-

Posts

1,412 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Martin W

-

Hi BE -- As I watch this build -- and it was the same for the Fifie -- I'm struck by my ignorance of these vessels. The details you're adding, and the basic sailing structures continually surprise me (ok, the ladder makes sense). Clearly my understanding is limited to a small range of 18th-century ships. And since much of my mind has always resided in the Baroque to Romantic eras, they are what seem natural to me. So, following your craftsmanship and research is an education not only in technique, but also style and utility of an era and region. Fabulous! Cheers Martin

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

Oh man! I can't imagine -- or, maybe I don't want to imagine -- fitting those rubbing strakes. They line up perfectly, but you say nowt about how much spiling you had to do. I can see why you're staying away from the black. With the other bright colors, it would make for a bit of the peacock. And I have to confess that seeing the angle of the rudder made me do a double take. A rather upright bow and sharply angled stern -- how very interesting! Cheers, Martin

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

Hello BE -- This is a sweet build. With the planking on the lines of this boat come out, and I have to say they are fascinating with that sharp bow. Your work is as precise as always and I for one appreciate that holly plank you had to use because it shows up the amount of spiling you had to do. But William's face does not look at all guilty. C'mon, confess it: you staged that photo. 🤨 Hope you enjoyed your trip. I think we're all getting itchy feet. Good luck. Martin

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

Fiddling work indeed, but neatly done. The shot looking down to the deck is great! Cheers, Martin

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

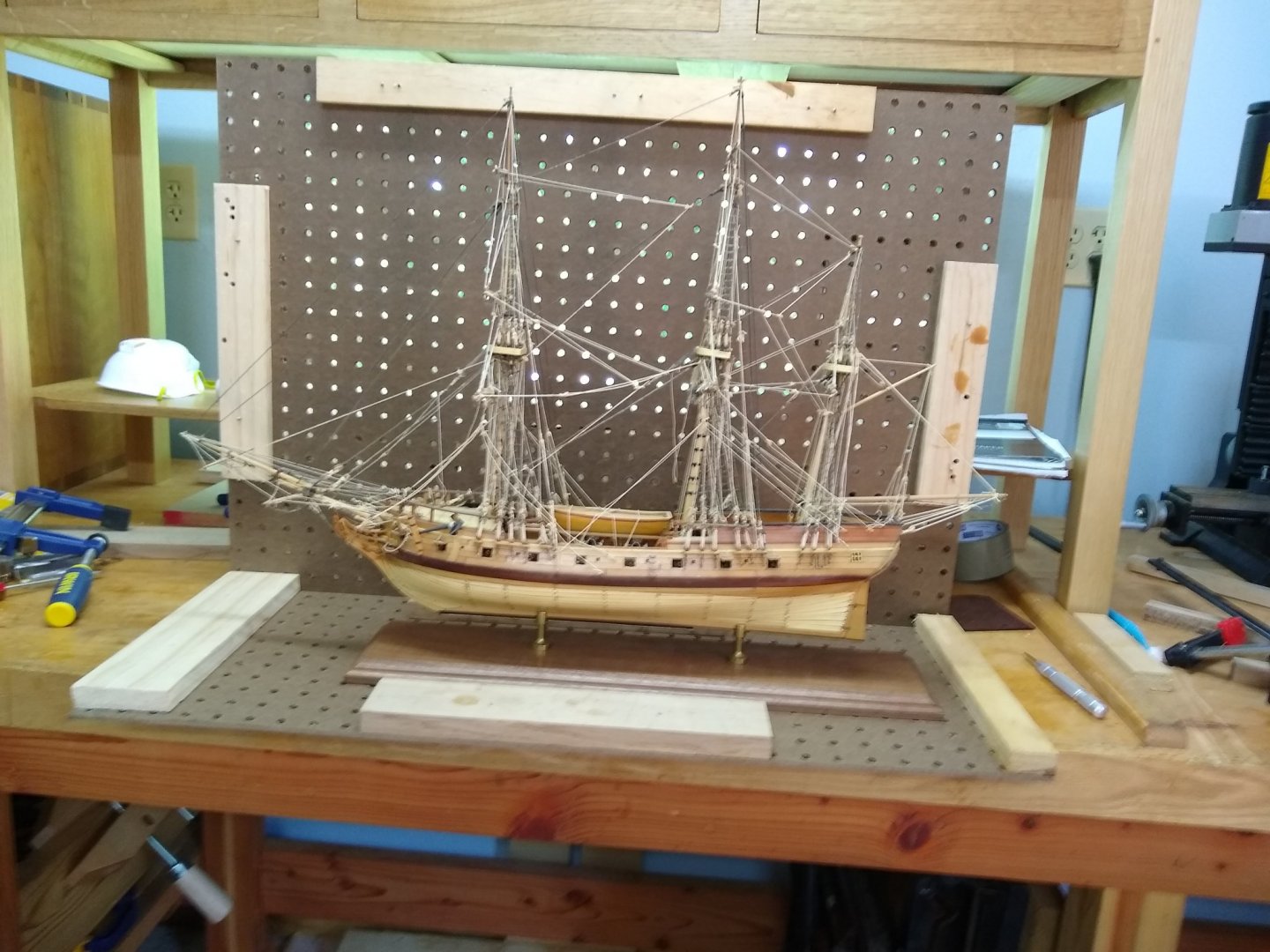

That's a pleasant looking work space, BE. I have to admire your woodworking bench with the dogholes and front vise. I'm gearing up to build one for myself, so that I can build drawers and another bench for the basement, where my boatyard will be. I also like the way you've neatly stowed all your equipment. Frankly, I'm jealous. Martin

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

Terrific, BE. And I shall be following you to Zulu. See you there, Martin

- 195 replies

-

- lady eleanor

- vanguard models

-

(and 1 more)

Tagged with:

-

Hi Jason -- I hope you've survived the blackout and that your electricity is back on. It's hard to work on a build in the dark, eh? Cheers, Martin

- 800 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

You've listed the very reasons Mrs W of the Hills was able to convince me (she didn't have to work very hard) to move here. Plus there's a sizeable woodworking community. Here's proof of just how rural we are: Cheers, Martin

- 195 replies

-

- lady eleanor

- vanguard models

-

(and 1 more)

Tagged with:

-

Hello BE -- As I was touring MSW for new Swan builds, I came across this. What fun to read through the log of your progress, and to see you and William at it on a surprisingly different sort of project. As always your ingenuity in building in details like the baskets and the strops on the blocks is fascinating, and your narrative flair always entertaining. And I never thought there would be such reliable archival information on the fishing fleet! As I'm waiting (and waiting) to get my own work space together in my new residence, I'll get my modelling dose from watching you finish this and then moving on to the Zulu. Cheers, Martin

- 195 replies

-

- lady eleanor

- vanguard models

-

(and 1 more)

Tagged with:

-

You're right, Peter, it was a long drive. And even though it's technically the same country, Connecticut and Oklahoma are pretty different from one another. I haven't checked out any of the wine you mentioned, but I have had some local beer, and it's definitely potable. I'm itching to get back to work. Cheers, Martin

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Hey Peter -- I see what you mean about the height of the cutter's floor, but doubt I would have noticed if I hadn't been looking. Once you get all the rigging done, that detail will probably disappear behind all the other details to look at. Your yards etc look pretty good to my eye. That flattened area (hecadexagonal -- with the x instead o c, maybe? it makes sense in Greek) in the center is always a teaser. I tried out a few yards before my move up here and threw them all away for much the same reason you stated -- they were either too thin or uneven in the flattened areas. Anyway, it's nice to follow your progress, since I am still a way off from getting my boatyard established. Cheers, Martin

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Thanks everybody! Chris, 38 moves tops just about everyone I know. My parents were with an oil company and moved 32 times -- I settled down somewhere around the 25th, and REALLY hope this will be the last. Spy, it's great to hear from you. There was a time when the Swan class builds were all over the place, different, and exciting. I still hope that when I finish this Fly I can take on a scratch-build of a Swan at 1/4 scale, which will be much easier on the eyes. Ron, we're leaving town next week, and right now from the perspective of non-stop packing it seems both like an infinitude and much too soon. Jason, we will be almost neighbors -- I'll be in Winchester. When I get my wits about me again, and if CT doesn't enter a second shutdown, we'll have to get together to talk ships. Mike, I have gone around in circles about taking these two ships. I gave the Prince away, just because 3 of these crates wouldn't leave any room for the other things I have to squeeze into the cab of my truck. I reminded myself of Bob Fine's motto of one ship in, one out, and decided that someone else might enjoy looking at a model and maybe even get inspired to try their hand at it. Thanks for checking in, Toni, and thanks again for the suggestion about the peg board -- aren't you also about to make a big move? Florida? Santa Fe? They're both pretty warm. Cheers to all until I get to Litchfield County! Martin

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Hello Everybody -- For these past 6 months, I've started on some phase or other of the Fly only to realize I had packed away the tools I needed to get it done. I put together a batch of Syren's deadeyes, and used the sanding contraption to round them off, but then saw I had no equipment to solder the chainplates. I started on the masts and spars, and tried out different species of wood, ultimately ending up with the spruce that I used for the Rattlesnake. But then I only had stock long enough to cut 2 masts. And then packing took over. We bit the bullet and bought a house in NW Connecticut, having sold our house here much faster than we had imagined possible. I finished my last two woodworking projects (a blanket chest for my sister out of walnut, and a credenza for Mrs W out of white oak), then used my full scale tools for one final task, that of packing the two models I'll be able to take with me. Here's the process, based on Toni's sage advice. Here's the old Rattlesnake perched on a piece of pegboard, to which I've screwed some pieces of scrap that will hold the sides. The frame is the white oak credenza (minus the drawer pulls, which I've roughed out, and will have to finish carving in CT). Here you can see the back of the box that will encase the model. And here's the fully encased model: Next up is the Fly, which will be easier, since it's unmasted and will take a smaller box. It isn't on its final base yet, so I used a piece of one-by pine that I had lying around the workshop: The process is just the same as before, but with a smaller box, and with some baltic birch 1/4 inch ply I wanted to use up: And here's the last glimpse before getting to my new boatyard: The only problem now is that with no modelling to do, and no furniture or carving projects going, I can only twiddle my thumbs till we start the drive. I might have to take up beer-drinking. Cheers, Martin

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Well done, Ron. What wood are you using? I can't tell the actual size of the carving, but those cuts under the wings and separating the wings from the head are awfully tight. Are you using some kind of gouge, or ye olde exacto? For most of my carvings, I had to resort to using dulled exacto blades as scrapers, and found that strategy more effective -- and less destructive -- than the more straightforward one of gouging out waste. Cheers, Martin

-

Ron -- How many times do we all have to learn that a big part of model building consists of gnashing the teeth and using language that would make a sailor blush? I spent the weekend out in my woodworking shop cutting dovetails for drawers. When I tried fitting the pieces together nothing would hold. And then I realized I had cut tails for pins, and had to do them all over. So I know your feeling. Cheers, Martin

-

Definitely cooler, more wine, and probably only the occasional remnant of a hurricane: Connecticut, where I'm already designing (or dreaming of, depending on whom you talk to and whether my wife is involved in the conversation) my boatyard/wood working shop. When we'll actually manage to get there is another issue. Till we do, and I get a work place set up, I'm mostly entertaining myself by watching other builders' progress. Cheers, Martin

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Hi Peter -- Beer is always good, even in the cold. I don't have my classical sources at hand right now, since I've packed them up in preparation for our move out of the prairie. But I do recall a warm evening in Cambridge with some friends, when we were foolishly drinking merlot instead of IPA, and we entered a wager into the College Betting Book about the construction of Bellerophon's belt. Whether the bet was ever resolved, I can't say, because of that initial error of drinking merlot in such warm weather. Never again! Martin

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Wow, you've added metallurgy to your impressive set of skills. Getting the right sized anchors seems to be a persistent problem, and you've solved it. Ditto with the chains. Having rejected the ones that came in my kit, I'm trying to get my nerve up to re-learn silver soldering techniques for the umpteenth time. So tell me, where do you get your bass wire? All that I've bought locally has been coated with something that prevents soldering. Cheers, Martin

-

Well done! I'll raise a glass or two in your direction! And I agree about Bellerophon's breast plate -- it should definitely be gold, or at least bronze. And as I recall, there's something about a belt, though I can't remember the details. Cheers, Martin

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Hi Ron - When I was dry fitting my head timbers, I pinned them in place. That gave me a modest success in judging how everything should come together, since pins slip and the pieces rotate around the pins. But still I could get a general sense. With your precision that might not be enough. I'll be eager to see how you solve that problem. Cheers, Martin

-

Thanks, Ron, I've just placed an order. If I recall correctly, a wood supplier did once advertise on MSW. I used to have their site bookmarked, but have never ordered anything from them. If this works, then I'll be thrilled, because in my view there can never be too many wood suppliers. Cheers, Martin

-

Hi Ron -- That's an interesting series of experiments on getting a sharp line on your blacking. If the tung oil doesn't prevent the seepage, and if you're thinking of keeping the unblackened area natural and unstained, then why not use something blonde shellac, or varnish, or even polyurethane? Maybe the blacking would seep under?? If you've already said this, forgive me, but where did you source your Swiss pear? I've started shaping some masts & spars out of a hunk of maple I had, and decided they are much, much too light (pretty close to white). I've always liked the mellowness of Swiss pear, and think it could be a nice match with the castelllo/boxwood I've used elsewhere, but haven't been able to find a source for modelling sized stock. And let me join the chorus of voices singing praise for your craftsmanship. Your joinery is beautifully tight and a pleasure to behold! Cheers, Martin

-

Great work, Ron. Your skill with handtools is impressive -- I have to admire the precision you attain. And that billethead especially is a charmer. I personally find 5 pointed stars almost impossible to get symmetrical. Could you say a bit more about your ebonizing technique? What is quebracho bark extract, and where do you get it? Cheers, Martin

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.