-

Posts

369 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by steamschooner

-

Eric, I think you nailed it on the deck planking, looks great! Steve

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Eric, I was thinking the area in blue looks like it has been pushed in somewhat. More so on the right near the paddle box. Planking would still be at a angle on the guard timbers. You are right that it seems to be a unusual way to plank.

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Eric, It also looks like the hull is pushed inward at the paddle box making it look like the decking would need to change direction. But if paddle box was pushed back out the remaining decking would line up fairly well. From what I can see in the wreck photo the planking at the stern looks like they used wider planking with narrowed ends with a fan shape. steve

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Eric, Did the missing deck planks straighten out or did they continue at that same angle? Its looks like a short run to the paddle box so keeping the planks angled should not have been much of a deal for the builders.(Just my 2 cents worth) Steve

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Lady Washington Brig pulled out

steamschooner replied to rwiederrich's topic in Nautical/Naval History

I worked in the Grays Harbor area when they were building her and would often stop by and see her coming together.- 16 replies

-

- brigs

- sailing ships

-

(and 1 more)

Tagged with:

-

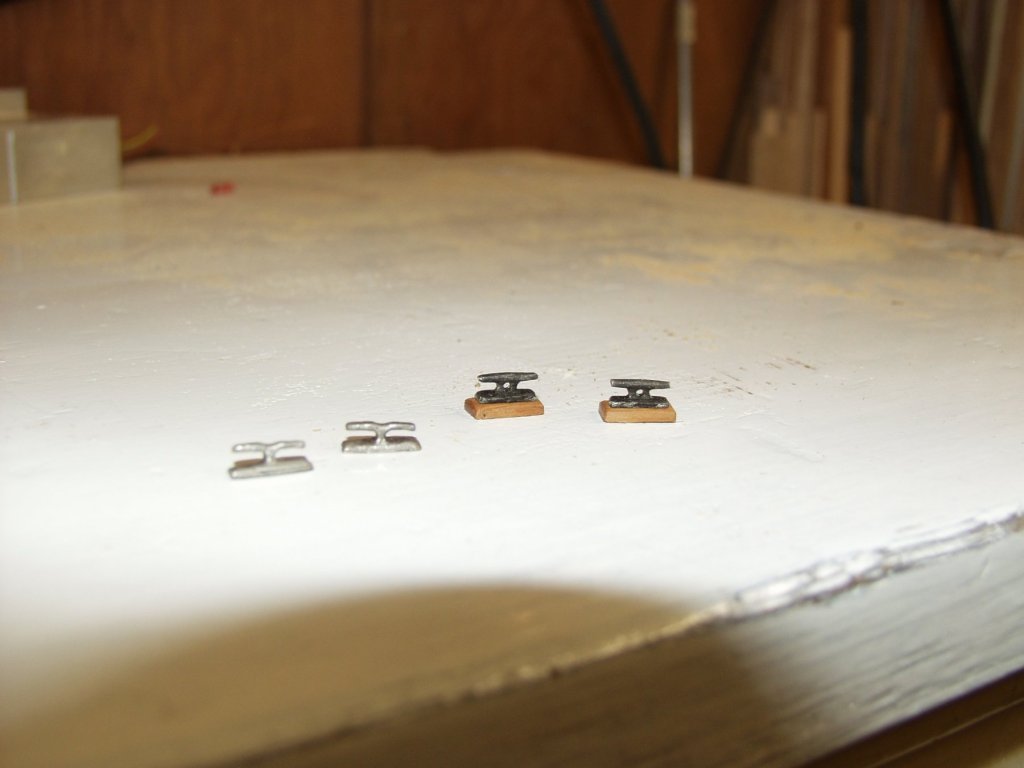

Just so you all know I do work on my model from time to time. Like most I have many spring and summer things to do and do not get to spend much time in the shipyard. I have managed to cast some deck cleats( twice ) The first ones I ended up not liking, in photo on the left. The second ones are more correct with the wood block base as I have seen examples locally. For my stays and shrouds I used some telephone wire That had four coated strands and each strand has 7 small copper strands. After cleaning the coating from the wires I separated them and twisted up 3 strands for my davits and stack stays also aft mast shrouds. For my main mast shrouds I twisted up 7 strands. I used a single strand as whipping to tie off eyes. the copper wire will take L.O.S. nicely.Now on to the shroud bars/ladder.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Nils, What a wonderful project, very nicely done.

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

moxis, Do overs are the norm around my shipyard, sometimes more than once. Railings look super!

-

Eric, Your hull looks very good, I wonder did they paint the bottoms on these early riverboats or use some sort of tar or pitch mixture?

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Patrick, I have been at the bench just not alot to show for it. I did manage to get these little buggers made. Two on left the line was to heavy and they came out a little big for scale. I liked the color though. Middle ones are cotton string which was the right size scale wise but the color needed help. I colored one on the left. The three on the right is also cotton string that I found in my line stash. It had a reasonable color and the scale size worked out. Still need some triming and maybe a little coloring/weathering. Now it's on to the bow fender..... oh boy!!

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Eric, The planking is looking very nice. Since no body knows how it was planked who's to say you are wrong in doing it the way you are. Like my project there is alot of best guess when working out construction. For me that is part of the appeal of building a boat/ship that has not been modeled before. The few photos I have show no planking on the bottom side of the guard timbers( later boats )

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

It's been awhile since I posted on my build. As some of you know I have been casting parts for my build. These are the latest, some anchors for the fore deck. I made up a master out of brass and copper. Made a vulcanized rubber mold to fit a tray a friend made for me. Spun up some anchors and added a cross arm made from copper wire with a small copper ring soldered on for a stop along with a couple small blobs of solder for the balls on the ends. Lightly sandblasted and drilled for arm, chain ring with a little color added.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Eric, How do you plan to form the transition at the bow? Will the planking butt together on the center of the keel? or will there be a plank that runs the length of the keel? (which you can see in the recovered stern, tiller photo ) I wonder if in real construction if they used chine logs at the point where the side planking meet the flat bottom planking. Putting some blocking between bulkheads, or moving the ones there will give you some backing for those drop planks. At some point in the future I hope to build a stern wheeler from this area so I follow along.

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Moxis. Are two decks and cabins going to be removable as one piece to get at the gear in the hull? The deck looks very nice!

-

Eric, I thought maybe what I had said made you take things apart. Glad to see your fix, it looks good!

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Eric, I don't remember what scale you are working in but are your planks to scale? Do you know the sizes of the planks on the recovered stern? Comparing the photo of the stern and your model It looks like your last bulkhead is shaped differently than in the photo. Since most of the bottom will not be seen and most likely painted matching the original is not as important. My 2 cents

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Moxis, I also like steamships so I will be watching your project come together. I'll sit next to Nils.

-

Patrick, Not sure whats next I have some ideas. Maybe finish up one I have on the shelf.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Well I have gotten a little more done, Now have boat tackles made,name board on cabin top, oars for open boat.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

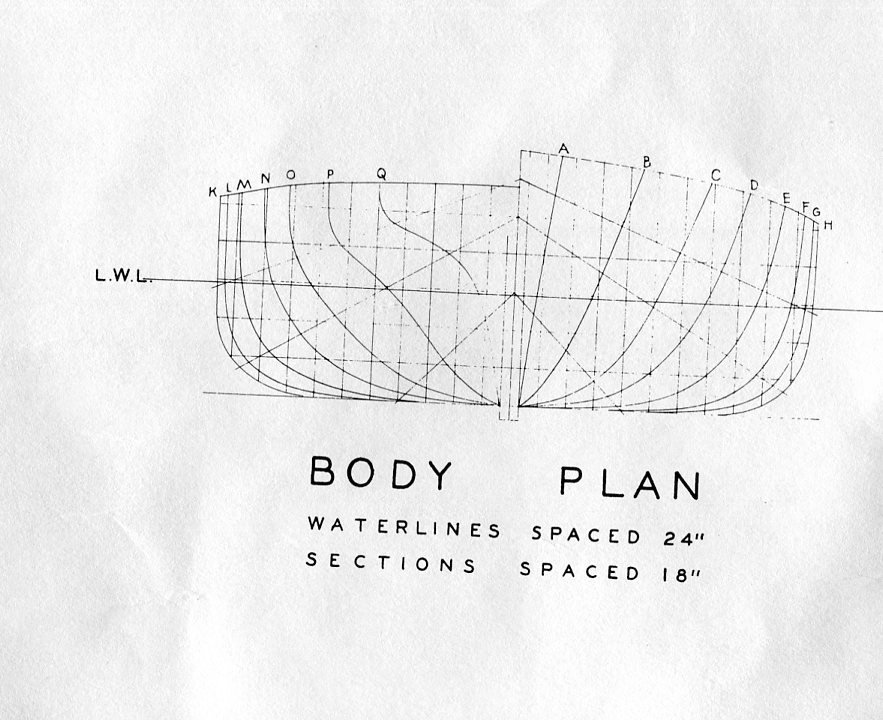

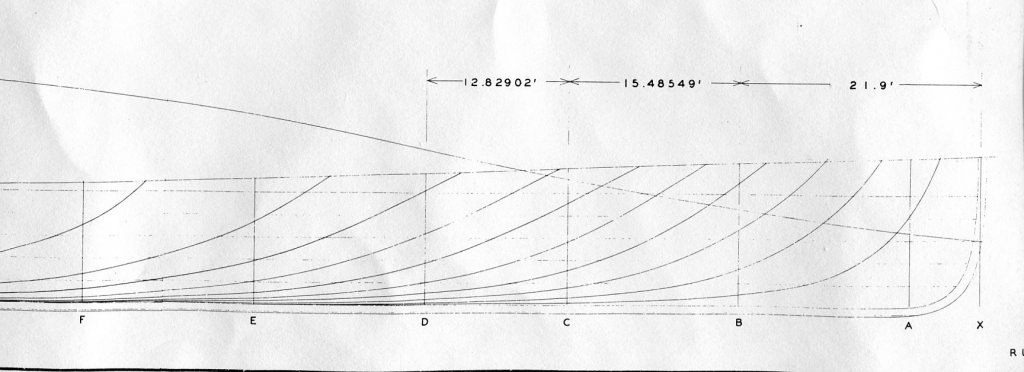

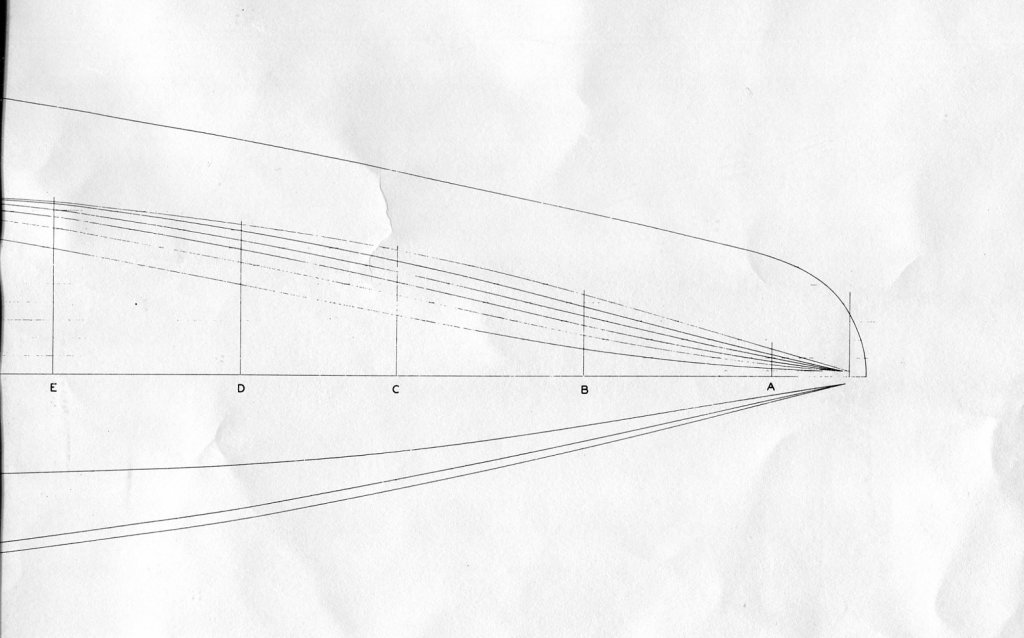

Eric, Here are some scans of the James M Donahue of 1875, hull lines, body plan and the bow area if you want the stern lines I can scan those also. Hope they are of some help.

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.