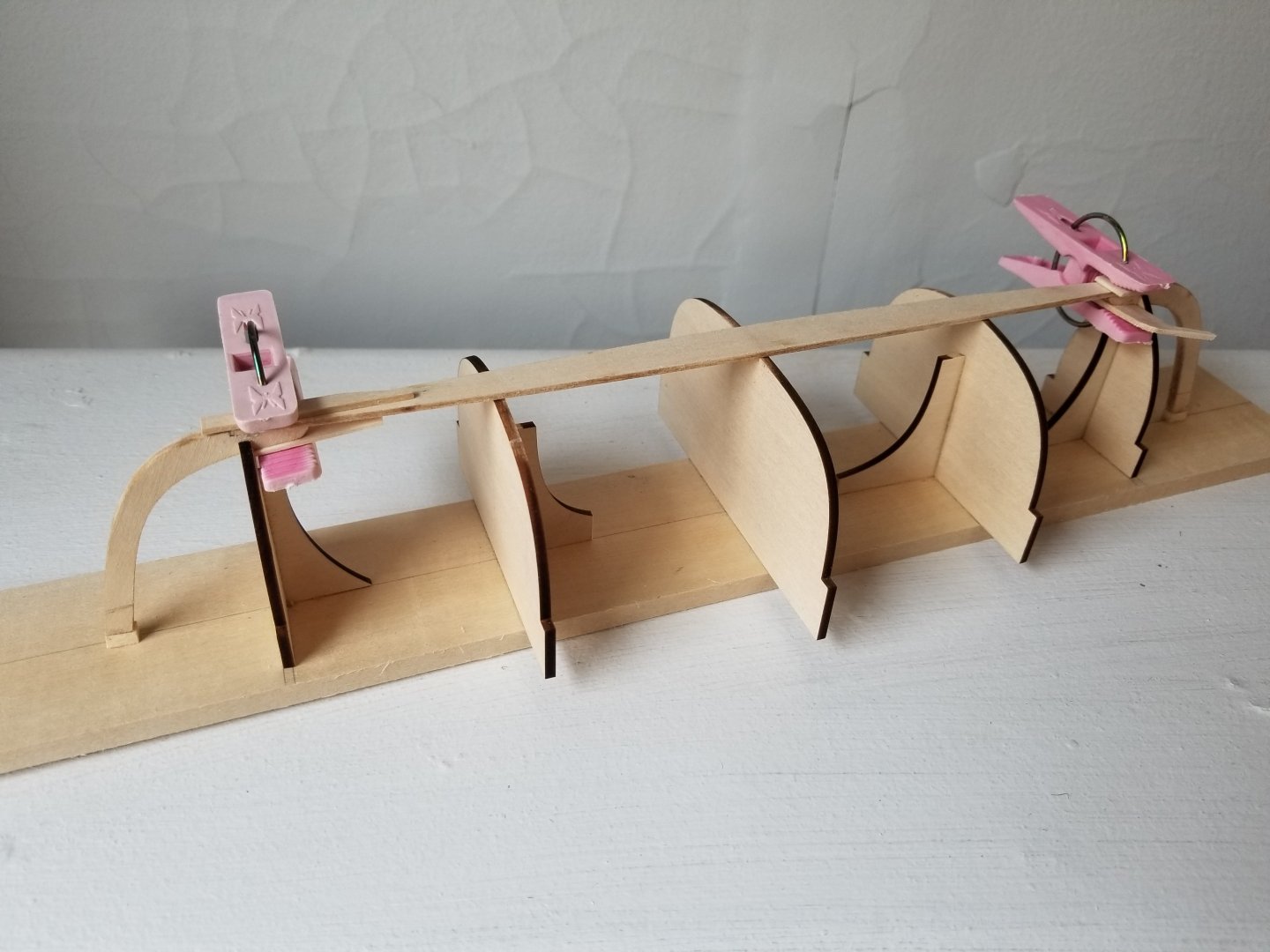

Progress has been very slow, but I finally got started on making the upper layer of thatching. It's still tedious work, but I think I'm getting better at it. I've certainly had a lot of practice! This time I'm making both at once, which is a faster, although it's easy to get the strings crossed. I've also begun work on the stand. I felt like the stand for the dory and the Cargo Canoa looked a little heavy, so I thought I would do something a little less obtrusive out of 1/8-inch square basswood strips, which I've stained to match the hull parts. I still need to connect them, but I was able to test the base. (Please ignore the mess all over the table). I'm not sure how I like the stand, it might be too high, or maybe it will look better once a horizontal support joins the bow and stern stand pieces. More and more I'm finding that I like the look of a more minimalist stand, like a bit of brass rod that locks into a slot in the keel. Unfortunately, that would be very difficult to make in this case, due to the lack of a keel. Any holes I drill in the bottom go into just 1/16‐inch thick basswood, after which there's a roughly 1/16‐inch gap, then the floor planking. Finally, I should mention that this build's time to completion has been extended again. It now seems likely that I'll be moving internationally over the summer, by flight rather than car. It will be very difficult to pack the Canoa into a suitcase once it's fully rigged, but it's quite portable as long as it's just a bare hull. So, while I'm hoping to build many of its individual parts, I'm probably going to have to leave the rancho and mast/sail/rigging off for now. (In order to actually be able to finish a model that will be portable when complete, I've started the Midwest Maine Peapod kit, which is fun so far.)

- 163 replies

-

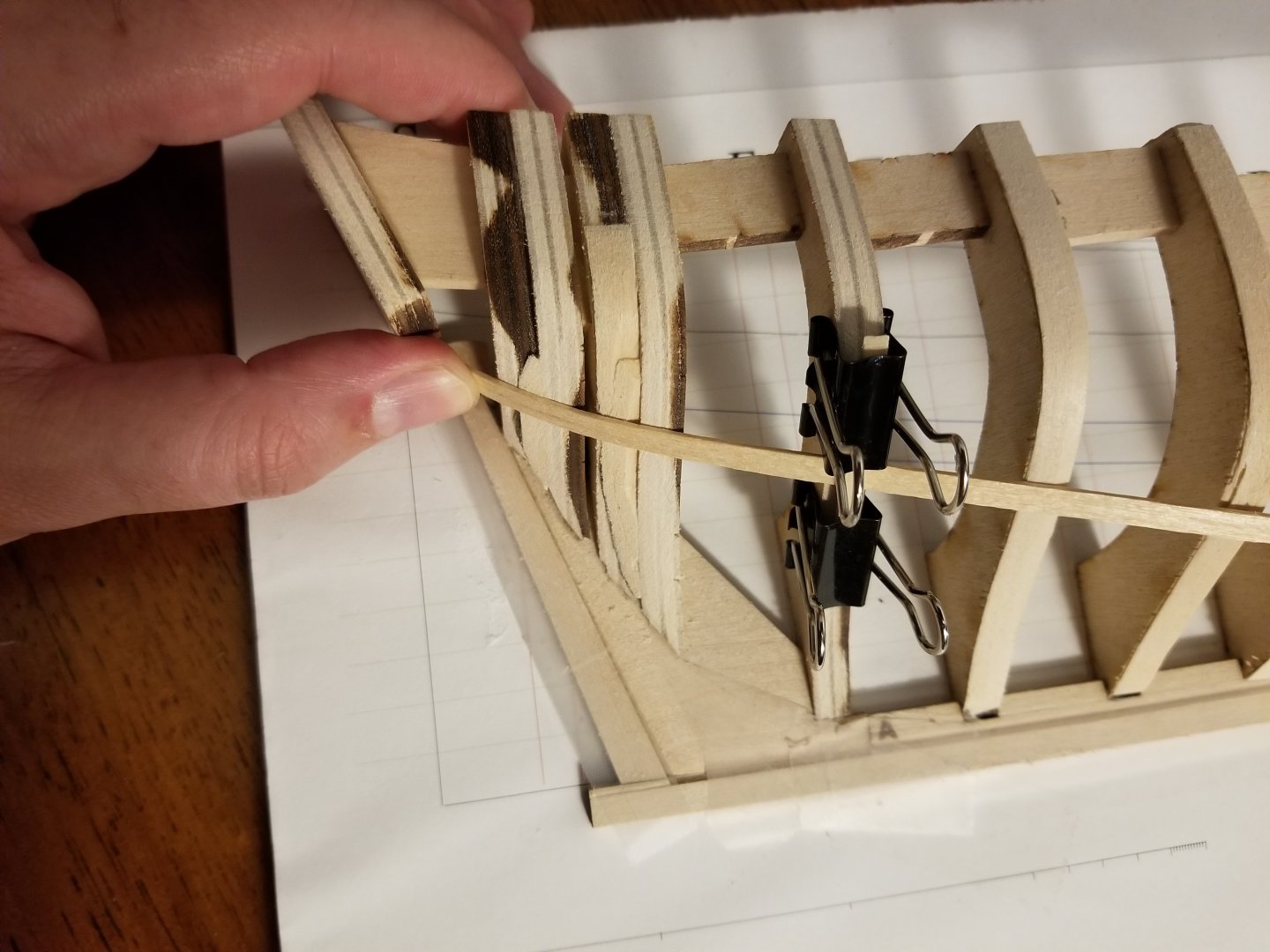

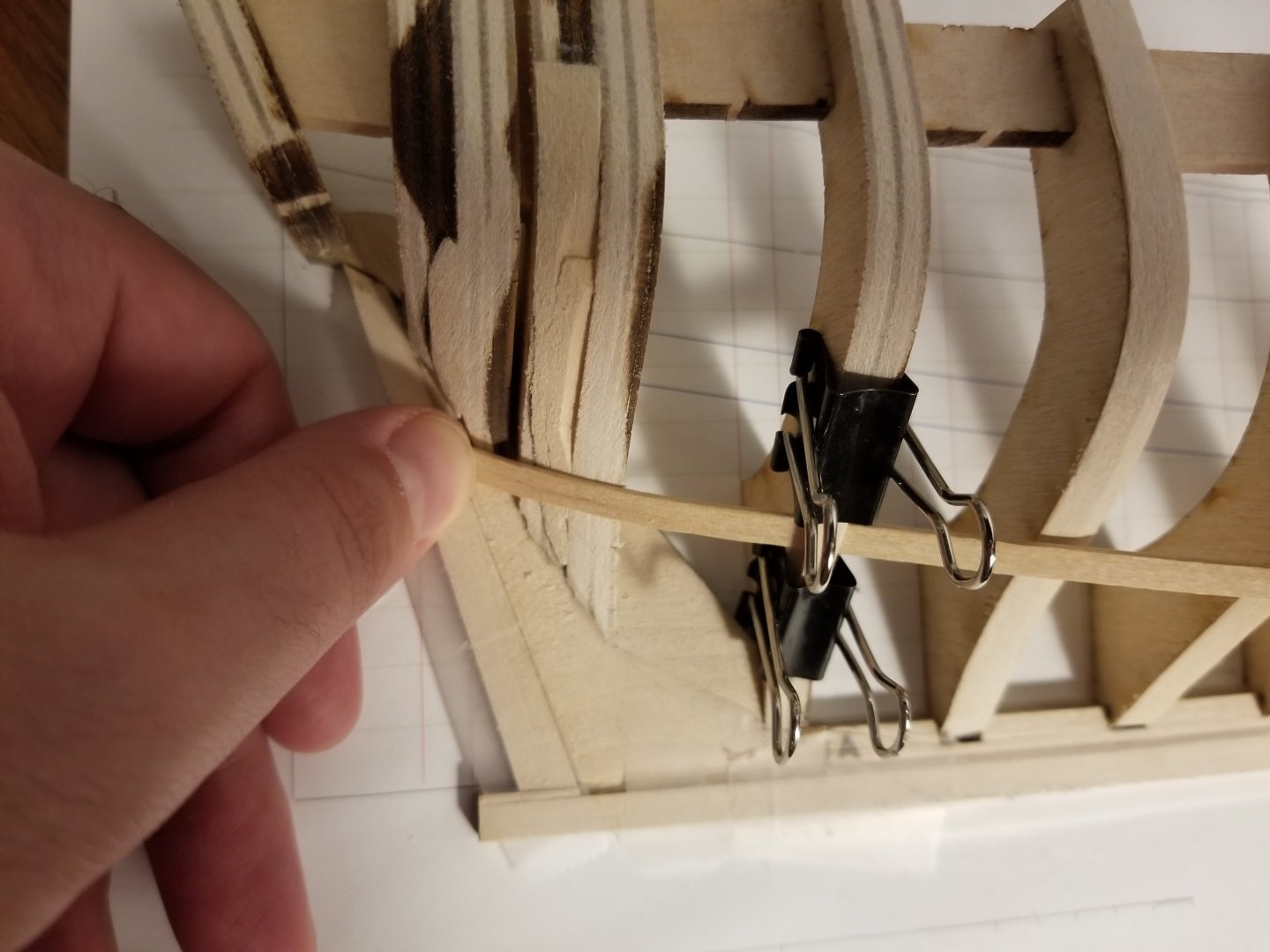

A bit more progress on the planking. I'm bending each plank with water and heat and allowing it to dry in shape before gluing, which should help keep the hull from springing shut once it's taken off the formers but means that I can only do a pair of planks or so per day. Lacking a rabbet, there's been some variation in where the planks end on the stems. I don't think it will be a problem once thinks are sanded and painted, though. Thankfully the 1/16-thick planks should be able to withstand a bit of aggressive sanding, which seems to be the only way to make this strip planking method work. Although it's difficult to see, I began tapering the planks after the fourth strake. My plan is that the first strake will be covered by the rub rail, and there will be a stripe of paint below that, so I am hoping to use the strakes to help guide making an even paint strip. One issue that I've run into is that the planking strips aren't totally consistent. Some are slightly narrower or wider than others. Unfortunately, as a result my planking runs are now slightly uneven at one stem. I'm trying to correct the issue by better shaping the next strake. In any case, another set of planks is now drying overnight and will be glued tomorrow. Clamping this hull has definitely been a bit tricky!

-

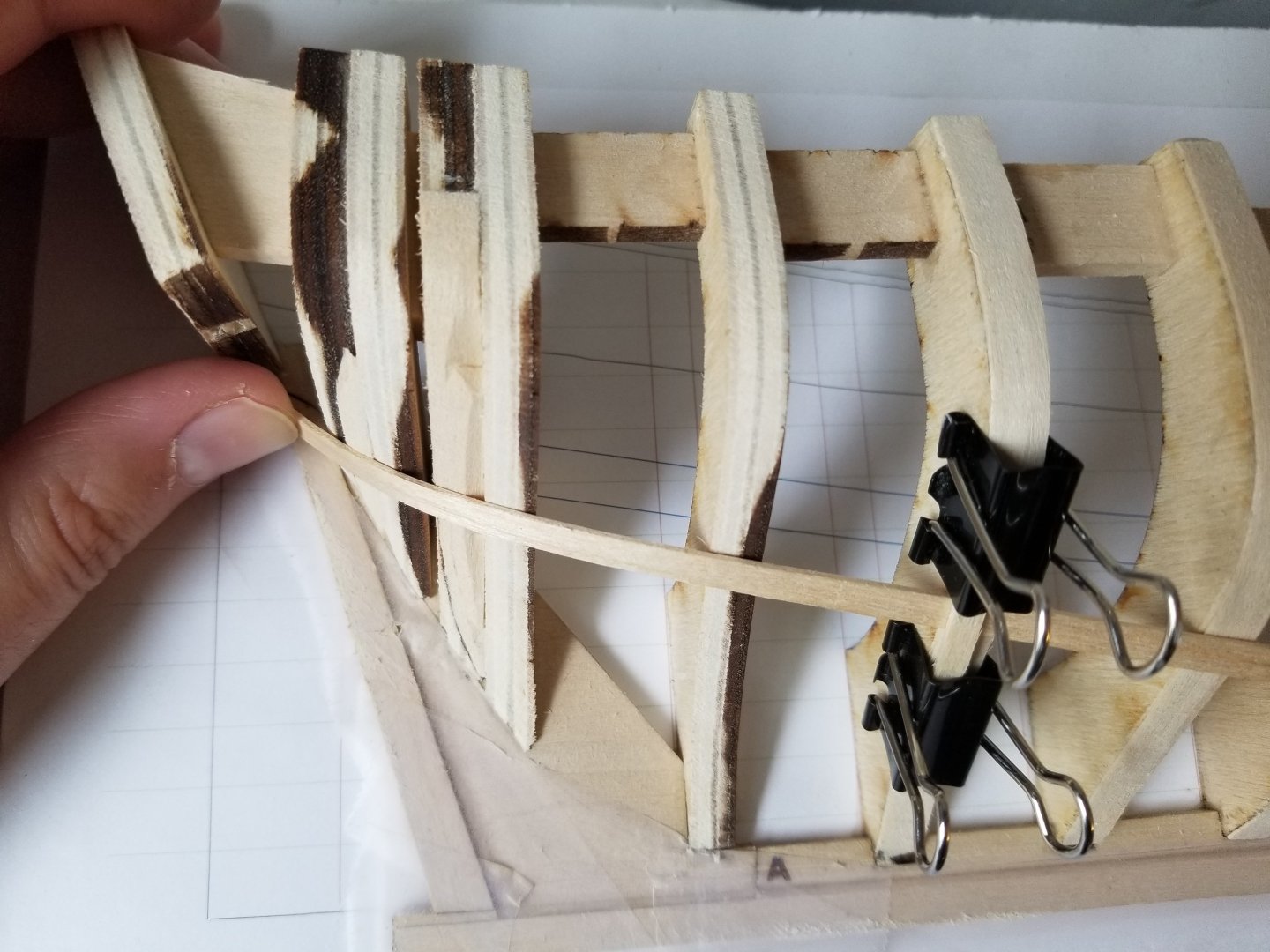

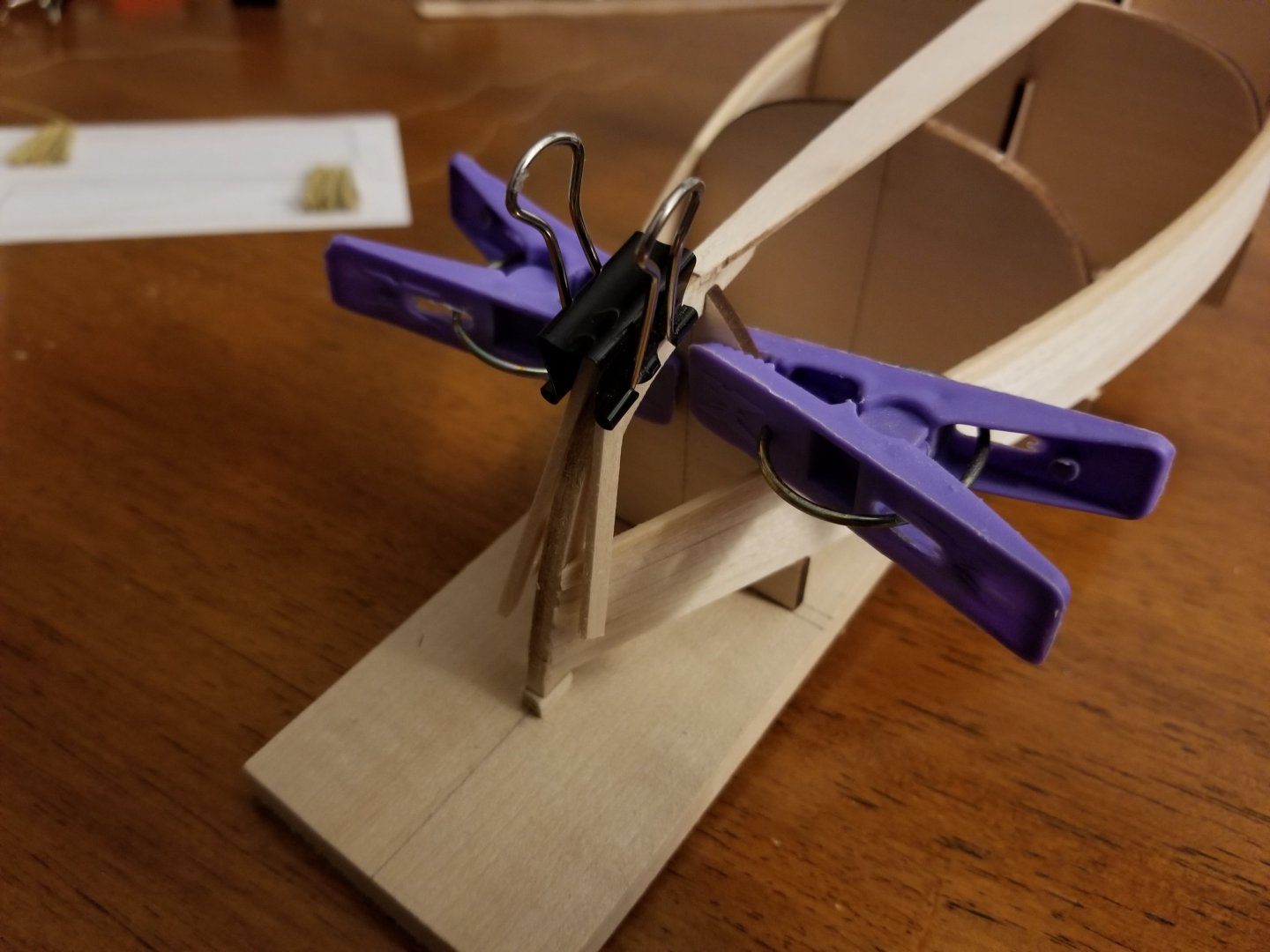

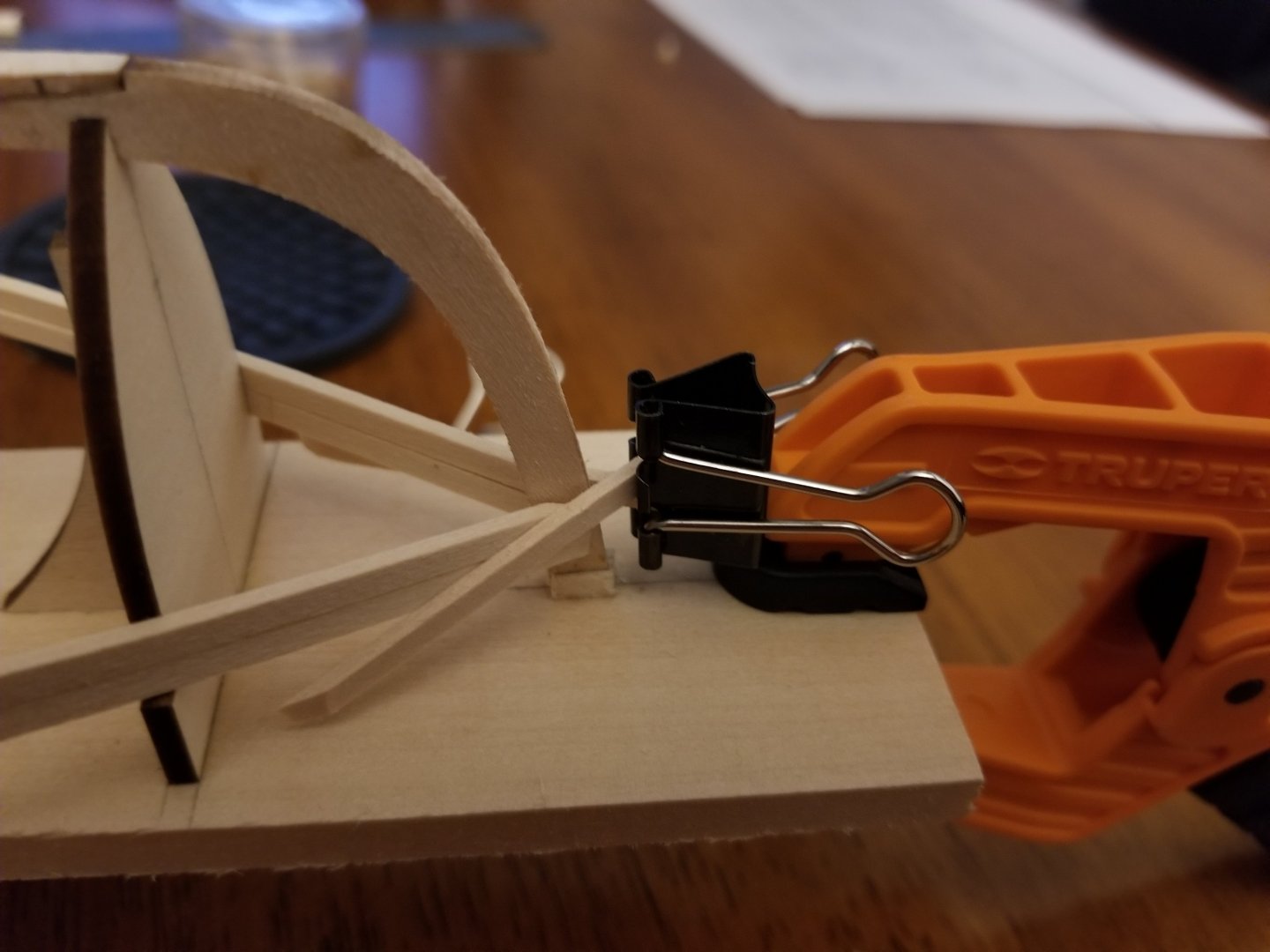

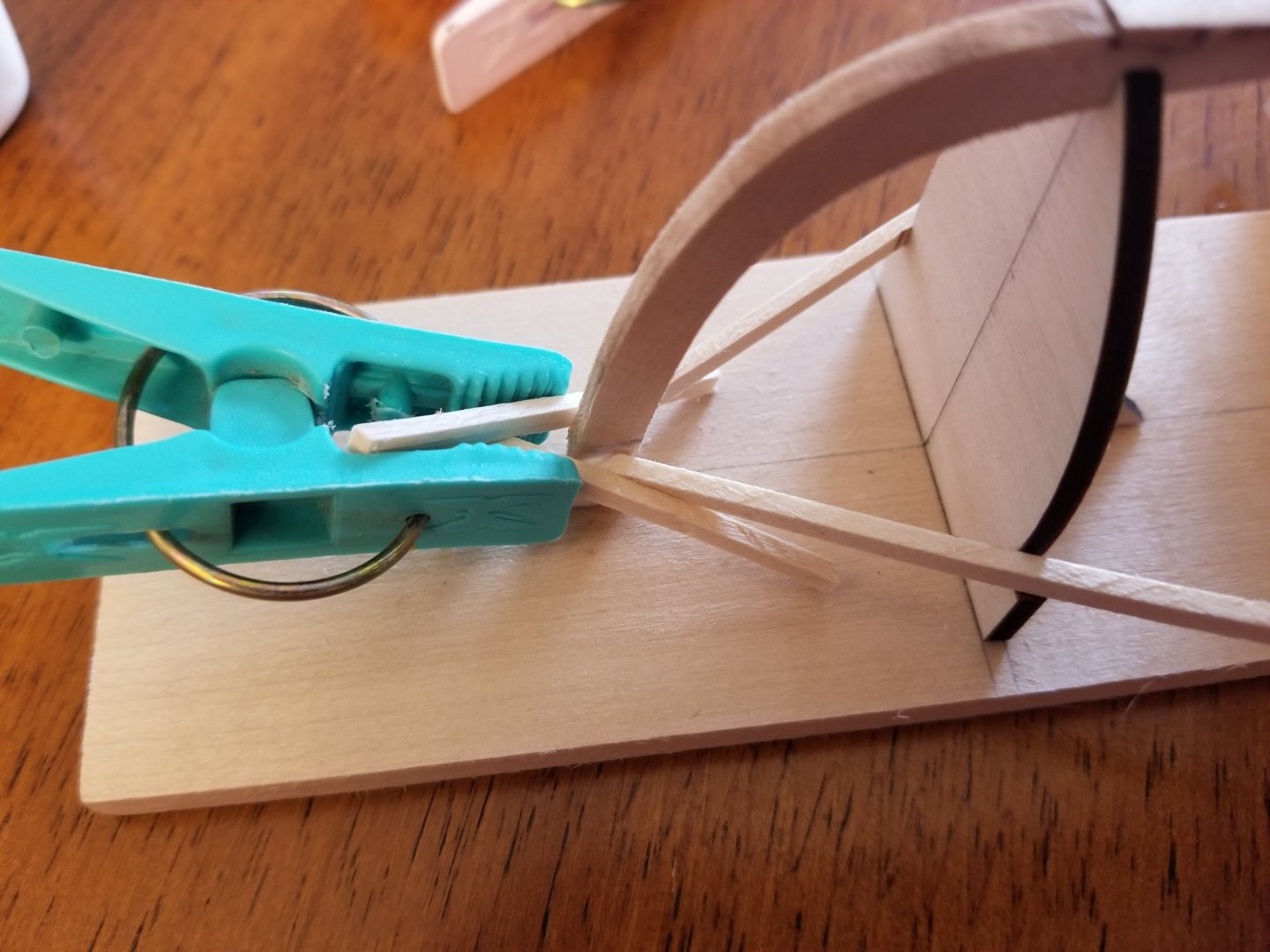

Strip planking the hull has been fun so far, although I think it's going to become more complicated soon as I get closer to the keel. The strip-planked hull starts at the wales and then moves in toward the keel. Some other logs noted that the hull tends to squeeze shut once it's pulled off the formers. To mitigate that, I've been bending the strips by soaking, heating, and letting them dry in place. Slow, but nothing too bad. It's great to start getting a sense of the hull shape, even with very little planked. I've been trying to do both sides at the same time. It's working ok so far, but definitely requires some creative clamping. One of my solutions is seen below: That turned out to be a pretty delicate balancing act, though. Many times, the clamp assembly wants to spring back off the hull. Using a large clamp to hold it in place has helped, although it will be harder to do the further up I go: I somehow cut one of the strips slightly too short, and didn't notice until everything had dried. As the strip is glued all along the length of the other strip, it was still held securely in place, but there was a slight gap. I was able to add a bit of scrap wood to fill the gap. It doesn't look great now, but should be smooth once sanded and painted: My plan is to do the first three or four strips without additional shaping (besides slightly beveling the edge). Then, I'll start narrowing the ends a bit.

-

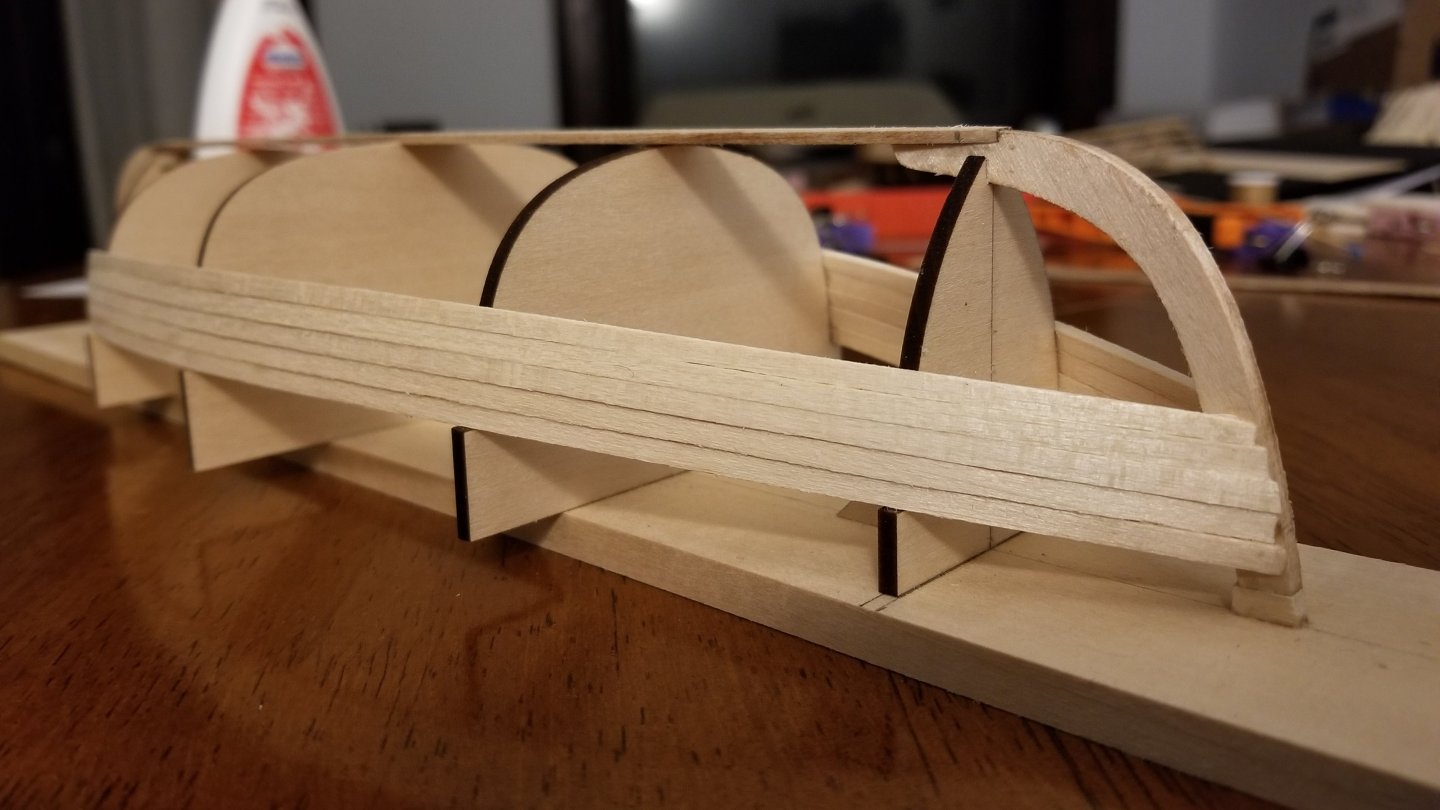

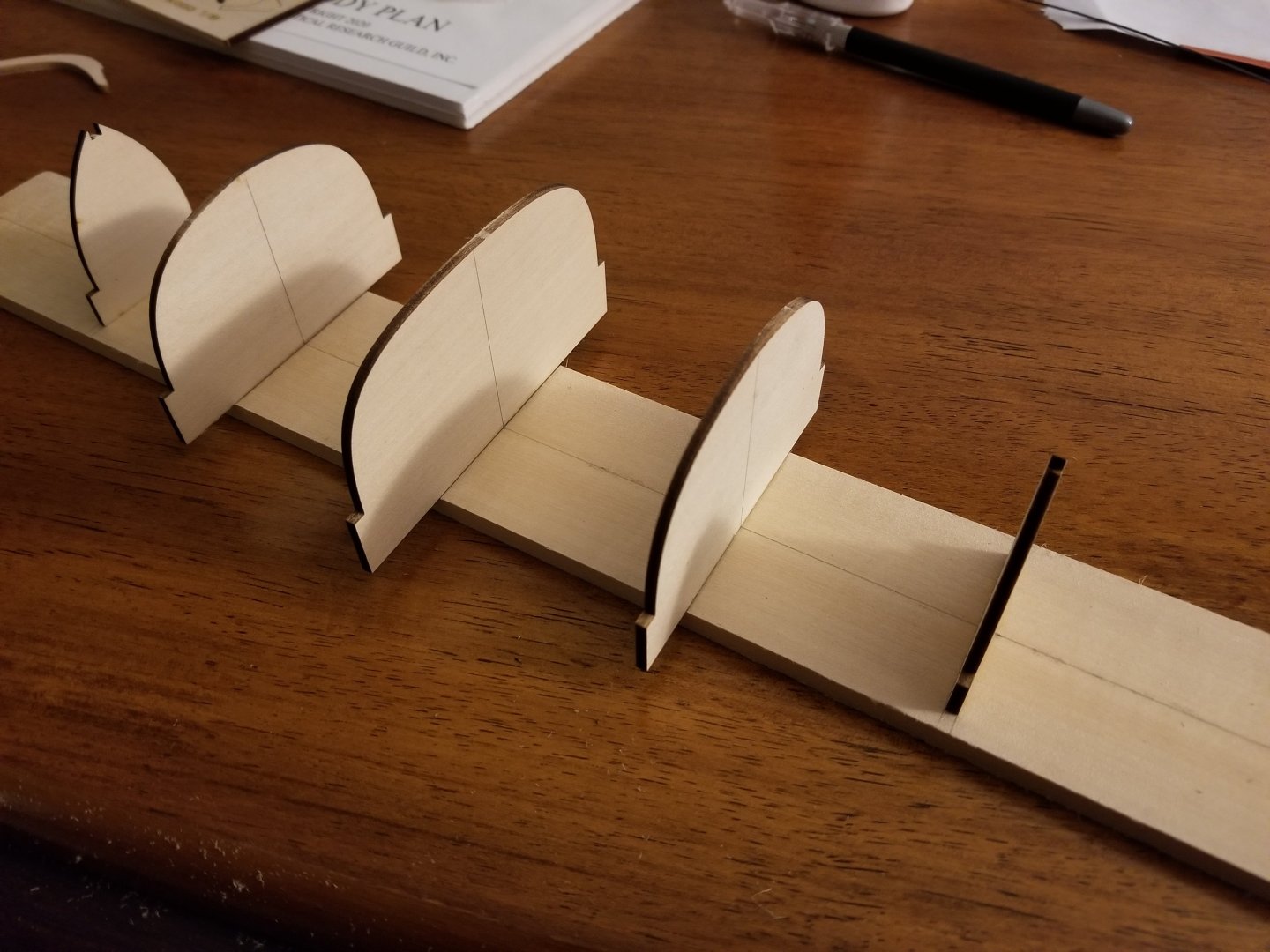

My other builds are going through some doldrums at the moment as I'm working on very tedious parts, so I felt like starting a new build. I thought that I should make some progress on the stash of kits that I've accumulated--the Model Shipways Lobster Smack, Midwest Peapod, Corel Sloup, and Disar Jábega. I limited myself to rowing vessels, given that it looks like I'll be doing a big move this year and it would be complicated to pack something with sails, so I was left with the Peapod and the Jábega. I really wanted to like the latter. Seeing Spanish fishing boats, including a Jábega, in the Barcelona Maritime Museum was what got me interested in picking up modeling. But Disar's kit leaves a lot to be desired. From reputation, I expected some issues and simplifications, but I hadn't realized that the model's hull shape barely even looks like a jábega, being weirdly squat instead of sleek. So, I decided on the Peapod. It's a very straightforward kit. The hull is built shell-first on a mold, with frames and other internal pieces added afterward. I didn't take a picture out of the box, but the wood's quality is solid and the laser-cutting seems fine. You get a nice plan sheet and some fairly thorough instructions (although they're a bit skimpy on details on how to actually plank), a solid build board, several laser-cut formers and other parts, and a few bundles of sticks. Everything is basswood except for two mahogany strips for the rub rail. Although I enjoy doing research on the boats I'm building, I think other build logs have generally covered it for this one and have pointed to useful sources and the like. Basically, it's a small Maine workboat, notably used for lobstering but also for all manner of other work, as it has a seaworthy and capacious hull that rowed well. (Some were also sailed--I'm looking forward to robert952's kitbash to build a sailing peapod). The kit includes plans for a lobster trap, and even a tiny cast-metal lobster, so I may build it that way. But by now I've already made two lobster traps--which is a lot for someone who's allergic to shellfish!--so I may look into some other fishing activities to model intead. One thing I noticed is that the kit's construction method is not necessarily accurate. The kit's hull is strip-planked with a ton of narrow 1/8x1/16 inch basswood strips. Some modern peapods are indeed strip-planked, but historically they were either lapstrake or carvel-built using wider planks. I briefly toyed with converting the build to one of these styles by shaping my own planks, but the formers are very widely spaced, which would make it difficult to determine the shape of the strakes. So I decided to just go with the strip planking--the hull will be painted anyway, and existing build logs show that the result looks nice. There are a few build logs already that have been quite helpful in understanding the kit and some of its issues. Right off the bat, they pointed me toward the problem that the formers are very flimsily-attached to the building board. As can be seen, they're just edge-glued to the board, after you mark the centerlines and locations to get everything aligned. So, I added some supports cut from scrap. I think the curves add a nice almost art deco touch. The photo also shows my second deviation from the instructions. The instructions have you just glue the stem and sternpost to the keel plank. I did that, and then realized after that they weren't squared. I was wondering how to hold the posts vertical when I realized that I could just install them on the building board first, using the centered formers to hold the posts squared, and then could glue the keel plank in place on top. It took a bit of work to figure out the right location for the posts so the keel plank would fit the notches. I also had to prop the posts up on some 1/8‐inch scrap in order to get the posts to sit right. The other option would have been to remove a very large amount of material from the former notchs instead, but I decided to just add the scrap (althoughI still had to slightly widen and deepen the notches with a file). In any case, I was able to install the keel plank after marking the frame locations as per the plans. I noticed that the keel plank was hovering a little over the second and fourth formers, so I slid a piece of sandpaper under the central former to lightly sand it down. It worked well and didn't significantly change the former's shape. The next post will discuss the beginning of the planking process. All in all, this is shaping up to be an enjoyable, simple little build. (Knock on wood)

-

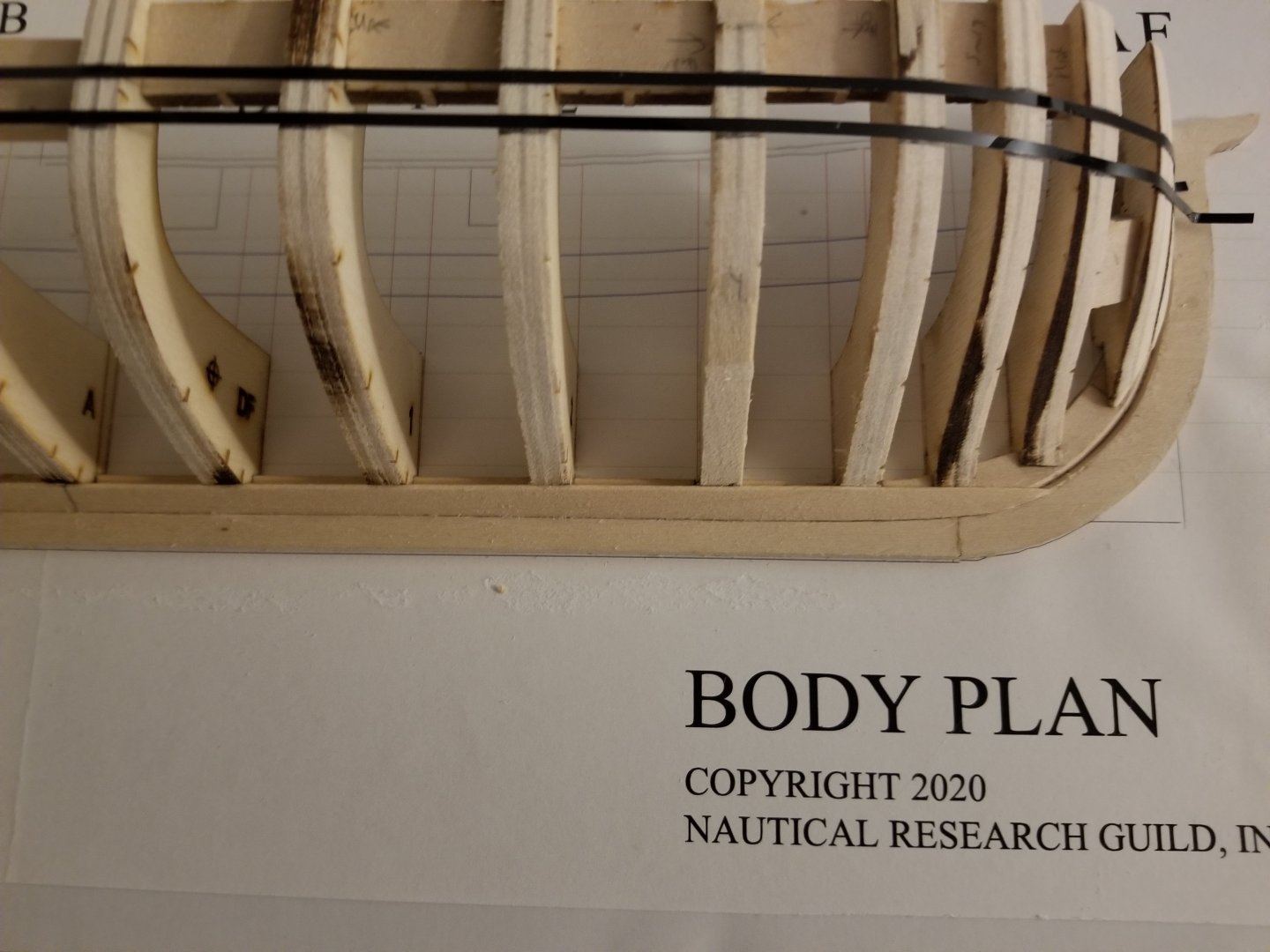

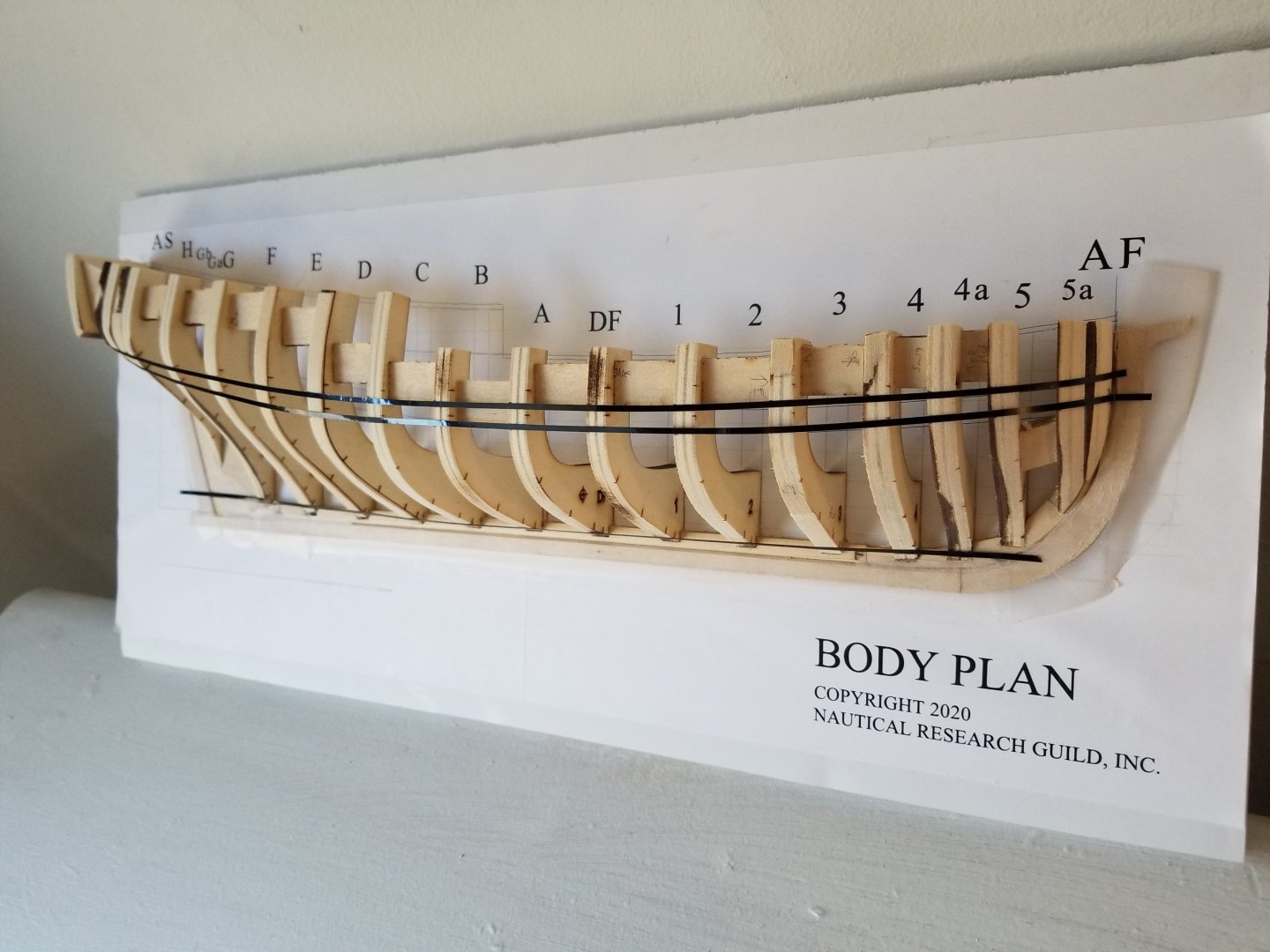

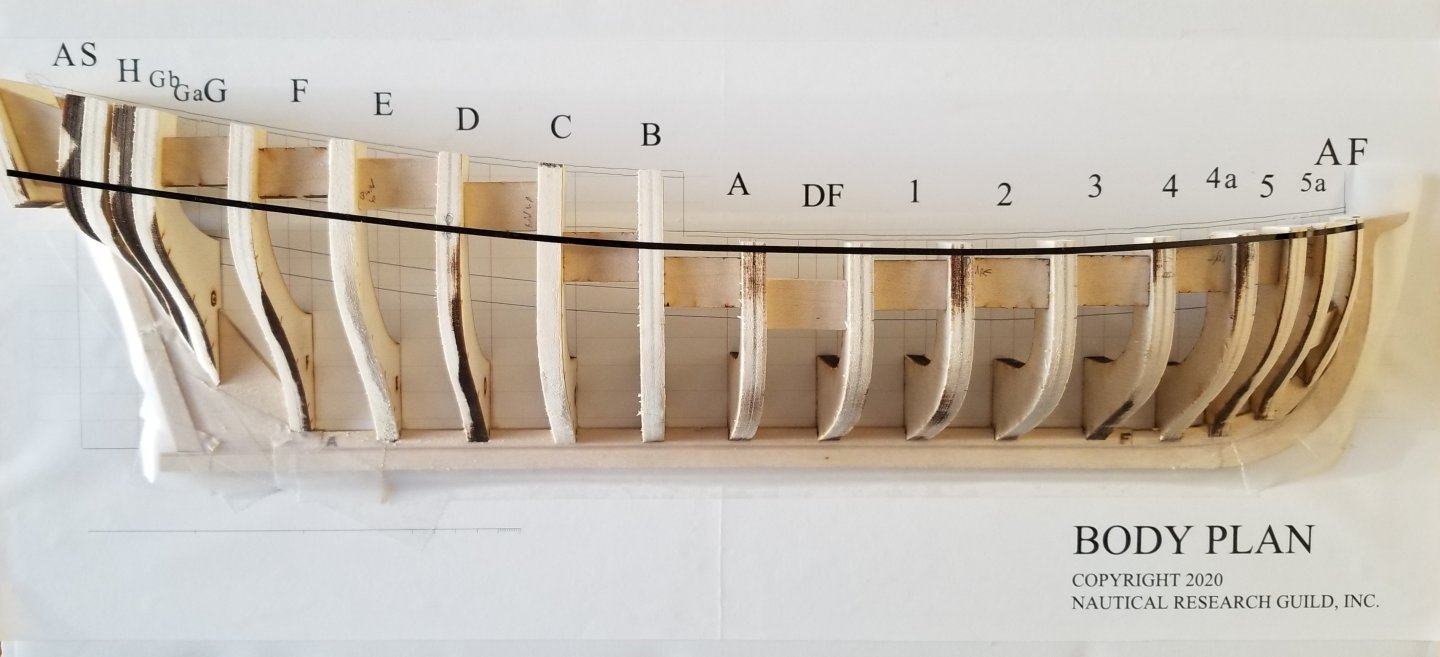

Slowly but surely, I'm getting closer to finishing the fairing. I've been barely able to work on it lately, but today I was able to grab a few moments and sand out on my balcony in the sun, so that I wasn't leaving dust in the apartment. I decided to use a bit of chart tape to check on the fairing. There are still some high spots and shims needed, but it's getting close. I'll either need to shim frame D or sand down frame C (to the right, which was already shimmed). At the bow, I initially thought I would need to shim frame 4 (and possibly 3, to its left). When I used the chart tape to check at other placements, though, I found that the real problem is that the upper part of frame 4a needs more sanding. I also decided to start shaping the counter to get a better grasp on the curves at the stern, although I still have a bit more sanding to do there. I beveled the edges and placed it, but I'm not sure what I'll need to do to get a better fit (besides sanding more, of course). The corner of the counter stands way out from the frames.

- 23 replies

-

- half hull planking project

- half hull

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.