-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Blueskippy

-

Hey all you have done is open the box, and we are already at the end of page 2. Syrens 112 page record will be broken before you get your tools out at this rate lol. I will sit and wait patiently with the others.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi Piet have been quietly watching and am seriously in awe of your sub. Skippy Ps. Your flying technique sounds eerily familiar to a recent holiday flight I was on. Lol

-

A short deviation from the main build: Whilst in a local hobby shop I acme across some larger section planking going cheap (app 1.5mm x 8mm) and this gave me an idea for the display stand: I cut the strips to size and laid them with a butt shift: I then drilled for the treenails and inserted these with pva: Then .5mm black cord caulking, a walnut border and some coats of semi gloss varnish and here we are: It mirrors the Pickles' deck and I think looks ok.

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

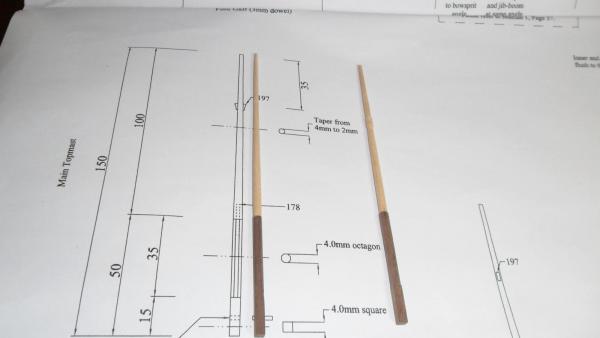

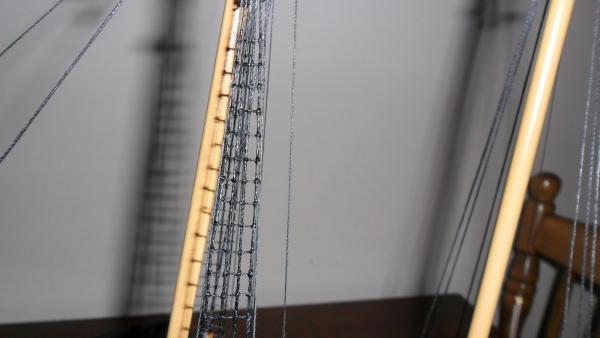

Masts and Standing Rigging So the next step was to manufacture the masts and crack on with the standing rigging. The masts were made as per the instructions, from square stock and dowel joined with brass pins: These were then painted (as the supplied wood did not stain very well) Yellow Ochre and Black, and stepped into position: Then the standing rigging was added, as per the instructions. First the shrouds, and main/fore tackle: Then the back stays: Followed by everyones favourites;;;;;; the Ratlines: These were stained with indian ink and our favourite job is finished. I did deviate from the kit in two areas: In BE's Pickle log, he pointed out that the instructions stated that the fourth shroud on each mast was in fact a "Backstay" and as such would not be included in the ratlines. His pictures showed that this was visually awkward with the ratlines across only three shrouds giving little room for the crew to clamber aloft, and he eventually decided to link all four "Shrouds" with ratlines - with pleasing results compared with the instructions. I decided to go a slightly different route, according to Petersson's "rigging fore and aft craft" the Fore mast has all four shrouds "ratted" and the main is linked only across the first three shrouds - the gap between shrouds 2 and 3 being wider to admit the gunport, giving a wider expanse over just the three shrouds and therefore more room for the crew to climb. and this is the way I went.... mmmm??: My second deviation - also from Petersson - was to add the finishing touches to the Fore and Main tackles. this was achieved by inserting an eyebolt at either end of the channel and running a rig through the dangling pendants on each mast using 2 single and a double block on each. Well after adding the rest of the stays, the standing rigging is done. Just booms, spars, running rigging, ships boat/s and finishing,,,,,, loads yet eh!!

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Gregor, Another option for you to think about is RB Models: http://www.rbmodel.com/index.php?action=products&group=011 I used theirs in my sherbourne and found them of high quality and very low cost. You may be able to see them in my galkery pics listed after my signature. Btw your Sherbourne is looking superb.

- 210 replies

-

- Sherbourne

- Cutter

-

(and 5 more)

Tagged with:

-

Cheers Jason. The hour was only the assembly part, that did not include painting/blackening. The photo is if the best one by far and I refuse point blank to post close-ups of any of the others lol. Kudos on doing that many for your Snake.

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

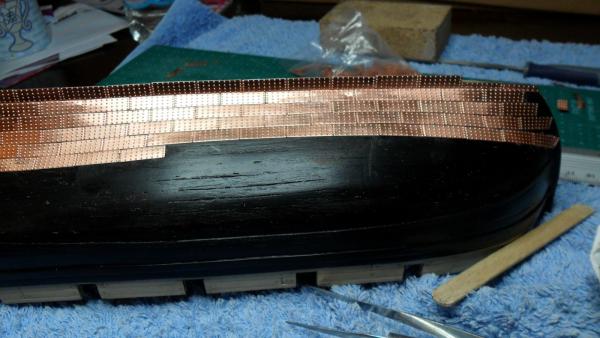

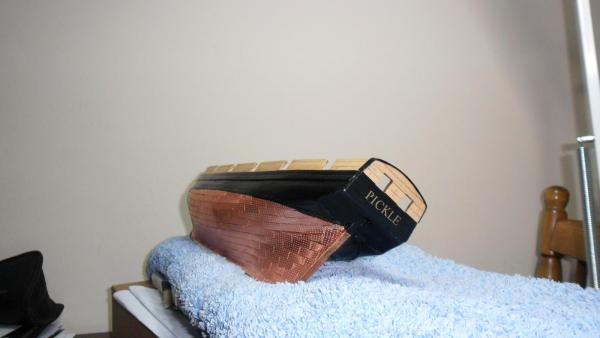

Plating Finished and Deck furnishings installed With the arrival of the extra copper plates work continued andthe Plating was finally finished: I am reasonably happy with the plating, though on close inspection it is rough in a few areas, but as a first effort it is not an embarrassment My next build is not plated, but I think that the next time I need to plate I will try either the Amati etched plates or even go the whole hog and try the copper tape that the Model Shipways builders use. After the plating was completed I made up the Bowsprit and mounted it along with the final fixing of the deck furniture: You may notice that The Carronades are fitted but I have not described their build......... Simple "They are an absolute %#~@*!!!!" The instructions, the quality of the parts and the final impression is superb. The size of the things is absurd: the overall finished item is app. 1.5 inches long and about .75 high (guesstimate) and has a grand total of .... wait for it.... 18 pieces: 4 wood, 5 brass etched pieces, 4 etched eyelets, 4 pieces of brass wire and the barrel itself. They take about an hour each (without the rigging, and on a good day) and would try the patience of a saint! my finished articles are ok for "stand-off" viewing but that is about it: For a better narrative of building them it would be better to look elsewhere on this site, as there are a number of superb examples that far outrank mine LOL. Next up is the building of the masts, and then Pickle can go "Vertical"

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Guys for your comments. Beef, yes I was pleased with the maple - at last a good choice by me!!!" Catch up I am going to run through all of the jobs I have done since the last update - because of my pc problems I am a fair bit ahead, and because of the plating and decking problems (to be revealed) I have a fair few bits done, but out of sequence. Decking As I mentioned early on, I wanted a different effect on the decking than the Sherbourne, and went ahead with the Cartridge paper caulking. Unfortunately though the effect was exactly what I wanted in places, it was very varied. So I ordered some .5mm tanganyka from CMB and re-laid it (on top of the previous) with HB caulking on both sides of the planks: This picture was taken later as in my frustration I forgot to take any pictures - I am very pleased with the effect, and using 3mm 4mm & 6mm planks worked well, though I wish I had bought the 6mm in a different wood to frame the inner and outer decking better. Deck Fittings I built up the deck fittings as per the instructions, but with four additions/changes: As per many other modellers, I exchanged the multi-part windlass for a 6mm walnut rod, planed (succesfully-ish) to an octogon. I added cannon ball holders either side of the gratings, and along the back of the main hatch. I replaced the rear grating with a glazed (humbrol clearfix) 4 pane window affair. And finally the walnut "Chimney" was replaced with a chemically blackened brass one (Carr's - superb stuff, and easy to use too. I had mixed results with the Krick stuff): And this is the Pickle as she stands today: Ps. I spoke to caldercraft today and they are sending a pack of 100 plates foc..... though I did get the impression they did not believe me completely

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

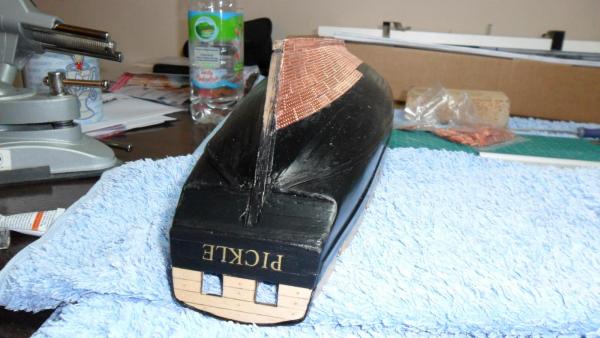

Due to a few problems the next few posts are a bit out of sync, as I moved from job to job whilst awaiting supplies. Plating and Shipmate Firstly I am going to follow a growing trend that I have seen on a couple of other logs and introduce my building partner Billy: Now for the model: the plating went very well and I am very pleased with the initial results: But for some reason there were not enough plates provided. As this was my first venture in to coppering there were obviously a few mistakes, and I did scrap about 15 or so plates, but I estimate that I am at least 50 - 60 short. I first checked other build logs and found that in general Caldercraft seemed to supply ample plates, so I set about checking my measurements. After 3 tries, I have decided that my waterline is correct -I used the supplied jig for lifting the front of the keel and a 50mm height is what I seem to have. I am completely at a loss and have decided to leave it as is and order some new plates. so until then I will get on with the many other Jobs awaiting me and Billy.

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks guys, I have been inspired by the all the logs on the site - love your scratch built launch Tony, and your Pickle BE is special and a great source of reference for me. Pickle is looking better than I hoped at point, though as you will see as I catch up, a few problems do develop quite soon !!

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

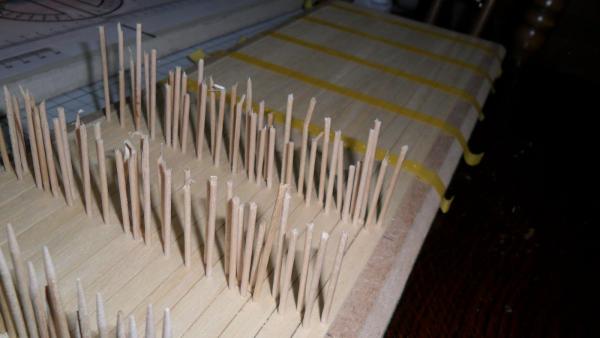

I have been unable to upload pictures to my pc, hence the delay in posting. Planking above the Black Strake The next step was to plank the area designated for yellow ochre paint, as mentioned before I have decided to use a light wood rather than paint, and some Maple was sourced for this. First the planks were cut to length and clamped wet to the hull - following my earlier problems these were left on the hull until perfectly dry: I then used pencil caulking and glued into place, then using holes drilled through from the inside I marked and cut the gun ports: Next the treenails were drilled and the coctail sticks were brought in: Lastly the treenails were cut back and sanded and the job was finished:

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

I agree with you Jason BE's idea was poached by me also on Sherbourne, great idea - easy and effective. By the way your "Snake " is looking superb

- 800 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

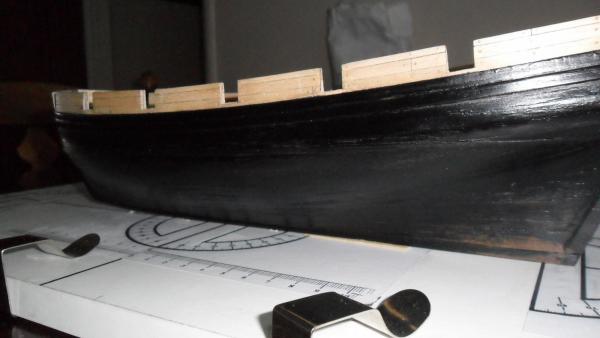

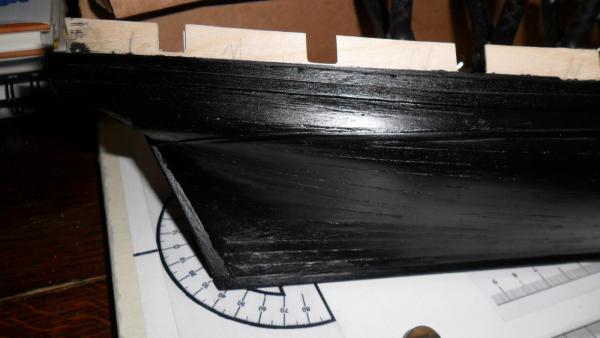

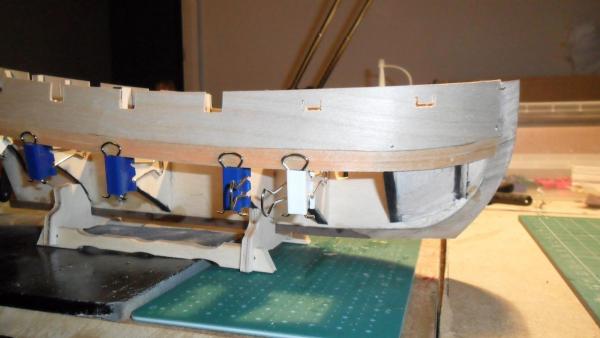

Second Planking, Waterline & Paint So ahead with the Second Plank, I had decided that the planks above the whale were going to be in plain wood - with all the work we do with planking I wanted some showing, and as this wood should be Yellow Ochre, I decided that a pale wood varnished would be nice. The planking went ahead with few problems, except I followed the instructions and forgot some of the advice on this site. JoTika/Caldercraft state that the wood should be soaked to aid in bending, and then glued damp to the hull with CA, this is all well and good but their supplied walnut SHRINKS after soaking leaving gaps - admitedly this is only my second effort at planking and chamfering could be some of the cause, but definitely not all. But overall, as this whole area would be painted & filler could therefore be used, not a total shambles, and so a strip of plasticard was added at the waterline to mark the edge of the plating as per Blue Ensigns build, and the help topic on plating....... along with the mentioned filler, which also helped where my initial fairing of the bulkheads was not upto scratch (must try harder, as my next build choices all have large unpainted/unplated areas) Then it was an easy task to mask and spray the whole thing in Satin black: Three things I have come to understand is that whether the instructions are good - as per Pickle - or scarce - as per Sherbourne - it is a good idea to dilute them with a good pinch of MSW advice! You can not spend too much time in preparing the bulkheads etc ! - though you can obviously oversand! Soak and pre-shape planks, then allow to dry thoroughly before fitting! Think,,,,,,,, Think,,,,,,, then do!

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Timmo, that panel looks perfect, you have me worried now Granado is one if my choices for a next build, and that has set the bar high.... O will follow your progress with interest/dread lol! Keep up the good work

- 366 replies

-

- granado

- caldercraft

-

(and 1 more)

Tagged with:

-

Aside I wanted a break from the planking and decided to start a project I had been looking forward to, which was to try a new (for me) method for deck planking. My previous effort on Sherbourne was with Indelible pen caulking and treenails, and though it looked ok from a distance,,,,, Pickle deserved something better (hopefully): Sherbournes deck: The new method was based on a number of ideas from build logs and help files on MSW, and is as follows: Planking is laid with a sliver of cartridge paper between the joints: The paper is then cut back with a scalpel, and .65mm holes drilled for the treenails: Bamboo cocktail sticks (£1 for 400, at the Tesco shipwrights) are then pva'd in: After cutting back the coctail sticks with a SHARP knife the deck is scraped with a razor blades edge: Then just a couple of coats of satin varnish and the deck can be fitted into the hull: The final effect is -to my mind - a vast improvement on my first attempt, but I am not sure if it quite the effect I was looking for?! Oh well I have put the second planking off for long enough,,,,,, wish me luck

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

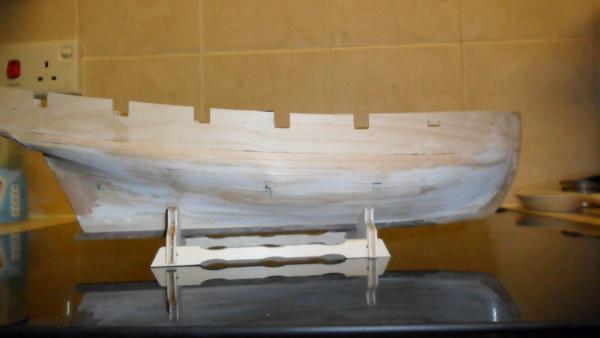

Planking begins I hoped that this time around my first planking would be of a better quality than my first ship. Sherbourne took me a few hours to plank but what seemed days to fill and sand. Things did go better but not perfectly as the following photo's show: After 4 or so planks were attached each side, the problems started, so with a brave heart I progressed to,,,,,,, starting at the other end (keel) This did seem to help and the overall finish was better than Sherbourne, but by no means perfect. Filler was applied and sanded and in a very short time, the cheeses grater effect was removed. There looks to be a LOT of filler, and there is but not as much as it seems - Honest! - the brand I am using seems to have a paint like effect where applied,and when sanding leaves a residue like a primer Good/Bad?? I am unsure.

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

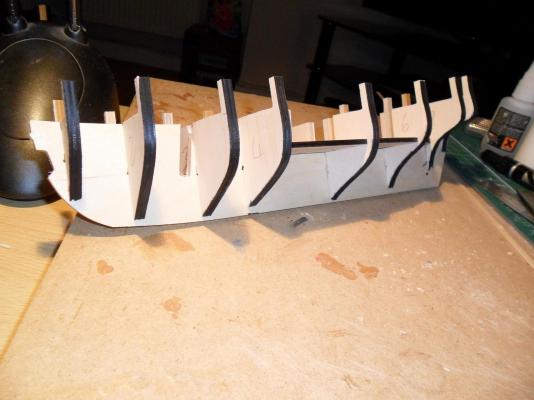

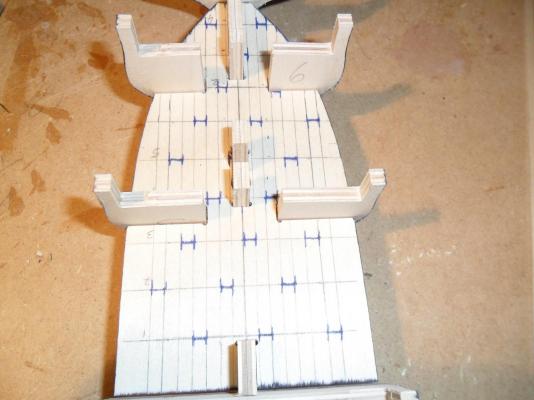

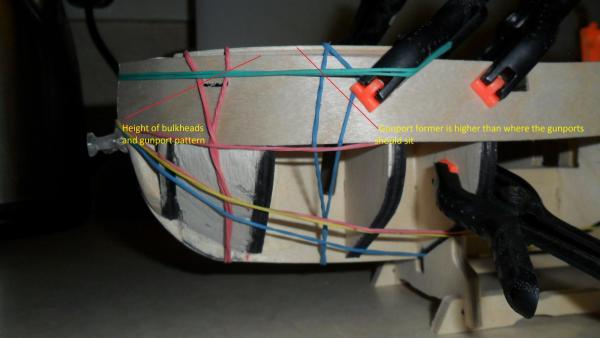

Initial Build I glued and fitted all the bulkheads and dry fitted the lower deck, this was easy all the pieces were a good fit and the operation was a "goodun" Beveling and first Planking. So rain has stopped and dust can be produced! I beveled the edges of those bulkheads that needed it - being sure to leave a continuous line of black on each bulkhead - and inserted balsa between bulkheads 1 and 2 to aid in planking. One point to note: I originally dry fitted and bevelled the planking guide - BE careful the guide comes too low and is a B*%$h to bevel by hand. I eventually ripped it off and just went with the balsa. Finally the beveling was complete and we can move on to the gunports and first planking. Fitting the gunports was again easy, but on reading the instructions, and other build logs it is very important to fit it correctly. The supplied former for the gunport pattern sits a lot higher than the bulkheads.... The gunport pattern sits to the height of the bulkheads NOT THE FORMER. Next instalment - Planking, and probably loads of filler and sanding.

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks jrb, I inserted balsa between 2 and 3, andit is certainly helping( Iam half way through the first planking I just have not had time to post. Btw, Blue Ensign's log is a Constant source of reference,,,,,, simply superb.

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Plank lengths

Blueskippy replied to Blueskippy's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks Russ. This forum is superb for us newcomers, what did we do before the web??? -

Thanks for that Blue Ensign. Ship modelling is a steep learning curve, as well as the skills you need to develop, the language, and understanding the uses of each piece of equipment is just as hard. At least I know what the "tackle" mentioned in the Petersson book is for. .... i think Thanks again

- 87 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks John, Rain has stopped and sanding has started, standby for the next thrilling episode.

- 31 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Blue Ensign. Whilst finishing Sherbourne (my first build) I was looking for my next project and chose Pickle. It is bigger than Sherbourne with more rigging - which I have enjoyed - even though my ratlines are more RATTYlines - and the copper plating looked a challenge, alsoafter reading your build log (amongst others) I was sold. To the point: Pickle has arrived and progress has started, but whilst waiting for it I picked up a book on rigging "Rigging fore-and-aft Craft" by Lennarth Petersson and remembered your discussion of the 3 shroud 1 backstay or 4 & 1 In post #35. To sum up for others (as it was a long time ago, and you have finished Pickle anyway) JoTika/Caldercraft state that the ratlines only run across the first three shrouds, and that the fourth was actually a backstay, your point - proven by the trusty "Dick" & "Tom" - was that this did not give enough space to navigate the shrouds for a crewman. I could immediately see what you meant and decided to do the same when I got there, But my new book shows a third option somewhat between yours & Caldercrafts. "Rigging fore-and-aft" has three case studies, the third being an American schooner (Experiment) built in 1808 and of approximately the same dimensions as pickle (though it does have Topmasts and Topgallants). On Experiment the foremast has four shrouds, each connected by ratlines as would be expected. But the main only has three; counting from the Bow, shrouds three and four are a continuous line around the masthead as usual but attaching to deadeyes 2 and 3, and shroud two is attached to deadeye 1 with ratlines running between the three of them. Please bear with me it now gets difficult to describe; what would be shroud one stops at a block about a third of the way to the deck and is then rigged like a backstay (Though both masts have specified backstays) with its two ends each terminating between a pair of deadeyes - this would-be shroud is labelled "Main Tackle & Top". The foremast has a "Fore" tackle & top that is terminated on the Channel between pairs of deadeyes, but this is separate to the 4 shrouds. Finally getting to the point: The upshot is that by having the arrangement described above, the deadeyes are further apart than Pickle giving "Tom" more room to work, and in my opinion would look good, as well as being a bit different to the norm, But... Finally... the questions - to Blue ensign or anyone else who might know - 1. Is this American arrangement a ludicrous idea for a Navy Schooner of the time? 2. What are the ****Tackle & Top for - they are in essence - to my inexperienced eyes - the same as the backstays but laterally, which is a bit like a shroud anyway? Lastly I will apologise in advance if the above is a. stupid or b. indecipherable (I would have scanned the relevant sections but realised that copyrights etc forbade this). Blue Ensign, your Pickle is superb, I hope mine ends nearly as good. Thanks Skippy

- 87 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Tony I had the same idea about a ships boat and ordered a caldercraft one - accordingto their blurb the 19 foot one was suitable, ,,,,,,,,,, nope, it was so big it would not fit anywhere on the deck. My own fault for not measuring and taking their word for it. That said it was lots if fun to do and using an idea from another manufacturers advert, I mounted it as if being towed as you will see in the gallery (I have since added the tow rope). By the way your Sherbourne looks superb, cant wait to see the completed article.

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.