-

Posts

2,127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by JSGerson

-

-

Der Alte Rentner: I didn't know I was a muse! I thought I was just an old fart😁

- Nirvana and Der Alte Rentner

-

1

1

-

1

1

-

Mtbediz: Your hook style was what I was originally thinking of doing. It was just the sheer number of them that seemed daunting that I considered purchasing them. Hand crafted hooks might still be the way to go. I'm not certain that twisting flat plastic or PE hooks is worth the appearance or effort.

Geoff: I agree with you 100%. You can't get bored with this build and I've been at it since 2017.

Jon

-

Thanks for the possible solutions. I have some plastic ones to experiment on. I'll have to think about an easy, safe, effective, and efficient heat source.

Jon

-

Things are going to get crowded on the gun deck. To install the guns, the anchor ropes and chain need to be installed first, as the guns’ tackle will lie on top of the anchor cables. Also, the structural elements such as the diagonal knees, stanchions, and spar deck beams and braces all need to be installed in concert as I move down the length of the gun deck. Don’t forget, all the gun deck furniture that was fabricated earlier needs to be installed as well.

So, to start off simply, gun rigging also requires six hooks per gun which need to be either fabricated or purchased. Syren offers plastic hooks but unfortunately, there is a problem. The problem exists not only with Syren’s product, but with other manufactures as well, be it plastic or photo-etched. The eye of the hooks is parallel with the hook itself. In the picture below, you can see the actual hooks have the eye turned at a right angle to the hook. It appears, I will have to fabricate at least 132 1/8” hooks just for the gun deck. I haven’t checked out what the kit has supplied for the spar deck. If anyone knows a cheap supply of properly formed hooks, I would be very interested.

- mtbediz, Ryland Craze and Geoff Matson

-

3

3

-

In preparation for the fabrication of the guns’ train tackle and breeching lines, a jig was made to facilitate the fabrication of those lines off-ship. Because the kit obviously does not have any supplies for the gun-deck guns’ rigging, 3/32” single blocks, 1/8” double blocks, 0.018” and 0.030” scale rope was ordered from Syren Ship Model Co. Those should arrive next week.

- Ryland Craze, Unegawahya and mtbediz

-

3

3

-

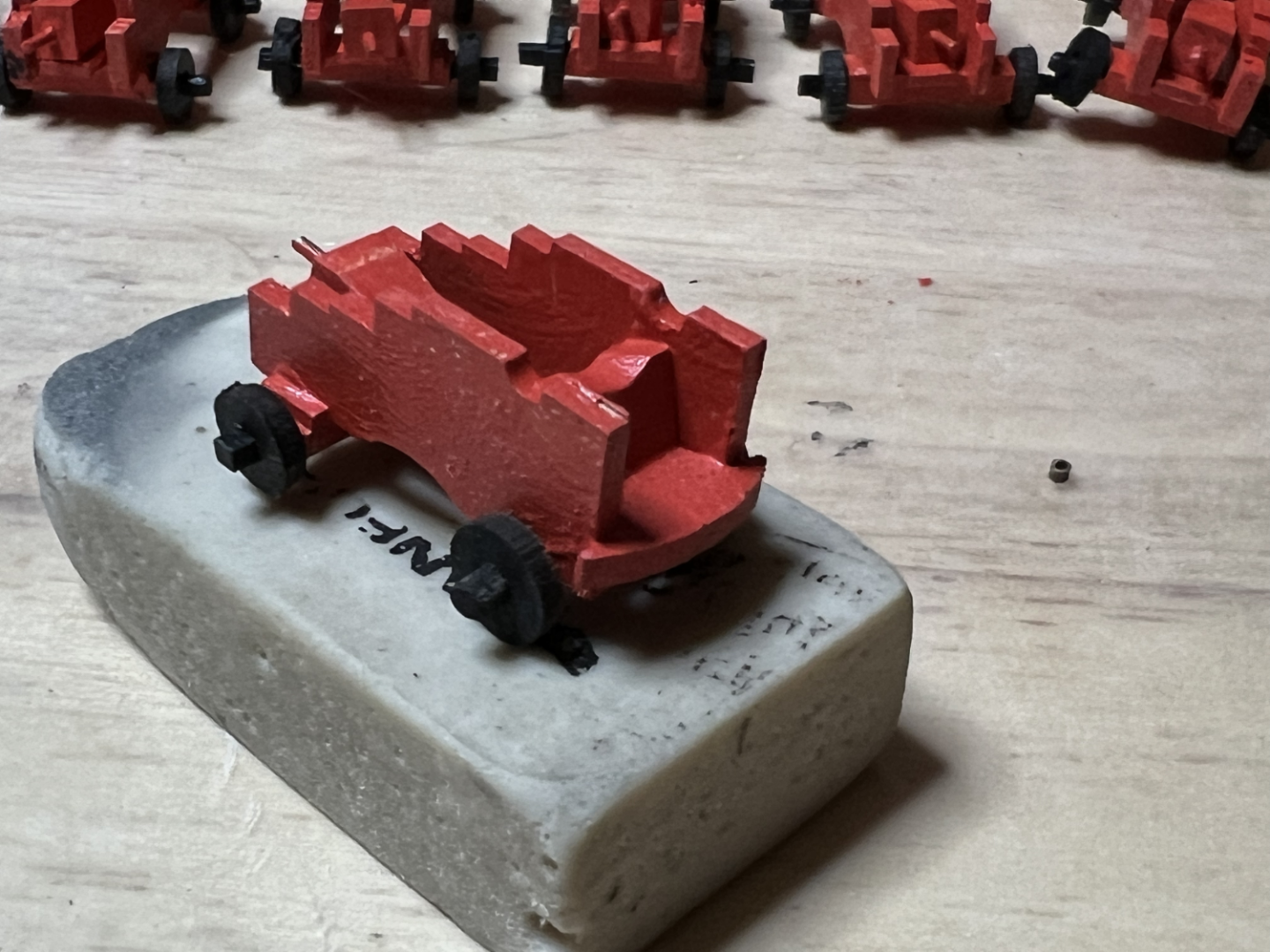

Jax Black arrived and seemed to work just like Blacken-It, so all the trunnion caps were blackened. They were fastened to the carriage with CA very carefully so that the barrel could still rotate for final adjustment when the guns are placed in their final positions. Due to their function, the quoins are not glued in place awaiting that final placement. In addition, black dots were painted on the carriages to represent the black bolts. At this scale and final viewing location, that’s all that is needed. When I looked back at the practicum for the spar deck, that is exactly what Mr. Hunt did for the cannonades’ bolts.

-

Helmar: I will definitely drop your name should I concede in my attempt to fabricate the companionways. Thanks for the info.

Jon

-

Helmarsowick: Thanks for the info, I'm tempted. If I may ask, what/how does he charge? I've got the kit's and the US Navy plans. Be that as it may, I think before I do that, I would want to give it a shot myself following Ken's lead. I mean, it's the point of building a model. I just need to know my skill limits.

Jon

-

GGibson: The lazy susan was made as a mosaic pattern with blocks of wood by my uncle. I inherited it in 2020 and found it quite useful. The only "problem" is that I would like to be able to lock it in a fixed position at times, but haven't spent much time figuring out a solution yet. BTW, Peaches is a she and is 14 yrs old. Not once has she ever touched my work benches. She's a really good girl.

Helmarsowick: Those companionways you made are glorious. There a number of them on the Constitution that I will have to fabricate and plan to follow xKen's (Ken Forman) build log for them. He silver soldered his. He designed the cross section kit of the Constitution for Model Shipways. I think you put are giving him a run for the money. Is that one solid piece straight out of 3D printer?

-

Helmarsowick, that's basically what I did for the Rattlesnake. I got the unassembled unfinished case from Model Expo and the table from another online source. I had to cut the vertical corners to size and buy the plexiglass. The table was complete, no work to complete. Still, it wasn't cheap; and this model is twice as big as the Rattlesnake! But, I can put it off for a while at the rate I'm building the model. See picture below for one of the reasons I'm so slow

Jon

-

GGibson: I'm anxious too!

Geoff: Not only do we have to encase this baby, but I'll need to buy a table to put the case on (see my Rattlesnake), and find a space in my house to display it. Since I don't have any normal sized wood working tools or the cabinetmaking experience/skills in using them even if I had them, I'll have to buy a custom case or pay someone to make the case for me. Any way I look at it, it's going to cost a bit of money.

Jon

- GGibson and Geoff Matson

-

2

2

-

I've kit bashed my build by adding the gun deck. I now am in the process of fabricating 22 gun carriages (I've already have eight dummy guns) and still have to rig them all. I will be doing a complete carriage rig so, I understand how you feel.

Jon

- mtbediz and Geoff Matson

-

2

2

-

Good to have you back. I look forward to your future posts.

Jon

-

When I tried to blacken the caps, I realized that the last of my Blacken-it solution had lost its potency. It seems that the company that made the stuff is no longer in business. So, I must wait until my order of Jax Black arrives. I’ve never used this product, so we’ll see how it goes. In the meantime, I’ll be adding all of the eyebolts and rings to the remaining 21 gun carriages. In the image below, the cap is dry fitted and unblacken.

-

Gun Carriage Eyebolts, Rings, and Trunnion Caps

Gun carriages have several eyebolts and rings to facilitate the movement of the gun assembly during firing and positioning. In numerous builds I’ve seen posted, it appeared to me that the eyebolts used on their gun carriage were way out of scale – much too large. Relative to those, mine may appear too small to many viewers.

Using the US Navy plans for the 24” pdr. gun carriage as my guide, it shows for each carriage side, three horizontal eyebolts at approximate 1½” ID or (0.02”) 1/64” at scale. Making that size eyebolt is nearly impossible (for me) and not practical, so I’m using 1/32” eyebolts. These I have purchased from Model Expo and used over the years. One of the eyebolts has a 2½” ID or (0.036”) 1/32” at scale ring attached. To maintain the illusion of size difference, I used a 3/64” ring. The eyebolts on the forward and aft axials are 1¾” or (0.023) 1/32” at scale. Again, to maintain the illusion of size difference, I used a 3/64” eyebolt. In lieu of black paint, the hardware was blackened.

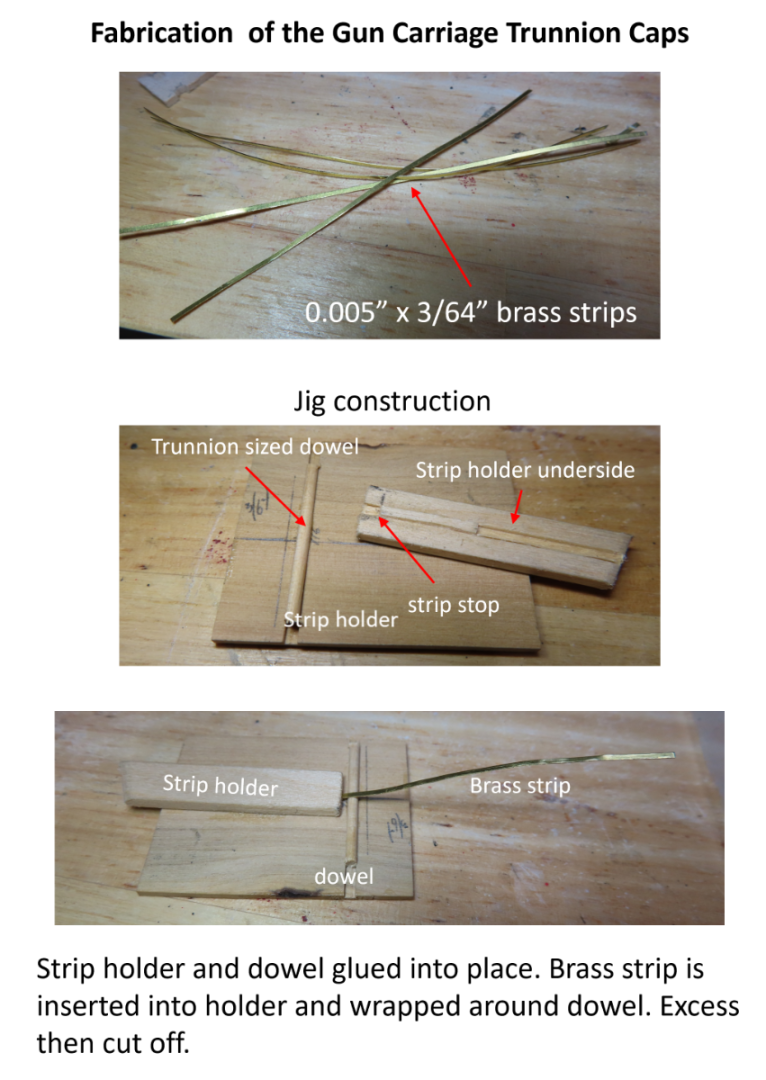

The trunnion caps although simple in construction, were a little trickier to handle and form due to their size. I made mine 3/64” wide by approximately ¼” raw length. It shortens up when shaped around the trunnions. To facilitate its fabrication, 0.005” thick brass plate was cut into 3/64” strips using the Byrnes saw. These strips were fitted into a simple jig to form their cap shape. The jig basically held down one end of the strip at fixed length, while the remainder was pressed over an equivalent trunnion diameter dowel. Then the opposite end of the cap snipped off the remaining length of the strip.

-

I re-read your build log because you have long surpassed me and now I’m following you. It was then I realized that you did not use the cannons or cannonades that came with the kit, but purchased them. You also purchased the ships stove which I tried to recreate from scratch. Where did you get them from?

Once I get to the spar deck, I plan on modifying or replacing the kit’s cannonades so that it reflects the actual cannonades used in 1812. The present ones are incorrect replicas except for the two that use a screw to adjust elevation. I’ll have to scratch build all the carriages as well. You did a beautiful job.

Jon

-

-

- Stevenleehills, Unegawahya and mtbediz

-

3

3

-

Well, I’ve finally completed fabricating the gun carriages and glued together all the wooden parts save for the quoins. BTW, the quoins shown in the photos below did not have their handles installed at the time of the photo shoot. They were made from 0.032” brass rod.

I’ll glue those down for the final adjustment of the gun barrels, after the carriages are completed. Next up, is painting the carriage bodies red and the axials and wheels black. Still to come are the addition of the metal hardware and rigging. To give myself a preview, I’ve temporarily placed the gun assemblies in their positions on the gun deck.

-

Without seeing your situation, I would use CA glue provided you have enough surface area to glue and that the surfaces to be glued are clean.

Jon

-

Peter, at the bottom of MS webpage, there is a button for "parts request." Also I have listed their phone number as (800) 222-3876. I don't know if this number is still viable as I haven't had a need to use it for quite some time.

BTW, if you ever buy just one hobby power tool, The Byrnes saw is worth every penny.

Jon

- ERS Rich and Ryland Craze

-

2

2

-

I looked at Rich's log and his cathead sculpture looks a little oversized. The sculpture edges should be flush to the cathead. Therefore, the 1:87 Constructo sculpture might be just the right size for the larger scale 1:76.8 MS kit. Luckily, only a knowledgeable viewer would be aware that the Rich's and my sculptures are not the same as the actual ship. When you think about it, I'm really surprise the MS kit does not supply a precast sculpture.

Jon

-

Those cannons are coming in very handy right now. Thanks again for making them available.

Jon

-

I thought I would bring the conversation of the cathead carvings back to your log instead of continuing on Unegawahya's log. I was getting a bit confusing as to who I was commenting to.

How to create the cathead sculpture: As I mentioned on Unegawahya's log, there are only two ways. Either carve them yourself, or purchase a similar one online which I did. If you are going to attempt a carving, you might want to look at xKen's (Ken Forman) completed log starting at Post # 756. He's a professional model maker and it worth looking at his complete log. His is a true carving out of wood. An alternative to that method, is to use Scuptey, a clay like substance that is baked once the sculpture is made. I saw this done, but can't remember who did it that way.

Jon

USS Constitution by JSGerson - Model Shipways Kit No. MS2040

in - Kit build logs for subjects built from 1751 - 1800

Posted

Good idea Tom!

Jon