-

Posts

1,625 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Adrieke

-

after the war Germany had no training ships left son in1957 they decide to build a new Gorch Fock. it was a modernised version of the orginal one (actualy of her sister ship Albert Leo Schlageter.she was launched and commisoned in 1958 and she is still in service. the albatros figurehead was lost, broken and replaced 5 times. the fore and main mast tops can be lowered so she can navigate the kiel canal and fir under the bridges the last 50 year 6 sailors died by drowning or falling down her main mast. she was fitted with a new auxiliary diesel engine in 1991 she participates in sailing parades and tal ship races (in amicable rivalry with the AMerigo Vespucci)

-

a bit of history about this ship. there are 2 ships wiht this name and they are named after the pseudonym of writer Johann Kinau who died abaord the sms Wiesbaden in WWI the first one was build in 1933 as a training ship. she has more then 300 ton steel ballast to make her safe and even when heeling 90 degrees would upright herself. she was not used during WW2 until 1944. in 1945 she was scuttled to prevent her from beign captured. She was salvaged in 1947 and used as a training ship by the Soviets and renamed Tovarishch. she sailed around the world and won the operation sail race twice. in 1993 she was deactivated as there where no funds for repairs. 1995 she was brought to the UK for restoration but this failed. in 1999 she was sialed to welhemshaven and in 2003 she was finaly transfered to Stralsund Germany and renamed Gorch Fock. She is now a museum ship and in poor but stable condition.

-

my wife was going to subscripe me to the hms victory kit ($15 AUD a week) . was very tempting but in a 120 issues the price would be a fair bit higher then if bought as a kit (even with the extras they provide) instead i said thanks hun but instead of doing this just add $15 to my weekly hobby budget and i can buy some other stuff with it

-

672 is not that much more then if you bought it as a kit and you do get the tool kit with it (dont know if the tools are good) and it does seem they give good step by step instructions with it for most of the other ones i have seen of them the price is a fair bit more (up to double the price of a kit)

-

X-Y Attachment for Dremel

Adrieke replied to Martin W's topic in Modeling tools and Workshop Equipment

thanks for the information jpett that gives me a better idea of this tool its so confusing for me since it seems lots of tools overlap in functionality . my aim is to slowly build up some essential powertools and to get experience with them so that when i decide to go from kit buiildign to scratch building i know how to use them -

X-Y Attachment for Dremel

Adrieke replied to Martin W's topic in Modeling tools and Workshop Equipment

as i am a total newbie to most powertools cna someone explain these combo drillpress/milling machines and most important what things you can and cant do with them -

hello DCironfist i get a notepad and the partslist. then i start with the first part that is not preformed and wirte down the dimension and type of wood and then underneath the length and the number of parts then i scan the rest of the list for the same dimensions and write them all down then i take the wood of that dimension measure the length and number of them now start with the longest length and fit them into the length of the wood till its comes up to the total length example : sapelli 1x3 2 times 200 3 times 90 1 time 400 20 times 30 i have 5 pieces of the wood with length 400 so i have 1 ful lenght one then 1 x200 + 2X90 = 380 thats 2 then 1 x200 x 1x90 + 3x30 = 380 thats 3 then 13 times 30 = 390 thats 4 then 4x30 = 120 thats 5 with about 280 in spare lots of work but its worth it

-

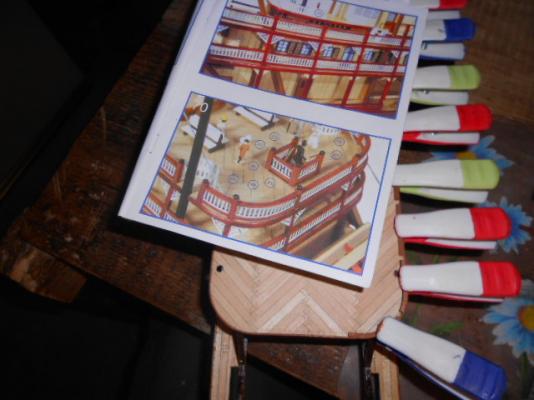

thank you Rebecca i wil check out these other glues. i sympathize with you as for me its mostly just sneezing runny nose headaches and a bit of wheezing which is already bad enough but so far i have had no asthma attacks. today i am certain that i am not happy with the door. have to think about it thats why i worked mostly on sanding the burnmarks of the curved railing parts also i cut a bunch of the straight railing parts and together with the curved one did a measure on how the 2nd dack railing should go. surprise surprise the ful scale plans are wrong. they show that the aft straight railing should be 35mm long but if you look at picture 70 in the instructions and count the railing vertical poles of that piece you come to 21 while the normal 35mmm piece only has 17 . that would mnake this aft part about 43mm and with the measuring i came to 44mm . close enought to be right also the two differnet sizes of part 186 are correct (why not number them differedntly AL) the longer ones are for deck 2 the shorter ones for deck 3 the last picture shows that way the railing vertical bar line sup perfectly

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

hello Jim yup its working now

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

hi John no i decided to not put windows in the doors

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

thanks for the comments Jim i have seen your build and its looking really good dont know how you do it i alreayd have trouble on my scale unfortunately for me my alergies are still the same. but now that i figured out what is causing the issue (the CA+ glue) i am wearing a mask when using itand so far i have had no issues again oh i noticed that the link to your robert E lee in your signature is not working

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

thank you Sjors so far he has just been doign his work . but i did tell him to put away that ukelele finished the first door. not sure if its a success or not also had a look at markign where the railing posts shoudl go so i can start making the holes. I hope John can figure it out because i cant. first there are suposed to be 4 preformed curved parts for the railing aft acording to partslist. however there are 8 acording to the drawing of the preformed part sheets. but they are actualy 2 different lengths with fitting them and using the plans it seems like they are not long enough. looking at the building fotos it could be that the aft middle railing is wider then the 35mm its supposed to be.

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

hello Ian i was refering to sheets 5 and 6 the parts to cover the hull as far as i can see there are no indications where to cut if yo want a waterline version. and no worries happy to help

-

hello Ian yes i think you can do it as a waterline model but you have to figure out where to cut the hul sheets to the correct size

-

lol nah thats my new workbench supervisor to make sure i keep it clean although he is a bit weird keeps asking : do you know the definition of insanity ?

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

HI John no i am alergic to dust, cats dogs and anything that has sharp smells. in this case i think its the ca+ glue as i had been using it a fair bit . so from now on i am using a mask to prevent this again i finished all the windows on the 2nd deck state room next the doors. from earlier trials just plain veneering the metal parts was not enough. so i am going to try to recreate how the metal door looks but then in wood. i will need to slice 1x1 mm sapelli strips from the 1x3 ones to get the fine detail so thats going to be a lot of fun. atleast there are only 6 of these doors

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

not much done this week. after cleaning up my workbench i had a lot of issues with my allergies this weekend. i did finish 8 of 10 last windows i ll be fitting them in tonight hopefuly

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

no worries glad i saved you a trip

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

yes its the advanced one just something to keep me busy when i cant be in my workshop

- 12 replies

-

- San Salvador

- card

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.