-

Posts

369 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by steamschooner

-

Welcome to MSW, Also a pacific northwester, Pacific County

-

Well not much to show but I have made/ changed a few parts. Thanks Bruce & John for the links, still looking for a little more info on cockpit layout but since these were owner built or built for owners they must have all been different. So I should be ok however I layout the cockpit, It's my boat right?

-

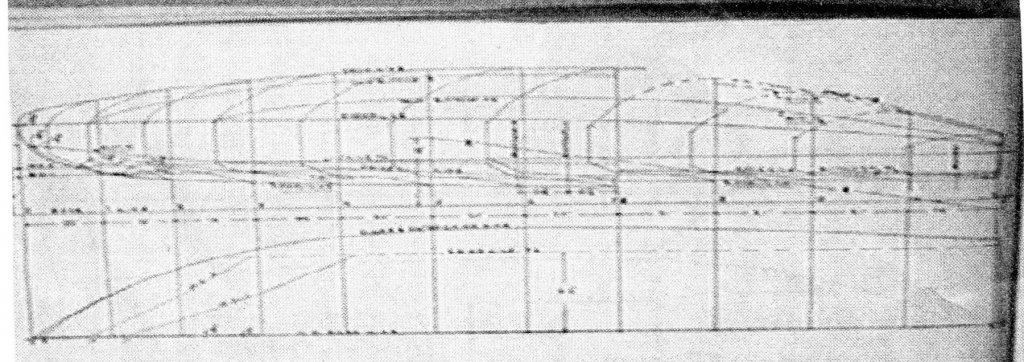

Well I decided that I would revisit a model that has been sitting on my shelf for 20 years or more. I got the plans for this boat from Motor Boating Ideal series of books/ plans ca. 1938 It was long before I had a pc and internet. One of the reasons I stopped work on it was because I just did not have enough info on the cockpit area. It was also a lesson in using veneers. So now I can research this class of hydroplane and get something going on finishing it up. If I am remembering correctly this was a Hacker design. Following pictures show what I have left after 20 plus years.

-

Thanks everyone for the likes and following along. Paul, My bad was not paying alot attention to the black board😄 Chris, Thanks and yes it was a long journey Kurt, Glad you like her I do have a few other tug builds in mind but not right away. Gary, I am happy with the finished project, pleased you like her.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Rob, I am in awe of the job you have done, she certainly will be a stunning model when finished.

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Michael, It's been a long journey but I am happy to get it done. Thanks for looking in. Patrick, Yes it does look like she is ready to go. I am happy with how it has come together. Thanks everyone for the likes.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Ok not done yet but getting close. The cabin is mounted for good and the stack is in place with the stays installed. Got those steering cables put in their place. Fenders are all tried off, anchors stowed Still have a number of things to do yet but I'm near the finish point.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Steamboats and other rivercraft - general discussion

steamschooner replied to Cathead's topic in Nautical/Naval History

I am thinking that that long tubular object is a grasshopper pole stowed. On the right hand side you can make out some links/shackles. The lifting poles have rigging connected to the grasshopper pole. And on the bow jackstaff you can see what looks like a cross tree for the ends of the grasshopper poles to rest on. Not sure if grasshopper pole is the right name but they were used to push off of sand bars and such. As for the bigger supports they could have helped in transfering the lifting load when pushing up off a river bar. I would vote stepped back decks as it was a working boat not a big river showboat.(other thread )- 281 replies

-

- Steamboats

- riverboats

-

(and 3 more)

Tagged with:

-

Straightening thin brass wire

steamschooner replied to vossy's topic in Metal Work, Soldering and Metal Fittings

I use one of these to straighten wire. Just center the wire in the middle of the three rollers close rollers on wire than pull wire though. I believe I got this from a bead store. -

Thanks, Patrick and Michael Here's another little job done. The J.C. did not have much of a bow fender so I think this will do.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

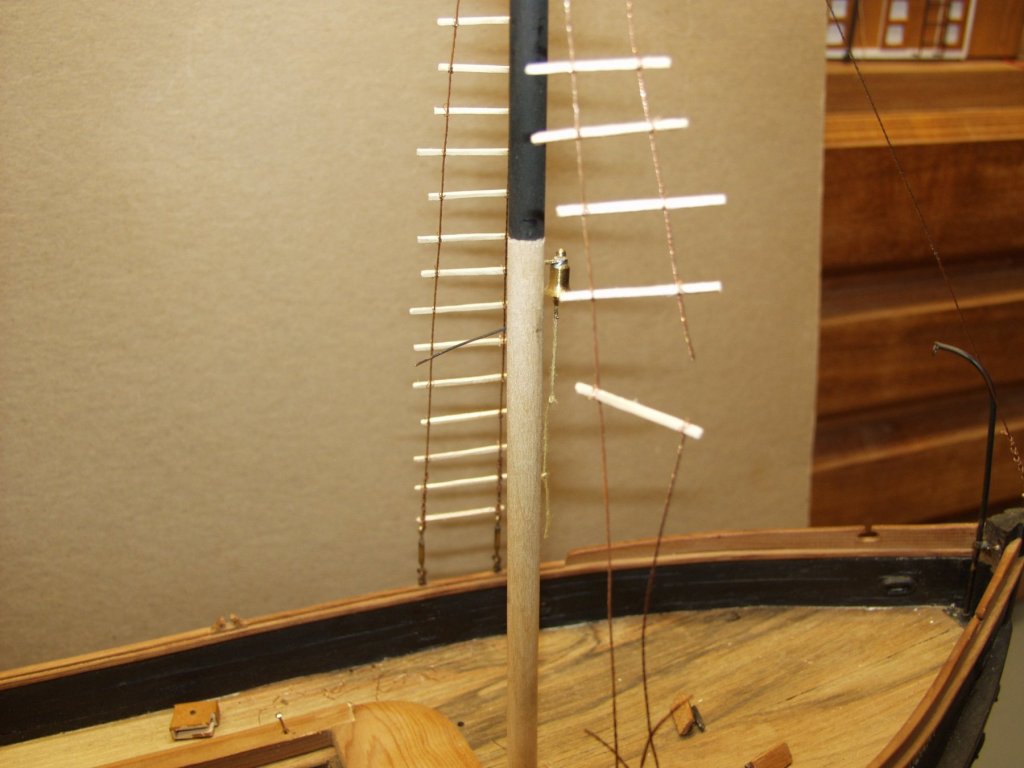

Boy! I guess I should get busy and post some progress. Not much to show for 6 months, but I did get my mast shrouds finished this time without cutting the wrong wire. I have also installed both life ring holders and have mounted both boats. Added a step on both sides of pilot house just to round things out.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Ilhan, Could it be that the wood used in the gangway is of a hardwood to hold up against heavy foot traffic. Plans show pitch pine as decking material which to my way of thinking is a softwood and would wear more under heavy use ( loading and unloading ). In the above picture do you think they could have gotten any more people onboard? You are right , questions ,questions. Steve

-

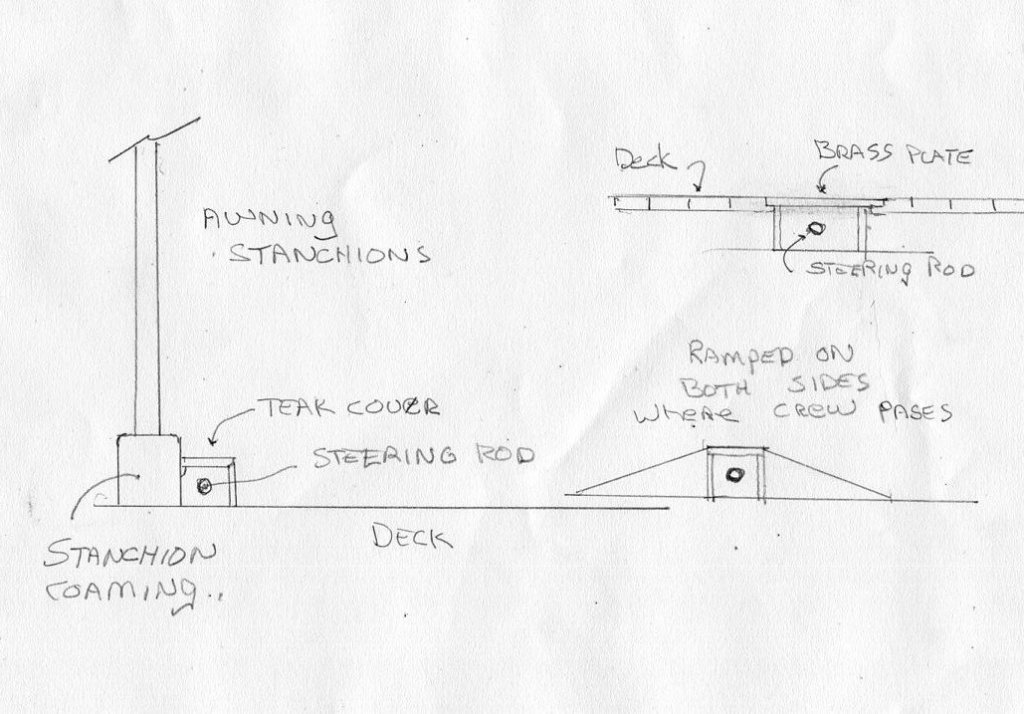

Ilhan, As near as I can tell from the plans posted,is that the main deck was decked with 4 1/2 x 2 1/2 pine from bow to stern. Both sides of boiler space as shown on plans and both sides of engine space must have been decked with wood just not shown on plans. Example; Note on plan (teak cover over steering chain ) Why have a teak cover on a steel deck? Same goes for the steering rods aft, why have fancy teak covers with out a wood deck? The gangways I would have the same thickness as the deck ( no tripping edges ) just the deck boards are much wider. Plans note ( for detail of gangway see special plan ) Do you have that plan? Anyway that's my thoughts on the decking. Steve

-

My drill to mill adapter

steamschooner replied to steamschooner's topic in Modeling tools and Workshop Equipment

Michael, I will keep that in mind, thanks for the heads up. -

Made this spreader adapter for my little drill press so I could use it as a mill. Light wood milling is all I will use it for but now I can adjust the depth of cuts. Happy New Year everyone

-

Ilhan, My current project uses a rod and chain type of steering. The rods run in a box like channel which the cabin coaming is one side of the box. The channel top is removable( bolted or screwed ) so any breaks can be got to. Where crew have to cross over there is a ramp butted to each side to prevent tripping. On yours the box like channel is pushed up against the rail coaming. The rail coaming would be one side of the box. Below is what I see in your drawings above. Steve

-

NRG's JOURNAL is now Digital

steamschooner replied to kurtvd19's topic in NAUTICAL RESEARCH GUILD - News & Information

Kurt. In the top post above you write that for digital $40 and additional $ 15 for both digital and print. In the NRG store It's listed as Digital $40 and $65 for both. So I guess something changed ? -

Just caught up on your build, doing a super job.

- 227 replies

-

- BlueJacket Shipcrafters

- Stephen Hopkins

-

(and 2 more)

Tagged with:

-

Sonoma Coast Wreck Hunter - North California

steamschooner replied to J Harreld's topic in New member Introductions

John, I have made a study of West coast wood steam schooners for the last 20 years. Much of the steam gear that was on steel ships were not much different. So if I can be of help let me know. Via here or by PM. Steve -

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.