-

Posts

655 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rlb

-

Congrats, Robbyn on a fine model. Especially with model ships, not everyone finishes what they start--you should feel good. Do I sense some excitement to begin the Syren?! Ron

- 234 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

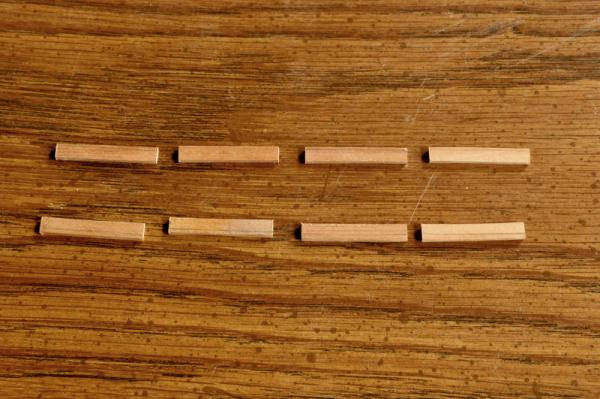

These can be made by hand, whether you need just the few you might be short, or want to upgrade a whole ships worth. Here's a batch I made, 5mm and 4mm--, Check my Oneida log, how-to begins at post #153 page 11. The brass jig I used can also be made of wood (as Russ does) if you don't have the brass or soldering skills. Ron

-

Thank you, Russ, Joe, and Elmer. Wood is probably a better idea for the concealed fastening pins. It doesn't bend the way wire can, so would offer more resistance and greater strength to the joint. On the other hand, wood will break if the bending force is strong enough. I put these in as some "insurance", and it does make locating the pieces properly when gluing easier. Hopefully there won't ever be enough stress on the pin rails to test them! Elmer, if you decide to build an Oneida, I'll do my best to help you, if needed. Ron

-

Pinrails: Here they are dry fit to the bulwarks-- Closer photo with my one homemade brass belaying pin--these (once all 80 or so are made!) will be blackened-- They aren't glued yet. I'm waiting to glue these and some more cleats all at once. I'm also waiting while I think about whether to stain the pin rails black, or leave them "natural"-- I think I need to finish everything else that's needed inboard on the deck, before finishing the outer hull (channels, chain plates, head rails). That means the mast pin rails, the pumps, capstan, mast partners, bowsprit step, the lower masts; the list goes on. Ron

-

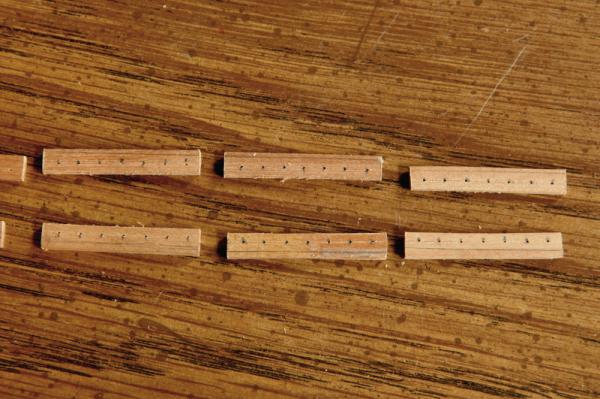

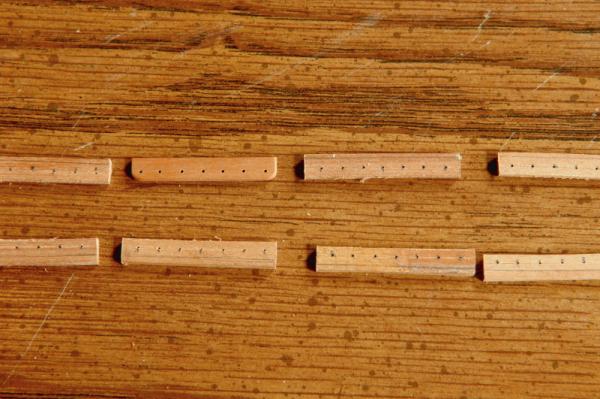

Pinrails-- Here are the pieces, roughly cut-- The pencil mark is scribed from the overhang of the rail, you can see that they are not all equal (especially the lower right piece--which is the forward most starboard piece). I scribed a line from the inboard face (unfortunately this doesn't show well in the photos), and marked the holes to be drilled with a pencil then a pin. The scribed line will get sanded away as the piece is thinned to the right thickness- After drilling all the holes, I finished one piece down to the correct thickness and shape, to make sure it would look right-- Here's a comparison between the rough pieces and the finished one-- When I was satisfied with this, I sanded the rest down, and epoxied brass wire anchors into each-- Here they are laid on the deck-- Next will be gluing them into the bulwarks. Ron

-

Hamilton, I've just seen your log now, because you've done the whole thing while I was on hiatus from my model! Amazing. You've done a fantastic job fixing and upgrading the kit weaknesses. She looks great. Cheers, Ron

-

And speaking of slow progress-- I've made 13 4mm deadeyes. Twelve will get attached to the channels on the hull, and one extra. My dowel won't yield the 12 more that I need, so I'm just going to wait until the rigging is under way to do those, along with the 3.5mm deadeyes that I will need for the top mast shrouds. By the way, I found one of the brass rings I had lost (not that it's of any real use to me now)! It's on to the pinrails, and miscellaneous deck work. Ron

-

Ilhan, You are making a beautiful model. I really like your decisions on where you have used different woods, and the limited painting. Cheers, Ron

-

Sam, Elia, Russ. Thanks for the words of support. Even though it's been a lot of trial and error making the pieces, I'm still having fun. (Well, not so much when I lose them!) I never considered wood for the jig, but it sounds like a good idea for small numbers. Even the brass "wears out". The hole pattern piece is pretty thin brass (so it's easier for me to drill the pilot holes, considering how many tries it takes to get right), and after drilling 40+ deadeyes the holes have become slightly enlarged. I don't need as many of the smaller deadeyes. Ron

-

Thanks, Wayne! I spent four hours yesterday trying to make the 4mm deadeye jig, with no success. They have to be tested by actually using them to drill holes in the dowel. While unsoldering failed attempts I lost three of the brass rings that hold the jig onto the dowel. How I could drop 40 deadeyes without losing one, and then lose these brass rings one after another, is beyond my comprehension, but that's how it went. I keep looking for them, but I haven't found any of them. Today, it still took a few tries, but I got my 4mm jig-- Across the top are just some of the many attempts at drilling well-spaced holes for the jig. They probably look okay in the photo but for various reasons, they're not. The jig and deadeye on the left is the good 5mm version. The next is the good 4mm jig that I made today, and a "blank" made from it. (only the holes drilled--it still needs filing work to finish) Next after that is an example of an unsuccessful attempt. The holes are not quite centered (poor placement while soldering the "holding" ring) and slightly too far apart (poor location of the holes on the flat piece). Those are are two main ways the jig can be bad. The holes can be poorly spaced, or the ring (which doesn't show on any of these in the photo because it's underneath the flat piece with holes) can be soldered slightly off in relation to the holes. Farthest to the right is another unsuccessful attempt, on this one, the holes are too close together. However, I think this spacing will work well for the 3.5mm deadeyes, so I will keep that brass piece-it just needs a 3.5mm brass "holding" ring made. I've wasted some of my short dowel on failed attempts, I'll be interested to see how many 4mm deadeyes I can still get out of what's left. Ron

-

I've been following this topic with interest. That last video was cleverly edited. In the last drill, the scene was cut before the gun fires, and spliced to an exterior shot of a different gun firing. I have my doubts that this group even fired the gun they were working. (And the breeching rope did look like it was just draped across the barrel of the gun--maybe so it wouldn't get in the way!) Ron

-

Nick, I think this will be a very interesting thing to keep an eye on. I'm thinking of some of the fantastic computer 3d ship models I've seen on the site, and it seems like a natural for the next step to be printing them out. You could print each plank and piece, and theoretically they would all fit together. No more sawdust! Surely, at the least all the metal castings and/or resin parts that come with kits could be made this way. And thinking of my current work on making deadeyes, how much easier it would be to simply print them out, in whatever size and quantity are needed! Whether this is a good thing or not is another discussion! Ron

-

Hi Sam, Yes, and there is no predicting which way these pieces will go when they attempt their escape. My floor is not carpeted, and if I'm lucky I can hear them hit the floor--it sometimes gives me a clue. I'm amazed I didn't lose one. Here are the 40 5mm deadyes (plus two spares--in case my luck runs out in the retrieval of escapees.), and what is left of the 5mm dowel-- Next I will make the 24 4mm deadeyes. I think the leftover dowel may be just long enough for these. If I don't get all 24, it's okay I only need 12 for the hull. The second 12 won't be needed until the masting and rigging is well underway. I'll sand the dowel down to 4mm, make a new drilling jig, and start on the next batch. Ron

-

Thank you, Brian. Still working on the 5mm deadeyes. All drilled and parted off now, and I'm just filing them one by one as I watch the World Series. Exactly 20 out of 40 (not counting two spares I cut) finished at this point. Time is spent on each one searching the floor, as, on average, I drop each one at least once! Ron

-

Thank you very much, Elia. And thanks also for your recent PM inquiry on the deadeyes, which ended up giving me the impetus to "get going" again. Good luck on your deadeyes. Getting right the spacing of the holes on the jig was not easy; it took me four or five tries before I was satisfied. And I'm sure the smaller they are, the more difficult it is! But the good thing is, once you've got it, they will all come out well. The strop recess I didn't do as I had described to you (which was a faulty memory!). Here's a photo, though I'm not sure how understandable it is-- I twirled the dowel against one edge of a triangular file, guided and braced by the pressure of my fingers, scoring a line that I later filed deeper once the deadeye was parted off. It was all done by eye and feel, and on some the scored line was not located as well as it could have been--indeed in that photo the scored line is too far down on the dowel, it should be closer to the end of the dowel. Ron

-

John, Me, too--catching up. Congratulations on finishing a beautiful model. You continue to inspire! I do hope you will update us later with a shot of Stag in her display case. Ron

-

Hello all, After many months, I have finally done some more work on my Oneida! Hopefully this will be a more sustained period of work than the last one. And it's not all that exciting to show--I've continued exactly where I left off--making deadeyes. Here's a picture of the materials and tools I've used in making them: a 5mm dowel of Cherry, a small brass drilling jig, pin-vise and bit (#71 0.65mm), a sandpaper block and assorted files-- Here's a closer shot of 20 deadeyes (half the required amount of this size). On the left are "blanks" with the holes drilled and a score line around the circumference. On the right are the "finished" deadeyes, which will eventually be stained black. It's very hard to see, but the finished one leaning upright toward the bottom is showing its backside, with the one hole that is not "eased" for the lanyard rope, as that is where the stopper knot will be, for the upper deadeye in each pair-- The pin was in the last shot for scale, but this picture gives a better idea of how small these are. And these are the largest on the model. Others will be 4mm and 3.5mm-- That's all for now, Ron

-

Thank you, Sam. I'm hoping to get back to work on my model soon. Regarding the ebony stain: I was unhappy with Minwax ebony stain--I was only able to get a dark brown, not real black. I didn't want to paint the wood, so I think I just googled "ebony stain" and started looking at web pages. Most described the iron in vinegar part, but I quickly came across the excellent article that included the "bark tea." ingredient. Yes, it's used to get more tannic acid into the wood, which in combination with the iron rust/vinegar turns quite black. I sometimes forget that the little stove is inside the hull! Ron

-

Hi Philippe, Thanks for the compliment, and I encourage you to start a build log for your Oneida. It would be great to see it taking shape. The Chapelle plan (and also the sail plan) is available from the Smithsonian Institution, here: http://americanhistory.si.edu/about/departments/work-and-industry/ship-plans Regards, Ron

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.