-

Posts

1,878 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck Seiler

-

I have the V2 version and have gotten as far as making the frames (while I work on another model). I have thought about using copper wire, with the end treated with a cupping burr. Once the nails/rivets are in place, they can be darkened using Liver of Sulpher...at least that is my theory. I am told LoS does not stain the wood. Alot of work, though.

- 48 replies

-

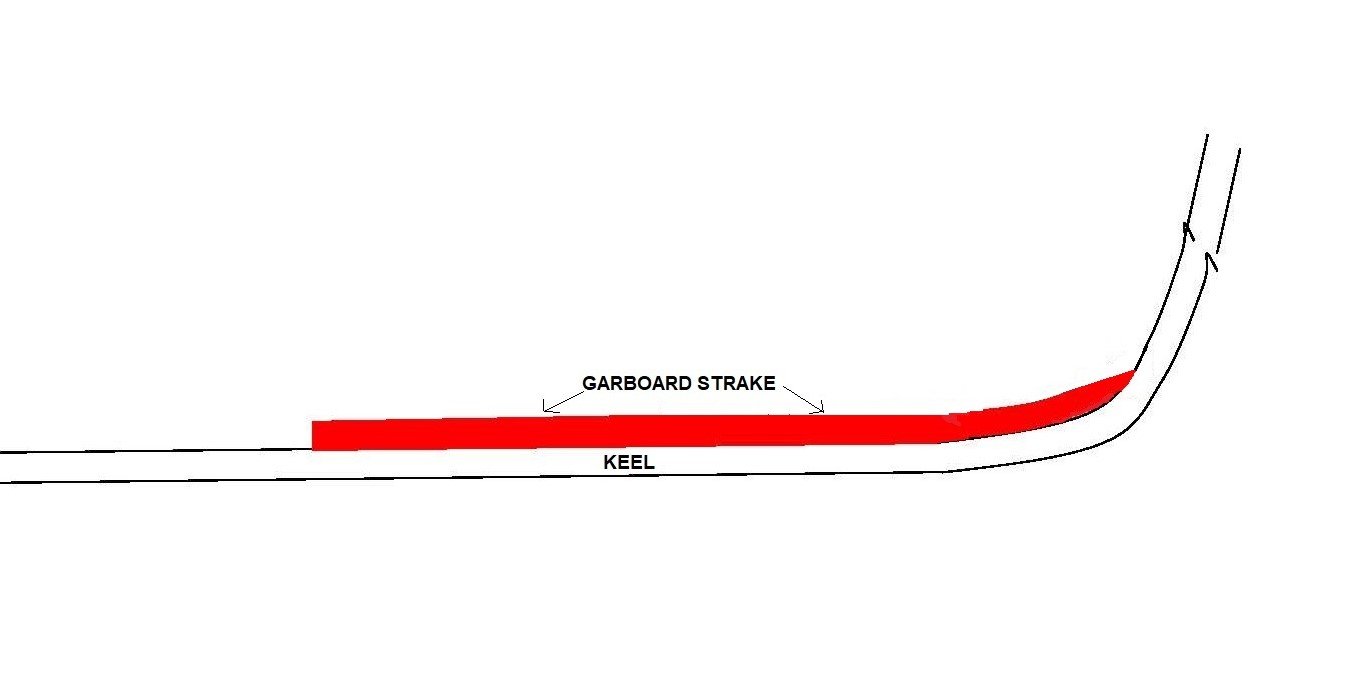

I had that problem as well. I read alot about it and followed many build logs. The light finally came on when I took what I had learned and started experimenting. By taking a test plank and sanding the bow end as I go, I test fit the plank. At one point, the plank fit snug with little or no problem This was normally right at the curve of the keel up to the stem. Working it out just from plans never worked. Test plank or cardboard template in conjunction with the model ended up working for me.

-

When I made the Pavel Nikitin "JOHN SMITH SHALLOP", I replaced the line with after market line. Two GREAT sources are SYREN SHIPMODEL COMPANY and ROPES OF SCALE. Both are MSW sponsors. ROS offers synthetic and cotton line while SYREN only has synthetic. Both are good.

-

Gap on flat bottom

Chuck Seiler replied to WGibson's topic in Building, Framing, Planking and plating a ships hull and deck

Riverboat hulls are really pretty basic...a flat bottom barge with alot of stuff on it. -

Gap on flat bottom

Chuck Seiler replied to WGibson's topic in Building, Framing, Planking and plating a ships hull and deck

Is what we are looking at the underside pf the hull or the main deck? Either way, I would sand the frame to the planking and plan the sides accordingly. If underside of hull, the sides could be slightly tapered inward. Ditto deck...It appears too small to notice. I build the steamer FAR WEST a few (hundred) years ago. I don't recall any waterways on a riverboat. -

Call me a heretic, but I liked the Alexander Kent/Bolitho novels better than Patrick Obrien/Aubrey. Welcome to the club. Good luck!!!!

-

I second Chris' comments about starting small AND checking out other "first timer" build logs. There are alot of good vendors out there, large companies and small operators. Check out the build logs to see what they say about quality of instructions and quality of material. I would recommend a kit that has some rigging and some planking (double plank on bulkhead) to get a feel for what you need to learn. Also recommended -pick something that interests you AND has numerous build logs to assist you. I know that doesn't answer your specific question, but I hope it helps. ALSO: Alcohol is your friend...to unglue the errors you made. AND You can never have too many clamps.

-

I would be reluctant to use oak in planking that small. The grain is quite coarse. I have been told beech is 'scale oak'. It is tight grained and easy to work with. I get beech from OCOOCH HARDWOOD. That having been said, if you are dead set on using oak and Modelers Sawmill cannot get it, Ocooch probably can.

-

I agree with Mark and Gregory...look into the NRG Planking Tutorial. It is much more than a "Read this or watch that" tutorial. It involves actually planking a half hull. I know that doesn't answer your original question...but it actually does. "Using planking (shipbuilding) methods they originally used" is complicated and not completely replicatable on a plank on bulkhead model. The tutorial teaches you about spiling,tapering, cheaters and spacers (and maybe edge bending) so your planking comes out right. Some start with the wale and work up and down. I like Mastini's recommendo about starting a half plank below deck level. It allows the next plank up to overlap (strength) and give space for waterways, etc.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.