-

Posts

2,580 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

exhaust??? it doesn't go any faster. I did however give some thought to hooking my vacuum hose to it

-

I have a Mastercraft table saw bought from Canadian Tire a few years ago. It needed a zero clearance insert plate as the one supplied accommodated angle cuts and it also sat below the deck surface which caused me some grief. I made my new plate out of oak... good and hard and flush with the table top, and it has made a world of difference. I then made a Cross Cut Sled and added an adjustable stop block. To improve on this I mounted my old (never used again) vernier caliper instead of a measuring tape. The pin that locks the fixed end of the vernier is an old worn out drill bit. So a drilled the hole with a new one and I knew it would be a perfect fit. The moving side is locked to the stop block by a profile plate on one side and a rotating locking cam on the other. As an after thought I drilled another hole to keep the cam Allen Key in as I am sure I would spend 20 minutes or more looking for it otherwise. This vernier reads to only two decimal places and has an accuracy of only +/- 0.01 inches. This is fine enough for quite a few of my cuts. The saw can only be raised 1-1/2 inches for this sled so it will be used on small stuff. I did not invent this sled... I found a version on YouTube and made some small improvement.

-

the Admiral may have something to say about that

-

Thank you Noel. I definitely will look into this product.

- 125 replies

-

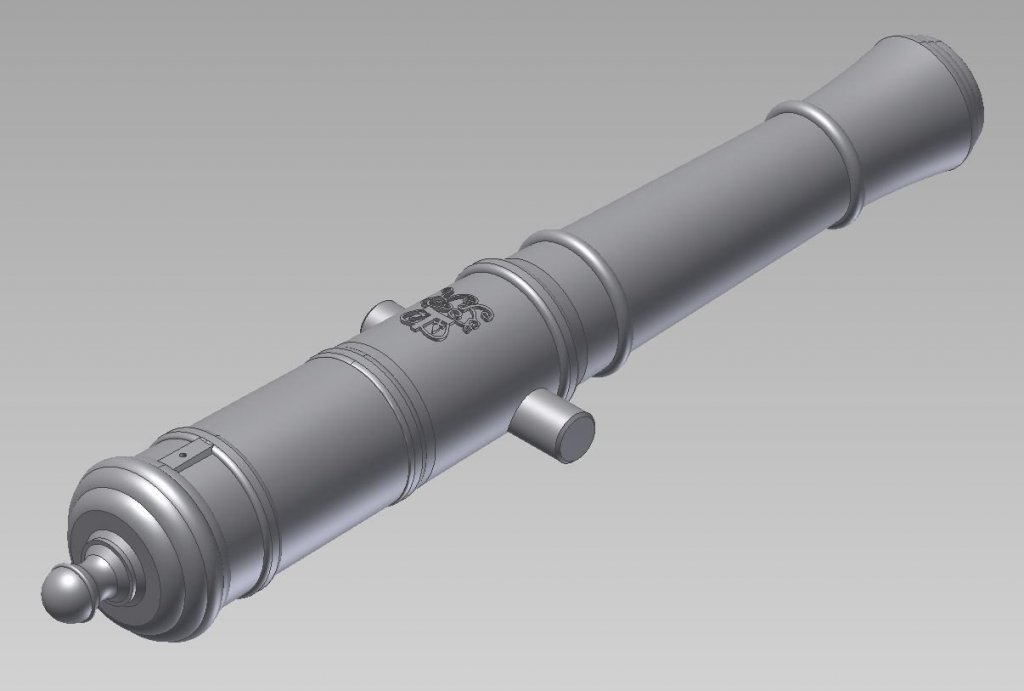

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

I think it is a distributor. Possibly they meant "brass-ish".

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

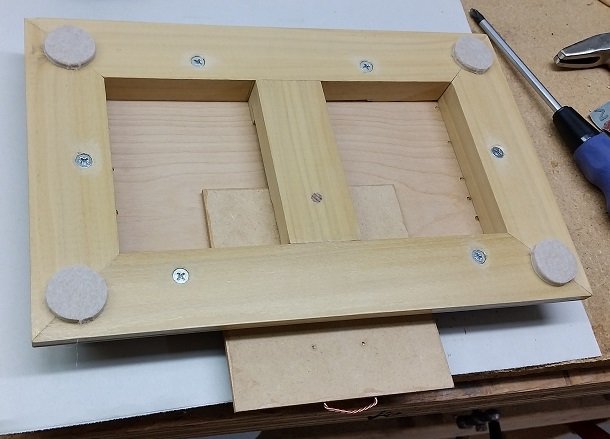

Found some stainless steel screws that were 3/8" (9.5mm) too long which worked out well after I cut the extra length off the pointy tip. This meant the amount that engaged (3/8") was all full form threads. Drilled the pieces and countersunk for the screw head. Assembled it all and the drawer would not pull out. I had to sand the thickness of the varnish off the frame under the sliding tray. Now everything works well. The new aluminium plates were installed, along with the felt foot pads... and a couple photos were taken. Next week (Tuesday) I take the 3D printing seminar and then I'll get my cannon printed up. You will hear from me after that. PS: Yesterday was our 43rd wedding anniversary.... today I turned a year older.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

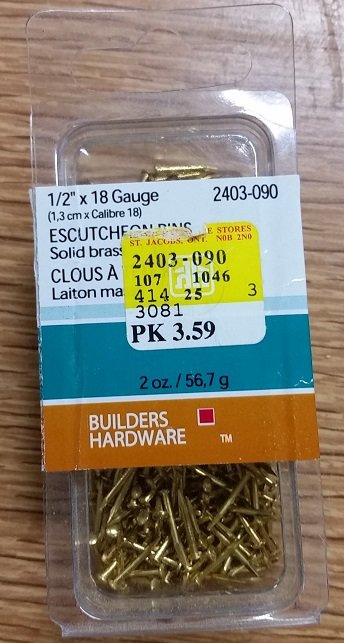

here is the packaging and description. I purchased these quite some time ago.. but that doesn't explain it. Staining done. Two coats of varnish done to seal the base frame. Assembly today. 3D printing course next week... and a barrel shortly afterwards.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

I tried acetone, scrubbed, washed, swished... nothing. Let it soak... nothing. Me thinks Home Hardware "got some s'plain'n to do".

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

Thank you Druxey but they are already blackened with a marker and installed. I had tried sanding any coating off the head and it didn't seem to help. I'll try acetone tomorrow just for the heck of it. Presently trying to figure out how to drill and pin two of the four trucks so it is fixed to the mounting board and doesn't roll around when she heels over when handled.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

After all the hullaballoo (of my own making) over figuring out how to blacken properly... it turned out to be very easy. I set up a work station, in the kitchen, on the counter, window to one side cracked open, stove overhead exhaust fan to the other side and turned on high. One small container with cleaning solution (drop of soap and ammonia). One small container with hot water and baking soda solution to stop the process. One large container with clean hot water to rinse parts off in after treating. One small container with hot water and a small amount of crushed rock liver of sulfur mixed with a wooden stir stick. Set this on my abandoned coffee mug warmer. Pair of latex gloves and tweezers. Cleaned, rinsed and dried the parts. Picked each part up with tweezers and swished (stired about in the solution while holding the part with the tweezers) them in the LOS solution for 5 seconds. Took it out and it was turning black. Did it again quickly... then once more and then into the baking soda solution... swished it about. Then into the clean rinse and done. Repeated this for every part. The copper blackened very quickly. The brass was a problem. I swished and waited and swished and waited and nothing. I let it sit for quite some time (20 minutes) and nothing. After 33 minutes they seemed to be dulling abit.... but it was wishful thinking. After 50 minutes I told myself to stop. I am thinking they are calling these brass but possibly they are not... the packing reads: "solid brass". As you only see the head of these I have decided to blacken them with a black permanent marker.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

Went back to the engraver's and admitted to my mistakes. Asked if he had an idiot's discount. Got a call today to advise they were ready and I could have the two for the price of one. Sweet

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

The poplar sub-base was just stained with a Minwax Penetrating Stain #260 - Pickled Oak to bring out the grain but keep the clear unfinished look. It is presently drying. A clear sealing coat of Varnish will be applied afterwards. The MDF will be varnished only. The sub-base will then be screwed to the underside of the mounting plate from below and felt pads will be added to protect table tops from any scratches. Meanwhile I've done some more research into using lump or rock form Liver of Sulphur (LOS) that I had purchased and used once before about a year ago blackening the staples on the keel of my ship build. That attempt had flaked off but fortunately I liked the end result. I'm guessing I possibly did three things wrong back then: too strong a mix of LOS to water, too cool a mix when the blackening process took place, and too long a soak in the mix. The following PDF is a summary of the instructions I'll be following. I have also included a MSDS for LOS. I will be doing some practise runs on copper wire and brass nails before I commit to blackening the pieces to be used. This will happen tomorrow. How to Patina Copper and Brass.pdf MSDS_LiverofSulfur.pdf

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

Well, I don't know you very well Druxy, but you seem very informative. I've noticed you've helped quite a few people on the forum (besides me). On the other hand I know David Antscherl is a master at modelling and very knowledgeable (because he does the research) and I'd trust him in a heart beat... but he'd want me to research on my own first, so I have done just that before I see him this coming weekend. Thank you again... BTW - I just explained to my wife how I wasted some money. YIKES

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

and now this... https://books.google.ca/books?id=7qwfBestmOEC&pg=PA73&lpg=PA73&dq=bolting+and+plugging+wooden+ship+deck+planks&source=bl&ots=ByXVbG9X2M&sig=EtcUEYK6IUb3MPaKNfqzrWa5vdQ&hl=en&sa=X&ved=2ahUKEwi-1Jr4m8reAhUETd8KHYoCBngQ6AEwFHoECAoQAQ#v=onepage&q=bolting and plugging wooden ship deck planks&f=false Funny how I couldn't find anything before. So it is officially bolted with wooden plugs overtop. Thank you Druxey for mentioning this. This I will never ever forget.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

and just found this in the forum with a slight change in my search criteria ( https://modelshipworld.com/index.php?/topic/14473-treenalingwish-i-hadnt-done-this/&tab=comments#comment-449644 )

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

I've spent some time trying to find information of deck fastening. In the Model Shipwright Magazine, issue 63 (dated March 1988) on page 53 is Part 9 of a good series of articles by David White entitled Traditional Wooden Shipbuilding. I think I will be allowed to post a screen shot snip of one paragraph (see below). It substantiates in part what Druxey had stated earlier. David White does not mention plugs but plugs make sense. I will continue to search.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

I could but it will likely look like heck. They have a special sheer for metal nameplates to assure the edges are crisp and flat. I could ask them to cut it for me.... but it was not the look I agonized over for a couple weeks. I'll have to sleep on this, but thank you for the suggestion.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

I have such a thing. Spring loaded barrel, fits in your palm...push with your palm. It bought it years ago to insert finish nails into things like picture frames or paneling onto walls. You have to be very careful with the amount of pressure. Never thought to try it on pins for a model. Now I have to find it again.

-

I wish I had caught it before the engraving was done.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

Next is staining the sub-base, blackening the copper and brass, getting one or possible both plates engraved again, assembling everything ... except the cannon itself. Should have all (but the cannon) done next week.

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.