-

Posts

655 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rlb

-

Cross-section by russ - FINISHED - 1/48 scale

rlb replied to russ's topic in - Build logs for subjects built 1751 - 1800

Nice, Russ. Sure sign of one who's been "bitten" is when they're in the yard cutting branches for compass wood. Ron- 69 replies

-

- frigate

- cross-section

-

(and 1 more)

Tagged with:

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

rlb replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Doris, I really enjoyed watching you create those carvings in the videos (it's deceiving to see artists at work--you make it look like anyone could do it--not true!). I'm amazed at how beautiful they look when finished and on the ship. Thank you for sharing the process, and the results, with us. Kind regards, Ron- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

I will need about 100 belaying pins for my Oneida model. To be scale accurate, they would need to be about .02 inch (.5mm) at their narrowest diameter, and .333 inches (8.5mm) length--this would be for a 16" real size belaying pin at 1:48 scale. Whether purchased or hand-made, this would seem to rule out wood. Most likely, I am looking at buying brass belaying pins which I will blacken. Any suggestions from you all as to where the most scale accurate ones might be bought, or have any of you tried to make them at this size? I don't have a lathe, although maybe I could work something up with a hand drill or rotary tool. Do I need to forget about accurate scale, and just go with what's available to buy? Open to suggestions and recommendations, Ron

-

Congratulations, Bob! Outstanding job on your picket boat. I enjoyed following along. Ron

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

-

I think I'll pass on those oysters, but Rocky Mountain Lobsters...isn't that a baseball team? Ron

- 552 replies

-

- maine lobster boat

- Midwest Products

-

(and 1 more)

Tagged with:

-

Cross-section by russ - FINISHED - 1/48 scale

rlb replied to russ's topic in - Build logs for subjects built 1751 - 1800

Nice work, Russ. It seems we are ever learning about the authentic ship building practices, as our interest and our reference materials expand (not to mention MSW itself!!). Our guesses sometimes come back to haunt us, but this is a handsom model, and thanks for sharing it. Ron- 69 replies

-

- frigate

- cross-section

-

(and 1 more)

Tagged with:

-

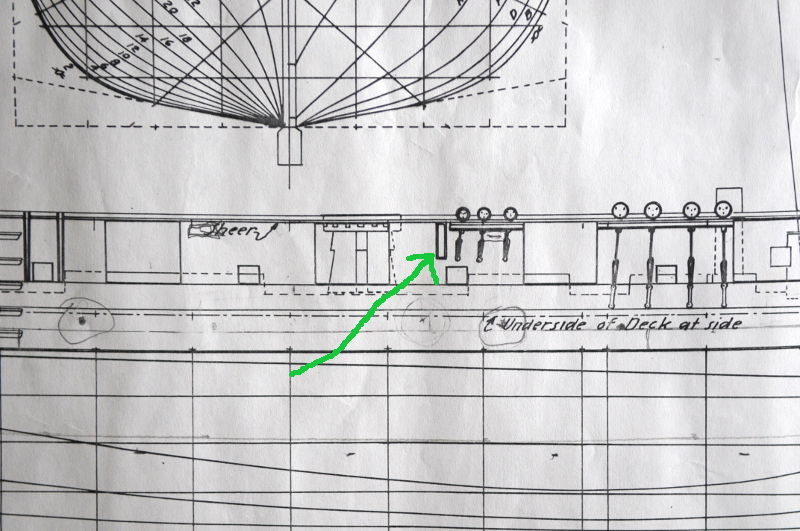

I spent the day today re-making two chesstrees. Here's the Chapelle drawing, and I based my first chesstree and it's location on this-- However, it's location doesn't quite work because Chapelle's chainplates aren't long enough. They don't include the topgallant and royal backstays. Corrected chainplates will move the chesstree aft. Since they had to be moved I removed the old chesstrees, and decided to remake them in a more typical shape. Old one on the left, new one on the right-- Here are the new chesstrees. In the first picture the piece on the left is in it's rough, beginning form-- And here they are test fitted on the hull. They need finish applied, and I'll wait and glue them on when I get to the chainplates themselves-- Just forward of the new chesstree you can see the "scar" where the old one was removed-- Ron

-

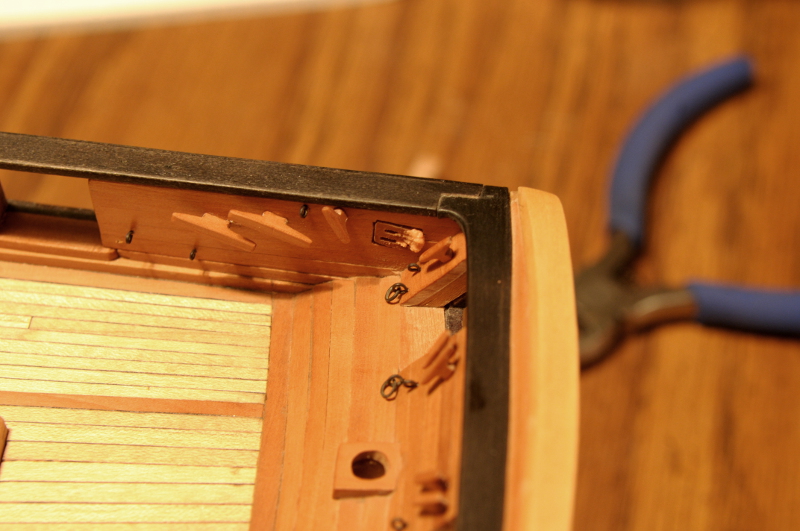

Slow progress. Here's a selection of pieces to be glued on: eybolts, eyebolts and eyebolts-with-rings for the transom gunports; some cleats for the running rigging-- And here they are glued in-- That double sheave piece poorly cut into the bulwark is bothering me. It doesn't stand out so much in plain eyesight, but I think I'll try putting some sawdust paste in the gaps. Ron

-

Thanks, Christian! Yes, my thought from the start has been to rig her, but without sails. It's a little foolish, though. Just the hull I could find a place to display, but I don't think have any where to put a rigged model of this size, especially considering the case it will need. So we'll see. Ron

-

Thanks, Steven! I was hoping to get at least a small update posted today. The cleats are ready, but I've been poring over Chuck's Syren rigging plans (a similar brig), trying to wrap my head around all that needs to be prepared for the rigging--taking into account some differences between the two ships, and trying to make sure I know where to install everything that needs to be installed. It's overwhelming! I hope to have some progress to show this weekend. Ron

-

A small update: About a 80 new ringbolts in the soup to be blackened-- Drilling holes for pins to strengthen the cleat attachments-- Eight large cleats, and about 16 small ones just about ready-- One thing I noticed in reposting all the old log photos--my green cutting mat has gone through some changes!! Ron

-

Ilhan, your work is not only precise, but it's also very beautiful. I just noticed those short curved planks on the forcastle, very nice work. Ron

-

Thanks, Brian, Sinan, and Patrick! Just a few more words on those small plates--I only plan to do them for the breeching rope bolts, though the Niagara replica also has them for the outhaul tackle bolts. And I'm cheating, my bolts don't go all the way through the bulwarks. That would make them much, much harder to install! The pieces are blackened, and we'll see them again when I glue the rest to the hull. I'll try to take a close-up photo then. Ron

-

Hi Amfibius, Here's a picture of the Niagara replica which shows what I was copying-- The ringbolt that secures the carronade breeching rope on the inside, extends through the bulwark, and has this small plate and a wedgepin (which is marginally visible) to prevent it from pulling out when the carronade recoils. I've read of people going to the trouble of making the tiny locking wedgepin!, but I haven't done that. I hope this explanation helps. I used a fine tooth small hand saw, and a file, to make the scarph joints, and no, I do not own a scroll saw! Ron

-

Nice, Remco! Whether you are "blocked" or not, everything you show us speaks quality. Thanks. Ron

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Emma C Berry by craigb - Model Shipways

rlb replied to craigb's topic in - Kit build logs for subjects built from 1851 - 1900

Looking good, Craig! From what l've seen of others' Berry builds this is challenging framing. Looks like you've got it under control. Ron -

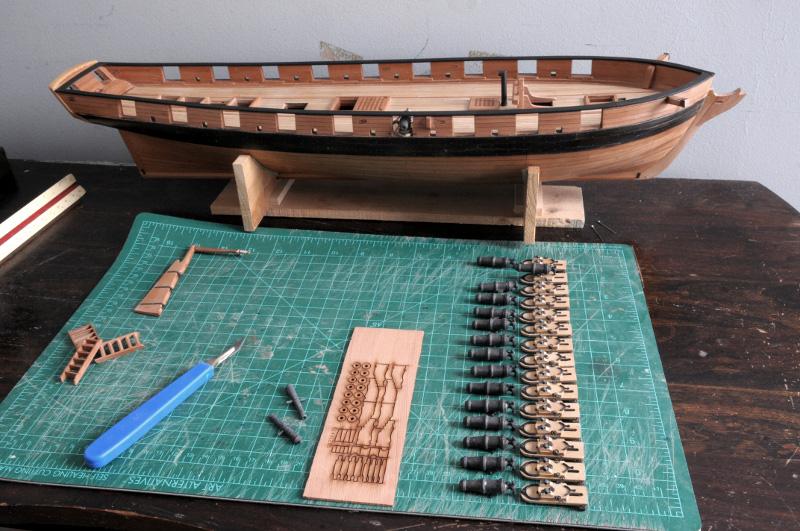

February 2013 In the days leading up to the great crash, work and experiments were done on the armament-- One of the long six pounder carriages was assembled, though not yet complete-- And a blackening glaze using surplus ebony wood stain was tried (with success) on the "greyish" metal guns-- Then more than the guns went dark for a few agonizing days. Ron

-

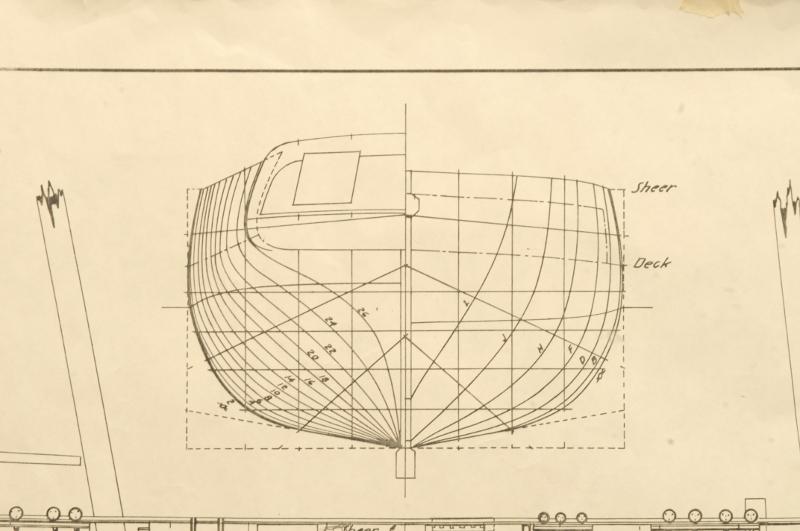

January 2013 Work to finish the transom was undertaken. The Chapelle drawing-- Possible variations given my particular situation with the transom-- The least decorative seemed most in keeping with the era of the ship, and the current state of the transom. The transom framing needed to be cut down where it raised above the bulwarks-- A very tricky top trim piece was carved from boxwood-- Finally, the stern portion of the cap rail is fitted, and stained-- Ron

-

Hey, Robbyn, You're the brave soul persevering through all the ups and downs to finish your build. I believe you'll know at the end how much to bite off for the next one!! Best, Ron

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.