-

Posts

45 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Poland

Recent Profile Visitors

-

Canute reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

Canute reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

-

etubino reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

etubino reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

-

etubino reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

etubino reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

-

mtaylor reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

mtaylor reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

-

ccoyle reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

ccoyle reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

-

GrandpaPhil reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

GrandpaPhil reacted to a post in a topic:

Pt. IV: Tools & Other Supplies

-

Intro to Card Models Pt. IV: Tools & Other Supplies

Paragraf replied to ccoyle's topic in Card and Paper Models

Chris, thank you very much for your posts that popularize cardboard modeling. When it comes to tools used in cardboard modeling, biopsy punches are very helpful. These are very sharp surgical instruments, suitable for cutting very small holes (1 mm, 2 mm). https://medicaldepot.pl/sprzet-medyczny/chirurgia/materialy-biopsyjne/sztanca-biopsyjna-z-suwakiem-1-mm-383245742.html. For modeling oval elements made of cardboard, e.g. for forming engine covers in aircrafts, such a tool is also used https://thecakes.pl/pl/akcesoria-do-modelowania/2611-zestaw-narzedzi-do-modelowania-kwiatow-z-masy-cukrowej-4-szt.html. Basically, it is used in confectionery, for modeling sugar mass but in card modeling is also very useful. -

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

-

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

-

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

-

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

BenD reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

-

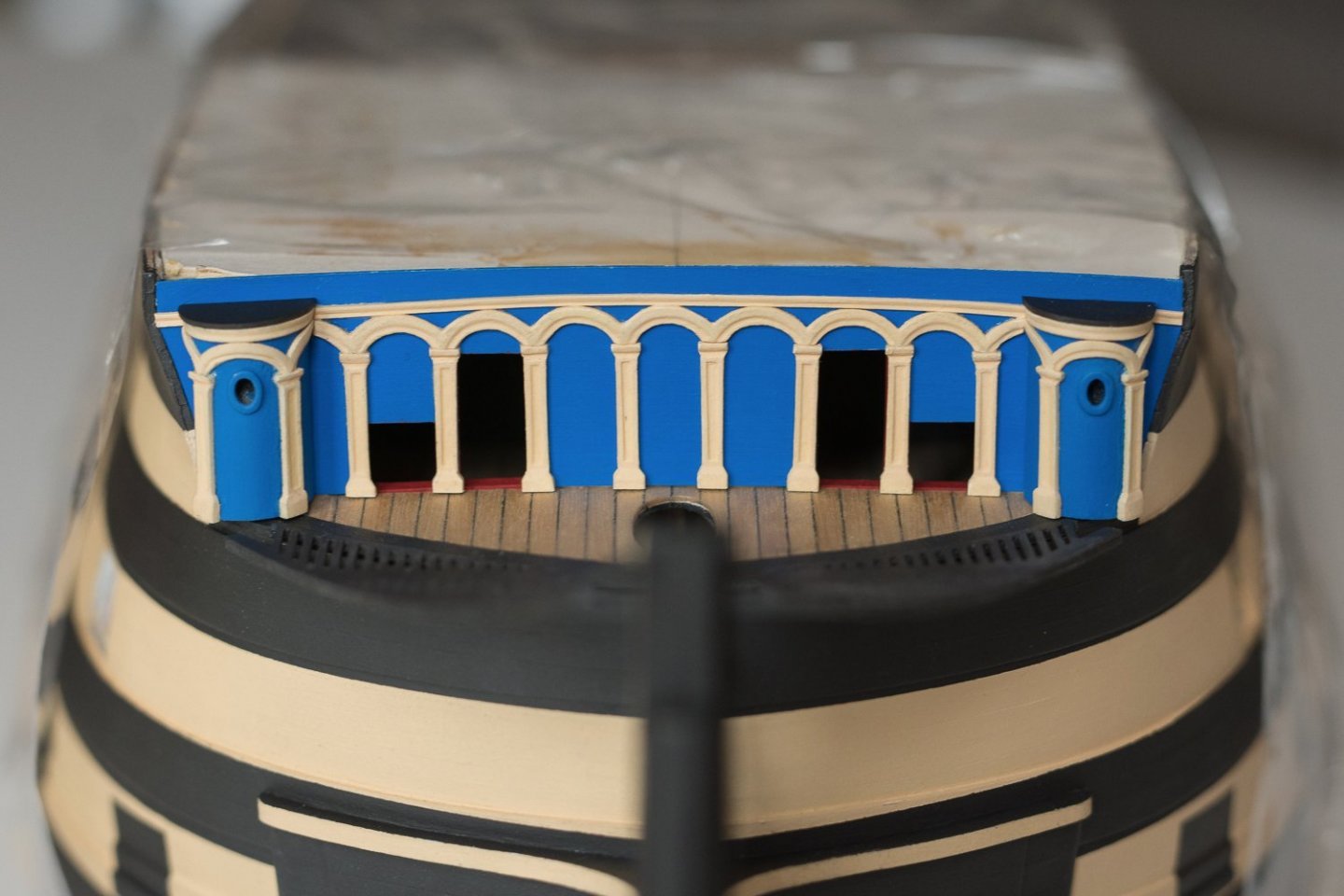

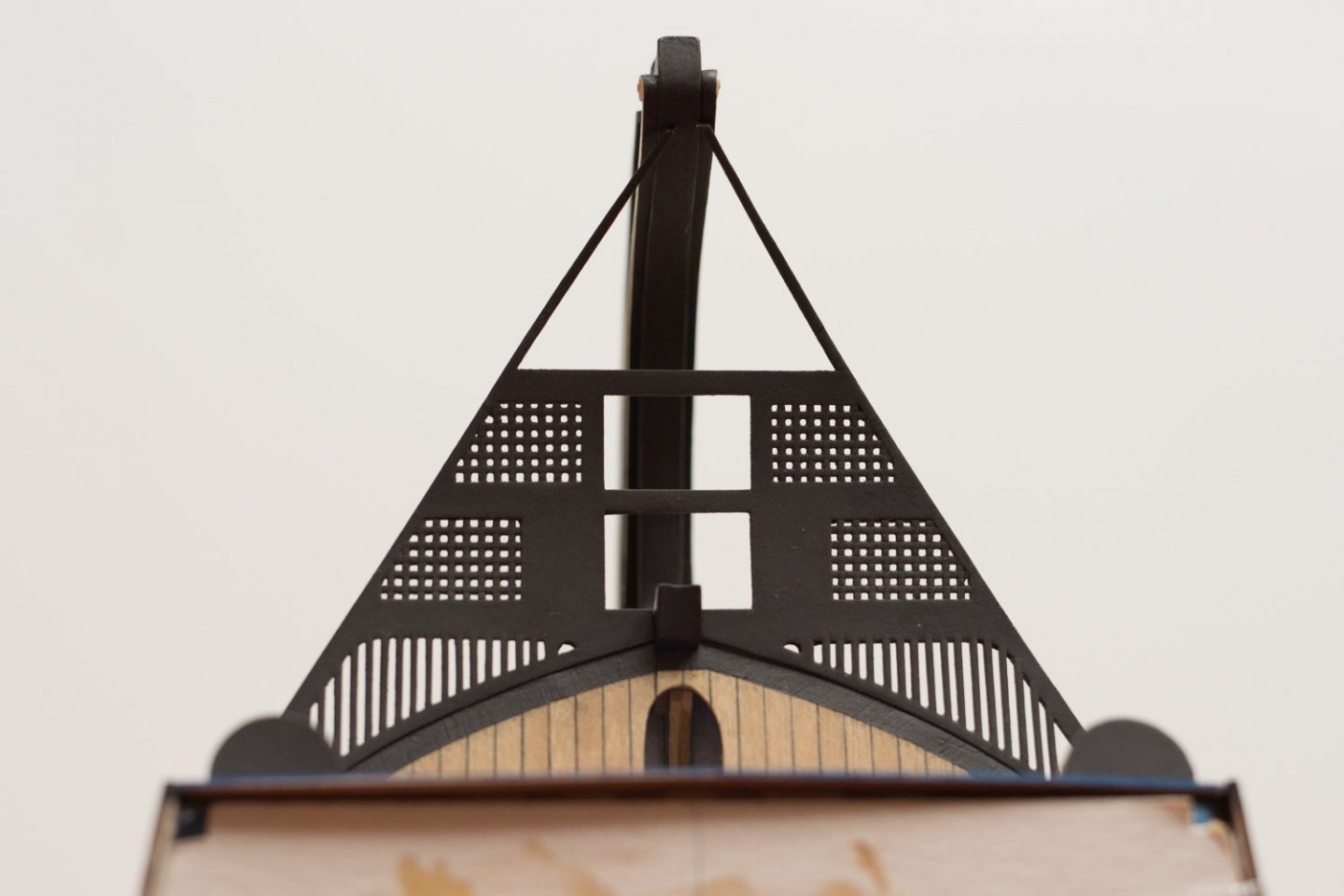

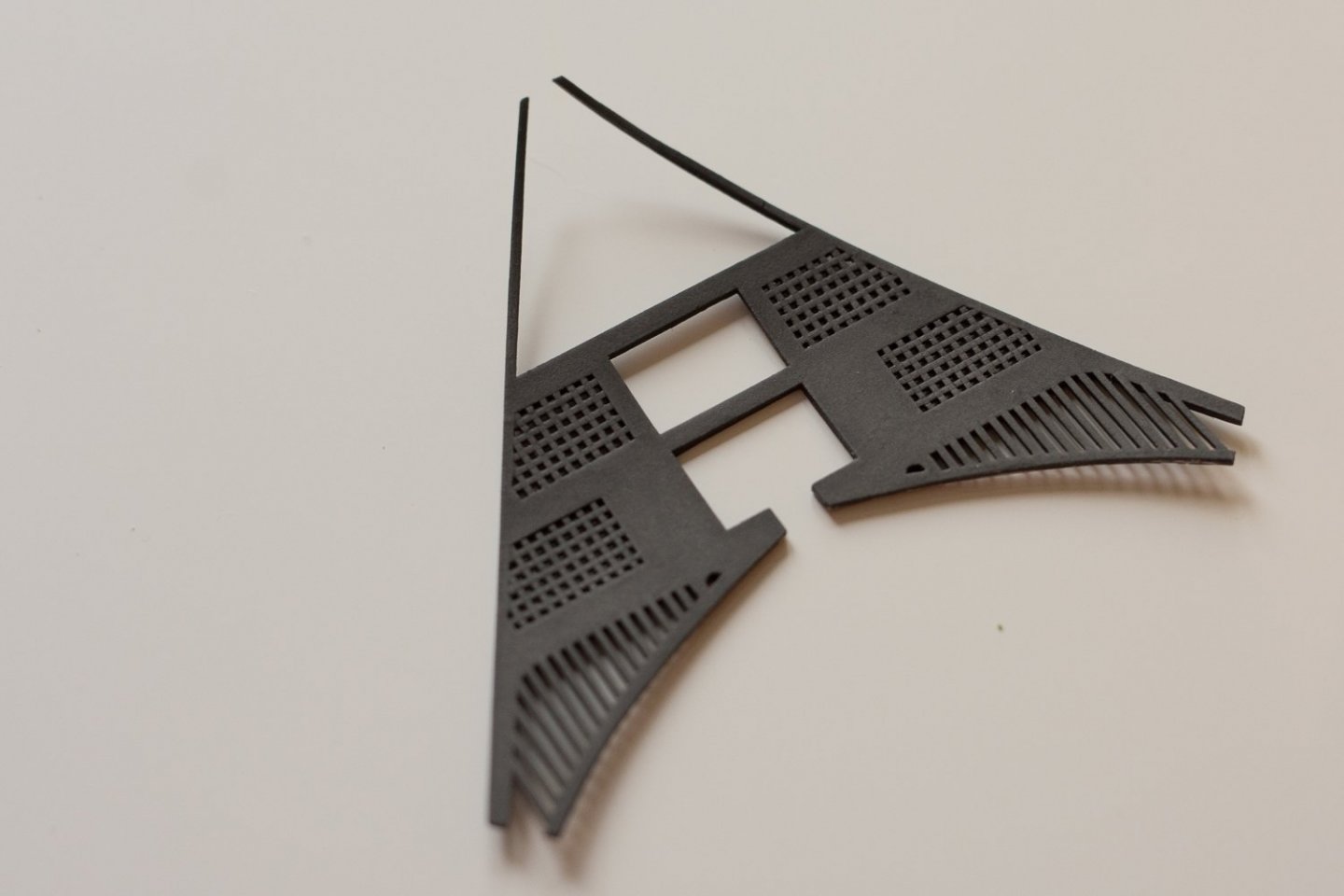

This time I used laser cut gratings, but it is possible to make gratings of this size by hand. Some time ago I made few of veneer; there are on the upper deck.

-

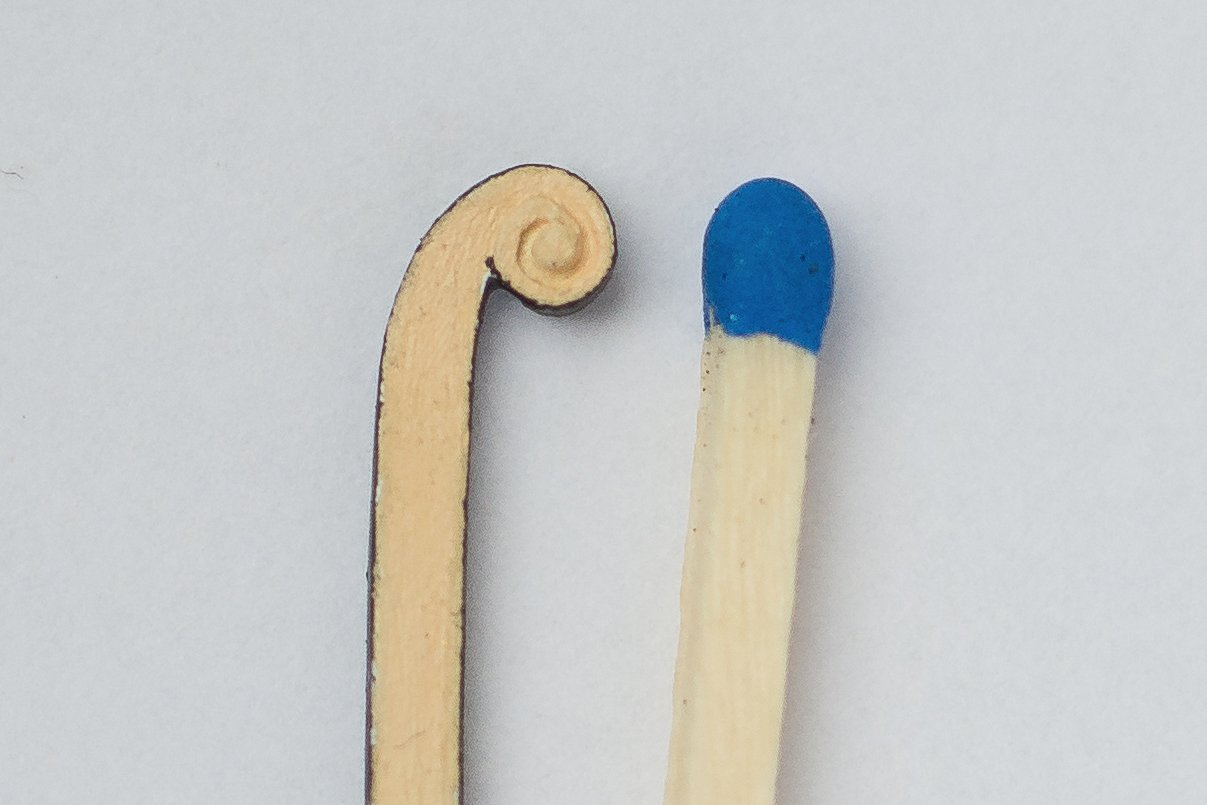

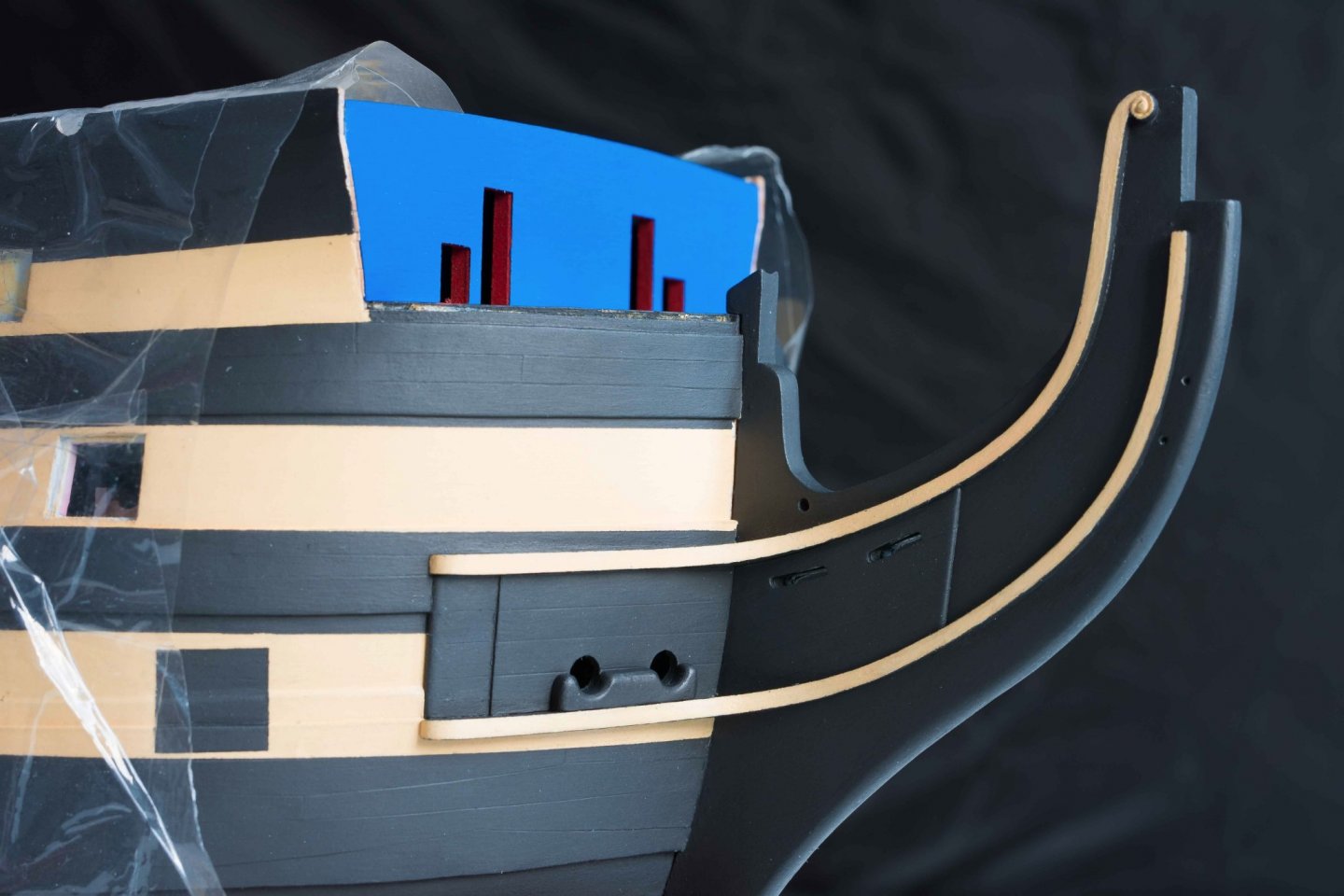

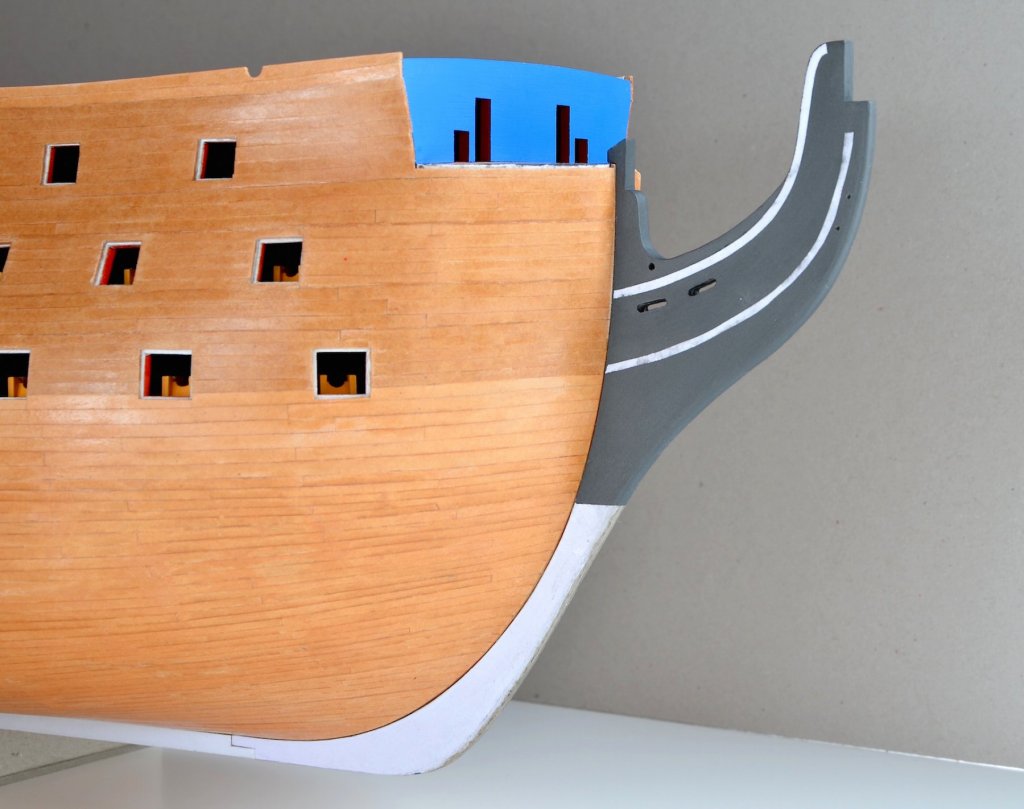

Hello. Small update of work in the bow section. The timbering at bow is not glued yet, because I have to do both main rails first. To be continued ...

-

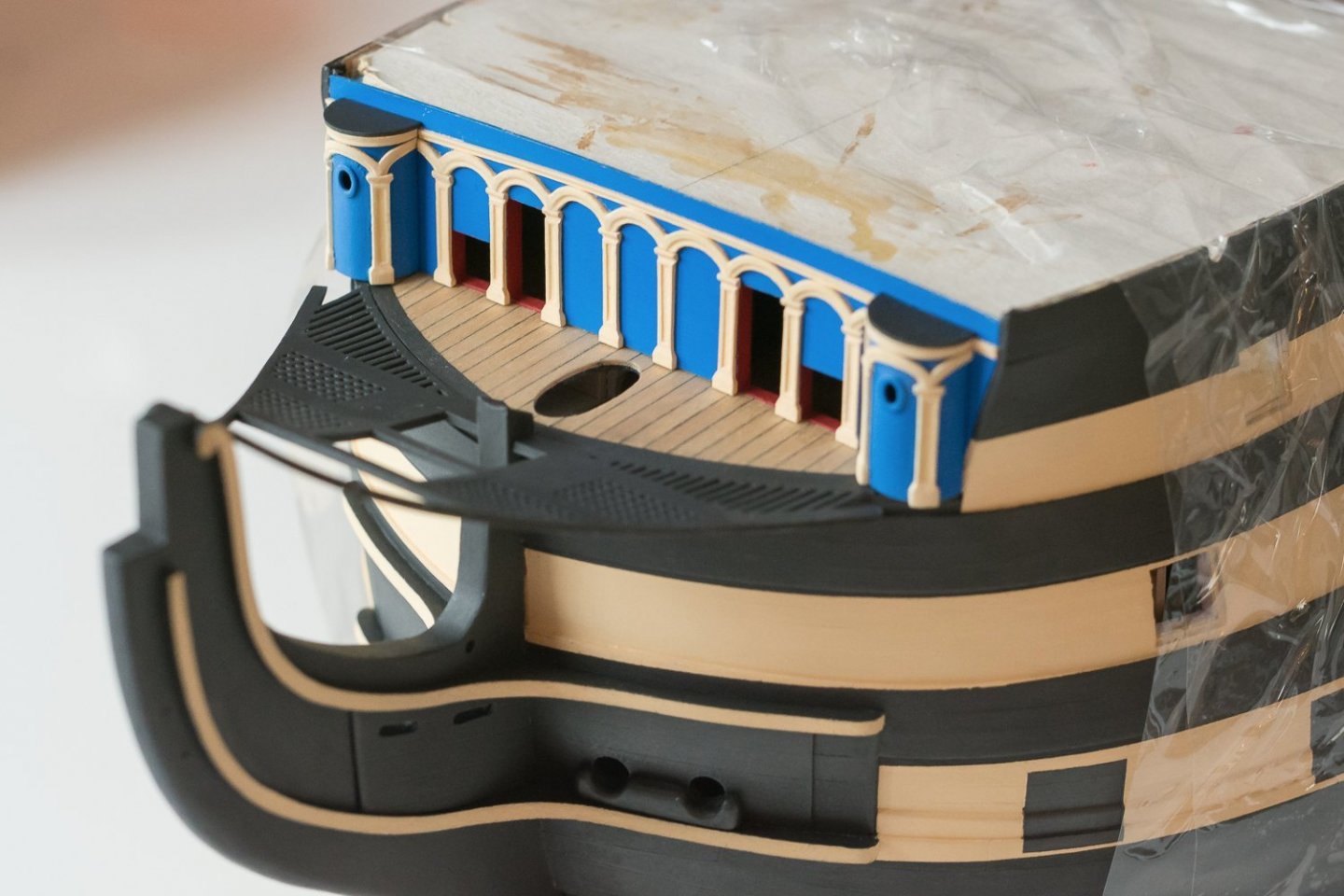

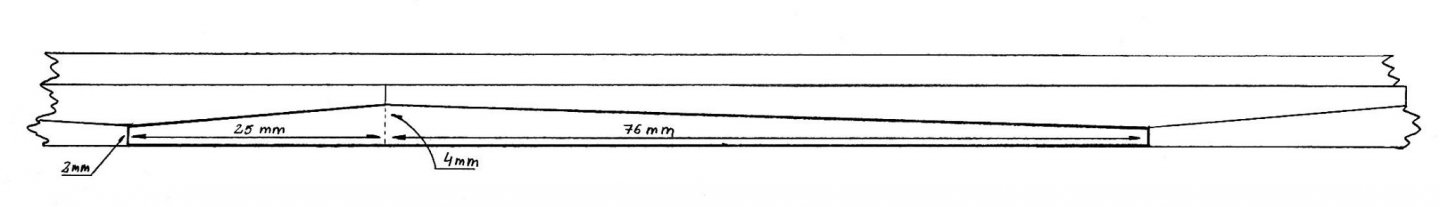

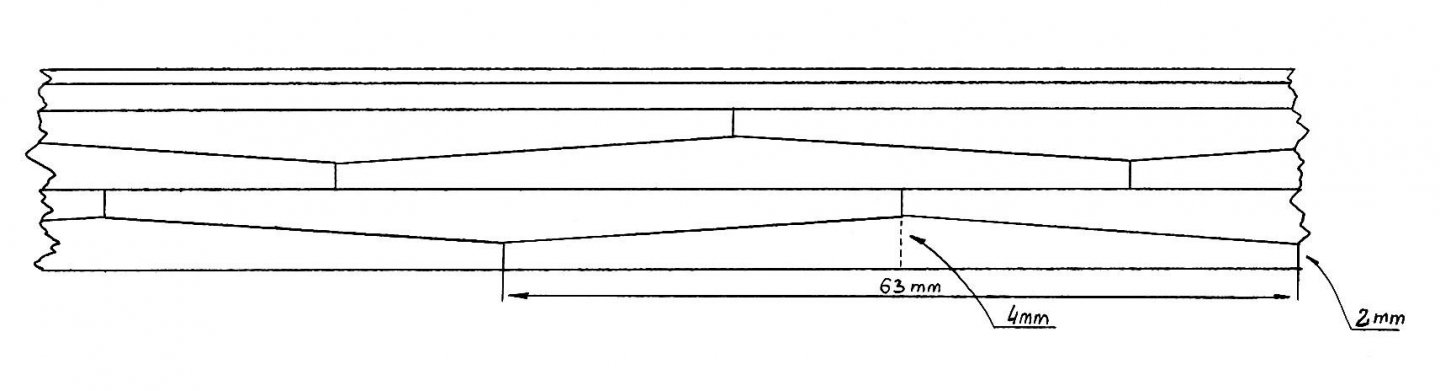

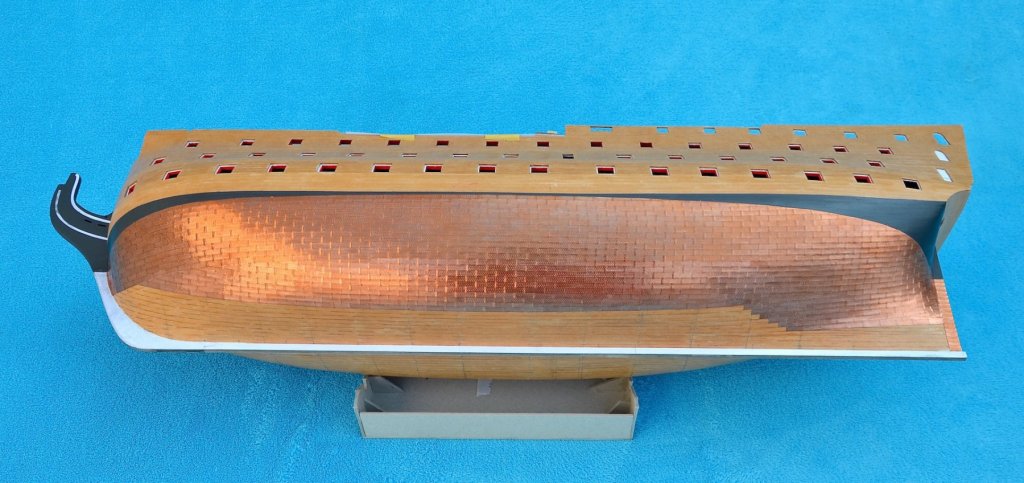

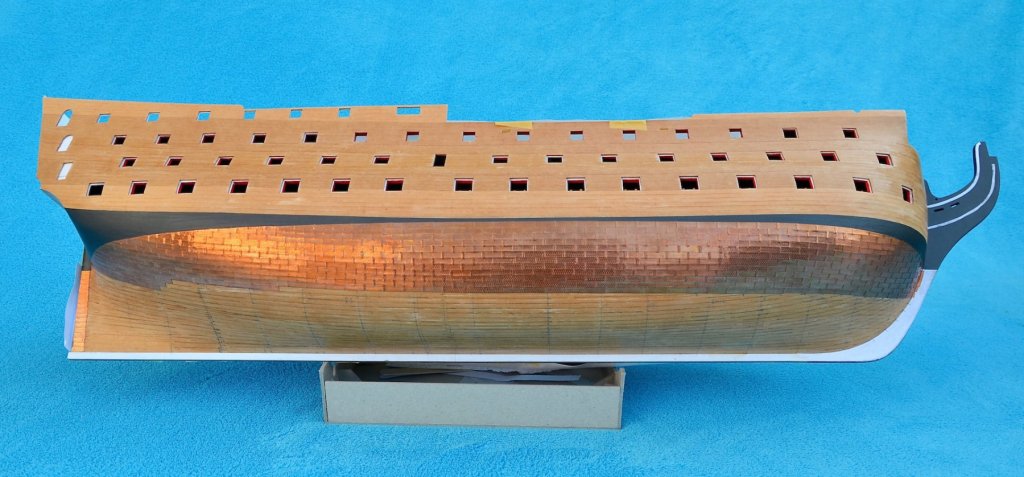

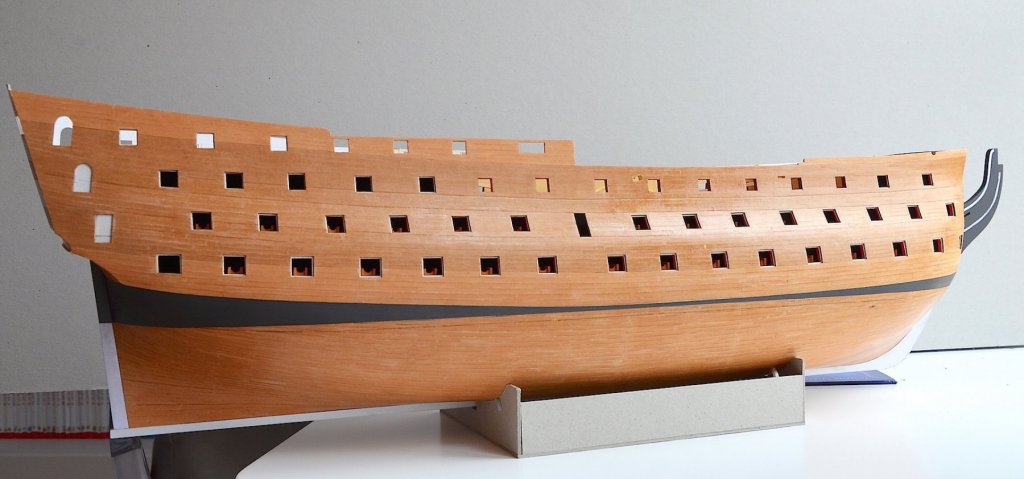

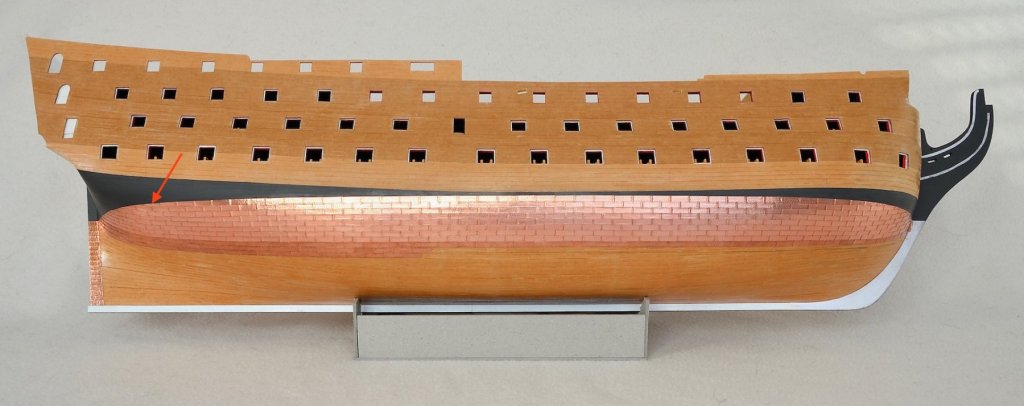

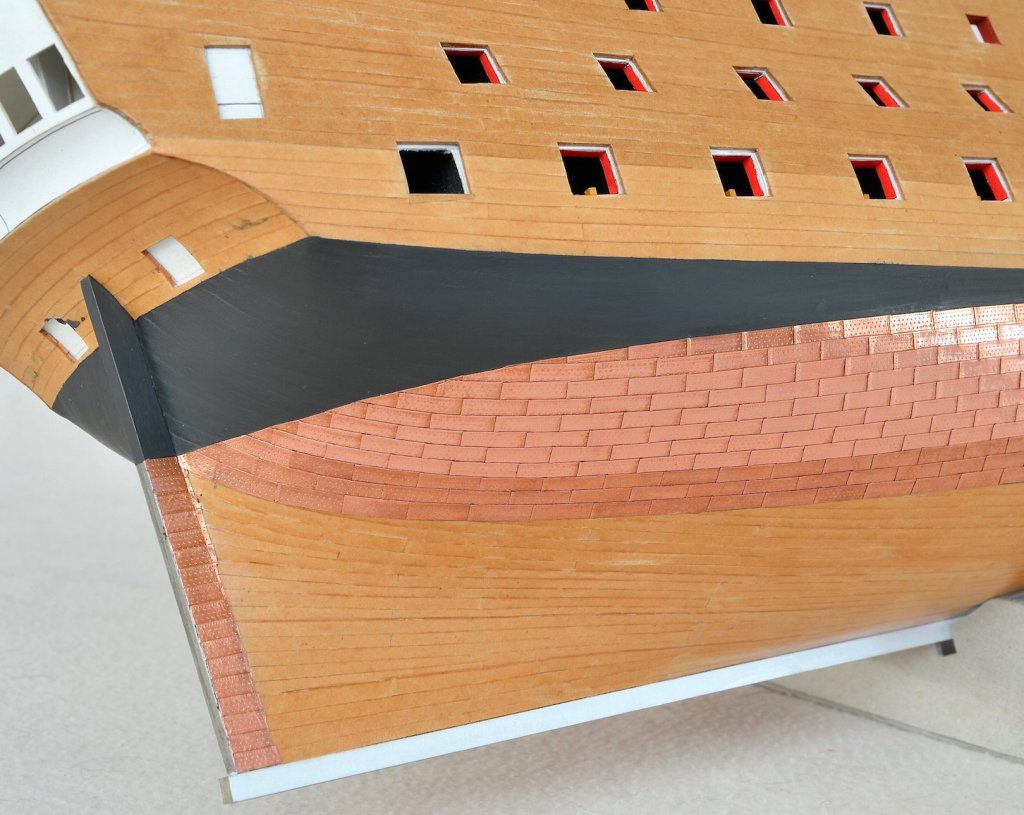

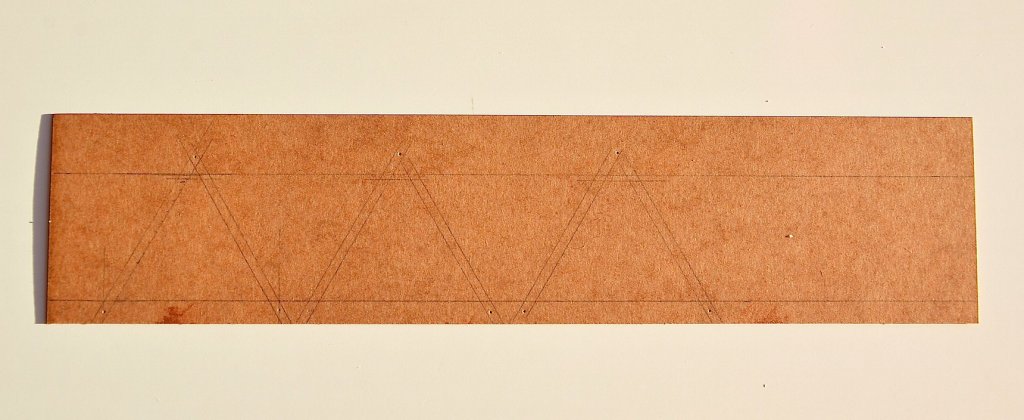

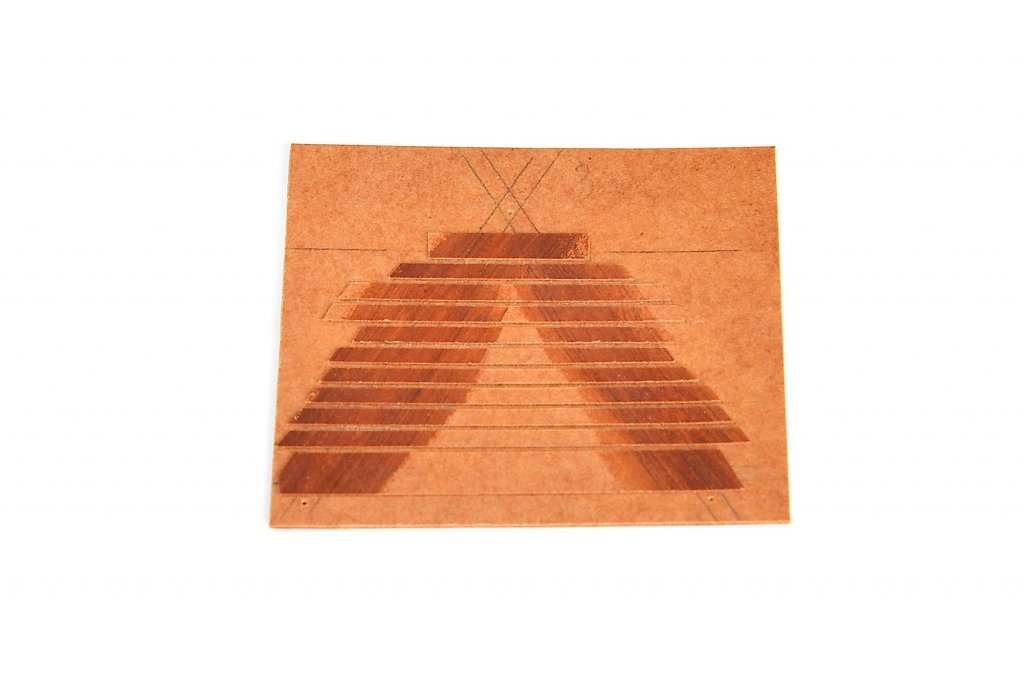

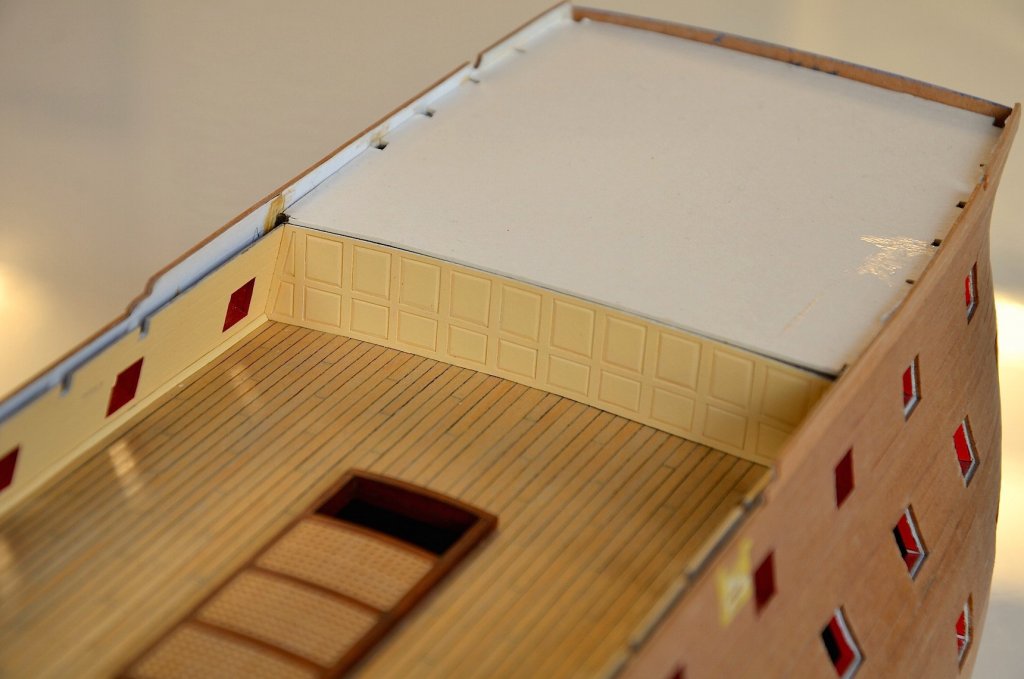

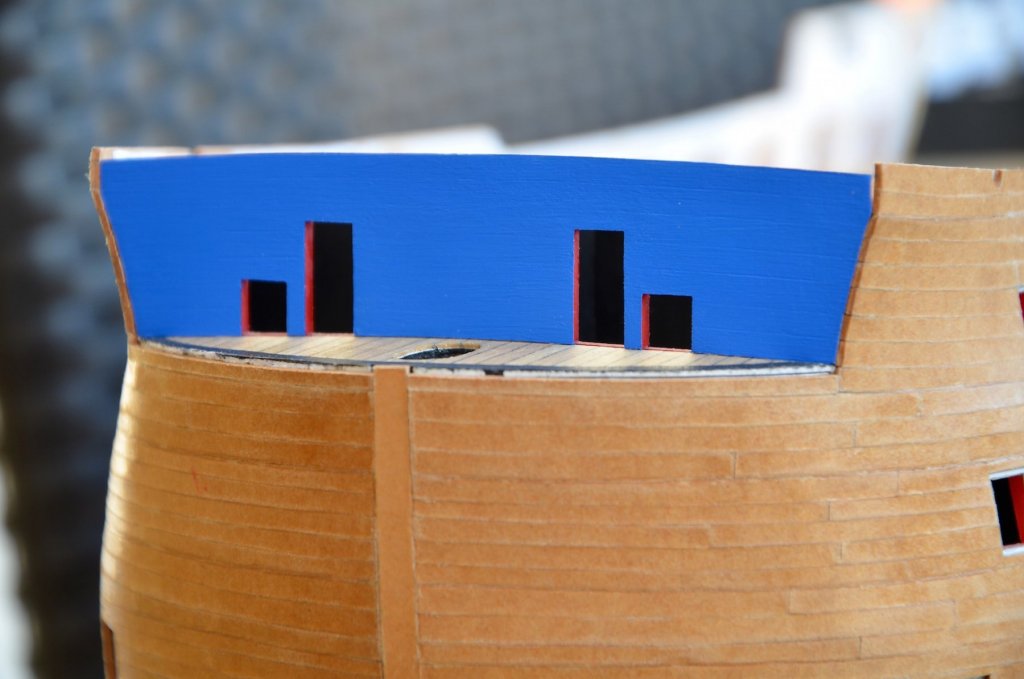

Hello. I haven't been here for almost two years, but I'm still alive and so is my Victory. As you can see in the photos, I decided to change the concept of the model and make it with the lids closed. I saw a model made in such a way and I liked this „checkerboard pattern” on the the sides so much, that I decided to do it also in my ship. So there will be no visible guns on the two lower decks. Before painting the model I've made the main, middle and upper wales on the sides. In Victory the main wale was put on in „anchor stock” planking. Each plank was fashioned with a double taper from the center of one edge, so that the planks laid side by side looked something like the stock of the anchor (see pict. below) The middle wale was put on in similar, but not the same pattern. One edge of the plank was tapered, but insted of the tapers being equal in length one was quite twice length of the other (see pict. below) Some people may notice, that the shape of the planks I've made on the main wale is slightly different than on the other models. In many models, the main and the middle wale are arranged in the same way, as in the second picture. Various sources give different information about the arrangement of these planks. I made them according to the description given in Longridge's book. Interestingly, on the current ship you will not notice the wales arranged in the so-called anchor stock. To be continued...

-

Paragraf reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

Paragraf reacted to a post in a topic:

HMS Victory by Paragraf – Shipyard – 1:96 - CARD

-

My suffering is over.😄 Never again. In my opinion it is not perfect, but it must remain so. To be continued...

-

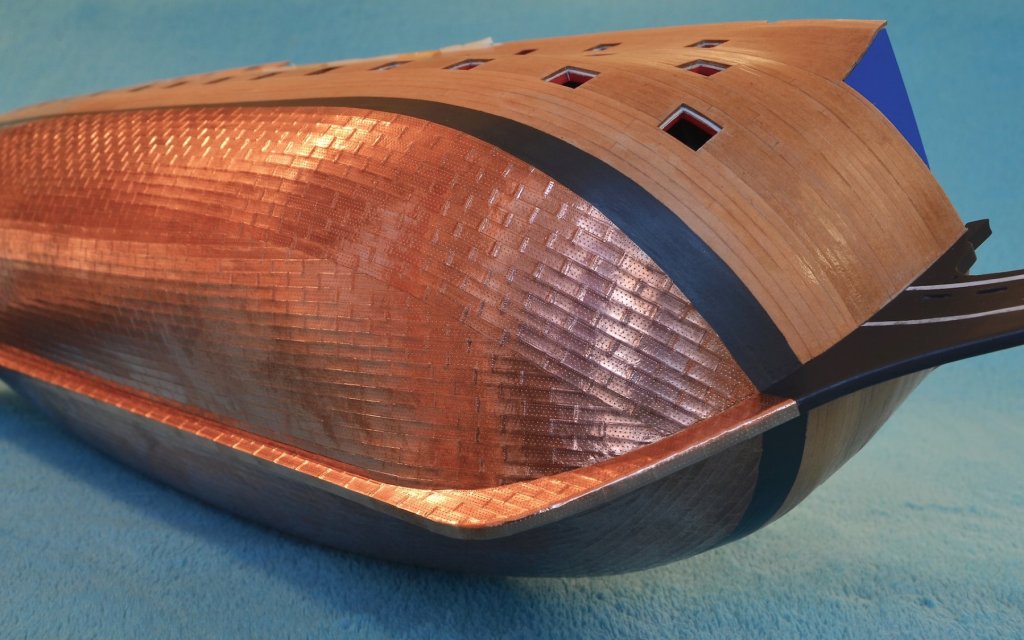

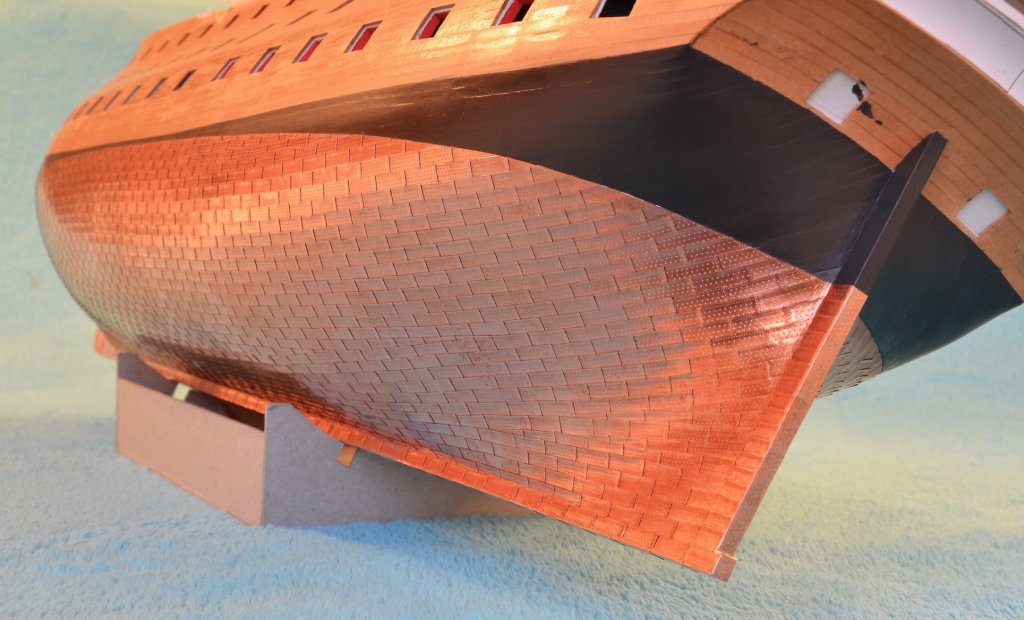

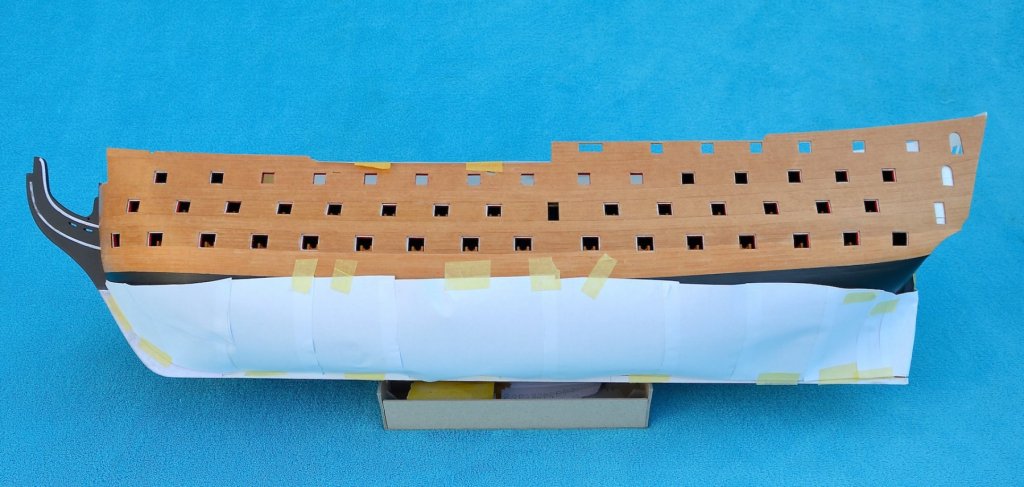

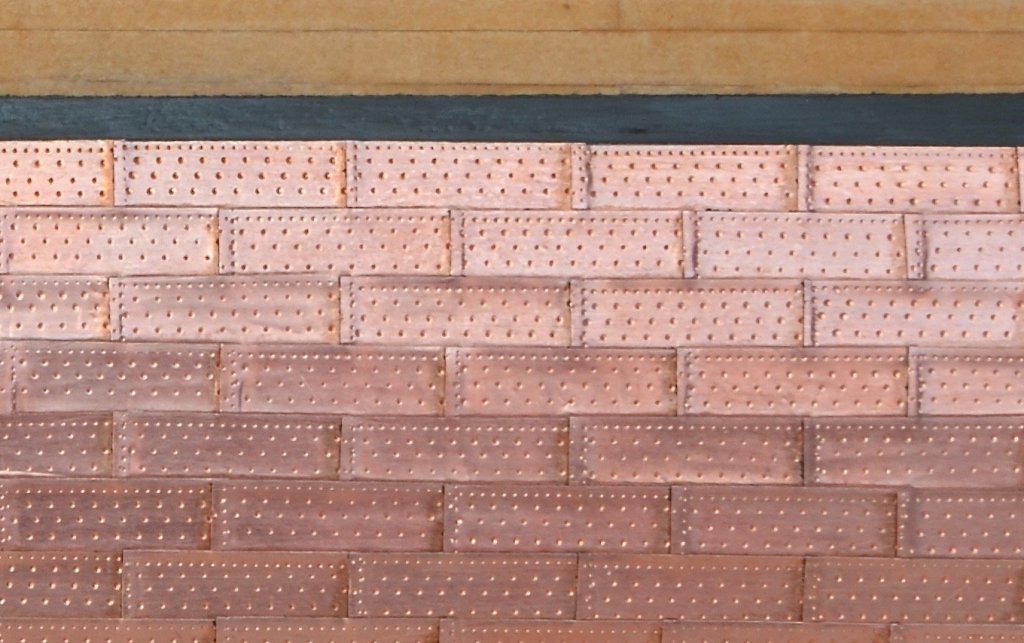

State of works for today. Copper plates on the port side. Copper plates on the sterboard (arranged the upper belt of plates). Bow part of the port side. To arrange each rows of copper plates precisely, I marked their identical course on both sides. A few stealers need to be laid in the aft part of the ship. I've made a kind of "shirt" to protect arranged copper surface. To be continued...

-

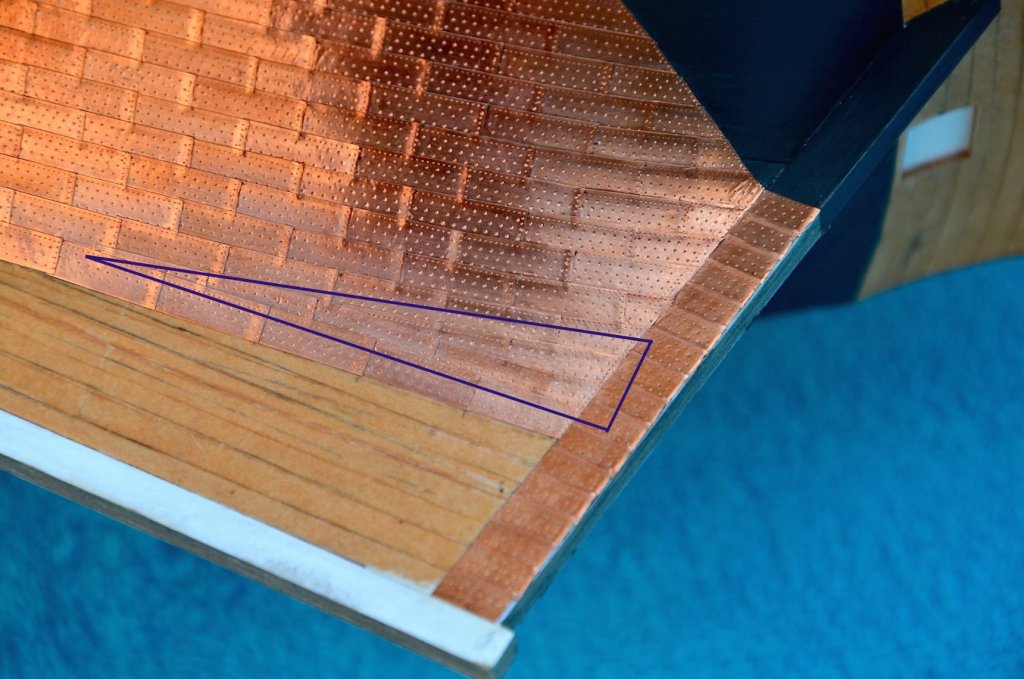

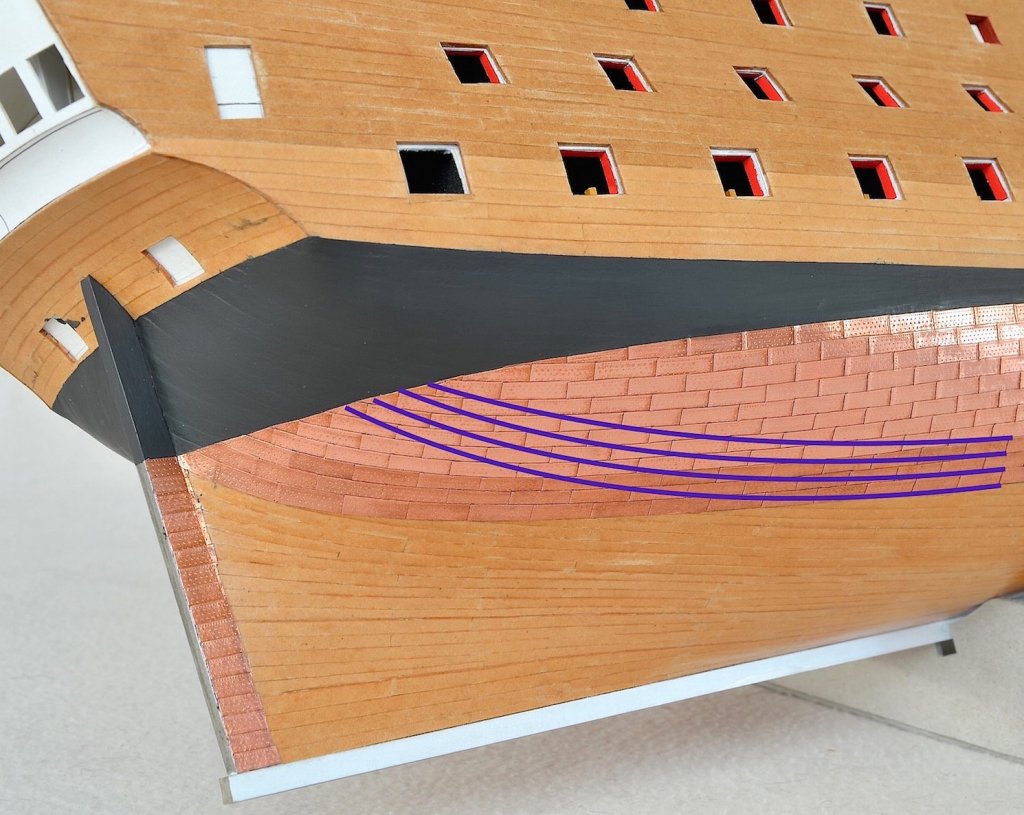

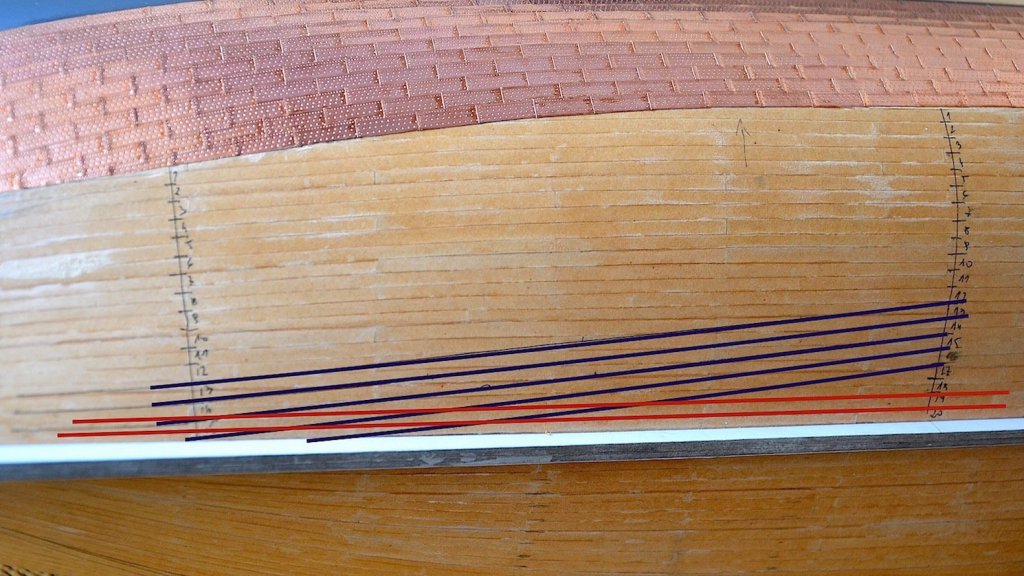

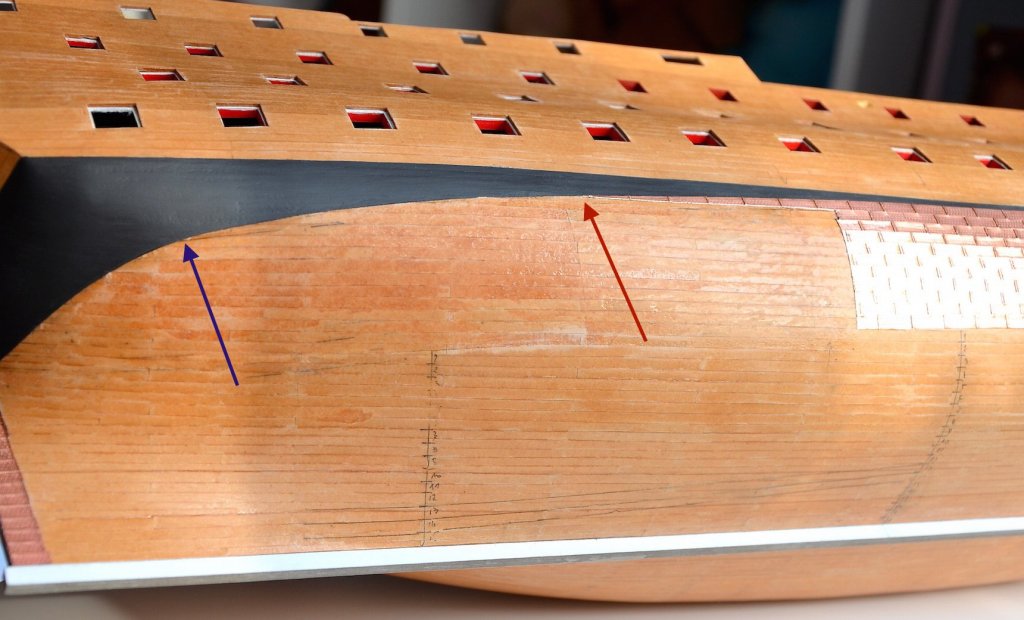

Today, the thing is not about the progress in building, but about why sometimes you need to destroy something to make it good. After gluing the plates I realized that I had started laying the copper cover too close to the stern. The copper strips should run here more or less according to the layout of the planks. In the picture below, I marked the correct layout with violet lines. Continuing laying of plates in this way, would cause their improper arrangement on the stern and in the bottom part. In the picture below you can see, that in the central part of the hull there is still enough space for 20 rows of plates, while in the part closer to the stern there is space only for 15 rows of plates. This way of laying would cause, that copper plates in the bottom part, at the keel, would be laid diagonally (lines of navy blue color), despite that they should be parallel (red lines) to keel, like planks. Therefore, I removed a large piece of copper plates (something about 200 pieces) and I'm gonna lay them again. Plates, according to a new calculations (I hope this time correct) I will start to lay from the point marked with a red arrow; I also marked the previous point from which I started laying - using a violet arrow. To be continued....

-

John the rotten started following Paragraf

-

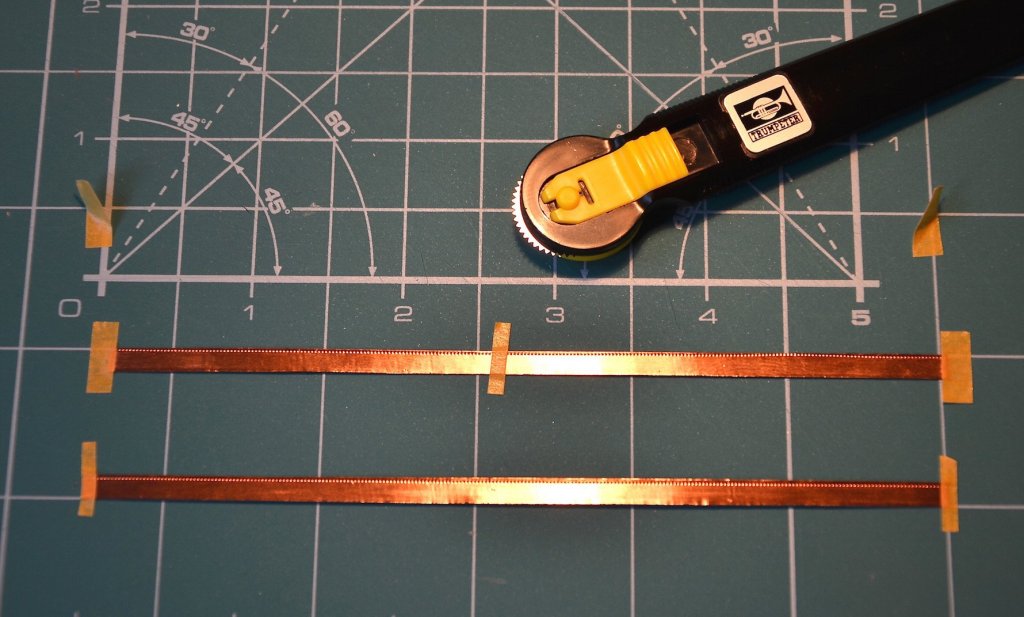

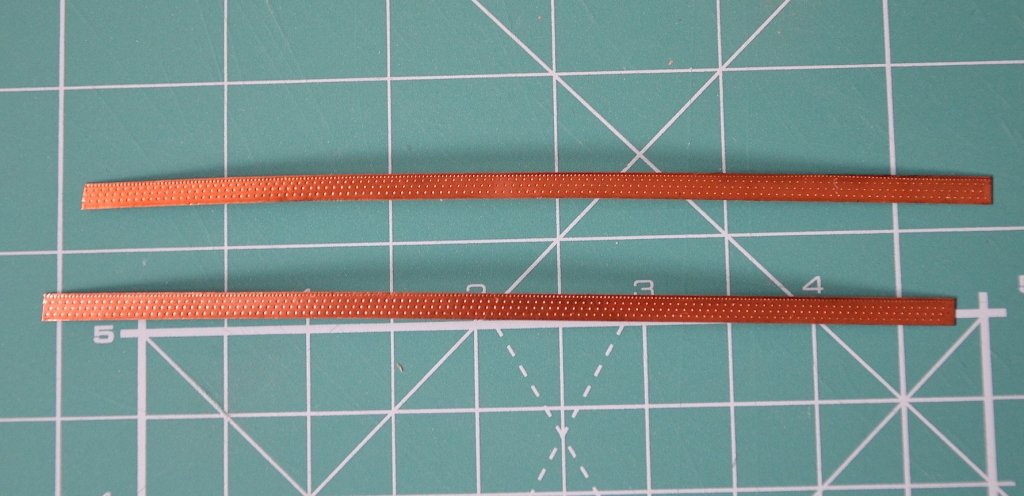

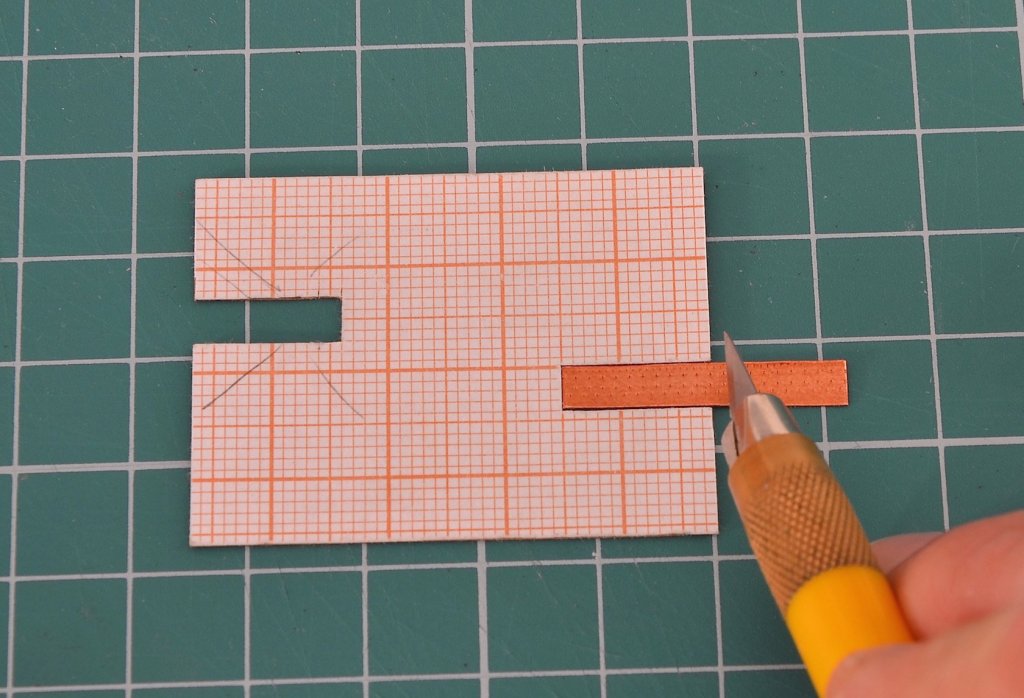

Coppering the hull. Before coppering, using a highly specialized tool, I marked the waterline, which is also the upper border for copper plates. Despite of the primitive method, it goes straight. The belt between the waterline and the lower border of the main wale (which will be laid in the future) I’ve painted black. Coppering is made from Ventura Tape copper foil, with black adhesive. Before cutting the strips imitating copper plates, I fastened a longer strip of copper (about 135 mm) to the cutting mat using a masking tape. Next step was to make an imitation of nailing; I used Trumpeter's rivet maker with densely spaced teeth (by Trumpeter marked with letter „A”) for nailing on the edges, and for nailing in the middle with less frequent teeth (marked as No. „D”). So prepared copper strips I cut - using a small jig – to plates of the correct length, specifically 13 mm.

-

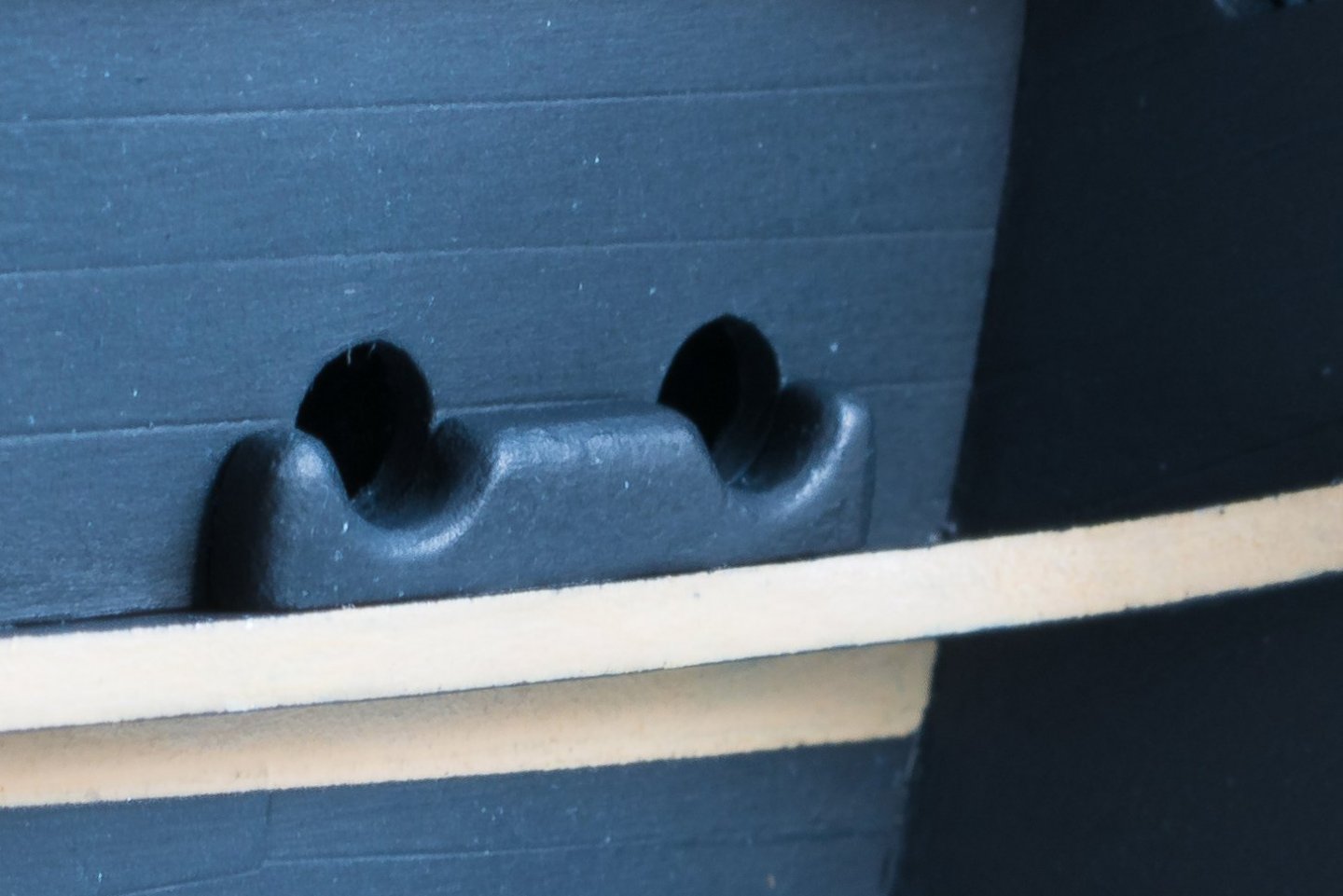

I've made knee of the head with holes for gammoning, bobstays and main stay collar, stern post and keel. To be continued...

-

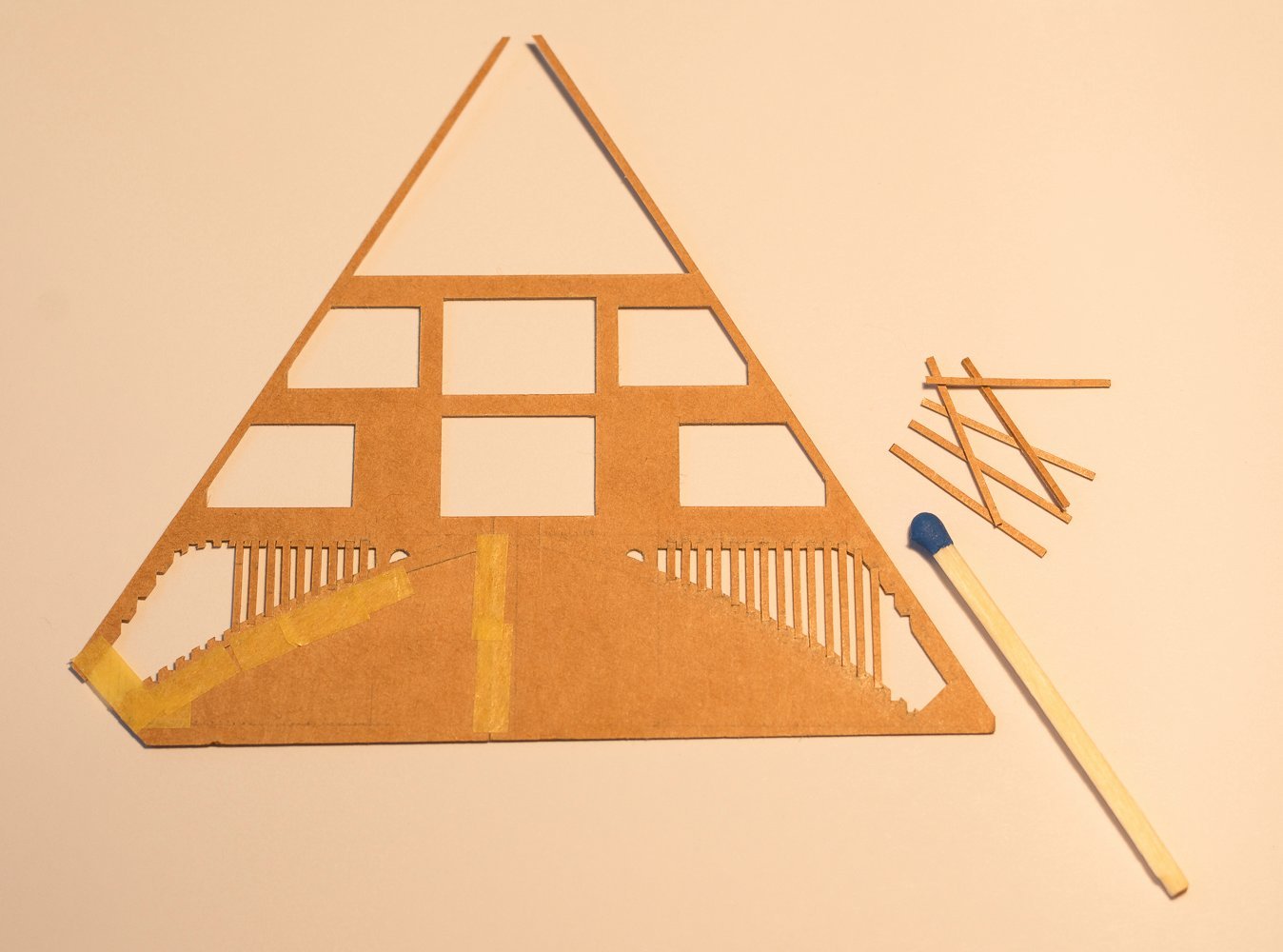

Small update. I've made the ladders, leading from the upper to the middle deck. Firstly I'd drawn the cheeks of the ladders, marking them under the appropriate angle (60 degrees), as a mirror image. Then, I glued croswide the painted straps of the pressboard; I set the distance between the straps by means of a spacer strip, corresponding to the thickness of the step. After sticking all the horizontal straps a kind of Christmas tree appeared. Then I cut off the cheeks of the ladders, cutting down on the lines drawn previously; It created a kind of comb with the slots in which I finally glued the steps.

-

Amateur. As for now, most of the parts are made by myself but kit is used as the pattern for cuting the elements. Perhaps I should change the topic for "Based on Shipyard - Card - 1:96"

-

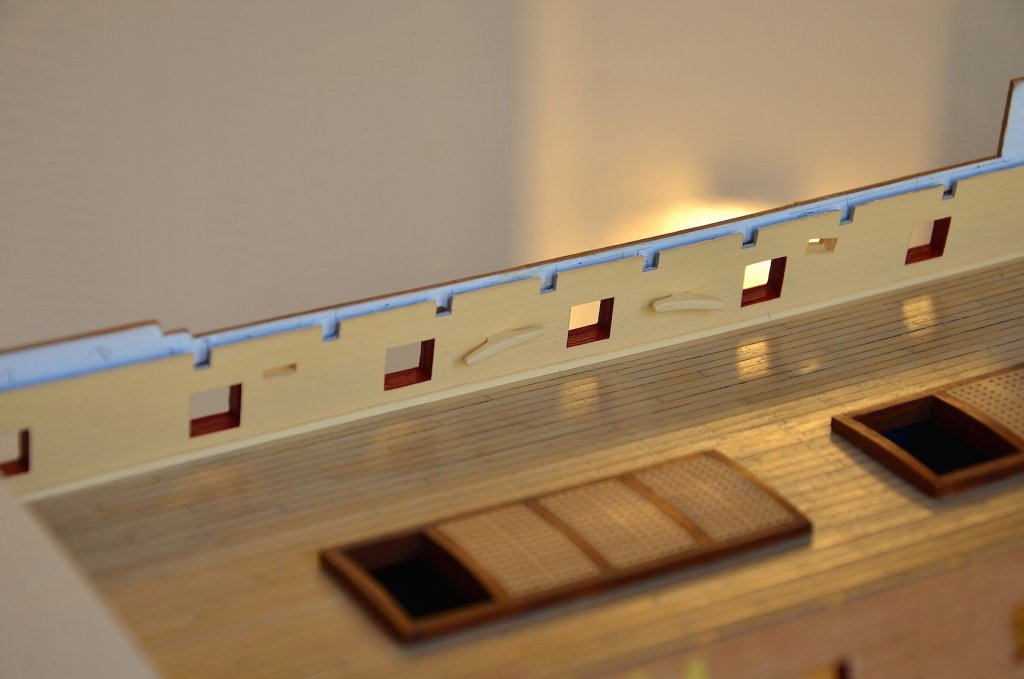

A few photos of my current work. Only several details have been added such as four giant cleats for fore sheets and main tacks and the deck beams. Deck beams are not glued yet; they are just lying. I've decided to change the beakhead bulkhead and lower the door opening and the gunports; this detail was done improperly.

-

Thank all of you for your compliments. Work still goes on, slowly but forward. Soon I'll show some update. The work is dragging like a turtle because there is not enough time to building the model. Additionally I decided to destroy some part of the current work and make corrections. I changed, for example, the look of the beakhead bulkhead and improved the gunports on the upper deck, which after the painting looked ugly. Modlerbob. Banding card planks is for certain easier than wooden, but cutting them is much more difficult because it’s been done handly. It really hurts

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.