-

Posts

38 -

Joined

-

Last visited

About EspenT

- Birthday 11/25/1974

Profile Information

-

Gender

Male

-

Location

Mebonden, Selbu, Norway

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

aaronc reacted to a post in a topic:

Lowell Grand Banks Dory by EspenT - FINISHED - Model Shipways - 1:24

aaronc reacted to a post in a topic:

Lowell Grand Banks Dory by EspenT - FINISHED - Model Shipways - 1:24

-

Taken Aback reacted to a post in a topic:

HM Armed Cutter Sherbourne 1763 by Glenn-UK - FINISHED - Vanguard Models - 1:64 - Admiralty Style

Taken Aback reacted to a post in a topic:

HM Armed Cutter Sherbourne 1763 by Glenn-UK - FINISHED - Vanguard Models - 1:64 - Admiralty Style

-

EspenT reacted to a post in a topic:

HMS Harpy 1796 by Glenn-UK – FINISHED - Vanguard Models - 1:64 scale

EspenT reacted to a post in a topic:

HMS Harpy 1796 by Glenn-UK – FINISHED - Vanguard Models - 1:64 scale

-

EspenT reacted to a post in a topic:

Norske Love by ZhangRenWing - Billing Boats - 1:75

EspenT reacted to a post in a topic:

Norske Love by ZhangRenWing - Billing Boats - 1:75

-

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Canute reacted to a post in a topic:

TFFM Swan Class Books

Canute reacted to a post in a topic:

TFFM Swan Class Books

-

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Canute reacted to a post in a topic:

TFFM Swan Class Books

Canute reacted to a post in a topic:

TFFM Swan Class Books

-

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

EspenT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Micb reacted to a post in a topic:

TFFM Swan Class Books

Micb reacted to a post in a topic:

TFFM Swan Class Books

-

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

-

EspenT reacted to a post in a topic:

HMS Harpy 1796 by Blue Ensign – FINISHED - Vanguard Models - 1:64 scale

EspenT reacted to a post in a topic:

HMS Harpy 1796 by Blue Ensign – FINISHED - Vanguard Models - 1:64 scale

-

I am a bit uncertain on how the final shape of the mast should be. @tlevine Should the mast be perfectly round from below the mast head and all the way down to the deck, or should some parts be left octagonal?

- 80 replies

-

- rigging/masts

- NRG

-

(and 2 more)

Tagged with:

-

dcicero reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

dcicero reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

-

EspenT reacted to a post in a topic:

HM Armed Cutter Sherbourne 1763 by palmerit - FINISHED - Vanguard Models - 1:64 - First Build

EspenT reacted to a post in a topic:

HM Armed Cutter Sherbourne 1763 by palmerit - FINISHED - Vanguard Models - 1:64 - First Build

-

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

-

Mr Whippy reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

Mr Whippy reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

-

Chuck reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

Chuck reacted to a post in a topic:

NRG Rigging Project by tlevine - FINISHED

-

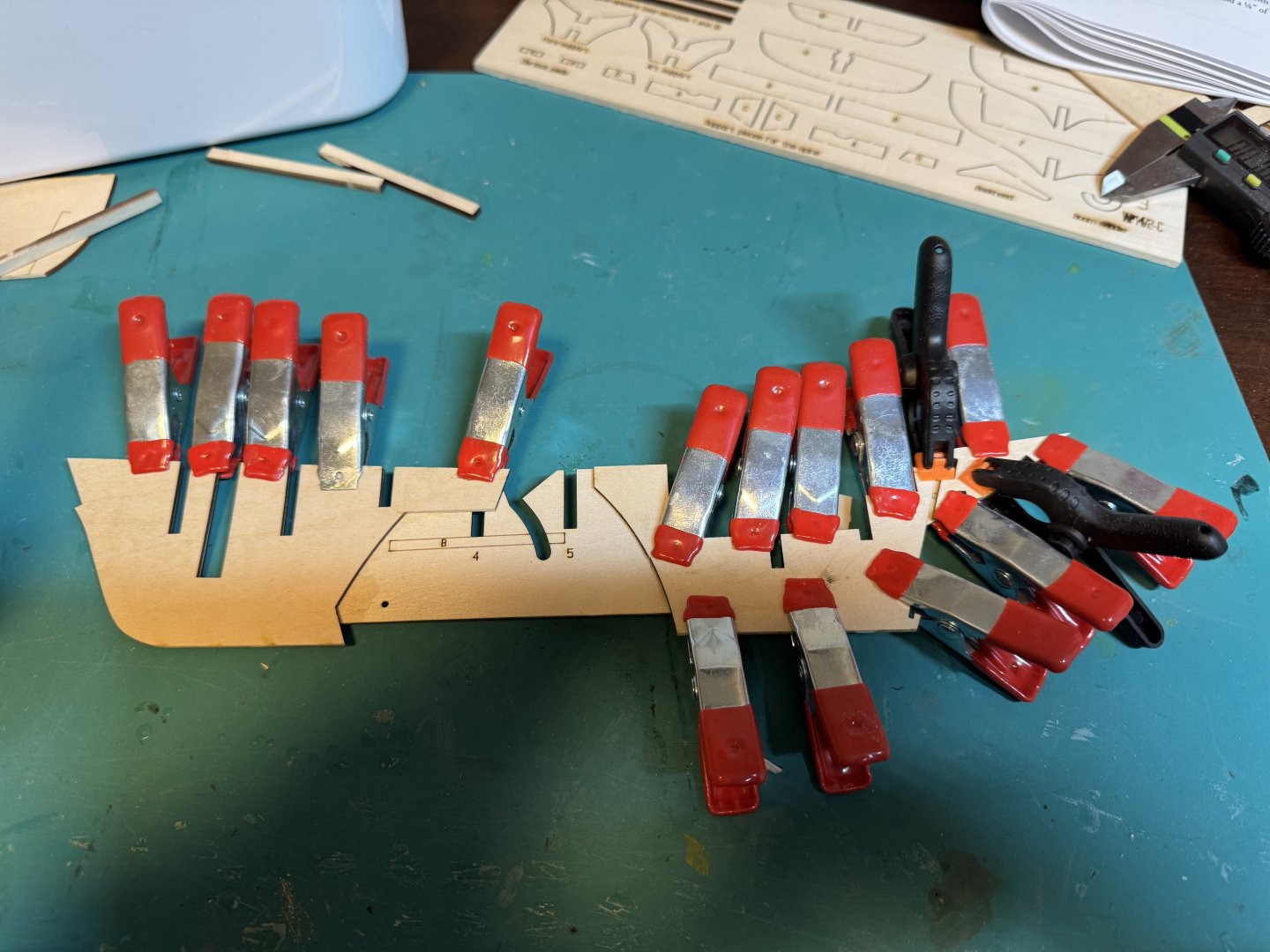

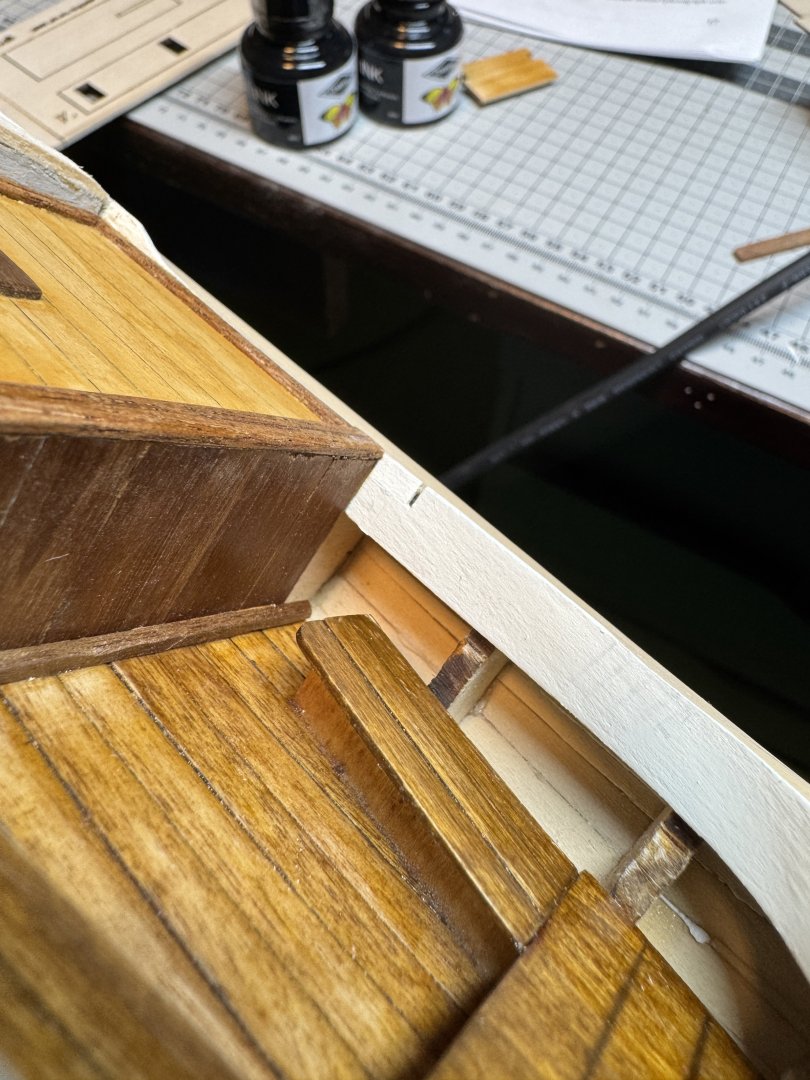

I bought this kit to help with my rigging skills. Even though I haven’t started neither masting nor rigging yet, I am really enjoying the build so far. Since the model is small you can also splurge on the choice of woods.

- 80 replies

-

- rigging/masts

- NRG

-

(and 2 more)

Tagged with:

-

Hello @BenD I am testing my new rope walk with different Gutermann E-series ropes. If I want to make .45mm rope I can either use 3 strands with 3 threads each if I use E121, or I can use 3 strands with a single thread if I use the thicker E382. Do you have any preference on the quality between the different methods? I am sure you must have tested a lot of different combinations 😃. More thinner threads or few thicker threads.?

-

It is a machine block, often called a 1-2-3 block after its dimensions in inches. It is heavy and has square edges. Very handy in many occasions. I have a 25-50-75 block since I use metric.

- 16 replies

-

- dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

Being a Norwegian I maybe shouldn’t say this, but I am skipping the Norwegian Pram for now. The plan is to finish the Lobster Smack and the Sherbourne. Then I think I will go to the two NRG kits I have here at my desk. Both the rigging and the planking should be useful. After that I think the Philadelphia Gunboat. so many choice and so little time

- 16 replies

-

- dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thank you. I am so glad I found this hobby.

- 16 replies

-

- dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

I clearly enjoy building models more than I enjoy writing about building models... Long time since I have updated anything here. I just created two more logs for the Dory and the Lobster Smack. I have been shuffling back and forth between these three models and I hope to have all of them done this month.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.