-

Posts

1,770 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SawdustDave

-

"Question I like the look of hard maple but have never planked with it. How pliable is it or is it on the brittle side?" Hi David.... No use of hardrock maple in my planking. You may be looking at the bamboo planking, which I love to work with. I could not recommend hard maple as a planking material for many reasons. Not at all brittle, and if milled very thin, it is quite pliable. It just tends to leave burn marks when milled with a saw blade. Requires lots of sanding to get a clean part with no burn marks. Great for carving, shaping, tapping very small holes, etc.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

SawdustDave replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Very nice work Nenad. "Patience".... You asked? That little deck house required an awful lot of patience my friend. Cheers- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

You got to have a little MacGyver in you modeling soul George.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

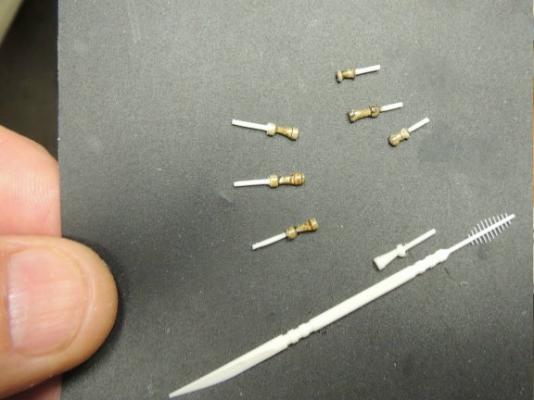

Belaying pins.... Quick post, just to share this little innovation I think many of you may like to try. As I got into the rigging of this project, I took inventory of my bone yard of blocks, cleats, and belaying pins. I discovered that, although I have four different sizes of belaying pins, none of them actually fit the scale of this ship. What I needed was a 1.2mm pin length with a 1cm shank. Remember the little plastic tooth picks with the bristles? Stained the heads with a dark walnut.... perfect.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks all for your regular visits and "likes" .... Like everyone else on MSW, I thoroughly enjoy your support, comments, and encouragement. If all goes according to plan, we will capture the presentation on video and share it as the final posting of this build. I can hardly wait to see the look on his face.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yves my friend. How are you? "Fast".... I would say it is far more a matter of putting in lots of shop hours, than being "fast". Mainly because I've decided to do the presentation to the good doctor on my next follow-up appointment, which will be December 4th. Think I'll make it? PS....Promised Chuck P today, I will come back and build the Cheerful a second time.... Much slower and according to his plans. Guess I'll have to finish the SOS first.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

A couple of full view shots. She's really beginning to come together now. Birdseye view.... I kinda like this low angle shot.... Thinking I might need to darken the keel and bow stem. Don't want to paint over the joinery and iron plates. Something closer to the bamboo hull planks might work more better. What think ye? If all continues to go well, by my next posting .... she will be tall....already working on mast and booms.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Major progress update.... Four days of rain and gloomy weather, plus the Admiral's off visiting our kids in Louisiana.... adds up to major shop time for Dave. After finishing up all those cannon riggings, turned my attention to a long list of small projects.... Over a dozen cleats and eyebolts, timberheads, belaying pin rails, boom crutches, inboard ladders, boarding steps, stern gun port lids, and several touch-ups. Beginning with the gun port lids.... I tried blue and black first....settled on natural. One little note on those tricky little boom crutches.... carved them out of two golf tees! Created the keel iron reinforcements.... with brass bolts. The channels and chain plates with deadeyes....also note the boarding steps. Inboard ladders....

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Of all my shop equipment, (3 table saws of different sizes, 2 laths of different sizes, band saw, drill press, chop saw, grinders, table sanders, thickness plainer, etc) it is the router that still makes me a little nervous. Loud and powerful, and moves a lot of material. Hand held is safer than table mounted, but you can't always use hand held on small parts....a real bad *** piece of equipment.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

What concerns me most with the setup is that you are pushing the material through the bottom of the blade.... with all the hazard of that spinning blade going on above the material. I trust Ed is very intensely aware of the potential danger and will be keenly focused when using. Careful mate.... We don't wish to see any of your blood on all that magnificent workmanship.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

SOS just sitting there..... Every day, saying "What the hell?" Can't you see I'm not nearly finished?!!!" Sorry Charlie. I'm very busy right now. Just be patient....Your time will come.

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Another Happy Birthday wish to go with the many others. We are all thinking of you pal. Dave

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Interesting addition to the ship.... A staff member asked me if I knew about the silver owl pin Dr. P always wears on his lapel. I had noticed it but never inquired about it. Turns out, there is a unique story behind it. This lapel pin was given to Dr. Pillsbury by a few years ago by another patient who is a jeweler. We all recognize the owl as an iconic symbol of wisdom and knowledge....right? So when he began wearing it every day, his staff, and then dozens of fellow UNC physicians wanted one of the owl pins as well. Last count, there are over 500 owl pins being worn every day by UNC physicians and nurses. Understandably, he considers that little owl pin very special. So, his admin. assistant gave me one of the pins while at my appointment yesterday. I used it to create a mold and cast this piece, which I painted blue w/black trim.... now mounted as a headfigure on his ship. I realize these small vessels did not usually, if ever, have carvings on their bow. This one does.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Congratulations on a really fine job Brian. She's a real beauty. I thoroughly enjoyed your superb log. Dave

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

That's what I thought Augie. Thanks for confirming. After all these years, I must admit, the proper nomenclature of ship parts is definitely not my strong suit. Thanks to a lot of help from you guys here at MSW, and Google, I manage to get by most of the time.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

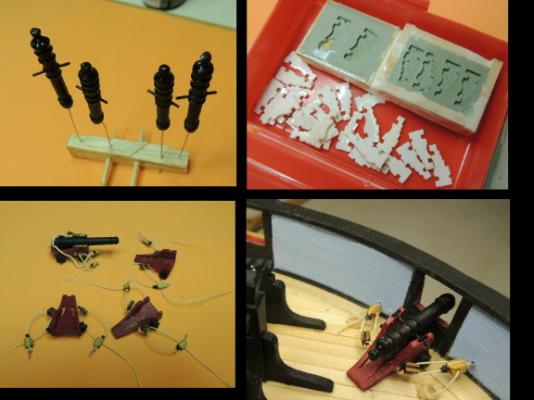

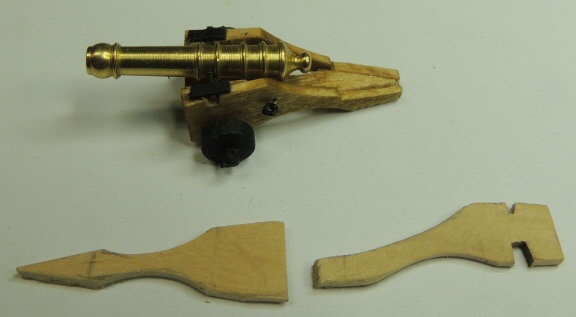

More cannons.... Another three days of working on the eight remaining 6 pounder cannons. Assembled and painted the trucks and wheels .... or do you call them carriages and trucks? Cast the cannons and painted them and mounted them onto the carriages. Now working on the pre-rigging of the blocks and tackle. Using 3cm and 5cm blocks. Note, at this scale, I am leaving out the hooks and serving the tackle directly onto the rings. Think I'll take a break from the guns this evening and carve the six cap rail timberheads.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks John. You can understand why I went to the little two-wheeled 3 pound cannon rig. That big ol' windlass really takes up a lot of space.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Here's an interesting link to a video I think all of you will enjoy as I did. https://www.facebook.com/stefano.simeoni.1/posts/766719033457113 Can you imagine building an entire ship with these tools? And the men swinging those mallets and axes with such skill is mind boggling to me. We really have become soft over the years, by comparison, huh?

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

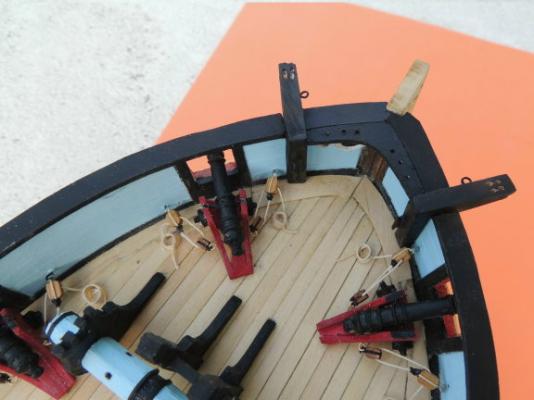

Good solid shop day.... Lot's of cannon rigging, but a few other items to break the repetition cycle. First, this little plate which will eventually carry the jib outhaul line from the tip of the bowsprit.... Then I cut and fitted the catheads and bow rail pin holder.... Finally, mounted all four of the small 3 pounder guns and two of the 6 pounders. Real nice to see the foredeck beginning to fill in. And the colors seem to all be working pretty well overall. Began shaping a couple of anchors this evening. They are always fun to build and rig.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Molding and Casting cannons.... I took a few quick shots of the process for those who might not be familiar with molding and casting. With over a dozen cannons needed, the options are.... Order manufactured cannons, turn each one individually, or use a master to create a mold and produce an unlimited number of identical units with castings. Personally, I enjoy the molding and casting process. For molding, I use "Smooth-On" urethane mold compound (2 parts).... cures in about 16 hours. For casting, I use Alumilite liquid casting plastic (2 parts).... cures in about 20 minutes The top left mold was created three years ago using the turned cannon seen in the pic. The top right mold was poured at about noon yesterday and removed early this morning. I used the brass cannons purchased for my SOS build to create a DOUBLE mold. The castings turned out great. In this next set of pics.... Top left, the cannon castings are painted black. Top right, I'm using a mold created years ago to produce the truck sides. Bottom left, the trucks are assembled and pre-rigged. Also note the comparison of the 4-wheeled truck that will be used for the 10 gun ports aft of the windless. Bottom right, is the smaller cannon installed in that first gun port position. Note the much improved footprint in that very confined space.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for the visit Jesse. Being from the area, you fully understand the color issues with this model.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just learning of your illness Angie.... So sorry to hear. Get well soon mate.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Sorry guys.... I just couldn't abide the "space issue" with that first cannon. So I will pull that one out and replace it with one of these smaller rigs I had developed for my SOS build. Smaller cannon and the footprint of the truck is better suited for the tight quarters. I am creating a casting mold from this cannon in order to make four of these units.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I really hate to see this project gathering dust while I concentrate 100% of my shop time to the Cheerful build.

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Right Ken. Don't want the good Dr. to be taking any heat over the color of the gun trucks. One down, 13 to go. This first one took me six hours, but that included a lot of experimenting.....plus, the fact that I haven't rigged a cannon in over three years. Really enjoyed this one....the other thirteen will seem more like work.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.