-

Posts

1,937 -

Joined

-

Last visited

-

popeye2sea reacted to a post in a topic:

USS Constitution by dafi - Revell - PLASTIC - To Constitution and beyond ...

popeye2sea reacted to a post in a topic:

USS Constitution by dafi - Revell - PLASTIC - To Constitution and beyond ...

-

popeye2sea reacted to a post in a topic:

HMS Victory by dafi - Heller - PLASTIC - To Victory and beyond ...

popeye2sea reacted to a post in a topic:

HMS Victory by dafi - Heller - PLASTIC - To Victory and beyond ...

-

popeye2sea reacted to a post in a topic:

HMS Victory by dafi - Heller - PLASTIC - To Victory and beyond ...

popeye2sea reacted to a post in a topic:

HMS Victory by dafi - Heller - PLASTIC - To Victory and beyond ...

-

popeye2sea reacted to a post in a topic:

Rigging scale for 1/85 Frigate

popeye2sea reacted to a post in a topic:

Rigging scale for 1/85 Frigate

-

popeye2sea reacted to a post in a topic:

Which is the oldest book on shipmodelling?

popeye2sea reacted to a post in a topic:

Which is the oldest book on shipmodelling?

-

popeye2sea reacted to a post in a topic:

Queen Anne's Revenge with Greek Fire by Glen McGuire - FINISHED - 1/400 - BOTTLE

popeye2sea reacted to a post in a topic:

Queen Anne's Revenge with Greek Fire by Glen McGuire - FINISHED - 1/400 - BOTTLE

-

popeye2sea reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

popeye2sea reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

-

Anchor Knot

popeye2sea replied to DennisL's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Trevor has the right take. It is almost physically impossible to tie an anchor bend or fisherman's bend in the size of cable used for a large anchor. If you look closely at the construction of the anchor clinch there is no actual knot. The cable is "clinched" to itself at several points to make a sort of loop to pass the bight through. Regards, Henry -

popeye2sea reacted to a post in a topic:

Soleil Royal 1671 by EricWiberg - Heller - 1/100 - PLASTIC

popeye2sea reacted to a post in a topic:

Soleil Royal 1671 by EricWiberg - Heller - 1/100 - PLASTIC

-

Revell 1/220 scale Cutty Sark assembly questions

popeye2sea replied to Racersonly's topic in Plastic model kits

Going by other Revell kits that I had, usually the A, B, and C variations are a choice you make before starting the rigging to determine if you want to show the vessel A - without sails, B - with plain sails (that is the square sails and the triangular jibs and staysails), or C - with full sails which will include all of the plain sails plus the studding sails. May I suggest you start a build log and we can follow along and help you out on your rigging journey. Regards, Henry -

There are plenty of reference materials that will depict general rigging plans, i.e. the differences between a ship, brig, barque, barkentine, etc. Once you try to refine the rig for wind and wave conditions, the variations are myriad. Not to mention variations in rig based on the time period the vessel belongs to. There are variations in reefing, hoisting, furling, dowsing, scandalizing, canting, bracing, and sending down. It would be a very big endeavor (plus, historically, years to learn). Regards, Henry

-

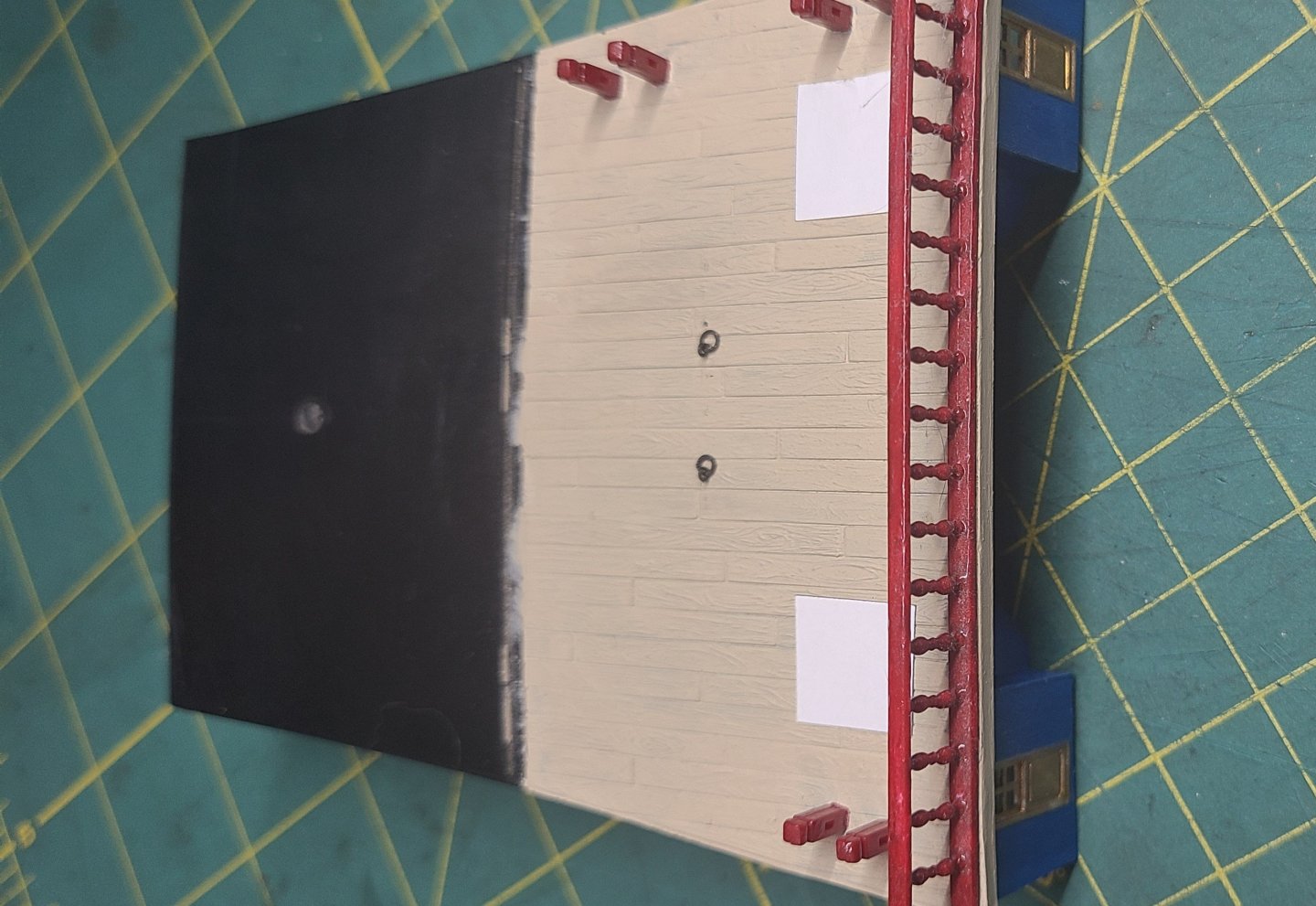

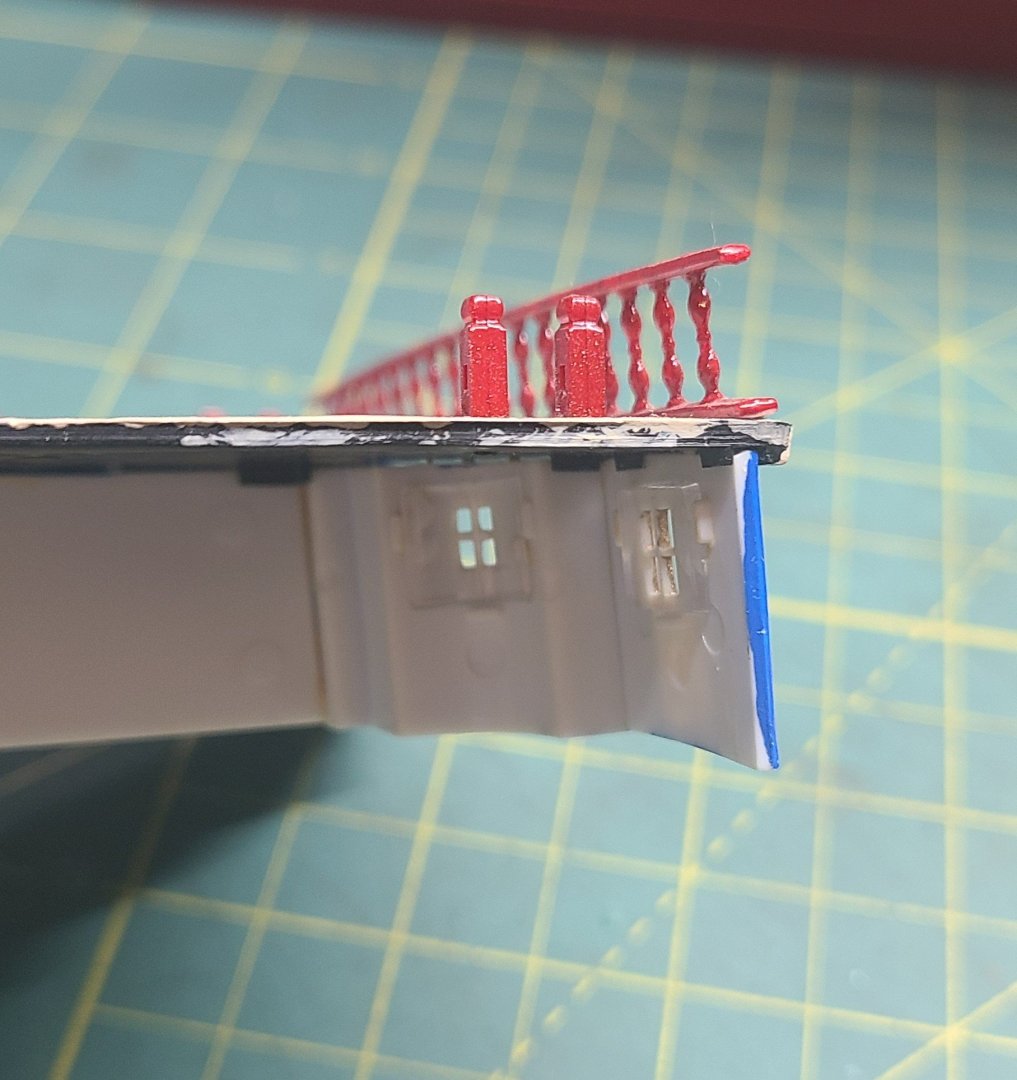

Sorry, I was a bit lacking in detail. Custom breast-rails. I was considering cutting in a companionway and stairs with a rail surround in order to access the poop from within the quarterdeck house. The companionways will go where the white squares are in the picture below. The stairs will curve along the interior bulkhead in front of the small window and end next to the door to the quarterdeck. I will be removing the rail that is there and using the balusters for the companionway railings. It bothers me that there is no way to access the poop or poop-royal decks. The area between the mizzen mast and the quarterdeck is too congested for an exterior ladder or stairs, especially with a cannon sitting where the bottom of a stairway would go. Regards, Henry

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

This is something that I have been contemplating doing for my build. As well as making internal access from below to the poop deck. Regards, Henry

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

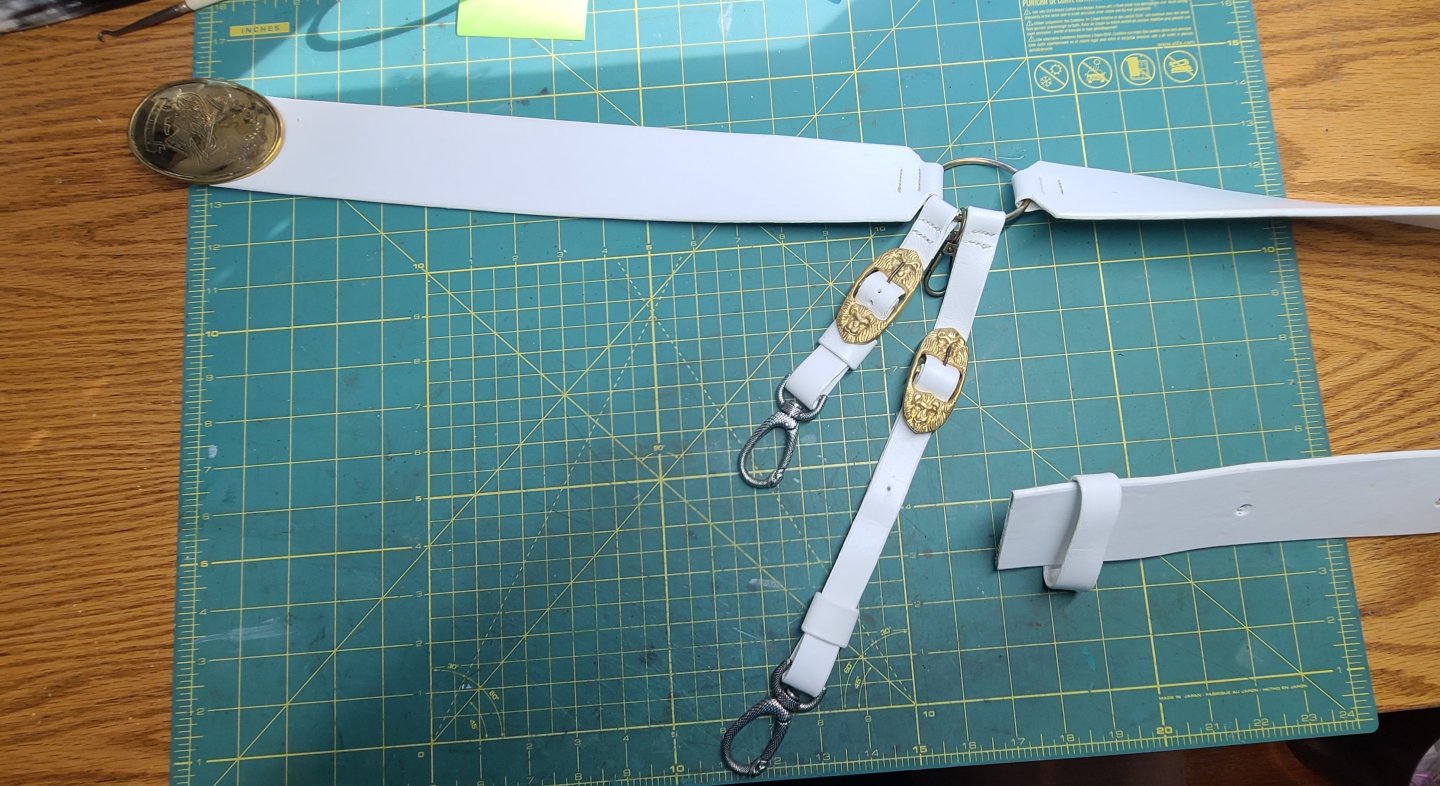

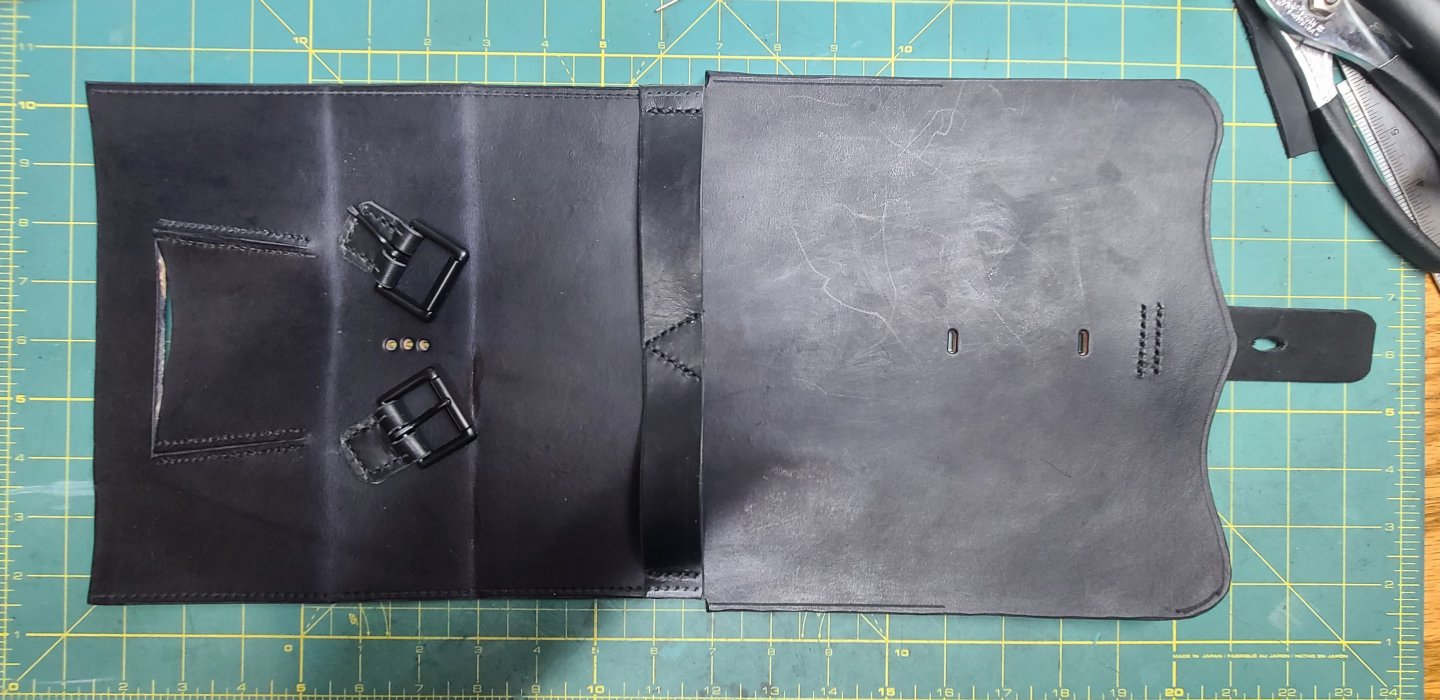

Finally, my new officers sword baldric. The back story: The current person portraying an officer in our unit has decided to step down. The next person in line for the position is me. Therefore I have had to start the process of acquiring and/or making a new officers uniform for myself. It is not an easy or inexpensive project. The wool and other materials have to be authentic and the tailor has to be familiar with period tailoring construction and techniques. Here is a breakdown of the items with cost. Chapeau Bras (hat) $400 Wool for coat $900 Waistcoat $150 Trousers $100 Hessian Boots $1000 Sword $350 Sash, Epaulets, Braid, Buttons, etc. $300 Seamstress/tailoring fees $?? not done yet. To date I have the wool, the trousers, the sword, and all the small accessories. The waistcoat is in progress with the seamstress. The hatter is completing my chapeau bras. It is going to take some time for fittings and such for the tail coat. But, the Hessian boots are currently stuck in France. That brings us back to todays topic. I have completed fabricating the sword baldric. Here it is The fittings, from left to right, are all stitched to a central ring that hangs at my left hip: Breast plate, front sword hanger, hook, rear sword hanger, shoulder strap. Here are some photos from an event last weekend showing how it is worn. In the interim between when my officers uniform is complete and now, I am portraying what , in the era, was called an orderly sergeant; a sergeant who was in command of a ships detachment of marines. I am, therefore, authorized to wear the sword and the sash denoting command. When the new uniform is complete I will switch over to portraying a captain of marines. In this next photo is demonstrated the use of the small hook that is installed between the two hangers. When 'in use' the scabbard depends from the hangers at an angle convenient for drawing the sword. When not in use the scabbard can be reversed and hung from the small hook. This allows the sword to hang more vertically along the left leg making it more comfortable to walk about without the sword banging around your legs. One more note: the decorative gold and red sword knot on the hilt of the sword actually has a function. The sword knot is composed of a long loop of braid with a tassel on the end which is knotted and wrapped around the guard. When in battle the hand is passed through loop of braid so that if the sword is un-handed it will remain hanging from the wrist and not be lost. That concludes the current leather work projects for the 1812 Marines. As new people join the unit I will make items as appropriate. I do not have any orders yet for neck stocks or fatigue hats, but those were also made of leather and I do have patterns made for them. Until next time. Regards, Henry P.S. on the right is my drummer who is wearing his new snare drum hanger and sword baldric!!

-

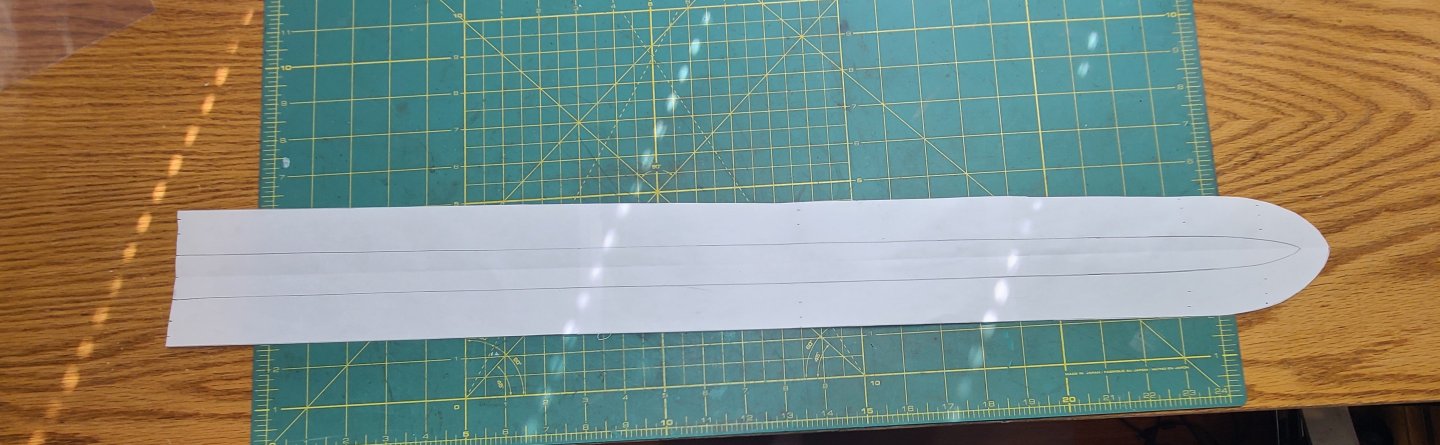

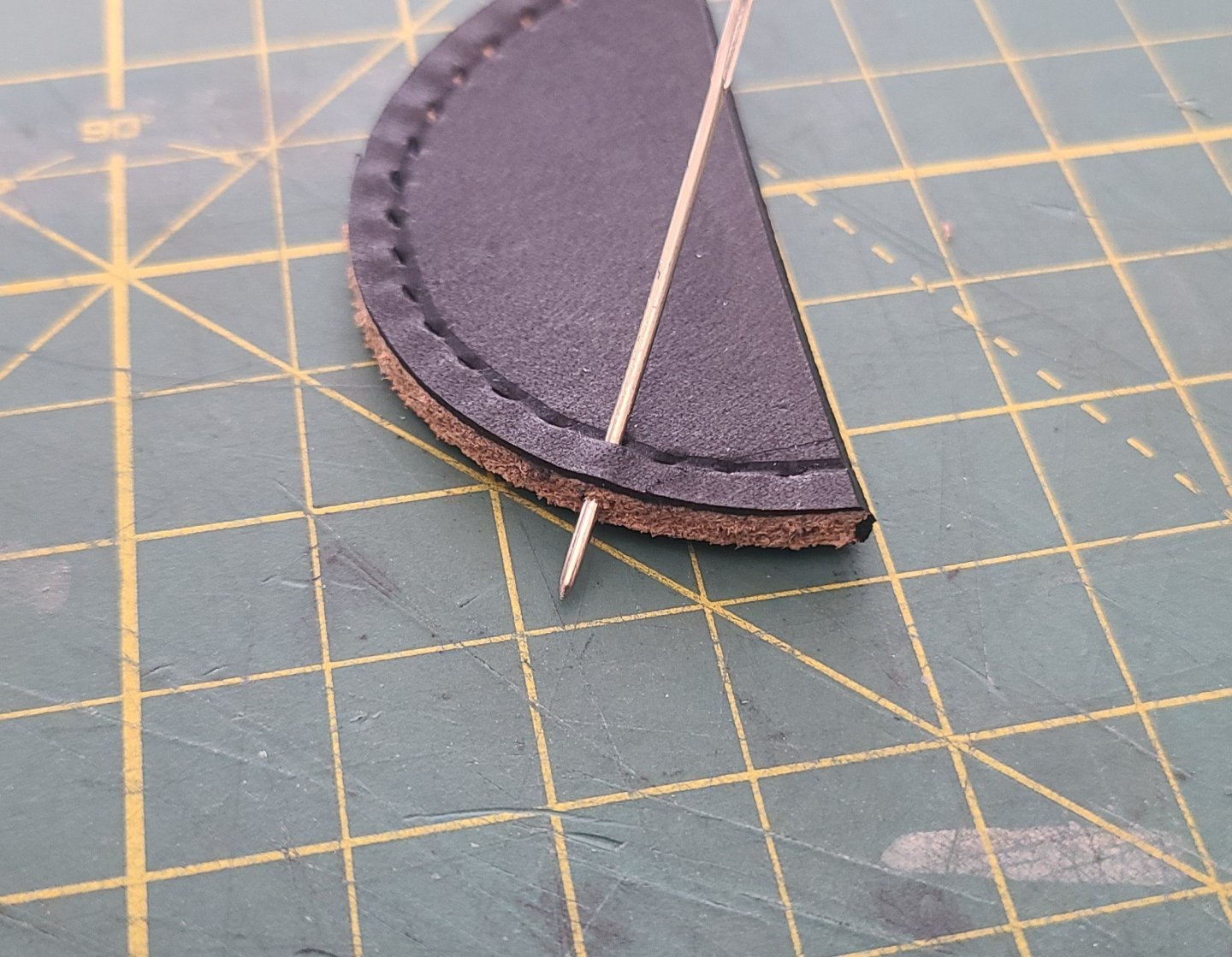

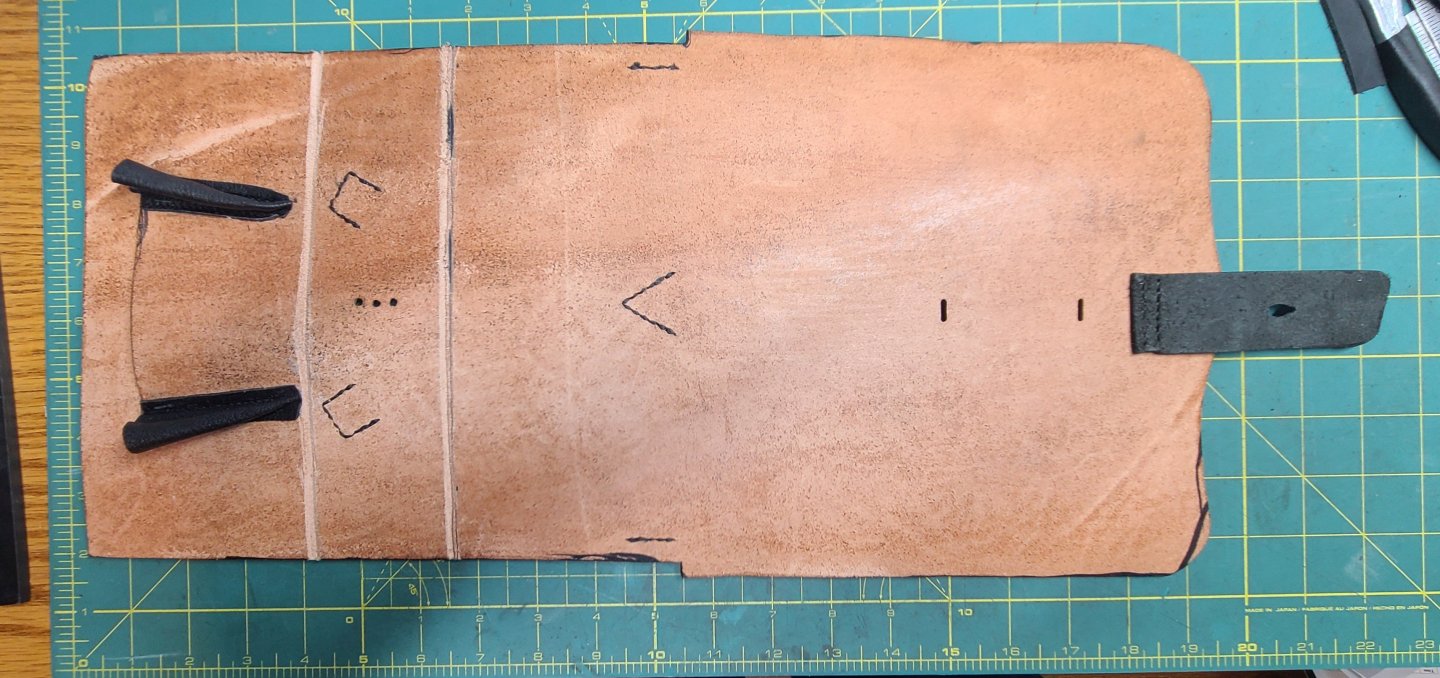

New sergeant scabbard. You can see in the picture of the old sword scabbard that the leather is old, dried out, cracking, and falling apart. Here is my first attempt at a replacement scabbard. First the pattern is made by tracing the sword onto paper. An allowance is added on either side for the width of the blade plus a seam allowance for stitching. Then a wooden former is cut out using the sword as a template. The leather is cut to the pattern size. I am using the same black leather that I used for parts of the cartouche box. The leather is folded in half length wise, finished sides out and cut edges aligned, and contact cemented together. A single row of saddle stitches are run along the seam allowance from the throat to just before the tip. The scabbard is then soaked, submerged in water, for about 30 seconds. After soaking the scabbard is allowed to sit for about 5 minutes to allow the moisture to penetrate all of the leather. Then the seam is pressed down into the middle of scabbard, making sure it runs centered down the middle of the face. Then hammer the seam down with a mallet. Slide the former into the scabbard all the way to the tip. Ensure that the seam is centered on the face of the scabbard. Using an edge slicker, smooth down the edges of the seam. The hammering and slicking helps to get the seam allowance flattened out and tight against the face of the scabbard. Now comes the pressing. In order to press the scabbard into its final shape I made a simple press out of two 1 x 2 pieces of wood. I cut a shallow groove the width of the scabbard seam into one face and then sanded the faces of the wood that would come in contact with the scabbard. Any imperfections in the wood will get transferred into the leather when you press the scabbard. Place the scabbard into the wood press with the seam in the slot. You can add pressure by standing on the wood or you can use clamps. Press the scabbard down hard. Take the former out of the scabbard and press it again. Now one last press with the former back in. Once the scabbard is pressed down hard, remove it from the press and check it to see if you have a good, clean, smooth, straight shape. Now you can let the scabbard dry, with the form in, 12 to 24 hours till completely dry. To finish the scabbard, the brass throat and tip guards are press fit onto the leather. You can see with the last picture that the seam on my scabbard is not very centered all the way down. That is because the sword is not symmetrical. The back of the blade stays relatively straight and the cutting edge curves a bit more towards the tip. I tried to make the pattern do the same thing but when I formed the scabbard up it ended up twisting a bit. I am not going to redo the scabbard. The seam side is worn towards the body so it is less visible. I will, however, re finish the seam so it is a bit smoother and edge coat it so it disappears more against the face. Regards, Henry

-

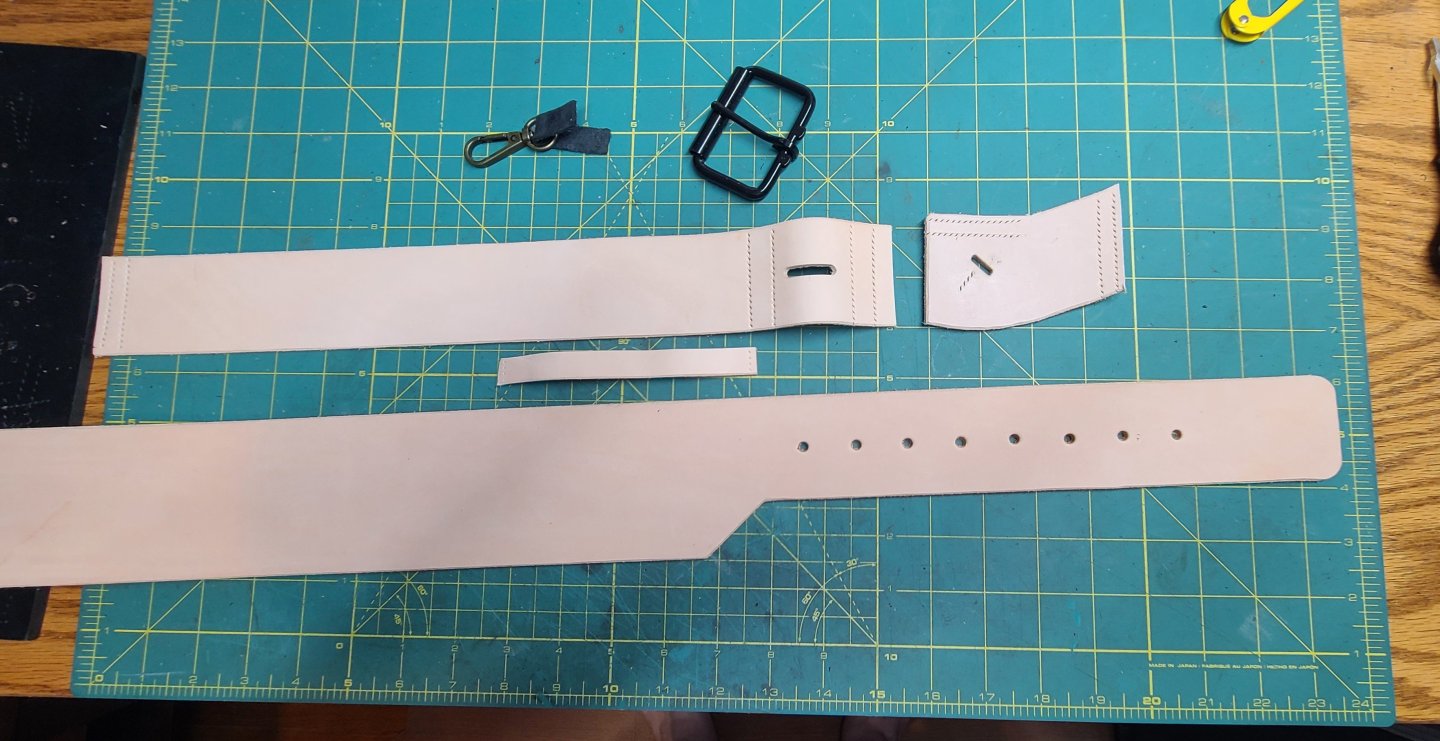

Moving on the the snare drum hanger. I designed a pattern for and constructed a drum hanger. The pattern uses the same design as the scabbard baldric except it has a different frog to hang the drum and a wider shoulder piece. The buckle is added to make the sling height adjustable. The snap hook is the attachment point to the drum and the short black strap on the hook is passed through the slot in the frog and cemented and stitch to the inside of the frog. Regards, Henry

-

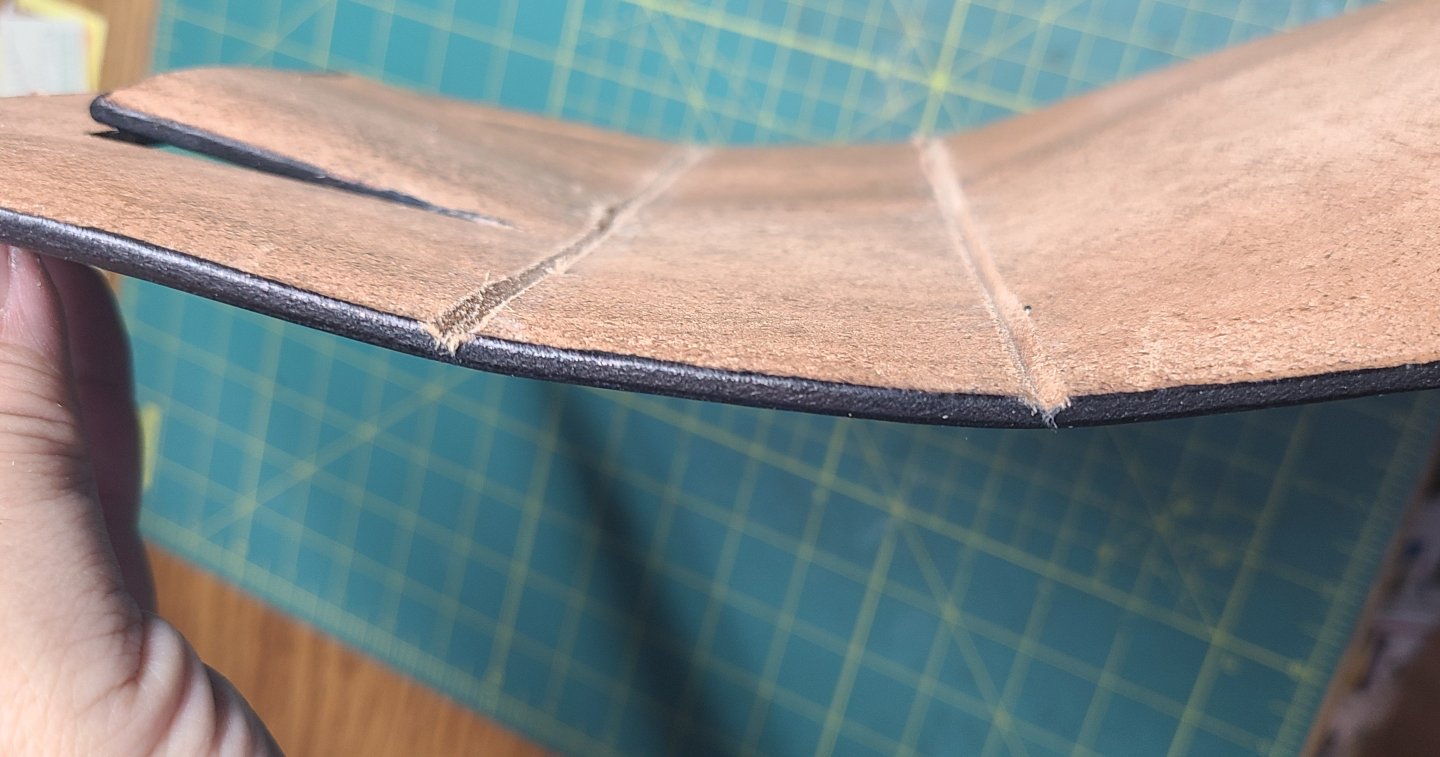

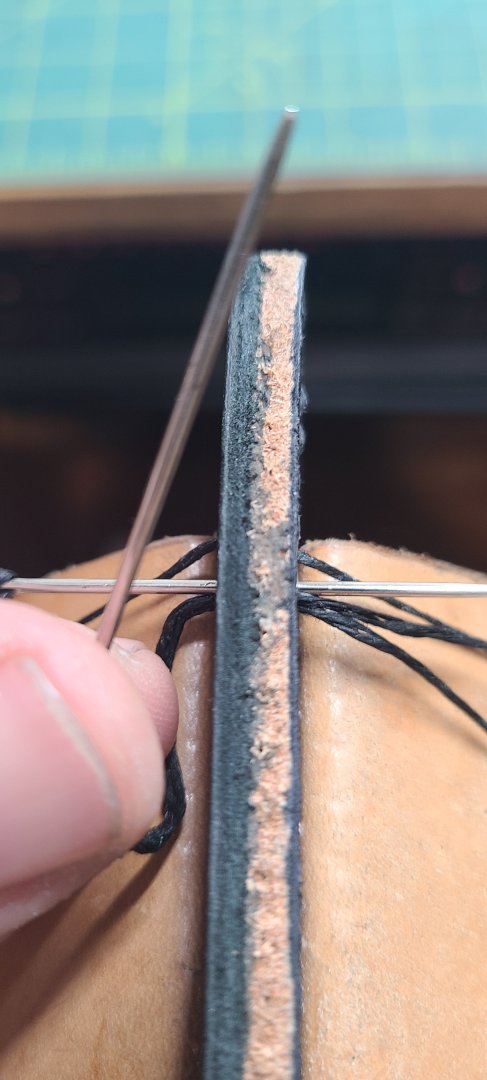

Final assembly of the cartouche box. In order to stitch the sides and end pieces into the box, I use a different stitch; the box stitch. The box stitch is different from the saddle stitch in that instead of the two pieces lying flat on top of each other one piece is stitched end to. In order to do this the holes are punched differently. On the piece that will be standing on edge, the holes are punched so that they pass through the edge grain instead of through the back face. You can't just punch the holes with a stitching chisel, eight at a time. Each hole has to be made with an awl one at a time, being careful to push the awl through at the right angle to come out of the edge in the right spot. It takes practice. (Once again, being the first iteration of this type of piece, mistakes were made). These photos are of the end caps for the box cover being stitched into place. The sides of the box were stitched into the box in the same manner for the final assembly One last item that I forgot to take a picture of is the leather toggle for the box closure. It consists of a strip of thin leather that is narrowed at one end and rolled up to form a toggle. The dimensions of the strap are determined as follows. The width of the strap will determine the length of the toggle. The diameter of the toggle depends on the length of the strap from the end to where it narrows. You can figure out the size your toggle needs to be by the size and shape of its corresponding hole in the closure on the bag. The portion of the toggle strap that is cut narrow passes through a slot cut in the larger end and holds the rolled up toggle. The toggle strap should be sized to fit the holes in the bottom of the cartouche box. (Those are the three holes punched in the bottom of the box seen in previous posts). I know it is hard to envision how the toggle is made, but there are YouTube videos if you are interested. After the toggle is formed, the narrow strap is passed through the three holes in the bottom of the cartouche box leaving enough length to toggle through the closure. A bit of contact cement is used fix the toggle strap to the inside of the box. Regards, Henry

-

Before I can finish assembling the cartouche box it must be folded into shape. To make that possible, two grooves have to be cut to form the bottom of the box. I bought another new tool, the v-shaped groover, to accomplish this. While it is not a difficult tool to use, it is a bit nerve wracking getting the groove deep enough to fold the heavy leather, but not go through the whole piece to leave a gash in the finished side. ( I was not entirely successful in this. Luckily the small gash is in a spot that will be covered by the cross belt. This was my first attempt at a cartouche box. Mistakes were made.) The various pieces are stitched on to the body of the box. Regards, Henry

-

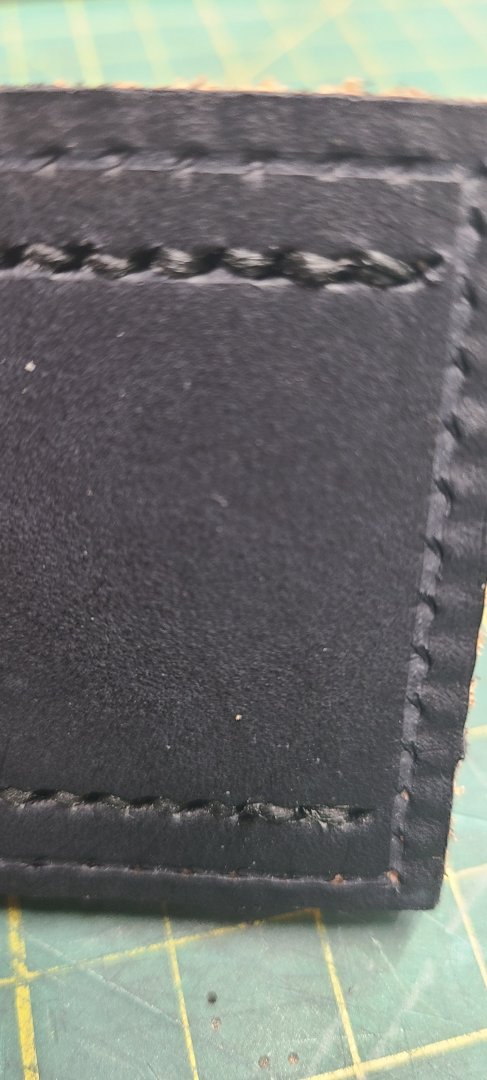

Back to the Cartouche box. Here I have dyed all the pieces black. Starting to stitch the parts together. After the stitching is done the finished seam is tapped down with a leatherwork hammer. The hammer has a highly polished, slightly convex face. Tapping the seam down sets the row of stitches down into the stitch groove and closes up the hole so they don't have that puffy, ragged look that you get after stitching. Regards, Henry

-

Next up is stitching up the baldric. Here is the piece being stitched. It is being held firmly in the stitching pony and the positioning is being fixed by the alignment pin. I am using a basic two needle saddle stitch. The needles are specifically made for leather stitching, They have a blunt tip and a large eye. You can see short demo of how the stitching proceeds below. The small overcast that is done before the thread is pull tight insures that the thread lays in the correct orientation in the holes to produce a consistent angle on the top face of the completed product. It is just a more polished, refined look than a simple straight stitch. You can also see in the video that I am wearing a set of leather finger protectors that I made. The thread will tend to cut up your fingers after a long stint of hauling those stitches taut. photos 5.mp4 Here are the finished leather cross belts Regards, Henry

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.