-

Posts

1,625 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Adrieke

-

not sure how you are going to proceed but this is what i would do. fix up the stateroom glue it all back on the deck and the ventilation openings . wet the ventilation windows dowels at the bottom and clamp it down so that you get a bit of bend in it aftyer drying the ventilation windows assembly has some wood parts to hold her in place. place a strip of 1 mm of wood on the bottom of it. then when yuo glue her in place you need to push in a bit before it clicks in place and she should the curve nicely its something i am goign to try (without glue) so i cna remove the top part i f necessary to fix the lights

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

thanks for the comments geoffrey,John and David i am pleased with the result in the mean time i have also worked on a way to get the stairs finished. i love basswood so flexible thats my goal for the next weekend then finish and install the stairs

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

thanks for the vote of confidence David . it has helpded i tried the overlapping John suggested and knew straight away it didnt look right to me after measuring the shutters grinding the beveled edges off on both sides still would not have been enough and as Josh siad i would end up with a long shutter between windows the only option left was the one i rejected at first because too much hasle/work i had to reposition some of the windows. after careful observation the best way was to reposition the windows next to each door and move them closer to the door. first i had to remove the already installed windows. luckily except for one i had only pushed them in as they fit snugly so that didnt take too long i also had to remove some of the planks and add a 1.5 mm thick strip of wood on the side furthest away from the door i tried to work too quickly and ended up with too much gaps between planks and window so i removed it all and started again and here is the end result : i noticed on the pic i had scraped of some of the brown paint on one of the shutters so i ll need to do a bit of retouch there i have now installed al the strips so i could paint them white on the inside. tomorrow i can work further on filing the repositioned holes to the right sizes, reinsert the windows and replank

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

wow Danny you are fearless . anybody want to invent a drill that drills at 90 degree angle

-

i have tought about that but i would need to cut into the frames because i have installed them sticking out about 1 mm. my idea is to grind of the taperd side where it sits against the window.

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

thanks for the comments Wim,John,Sjors and Dcironfist although i have run into a bit of a problem if you look closely on the picture wiht the shutters you will notice that there is not enough room to put the shutter next to it first i couldnt think why then it dawned on me that the orginal metal windows where smaller then the holes. about 0.6mm on all sides that translates into 1.2 mmm. i made the windows to just fit the holes leaving only about 9 mm between windows with the shutters each being just over 5.1 mm. the only option i got is to grind of about 0.6 mm of each shutter

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

dont feel bad John. from what you say you are already well on your way to get it all back right

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

well i didnt finish the windows but i feel like i did do a lot first the painting of the windows shutters is almost done i have also started installing all the windows on one side and also 1 at the front finaly i tried out the windowshutters on one window to see how it looks i suspect i ll be working on the planking and windows of the 2nd deck stateroom the rest of the week

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

hi John sorry to hear about your mishap. but i am sure you ll be able to make it all right again as Wim already confirmed it is curved. while the stateroom itself is straight. another AL mistake thats why i have refrained from working on the 3rd deck stateroom til i have the deck glued down and i can start to establish the curve in the 3rd deck

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

very nice John can i ask why you did not put the stove in ?

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

after 2 days of counting and drooling over the Gorch Fock i am now back to window making hope to have them finished this weekend

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

sorry to hear that Terry good luck with making your own

-

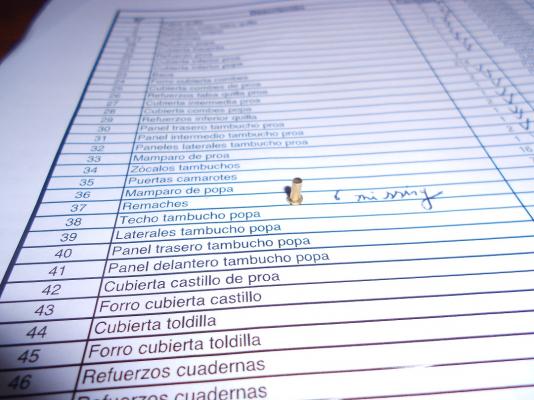

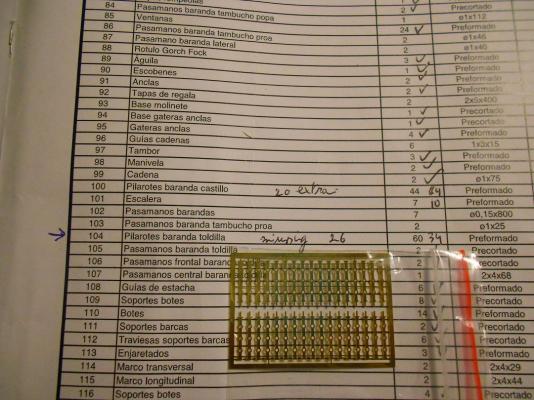

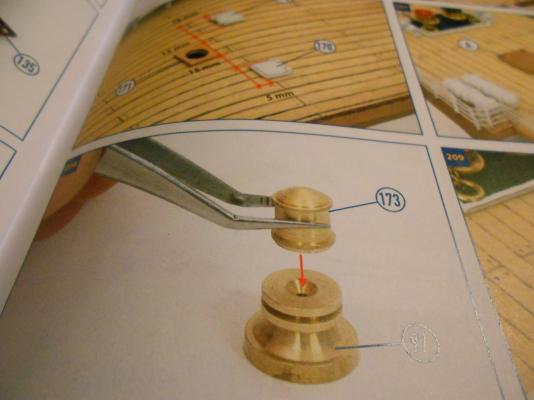

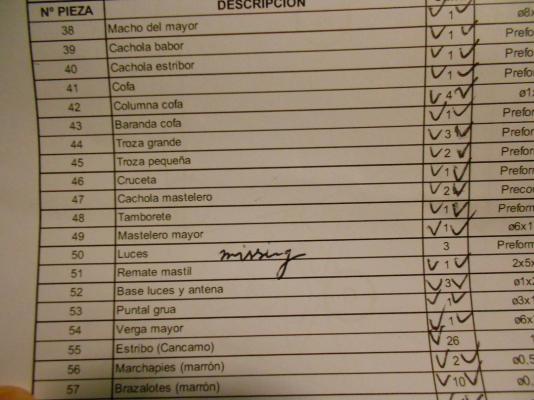

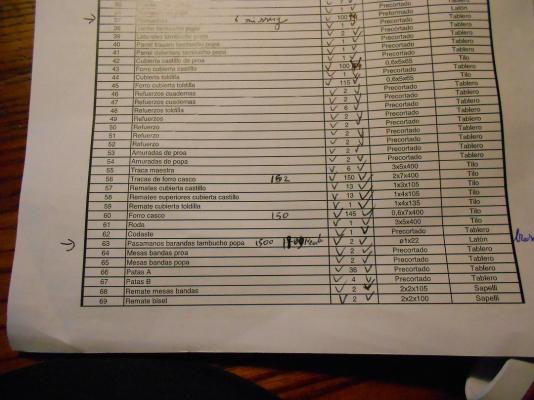

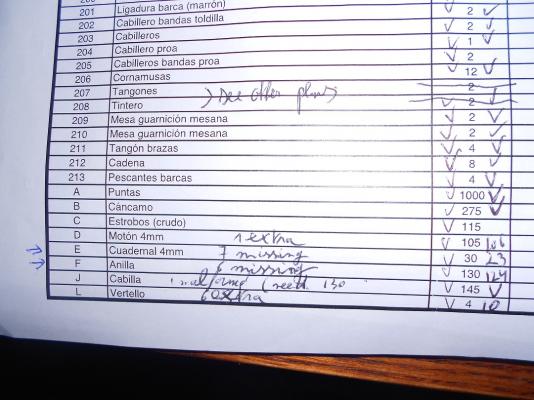

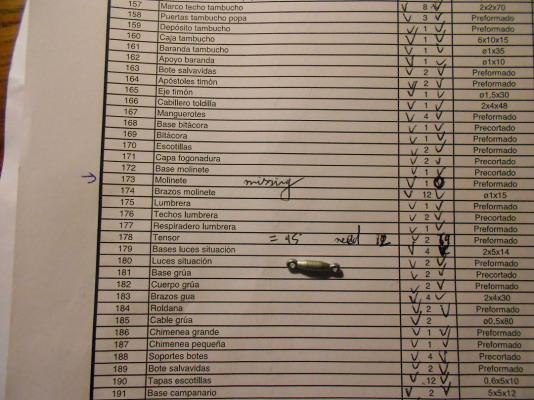

well i finished counting and i am actualy disapointed that so many parts are missing here the list 1) part 37 remaches (rivets) 100 needed only 96 included 2) part 104 pilarotes baranda toldilla (Railing pillars poopdeck) 60 needed only 34 included 3) part 173 molinete (kapstan ?) is missing 4) part 178 on hull plans and 95 on rigging plans Tensor (tension ) 82 needed only 69 included 5) brass wire 1mm diameter 1800mm needed only aproximately 1500 mm included 6) part E cuadernal (double blocks) 30 needed only 23 included 7) part F anila (ring) 3 mm diameter 130 needed only 124 included 8) part 21 on rigging plans luces (light) 3 needed none included 9) part 50 on rigging plans luces (light) 3 needed none included

-

he is just checkign to see if the water is deep enough to dock his fleet

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.