-

Posts

709 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by shihawk

-

Someone asked what building HMS Victory was like and I replied with "It is a series of highly repetitive building tasks; just as you get the hang of a task in hand it's completed and its time to move on to the next repetitive task." I am still at the planking stage and was just thinking to-day i must keep a record of usefull hints and tips cause it will probably be a couple of years before im planking again and ill have forgotten all im learning by then, same applies to rigging etc it can be years between builds and you keep saying i must remember that method for the next time,but never do . Maybe im just getting old . your build is looking great Glenn and as David said with the number of Victory builds going on someone should come up with a system of building large and cheap display cases Have Fun

-

Enjoy the toys .There can be no excuses now . Funny i got the 250 lathe last week , so far i love it and simple to set up and use Have Fun

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Could it be that sub -consiously your trying to delay the launch by sabotaging parts or is it just the thought of making that ginormous case .You could always fit sails ??? But seriously David a build to be proud of .Have Fun. Boyd

- 439 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

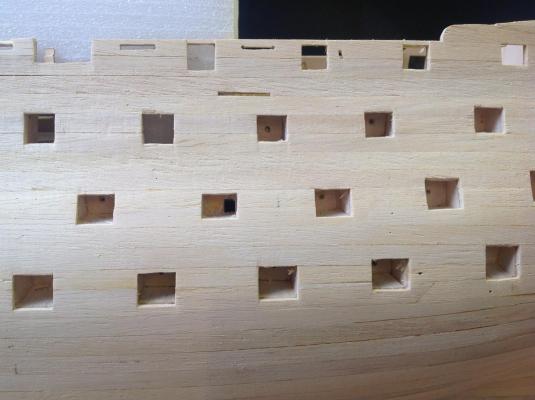

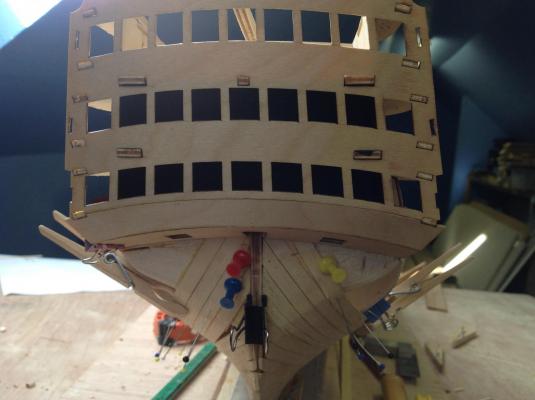

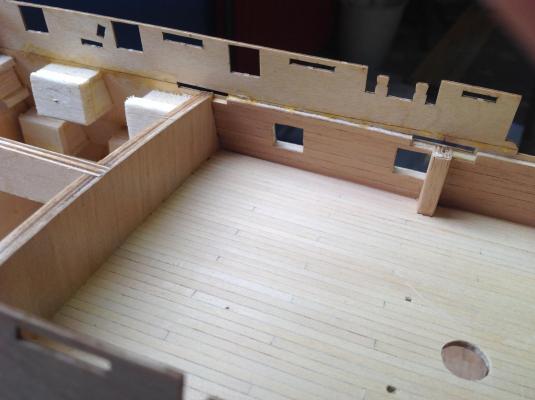

Finally got the first planking finished. Reasonably happy but as usual if i were to start again i would do it slightly differently . I started at the bottom and worked upwards then moved to top and worked down partly i was trying to figure the run of planks for the second planking ,and as you can see from the pics this meant i had to use a lot of half stealers (i think thats what you call them) but this was a good way to learn ,However i would like to avoid these as much as possible in my next planking if only for looks Am hoping that by tapering the planks from the start and planking from the keel to the lower wale i can avoid most of them , intend then planking from the lower wale upwards using it to cover any change or joints in the run of planks . Am open to any opinions or suggestions on this plan ,please feel free !!! As you can see from the pics i have only scraped the hull at this stage and hope to improve it somewhat with sanding and fillers ,but need to move outside for that process.I think some of the soaked planks shrank a little when dryed out (thats my excuse) but fillers will cure that .The gun ports still need a lot of cleaning up and am trying to figure out if i can line them before my second planking ,again any advice welcome , must experiment before deciding . As you can see from last pic the grating and stairs problem are solved, now need to fit cannon ball racks and scratch my carriages to finish the lower deck before installing the top one ,which i will have to split now to fit in .Still wondering about windows but plenty of time yet . I know i complained a lot about this kit at the begining but its quickly growing on me and from reading other logs no kit is without problems , maybe it was value for money after all???

- 413 replies

-

Sorry Keith i didnt mean to sound as if i thought you should do stairs etc i just curious if you did

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

Hi Keith ,never coppered but yours looks spot on ,did you cut out the gunports or just paint them black ? and what about the ladders ,did you bother ?

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

have just ordered 250 +4 chuck +chisel set tks for advice

-

tks Tony. Its from City Mark Gmbh and shipped direct from Germany ,Surely its only a matter of cutting the 2 pin of and wiring a 3 plug ,its still 240 v

-

Can buy Proxxon 250 for £112 + £12 pxp on Amazon. Is this a good price ????

-

Hi ,its not that difficult just be carefull of your deck if using anything big to cut out the beams .I finally got the second one done last nite ,might scratch all ladders to do away with the ply .Its al down to how fussy you want to be but i enjoy the small fiddly bits so why not .hope to finish the first planking this week .I went for cherry for second planking ,hope it works. Keep at it she s looking great.Have fun

- 413 replies

-

All i can say is CONGRATULATUONS ,and no one deserves it more ,nice one !!!!!!!!

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

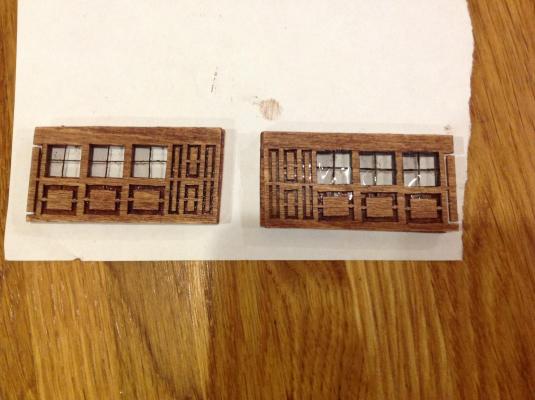

Thanks both for looking in, your opinions are valued . Can get Humbrol Clear Fix which is supposed to be the same .any experience ?? Not fully happy with windows yet wondering about outer frames but no hurry ill think about it for a while . Back to planking.

- 413 replies

-

been wondering about how to simulate the window frames as there are no etched frames included in the kit .Very hard to get wood strips fine enough so thought on thread .Did up a couple of samples and want HONEST opinons on what you think ? the one on the left is 0.25 and i think too fine .the right is 0.5 which seems better its also covered with a strip of light polythene (the bag the sheet of acitat came in )..look forward to any opinions??????

- 413 replies

-

Decided i would try fitting steps in one grating and it worked out ok so will do the other one as well as a break from planking, Wood looks a funny color in pic but looks better in real . Had been planking from the bottom but now changed and working from the top down using this layer to try and figure out the best way to go about the final planking ? Been thinking about window frames and how to get something small enough , newest idea is to try thread , havent seen it mentioned before and wonder if anyone has tried it might do some experimenting to-morrow

- 413 replies

-

your looking good Michael . its not untill you get a few runs of planks on you realise just how big this kit is .i also soaked the end of the planks overnight and then used a plank bender as well to get the extreme bends needed . your right to let the planks dry well before glueing as i read somewhere that the glue dosent work on wet wood .Be carefull when jointing the but ends of the planks ,i always try to spread the joints so that you dont have 2 or 3 together and make sure all planks are securely glued as a loose or springy plank later on will be difficult to correct . there is a great tutorial on this site which i have used several times and points out all the things to watch out for far better than i could . Im glad your enjoying the build cause for a beginner this is quite a challange but your doing a great job . We experts have to stick together . Have fun! Boyd.

- 47 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

hi Michael ,just looking in to see how your getting on . hope your still having fun . I dicovered from the BILLINGS site that this build was aimed at expert builders ,does this mean that if we finish it we can call ourselves EXPERTS . But seriously ,im assuming your still planking as i am ,timber not great but reasonably easy to bend although very thick.

- 47 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

Great minds think alike Been thinking it might be simple enough to make a false staircase . tks

- 413 replies

-

disregard my ramblings about the ladders in the last post ,have just realised i was fitting the small grating on the large hole and you have bone as the plans intended ,have fun .

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

Hands up my mistake ,trying to fit the small grating cover over the large hole . Plans must mean to forget about ladders to lower deck and leave hole planked same as deck .Problem solved or is it ,got me thinking maybe i should still put ladders in .Nows the time if ??? Thanks for looking in Patrick as you can see im creating my own problems now but thats all part of the fun . Im fairly happy with the deck although i picked the best timber for the main deck and there is some variation in colour which i hope wont be hilghted with varnishing ,time will tell

- 413 replies

-

Hi Keith i suppose your ready to start rigging by now ?? I have another small query ,this time about the hole left when the grating frame is fitted to the lower deck .I see from your log you planked the part with no gratings on it and wondered if you got this from the plans as i could see no mention of it . In the cc builds there seem to be ladders here down to lower deck but then we dont have a lower deck . Am considering cutting out the ply and fitting ladders but just wondered if i had missed any other solutions on the plans ?. Did you decide what wood to finish the hull with yet ? Boyd.

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

Morning David Thanks for looking in and suggestions [always welcome) .Cant see any mention of this problem in the plans and from reading the other 2 logs on this build they seem to have planked over the hole with deck planks . Im thinking why put a hole there and plank over it ,surely this cant be what Billings had in mind ? will look into ways of fitting ladders as i agree hatch doors wouldn t look right but no panic there is bound to be a solution ,there always is

- 413 replies

-

just a few pics to update progress Went ahead and planked the lower deck with 0.5 Maple useing the pencil method for caulking , has been scraped but not varnished yet which i hope will bring up the lines a bit more .I also planked the the insides of the hull although it wont all be seen a lot of it will be .Next pic shows a simple jig i made to cut the planking , also used it to sand the edges by putting 6 in on their edge and then for the caulking . Now another snag , compered to the cc builds i think we have a deck less which at least means less cannons to rig but as the last pic shows the hole in front of the grates where i believe ther should be a ladder bown to a lower deck is completely blocked . Of course there is no mention of this in the plans so as i see it i have 3 options .1 try to find matching gratings and cover the hole . 2 make hatch doors to cover the holes or 3 my prefered choice is cut out the obstructions and fit ladders which is how it should be ?? Might be best to do this before i finish the hull planking as i still have some access ?

- 413 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.