-

Posts

438 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Q A's Revenge

-

-

-

In posts #10 and #15 it was suggested that beeswax will degrade the line. Conservators wax (microcrystaline) was suggested as a better alternative.Would this work as well as bees wax or better?

David B

Not tried it yet myself though...

-

Getting tempted, couple if questions ... I understand it's 120 parts to complete and they send out 4 parts each month. Can you get them quicker if you want or do you have to wait? Is the price fixed at £5.99 an issue?

-

Looking good Michael, I like the box.

I was wondering if you had a ball turning attachment as well then read the text!

-

I've used Renaissance Wax on lots of different things including tools etc.

I'm getting a little low on supplies though so I'm going to try this one next as it's a bit cheaper.

They are both Microcrystalline wax so should be just as good.

For those that haven't used this type of wax it's a soft wax paste so should soak straight into rigging etc.

-

Looks like laser cut MDF?

-

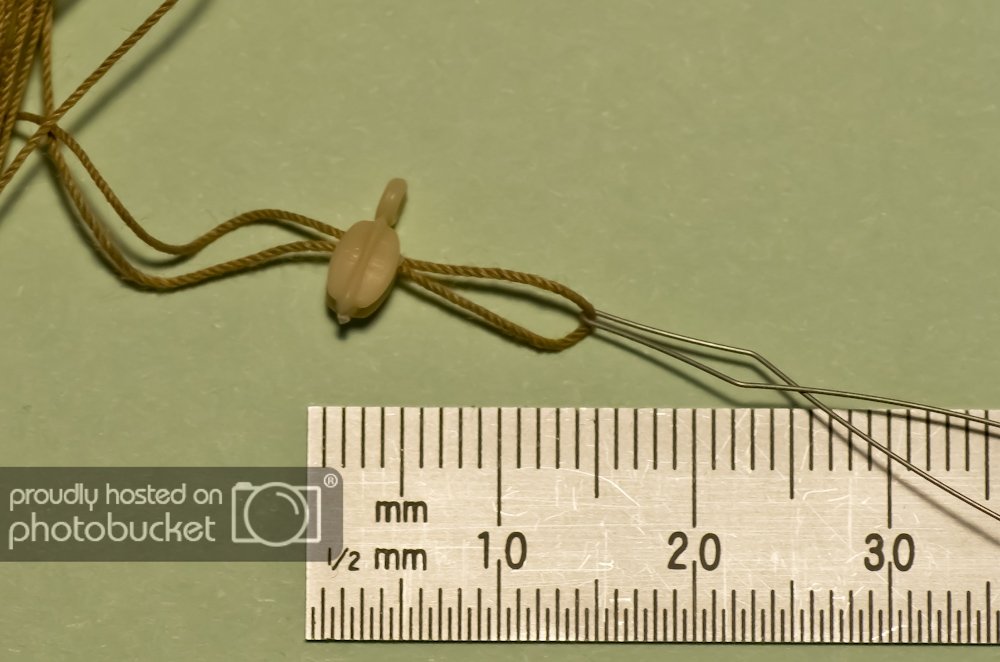

I only have these size blocks to try but it works fine. The wire pictured is the Stonfo Bobbin threader (nice little tool by the way) and is 0.29mm. The Clover threaders arrived and they are much finer wires at 0.19! The "rope" is about 0.4.

Aside from working well and not needing to do anything to the rope the threader also holds onto the block for you while the rope is threaded.

Not sure I'll use these particular blocks but I'll start another thread about that...

-

Thanks for that David, I'll have a look at that later.

-

Thanks for that Popeye. I seem to have all the fittings except the two lower parts of the masts and the strip wood. Will upload pictures soon.

Vic.

-

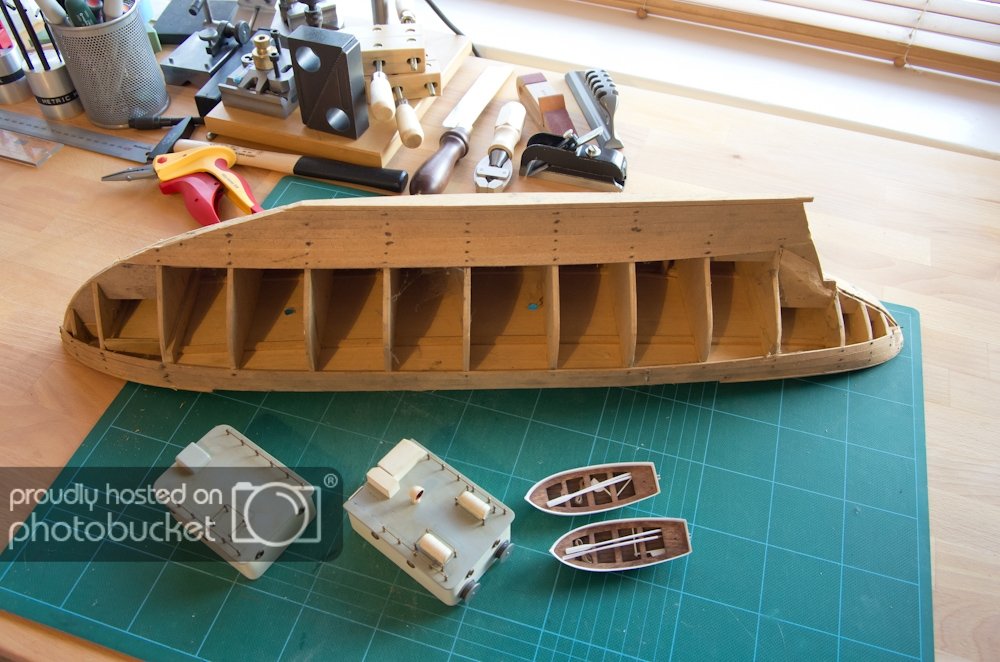

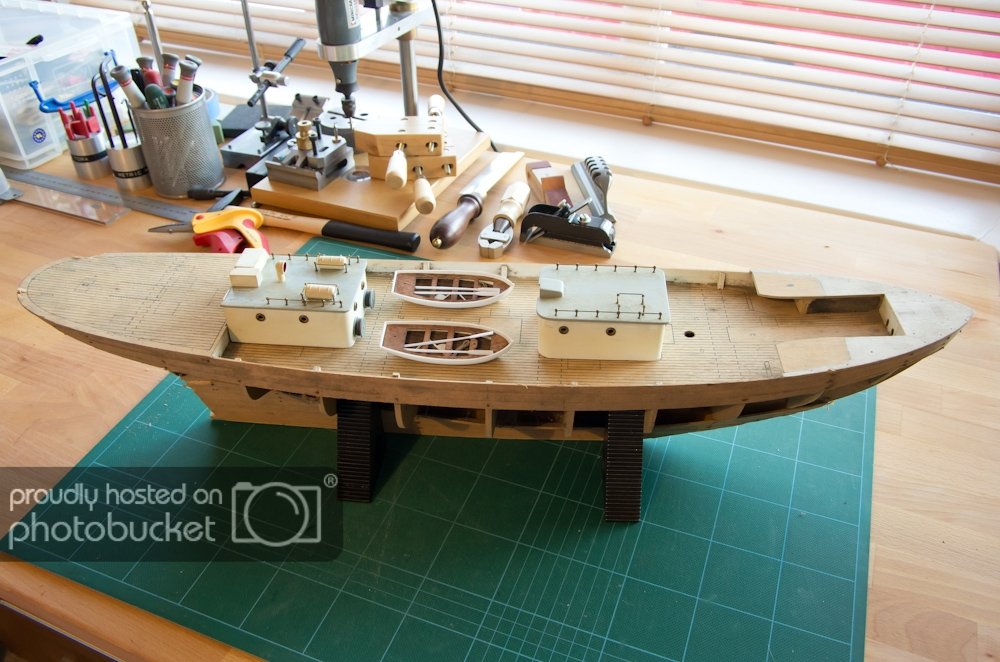

What to do. I started building this many years ago and gave up in frustration due to one too many interruptions! I still have nearly all the parts and the plans. Sadly several house moves have left the hull in a poor condition. I was a little unhappy with a few parts of the build at the time as well so now I'm not sure what to do. My gut feeling is to try to take it apart and trace the parts onto new stock material. Replicating the false decks could be a bit tricky for me though. I'll upload a few pics when I get a moment.

http://www.billingboats.com/images/BB5004%20Gladan.jpg

It's a limited edition now so doubt I could get replacement parts from Billings and they'd probably want more than I paid for the whole kit for them anyway!

Lots of dirt, dust and rusty pins!

-

These also look ok if you take the time to make a handle. Also on Amazon.co.uk with free shipping. ;-)

-

I've just bought one of these. I suspect it will only be of use for fairly large blocks but it was such a nice looking tool I couldn't resist!

http://www.troutcatchers.co.uk/acatalog/Stonfo-Bobbin-Threader-2-447-2458.html

-

I was wondering as well Craig. Think it may be this:interesting link - what are we looking for?

http://www.taimen.com/en/se/product/stonefly-bobbin-threader_99931416/103887

-

There's also a few here: http://modelshipworldforum.com/ship-model-rigging-and-sails.php

I'm bad Mark, I should have had those on the list. Now added.

-

Post #18 has a link: http://www.modelfixings.co.uk/thread_data.htm

That has metric data (maj dia) for American threads, no need to convert.

-

Something else that may be of interest is the relationship of the parts. On my bought ones the jaws are around 28mm thick, the pin is 9mm dia and the thread is M6.

Or put another way the pin is 1.5x the diameter of the thread and the jaws are 3x the diameter of the pin. I don't think anything is tool critical except if the pin is too large the hole for it could weaken the jaws.

As you've found out though, working with stock materials available will be easiest.

-

Probably the first one in the Rope and Canvas blog.

-

I have seen an American thread chart that shows the major diameter as a metric measurement. That's probably the best you'll likely to get because most folks work in either imperial or metric and don't really need to know what you're asking. It's sounds like you really need two thread charts so you can compare sizes. If I can find any suitable charts I'll link them for you.

Edit. Thinking about this some more can I share my own thoughts on suitable sizes?

I have some store bought clamps with 105mm long jaws and they have M6 threads on the screws.

If you want to make clamps with metric threads then I suggest that M3 is probably the smallest size you'll likely to use unless you plan to make some really small clamps. For my own use I've chosen M4 as a start and if I want to make something a little bigger or smaller I'll try M5 or M3. For some of the imperial sizes mentioned you may need to go down to M2.5, M2.2 or even M2 though. Be aware that although M3.5 and M4.5 are available in standard right hand taps and dies you might struggle to get LH versions!

Although I use only metric threads if I could get suitable taps and dies at a reasonable price I would most likely use 1/8" and 3/16" Whitworth as they have a nice coarse thread pattern for faster opening and closing!

Some thread data here:

-

Yes I've got the iPad app, it's pretty good!

-

Yes, as soon as my workshop is up and running I plan to make one. Probably something quite simple.

-

Nice to know Chuck. Would you like to share your modifications some time.

Vic.

-

I've been keeping a note of these links for my own research but perhaps they are of interest to others.

They are in no particular order. Please add your own links to this thread if you like.

Ropewalk links

http://mysite.verizon.net/ELLshipmodeler/ropewalk.htm

http://www.thenrg.org/resources/articles/ropewalk.pdf

http://www.densmodelships.com/2.html

http://www.maritima-et-mechanika.org/maritime/tips/Ropewalk/Ropewalk.html

http://www.midwestmodelshipwrights.com/newsletters/Feb2011.pdf

http://www.shipmodels.8k.com/Ropewalk.htm

http://www.modelshipbuilder.com/e107_plugins/forum/forum_viewtopic.php?7622.last

http://scotts-workshop.blogspot.co.uk/2011/10/how-to-make-rope.html

http://ropeandcanvas.blogspot.co.uk/p/tools.html

http://modelshipworldforum.com/resources/materials_and_tools/ropewalk.pdf

http://modelshipworldforum.com/resources/materials_and_tools/14frolich_style_ropewalk.pdf

http://www.naturecoast.com/hobby/ms110.pdf

Thread information.

http://modelshipworldforum.com/resources/Rigging_and_Sails/Understandingthread.pdf

- md1400cs, freewheelinguy, Jorge Diaz O and 2 others

-

4

4

-

1

1

-

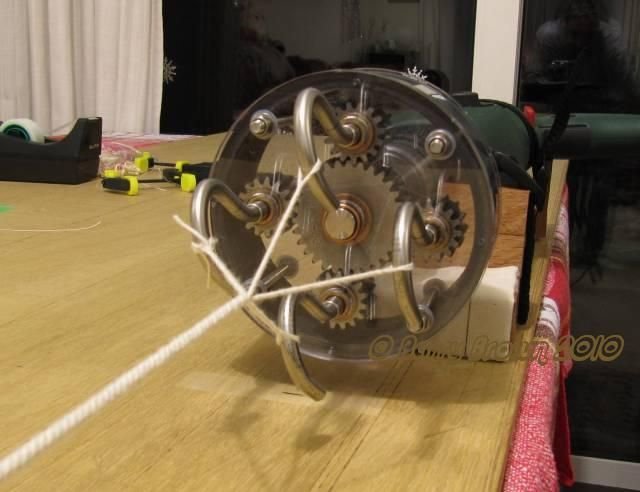

How do the two machines on this page work without using idler gears? The output looks pretty good and he's certainly made a lot of cordage with them.

http://ropeandcanvas.blogspot.co.uk/p/tools.html

-

Nice work on the spool holders Michael!

The Black Pearl steve-h - Hatchttepartworks week by week

in - Kit build logs for subjects built from 1501 - 1750

Posted