-

Posts

7,036 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin

-

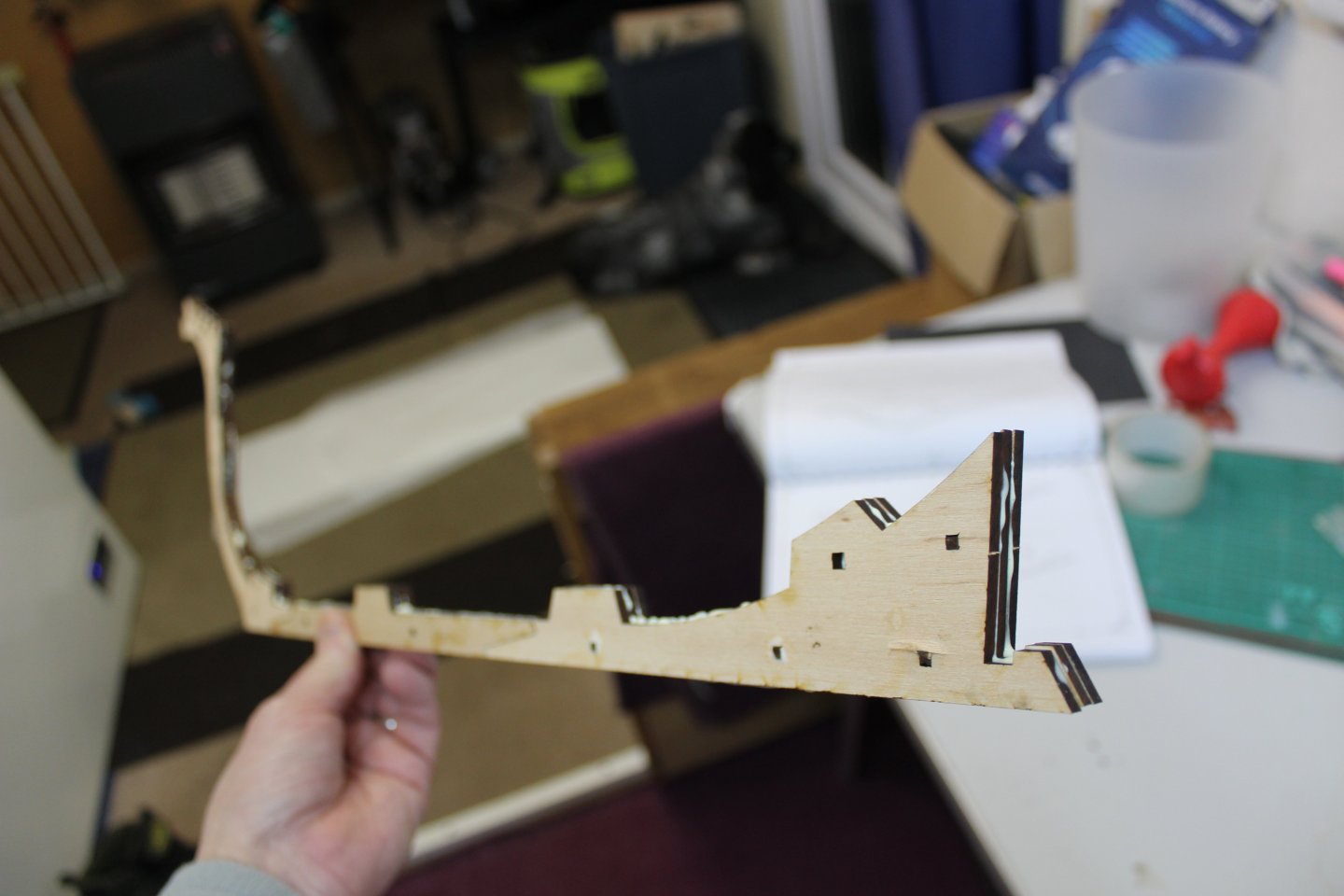

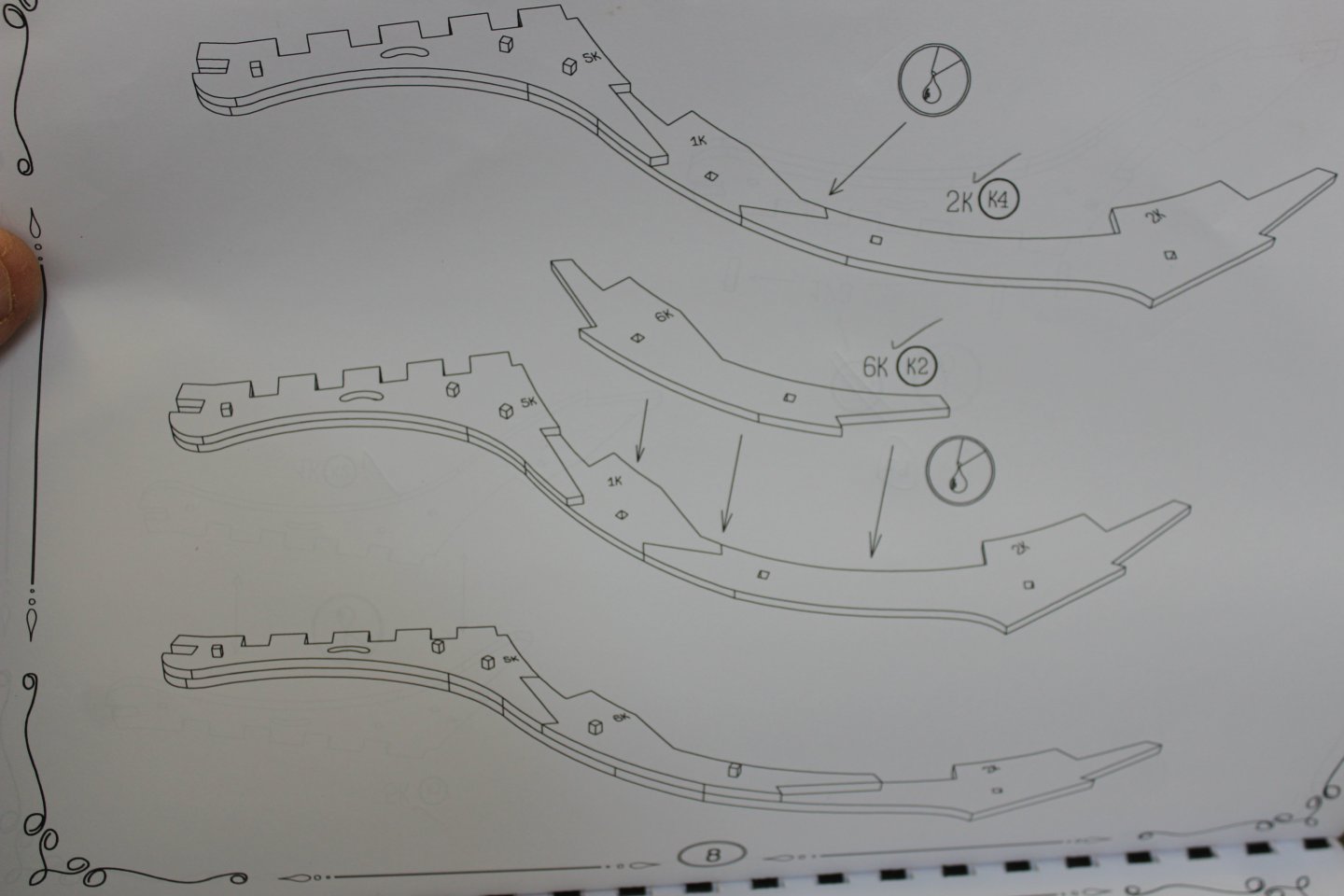

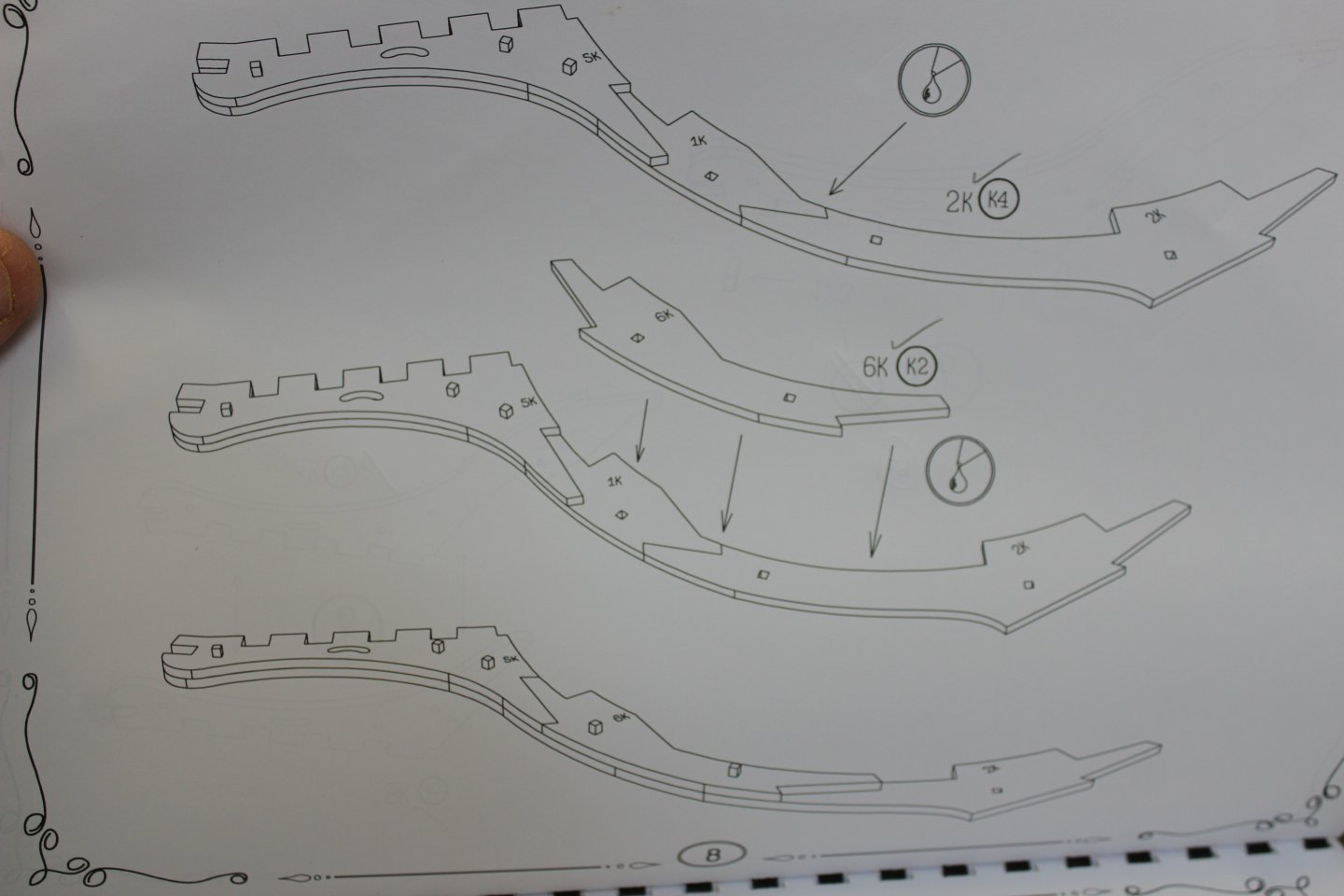

Good evening everyone day 9 not a moan at all, but the instructions could be better, there are a lot of mistakes with parts identification pieces are inserted in place then not shown again on the drawings, and lots of parts are not on the billets they are marked as being on, everything is there, just ov there has been changes but instructions not updated therefore the videos are a must, and there are loads of them (over 60) God kevin mk2 is back and already moaning about a kit from a war zone i have delayed (abandoned) my ideas on wifi lighting and ordered 12vt 5mm wired orange and yellow flickering leds, the wifi ones just dont give enough distance to work, unless i can find a better power source i am now at the sage of putting the upper decking in, and still dont know what colour stain to use, the hull will be in two tone oak, i have ordered a teak stain to see what it looks like The build is now firming up as there is a lot of bracing being put in and so far no issues, if you watch the vids all frames are now secure to the keel for interest only, if you can see down the upper deck ladder upper deck bracing, the individual plants sit on this

-

good evening everyone, thank you for comments and likes Day 3 all frames test fitted on centre line, and roughly faired 24 frames all needed some attention to get them to fit ok, most of that was just removing the laser char, and they have all been roughly faired, will sand smooth when they are fixed in position frame 1to3 go in together frames 1-9 need fairing frame 18 is not marked, but all frames passed that are reversed and need some fairing required

-

good luck with the build, now im back i can provide the popcorn

- 22 replies

-

day 2 today 16th Jan 26 a lot of frames on this build, 24 of them, they are all tight on the centre line, but just removing the laser char enables the to slide on ok, the fwd and after ones however have faring lines all over the place to ensure the plank runs flow ok but also to ensure they fit on the centre line and doubler, the beech is easy to work with and sands down quite fast the first three go on together, matched as a unit, i am however not ready for that and going to do all the frames before i commit to glue 24 frames to go fairing lines to get a good fit

-

Day 1 wed 14th Jan 2026 did a full contests check against the instructions the quality of the wood is excellent, and a lot of it, the frames from Ply are well lasered, the rest of the contents is mainly beech and again well cut with little laser burn, looking forward to this, so lets get on with it , everything was there, any issues now, i will blame the bois the centre line is made up from 7 pieces that are sandwiched together, and kept in place with inserts, this was then allowed to dry under weights the same with the Keel and then attached together with tape keeping them together whilst drying the next part has fairing lines marked on, so using a Dremel this work was quickly sorted, and sanded before fitting in place with inserts again, im noticing a few errors with part identification, , they are not always shown and some are not where they are instructed

-

good evening everyone, Welcome to my new 2026 build, I wasnt allowed to purchase this kit as the delivery costs and import duties were deemed to high by the admiral, but i dropped it into the basket to see how much, and it created an invoice, never ever seen that happen before, but i honoured the agreement and waited for arrival a great kit review here by @James H 1:48 San Bartolome by Pavel Nikitin - REVIEWS: Model kits - Model Ship World™ here are a few shots from each of the three boxes i received, i however never ordered the cradle or stand Box two box 3

-

This San Bartolome was supposedly a part of the ‘invincible’ Spanish Armada led by Alonso Perez de Guzman, 7th Duke of Medina Sidonia, from May to September of 1588. The Armada was battered in multiple skirmishes with the Anglo-Dutch naval fleet, composed of light and manoeuvrable ships led by Charles Howard. This clash is known as the Battle of Gravelines. Elizabethan Pirates excelled in that battle, especially the notorious Francis Drake. The confrontation between Spanish and Anglo-Dutch fleets lasted for two weeks. The Armada could not regroup and, refusing to invade England, headed North. The English fleet followed the Armada along the East coast of the British Islands. The Armada’s return was very challenging, having to go through the north side of the Atlantic Ocean, along the West coast of Ireland. Due to strong storms, the Armada’s ships were taken to the far North and West shores of Ireland. During this expedition, the Armada lost more than 60 ships, of which only 7 of them were lost in battle.

-

4 years later yes the fwd 1/2 deck is to short by 3 frames, an access ladder comes from the 1/2 deck upto the lower deck, i presumed the ladder went fwd to aft so i set my basis on that, in fact it goes port to stbd. i there fore ripped the 1/2 deck out and made a new one by extending it by 3 frames the deck frames now fit much better after being sanded, and all the storerooms have been remade, to me it looks better

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

good evening everyone Before i mention the build i would like to thank everyone for the morale support given to me over the last few months, for anyone who doesn't know, my wife went into hospital on September 2nd for a planned appointment, they admitted her there and then, and she passed away on 4th November, ov things were deteriorating prior to this event, my demise on the forums shows the decline. Christmas just gone was orrible, i hate new year anyway, and our 20 wedding anniversary would have been 29th December. Just the 12 February date to get out of the way, would have been Ruths 75 birthday. As of now im moving forward, i have new boats i want to build and unfinished projects i wish to finish, Enterprise, this kit frightened me, i was never comfortable with it, and i never enjoyed posting about it, because im stoooopid, i tried to do more than the kit provided for and never understood the terms being used when being asked questions about her, and so i abandoned her 0ct 2021. i have changed, ive build some good kits since then, i love the hobby i will have more free time to do things, subject to the bois and all the things i have to do and the 1001 things that the wife did lol this is my last full profile photo of her in 0ct 21 the kit only provides for the man upper deck, i wanted to put in the lower and 1/2 decks, so just before i put her away nothing quite fits and i have a horrible feeling i have underestimated the the 1/2 deck length

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

Good afternoon everyone following on from my thread, Life continues" Life continues - i have decide to bring this build back to the table whilst i get the mancave sorted out, i would like to say Merry Christmas everyone from the Boi's and myself

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

good morning everyone without notice the wife has been admitted into hospital, which has thrown a massive curveball in my direction, so i have decided to put all my present builds on hold like the Bounty, however i fancied doing a bit of rigging, if and when i get chance, so have brought the EX Amerigo back to the table to redo all the shrouds and rats

- 273 replies

-

- panart

- amerigo vespucci

-

(and 1 more)

Tagged with:

-

Good Morning Lyle im actually been looking at yr build as it is the most advanced one i have seen and has given me quite a few ideas, thank you, link to yr build is here HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale my build will be renamed as she will bear little resemblance to the original build and adapted from the kit, the wife wanted me to build her, so she will possibly be renamed "Ruth" i very quickly realised why so many of this kit go unfinished Internally the kit although bears very little resemblance to the vessel, and the kit contents to make something out of it is sparse and not very well thought out is pants to say the least, for example the cargo hold is to short as the lower foredeck is far to long, and the very high centre line, gives you a W shaped space lol. But i have found the biggest issue with adapting her, is keeping the frames in the correct position, other than the keel and the one side of the middle deck there is nothing to keep them lined up, the very least AL could have done was put some indications on the top deck if this is classed as a entry level build then double planking should have been included, i will be doing that with mine, this could be a fantastic kit, had they spent a few more Friday afternoons thinking about builders making and completing her

-

Good morning everyone progress has been made, but a lot of going back and forth, and reworks my problem with this kit is the lack of any upper hull strength, all the frames are just supported by the keel, the only deck that helps to keep the frames in place is one side of the middle deck, the rest are either been designed for the internal viewing, or are only small sections , therefore allowing the keel to flex all over the place thinking ahead i have been making templates to help kee things stable, but hope to show this as i move along lower foredeck removed and reduced in size, it was far to long and was adapted for the Bethia conversion to Bounty im currently in the process of making up some bulkheads, although unsure of what will be seen , as im undecided what cutaway needs to be done on the middle deck after deck remains the same templates before doing anything to the hold i duplicated the middle deck half to give me a fighting change of keeping the frames in place Cargo hold ongoing, i wanted to to be able to use this space, even more so after the fore deck was shortened, but the frames where they fit to the keel were all different widths, do the three middle ones were de-bonded and made the same, i also traced the outlines to allow template to be added to the frames under the fwd cabins and the pump well now im able to use some stained 1X5mm stained lime strips to plank the hold

-

good evening everyone thank you for likes and comments Lower decks perhaps overdid the staining on these, they turn much darker than anticipated, they they have been secured into the hull after the support beams were placed Hold well must have attempted this 5 times at least, i didnt want the open side and every time i redid it i found bits i did like, or it didnt fit as well as the previous version when i had a version built that i liked i then saw something that made me rethink it all. The AL version is more towards the the ship Bethia before she was purchased and renamed Bounty, as part of the conversion she had extra cabins built, and one of these sits in front of the mast well so i had to move the door forward and make room to put in a small extension deck, which will become the deck of the extra cabin access to this deck is via a ladder from above the next stage is to put in 5 cabins on the port side, but unsure how to do this, as the deck above has been reduced to allow the insides to be seen, bearing in mind the kit has nothing provided in this area, hopefully i will be able to show the middle deck in place to show the problem i have created for my self

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.