-

Posts

236 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Desertanimal

-

First like! Haha Love it! Such a wonderful build. Truly amazing work.

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

Truly impressive work! So inspiring to look at! Thanks for sharing it.

- 419 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

Chairs! Let’s see your chairs.

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

I was thinking the same thing. But there are plenty on Amazon. -

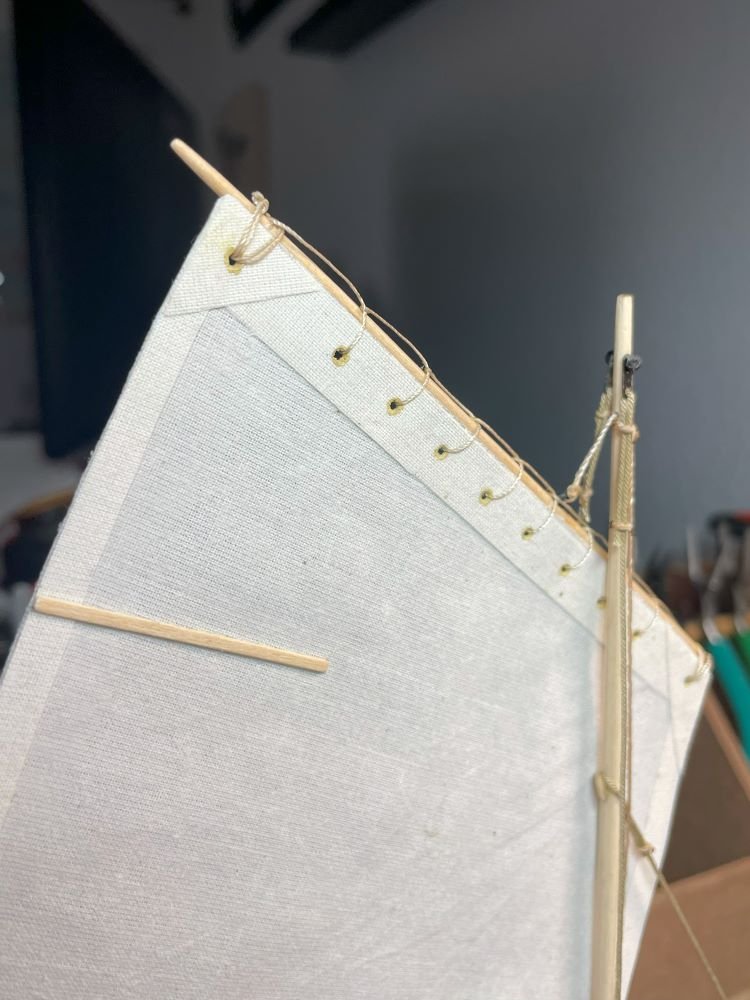

There has been progress on the pram. I have/had a concern with the sail. It seems too small for the boom and the gaff. You can see in the top pics how the corners line up with the associated hole or cleat. After much consternation and looking at the pictures in the instructions I decided to move parts and shorten the gaff and boom. Here are the results. The angle of the sheet is a little wonky. Not sure what was with all that. It looks to me that adjusting the sizes of the boom and gaff were the wrong move and making a larger sail would have been better but I didn't have sail material so that pushed my choice. I used some thin copper sheet for the chaffing pad on the mast. I rolled it around a paint brush handle to shape it and added a tiny bit of epoxy to attach it. Here is how I had to wrangle the rope to get them glued up. When you tie a half hitch it will loosen if there is no tension on it. Is that a function of nylon rope and is it less pronounced on cotton? I also had trouble cutting it close to the knot without it fraying. I used a soldering iron to burn off the little ends but that left blackened ends. (Angry face here). Trying a rope hank... I'll be making another one with the sheet. I've still got a little work to do. Some more weathering was going to try a little rust on the metal parts. Thanks for all that are following along. I'd love to hear some constructive criticism if you see something I can improve on. Chris

-

Chairs! Let’s see your chairs.

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

Where did you get that little four wheeled thing? I like that. -

Chairs! Let’s see your chairs.

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

I was actually thinking of the stool idea just today ! -

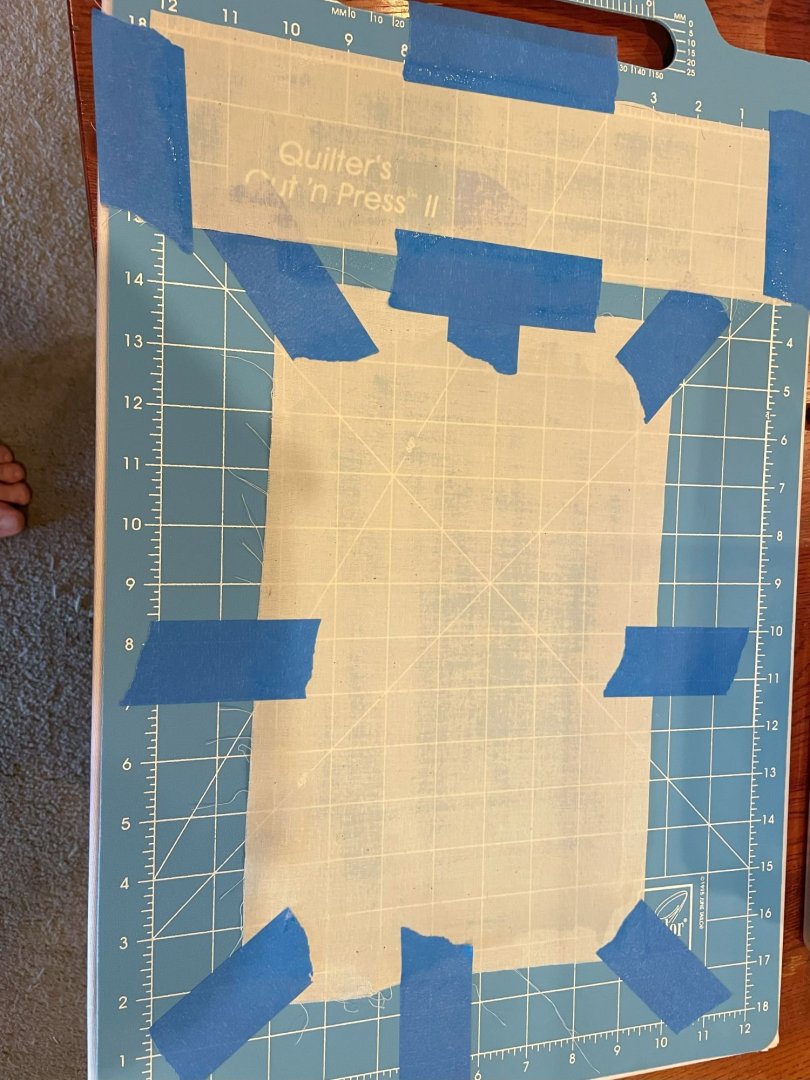

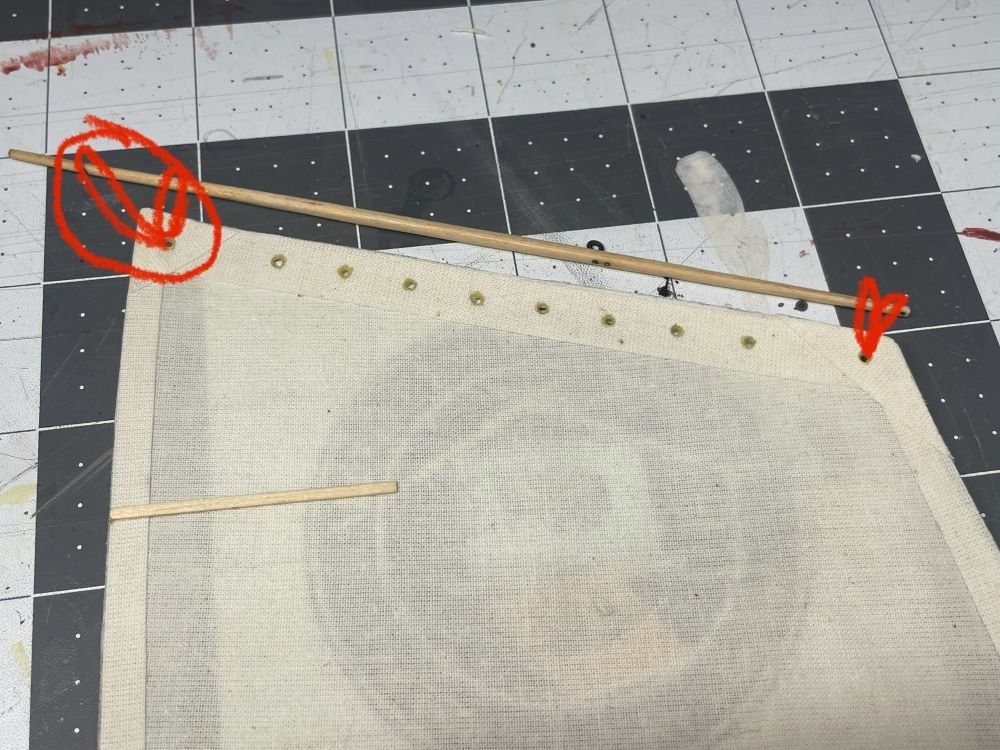

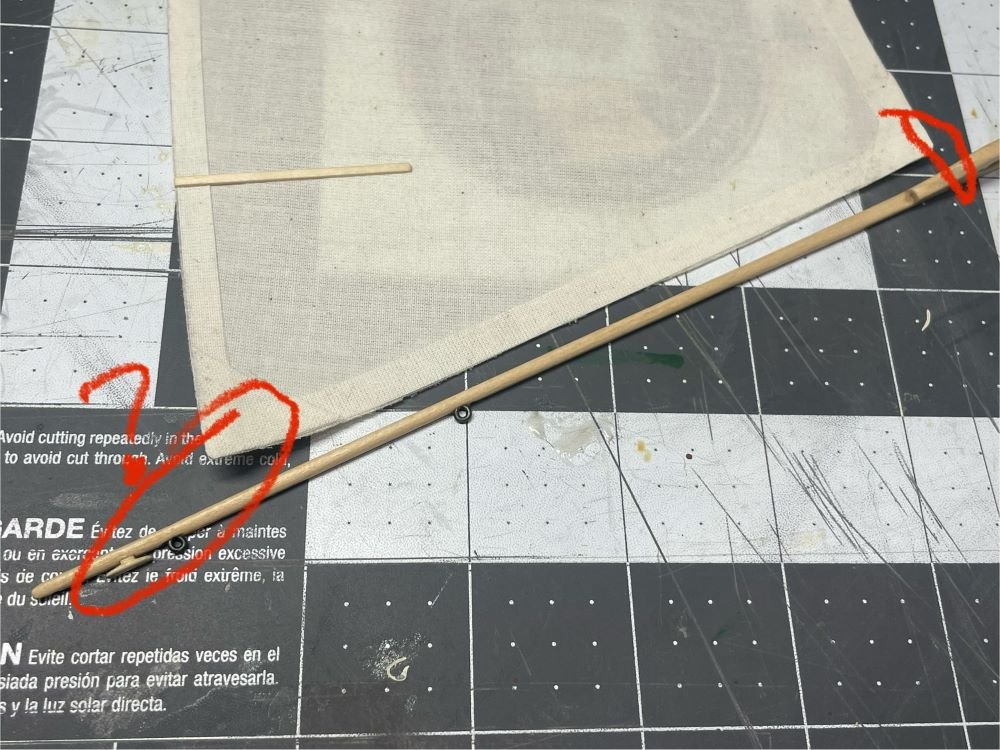

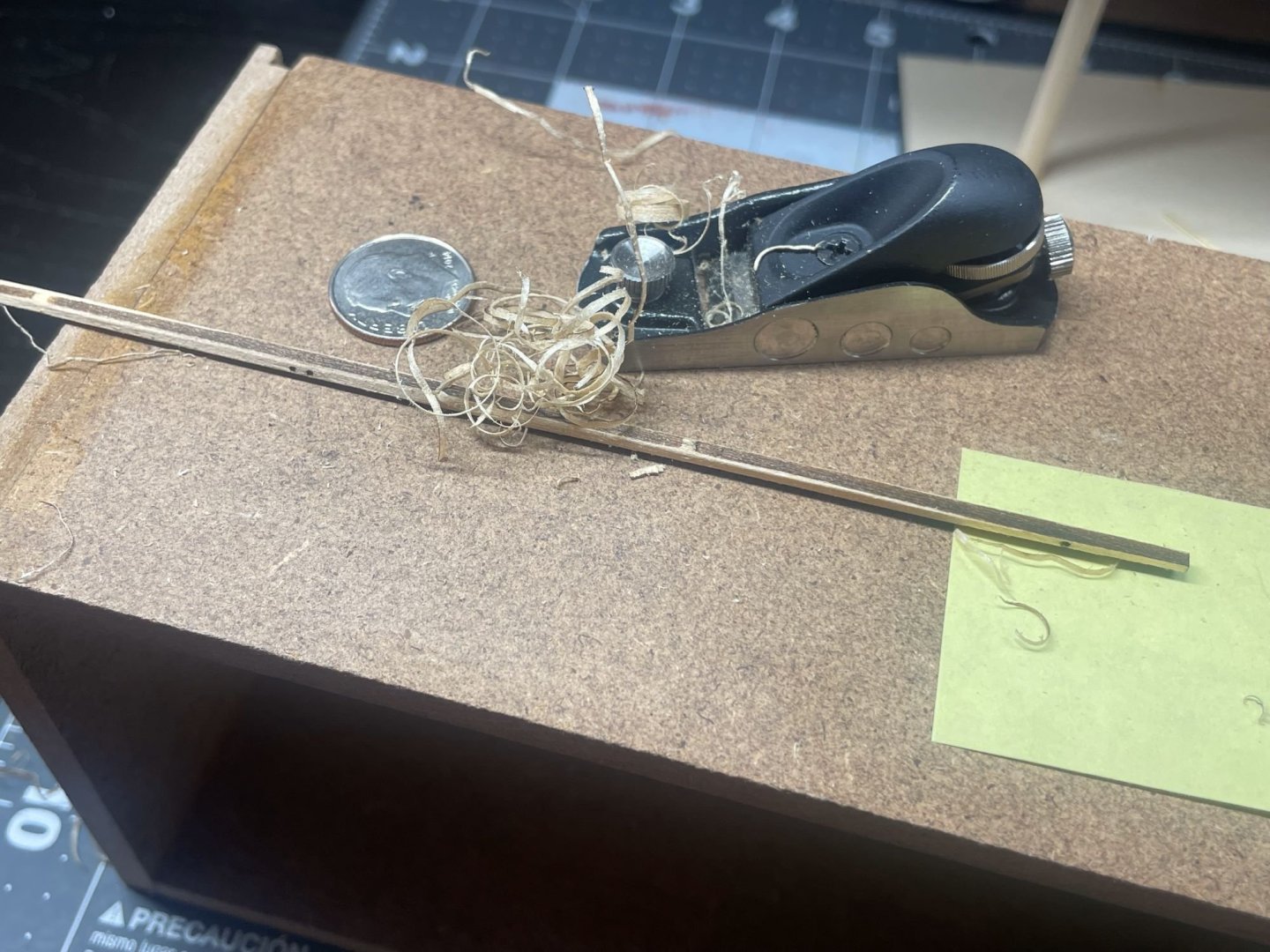

More progress, I got the painting of the white stuff figured out. I used Mr.Color primer and AK paint. I think they look good, maybe a little too shiny. Received my replacement block plane the other day. The first package came with the plane missing and the package obviously taped closed. Lee Valley replaced it with no issues but I hate that companies have to do that. I hate thieves. Anyway here's a picture planing the gaff. Some pictures of the other masts. (Are these all "masts" of some sort?) I made my own eyes with brass wire and blackened them. Also made an attempt to make a big bolt at the top of the mast. Started working on the sails. These are the pieces getting the glue treatment. I seem to remember the word "sizing" regarding the watery glue stuff. Where did I get that? I was considering adding some machine stitching to the sails but I kinda want this build done. So maybe on the next one. Thanks for checking in!! Chris

-

Chairs! Let’s see your chairs.

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

All nice chairs. Moonbug, that thing is a beast but I think out of my price range. At least what I’m willing to spend that kind of money on. I think I’ll be perusing Amazon to see what they’ve got. -

Chairs! Let’s see your chairs.

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

I hadn’t even thought of the term “drafting chair” ! Thanks guys! -

I’m curious what kind of chairs you all use at the workbench. My chair is so-so, I find I’m sitting forward quite a bit, like on the front edge. I don’t think I need to move around much so I don’t think I need wheels but I’m wondering if a stool type seat might be better. I’m also planning on modifying my desk so I have a higher work area like a watchmaker desk. I’d like some chair recommendations. Thanks!! Chris

-

You say it’s not the smoothest, but those planks look amazing.

- 65 replies

-

- Maine Peapod

- Midwest Products

-

(and 1 more)

Tagged with:

-

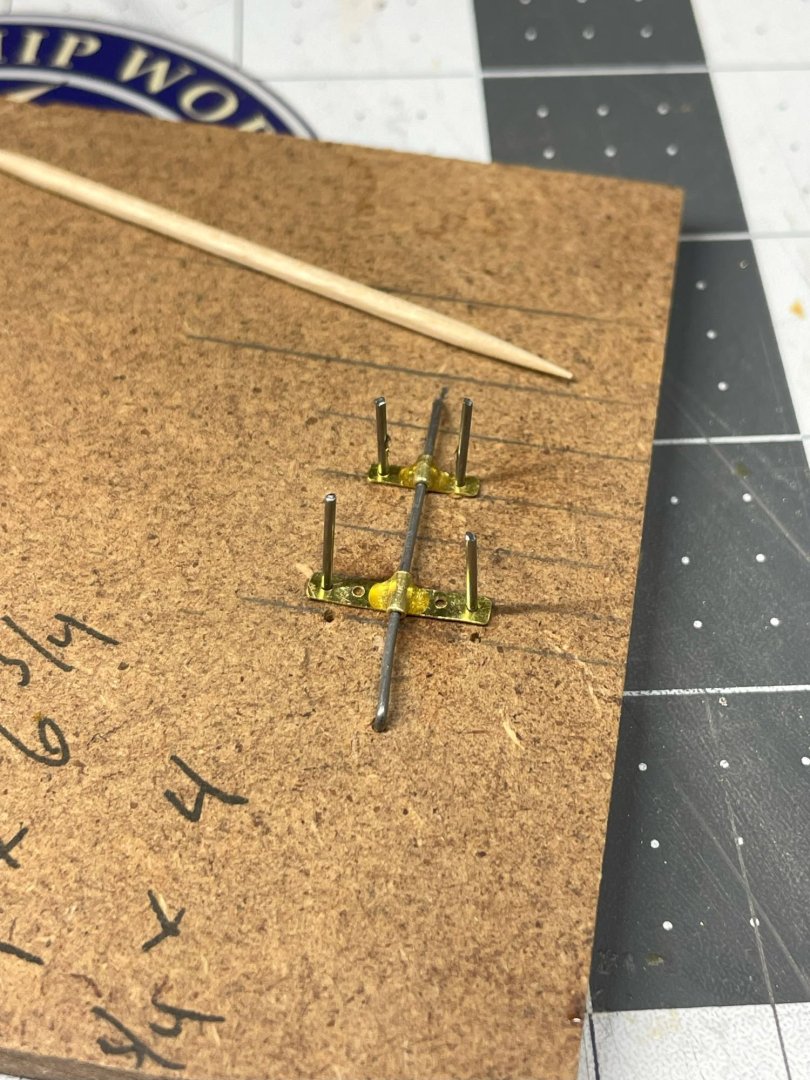

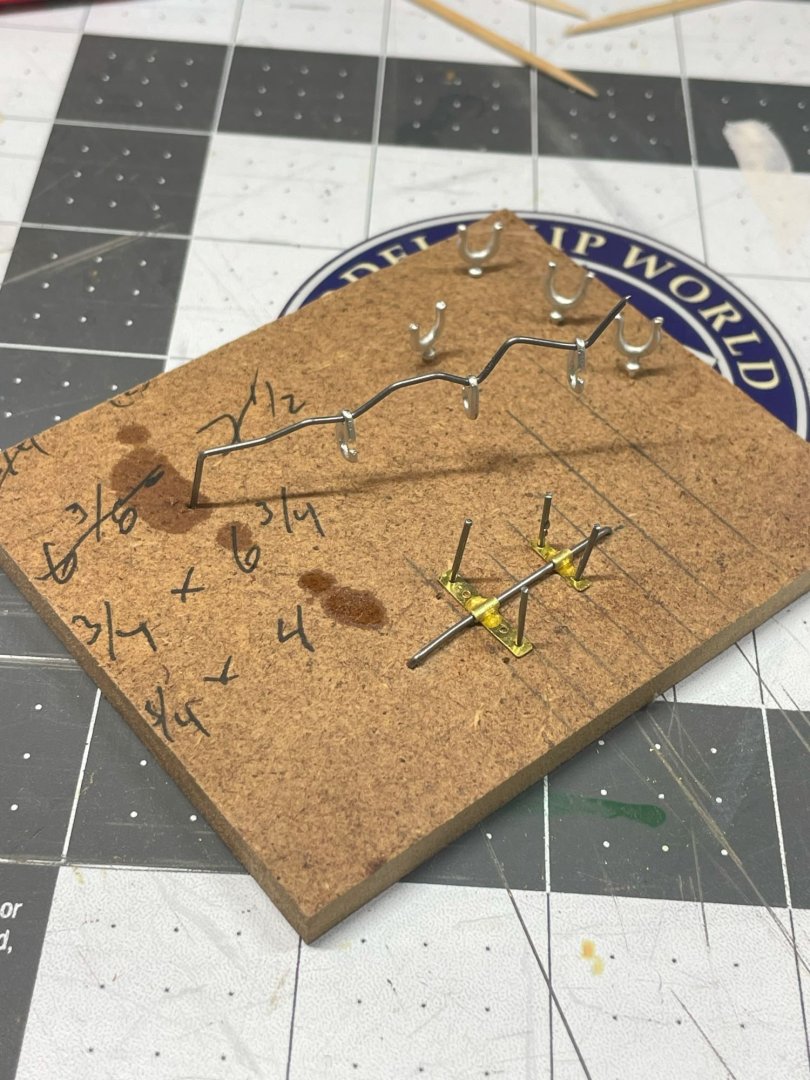

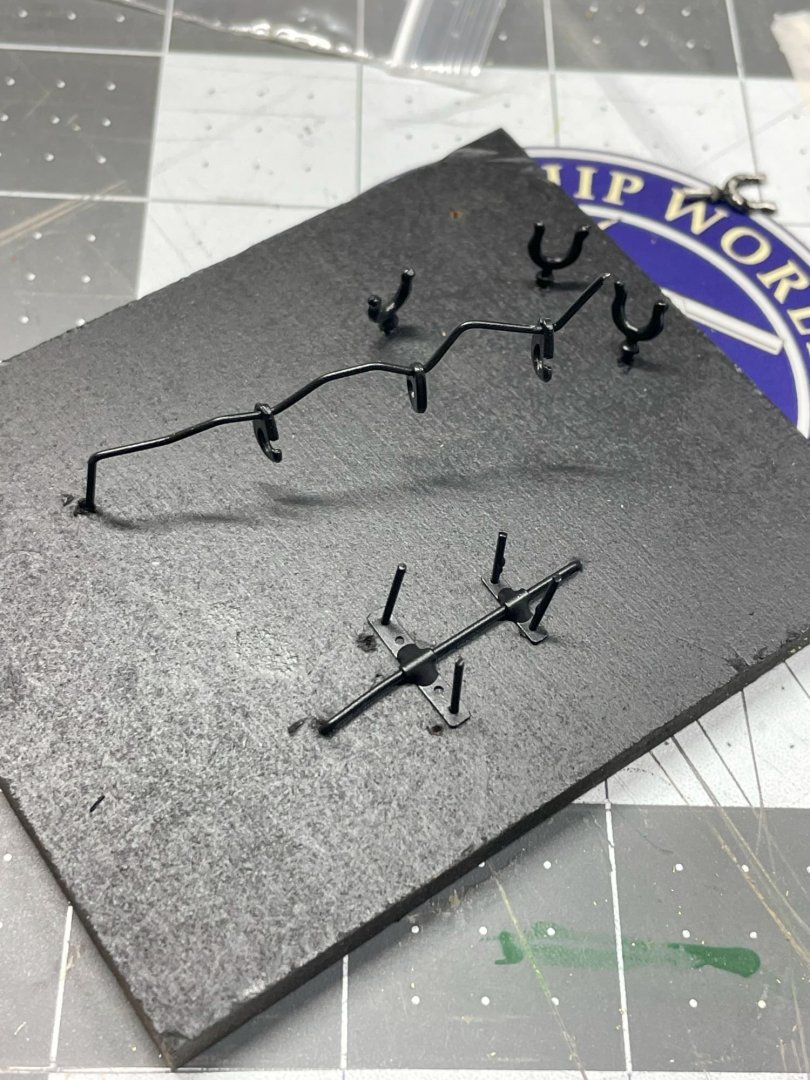

OK, I've started working on the brass and metal parts. First thing I did was make this little setup to hold stuff down. Then I used epoxy to put the tubes on. I couldn't decide between soldering or epoxy and figured I can't blacken either one so I'll go the easier route. The wires are .031 and I had to drill out the holes so they wouldn't deform. Setting up the other metal parts for painting. I was just using flat black spray paint. I cleaned the parts with 91% IPA. Spray paint magic! Or at least you would think right? Next I thought it might be a good idea to rub the painted stuff with a 6b pencil to get a more "iron" look. Umm, the paint came right off! Essentially you can get the paint off by rubbing your fingers on it. What the heck did I do wrong? I don't know if the brass is the same. I'm afraid to check. This picture looks like I'm asking "why won't my pencil graphite stick to these metal parts?" I swear it WAS painted!! HAHAHA I'd love some suggestions on the paint situation. Also on the rudder side, I'm thinking if I can get a small enough amount of epoxy inside the bend, and/or sand off any exposed epoxy, I'd be able to blacken those parts. However since I'm painting (trying) the gudgeon side will there be a stark difference in finish and I should just paint the other parts also? I appreciate all the support and comments! Chris

-

Following along. Looking forward to your journey! Chris

- 92 replies

-

Looking forward to watching this boat come together. What kind of mini plane did you get? I’ve got the Veritas mini block plane showing up on Monday, fingers crossed.

- 65 replies

-

- Maine Peapod

- Midwest Products

-

(and 1 more)

Tagged with:

-

Is there a quick method you guys and gals use when scratch building an item to figure out the size? I use a scale calculator online right now. Down side to do that is I need to find my phone, open the web etc. I’m fairly good with math but for some reason this scale thing gets twisted in my head. As an example I’m working in 1:12 on the sailing pram. I wanted to know what 1” was. Found out it’s just shy of 3/32 and close to 2mm. I thought hmm, I should write that down so I’ve got a cheat sheet of common sizes. Is there an easier way? Thanks! Chris

-

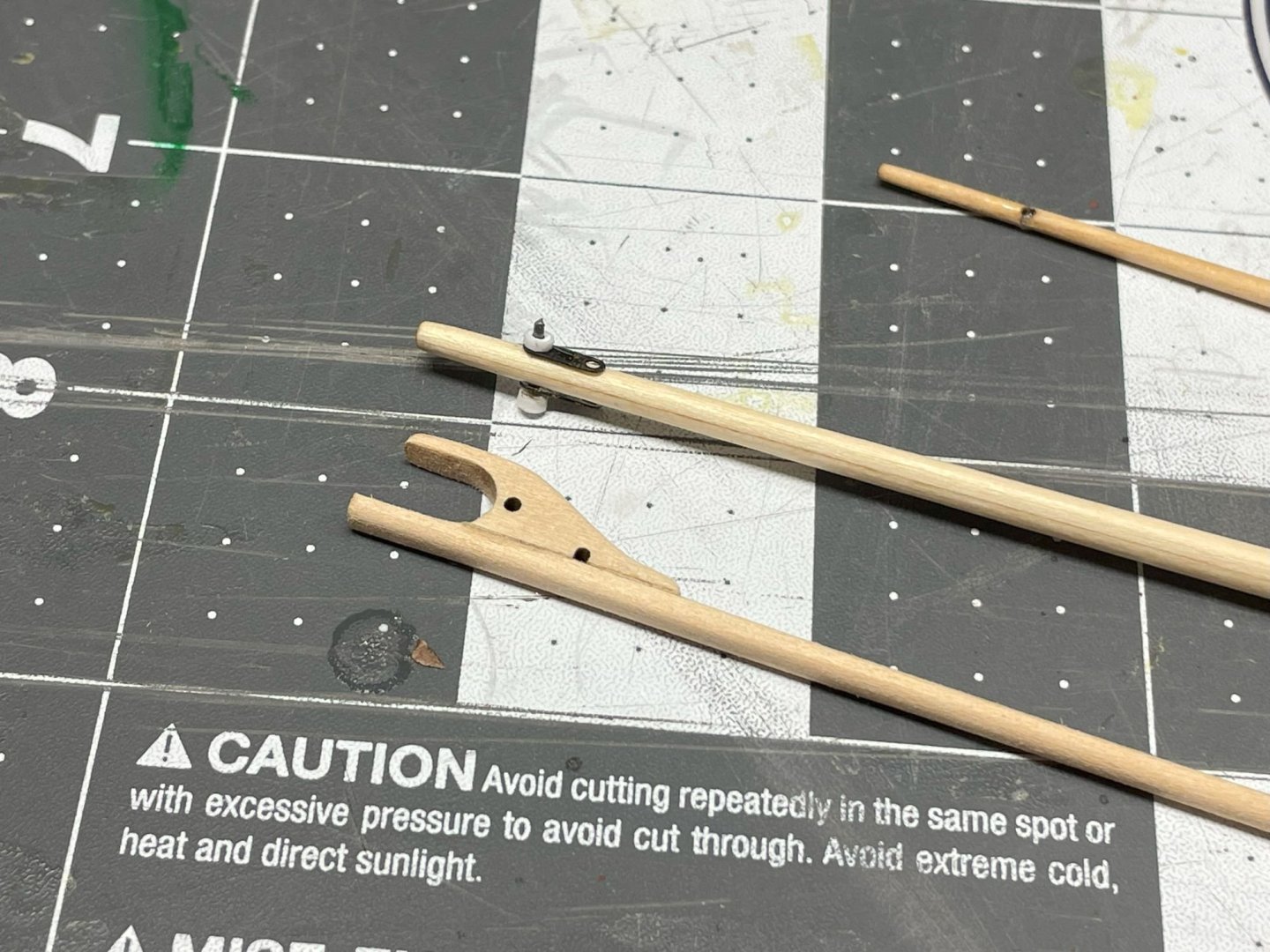

OK, there has been a little progress as I'm still waiting on supplies and tools. After looking at some pictures online, I noticed some tillers had a more ergonomic shape. So I decided to make one from scratch. It has the same overall dimensions as the original for the most part. It might be completely inconsistent with this time period or boat. If so please let me know. Then I decided to try my hand at some weathering/wear marks. I'm not really sure where these should be so I made what I hoped was an educated guess after looking at photos online. I can't find a lot that describes this boat. I'd love your opinions of my work and suggestions for what else to do. I'm thinking the boat should have more wear and rub marks but I don't know where to put the wear! (see what I did there?) I'd like to add a slightly dirty wash to the hull. Would that be appropriate for this time/boat? I'm not sure if these boats sitting out of the water was a common sight or not? I did this with watercolor paints. I'd like to try my hand with some dry pigment soon! Thanks again for stopping in! Chris

-

Jet 1020 drum sander

Desertanimal replied to SteveA's topic in Modeling tools and Workshop Equipment

Sorry I can’t help with that exact sander. I have a larger shop version of Jet sander. It’s an excellent tool. I’ve found it to be well engineered and when I had a technical issue they solved it right away on the phone. I’ve used it to sand pieces probably 1/16” occasionally.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.c807473c22293a2478e35560307fc80e.jpg)