-

Posts

2,611 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

I like those clamps. What method did you use to slot the oak jaws?

- 572 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

Martin - I did actual use paper clip gauges although you wouldn't know it from my results. I did everything you described...almost. The problem was that I liked seizing the deadeyes on my sizing machine. I could make them nice and tight. I would seize the first deadeye on the machine. Then holding it in place with the gauge on the model, loop the shroud over the mast to the other deadeye also attached to a gauge. A clip was placed on the looped 2nd deadeye to hold the shroud in position. Here is were it got squirrely. I removed the shroud from the model and seized the second end on the machine. I imagine due to the variances in tension, how it looped over the mast the second time in comparison to the first time, placing it on the seizing machine, etc. when finally installing the shroud, things didn't line up as intended. The deadeyes were all seized and glued at this point so I ended up with what I had. I did the best I could with the lashings. My original concern was I could not seize the shrouds insitu on the model and make it clean and tight. Well I got got clean and tight, but uneven deadeyes. I'll try your method on the next mast step. Jon

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

If I had thought about printing the name like you did, I don't know if I would have done the lettering the way I did (on a plaque). Either way works. Nice job on the capstan. Jon

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Your transom is coming along just fine. Welcome to the club. I had all kinds of problems with the back end of the model and had to get creative in order to get the ship's name on her. Yours came very nice. Can I assume you used dry transfer lettering? Your window frames look great also. Can you provide any detail as to how you accomplished it?

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

I just discovered your "new" build log today. New for me but you've started it back in March. I was wondering if you were aware of the work of Gene Bodnar at Model Ship Builder who built not one, but three cross sections of the Connie (1:32 scale) which could be put together to form the complete hull? If not take a look at his build log. BTW nice work on this build too.

- 572 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

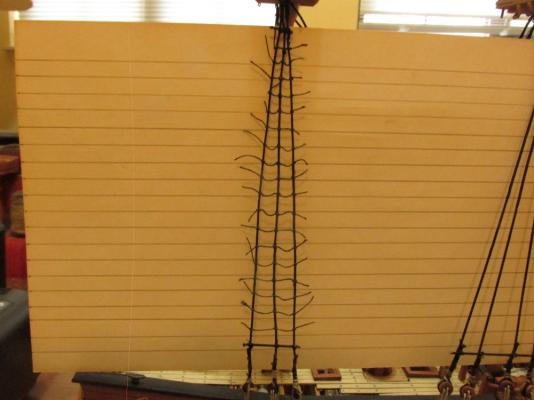

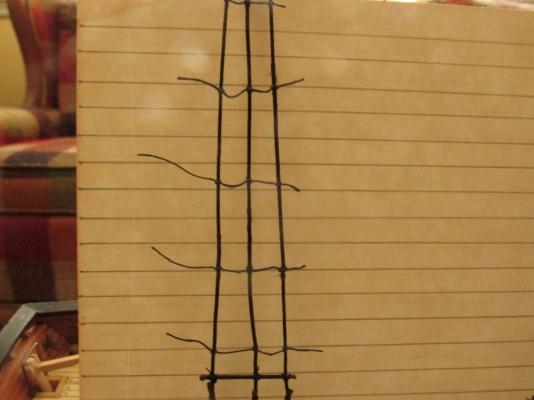

Once I was satisfied all was right with the world, a drop of CA glue was applied to each knot and the excess lines cut off, not with a scissors, but with a sharp X-acto knife to get as close to the knot as possible. It may not be the best ratline ever done, but hopefully it’s not too bad for my first.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

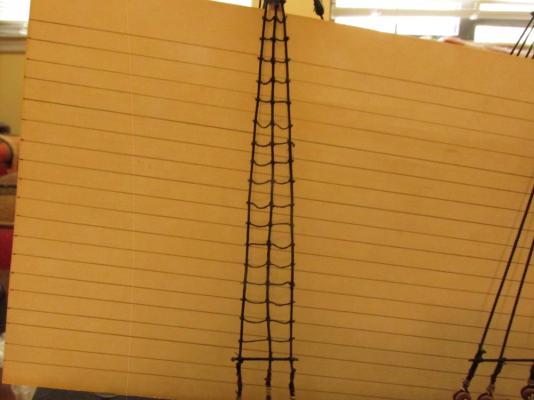

Ratlines All the staves were installed under the tops and above the deadeyes. The ones above the deadeyes gave me pause. Due to lack of my skill and/or experience the deadeyes did not line up was well as I had hoped. I was consoled somewhat because I had read somewhere that they did not always lined up due to the need to be adjusted due to wind conditions, moisture, etc. which affect their tautness. Therefore I attempted to minimize the obviousness of their irregularity by installing the lower staves a little higher above the deadeyes. After taking two weeks off from model building to visit Mom in Florida (she turns 97 next week) I returned home and realized that after looking at the model afresh, I could have lowered them a bit more but they were glued into place. Be that as it may, I plodded on. Per Mr. Antscherl’s instructions I started to install the ratlines using my thinnest cotton thread. Using an index card with the proper spacing of the ratlines laid out, I installed a line every third row without any glue so as to maintain the shrouds vertical straightness. A simple knot was used on the outside shrouds and Clove Hitch knots were used on the interior shrouds. Because they were not glued at this point, final line adjustments could be made.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Very nicely done. You are a better man than me. I'll be very happy just to get the standing rigging in place. Just out of curiosity since I won't be adding sails to my model, what kind of sail cloth are you using and why?

- 264 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

I was so new to model ship building at this point, I didn't quite understand what I was doing so was following the instructions blind. If you haven't already, I would suggest not cutting the top of the frames off. Hahn's plans are designed for the model to be built upside down with the top of the frames fitting into a jig. Therefore there is extra frame that needs to be cut off. If you know exactly what you are doing and are precise in cutting to exact length, it should work. If not, leaving excess frame to be cut latter while on the model give you a bit more leeway. The extra frame wood will also allow you to align the pseudo frames easier. In my case I had difficulty because I didn't understand what I was doing. I had never seen a wooden boat put together before at this detail level. Some of my resulting frames were too short, tilted at the wrong angle, etc. even though I thought I was cutting as precise as I could be. It is only latter that I understood the process and then it was too late in some areas. As for mistakes in the practicum, there are a number of them, most of which I have documented when I caught them. In the later chapters they get more numerous. If you have looked at the later chapters, you will notice there is not one photo of a completed model. That is because Mr. Hunt never completed it but just showed how things needed to be done...for the most part. He stated somewhere that he was building 4 kits at once and was on a deadline. It appears that he had to cut corners.

-

Based on what I can see in your photo, your gun port looks right. When I made these, my skills weren't the best so some of my port lips aren't exact. But at this scale, unless you look real close with a magnifying glass the variations vanish (at least with my eyes). You may want to prepare the gun ports for the port lids at this point. The upper frame of the ports needs to be notched to accept the lid hinges The hinges are the only gluing surface you have to attach the lids to the ports and they don't provide much surface area for glue. I have already knocked half of them off since. I used CA glue, but if I were to do it again, I think epoxy might be a better choice. You may even want to postpone their attachment to a later time when they are less prone to be hit.. Nice job so far Jon

-

The transom gave me problems. Bob ended up with 5 planks because it appears I may have chopped too much off the stern so I ended up with 4 planks. I thought I followed Hunt's instructions to the letter (as well as I understood it). How I messed up I don't know, but my stern was too short. Therefore there were repercussions down the road. I had to squeeze the rudder post into position, make adjustments to the deck were it protruded as well as adjust the "horse" behind the tiller. To be honest, I don't remember exactly what I did to ensure the plywood and framing that made up the transom, adhered solidly to the deck (it was 6 years ago - Have I been working on this for that long?), But looking at my photos, it looks like I was lavish with the glue knowing that this part of the construction would be covered up and that the side planking would eventually provide full strength. I don't think I pinned in place or I would have mentioned that in the log. You can see my initial progress on the transom and the problems I had. Part 1 Post #10 Part 2 Post #24 Part 3 Post #38 All I can say is be very careful here. Jon

-

Once the proper length was served, it was cut off from the rest of the wire and the two ends were dipped into some brown paint to represent the leather caps (not that you could actually see them) and lashed to the shrouds. There are still some fuzzys that still have to be snipped off.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

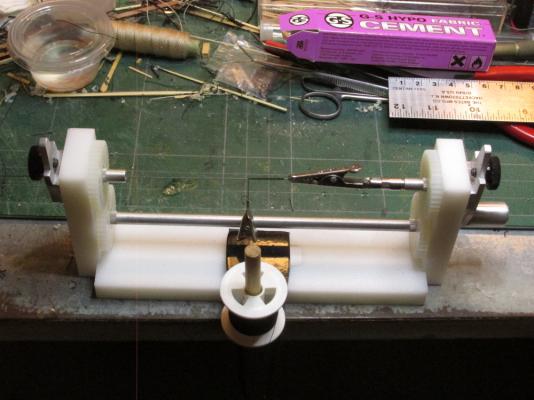

Ratlines – Futtock Staves Following David Antscherl, the next activity is the ratlines. In order to do them the Futtock Staves need to be installed first. According to Antscherl the stave was served rope. According to James Lees’ The Masting and Rigging of English Ships of War 1625-1860 an iron bar was used on some ships. David opted to use served bamboo (made with a draw plate the same as tree nails) in lieu of served rope for stiffness because you cannot see the difference. I went a step further, since you cannot see what material was served, why take the trouble to make bamboo staves? I used music wire which is very stiff and it satisfies Lees and follows Antscherl. The model calls for 0.8mm rope so I used 0.02” (0.51mm) music wire which when served should approximate 0.8mm. My serving machine was able to accommodate the wire and served it easily. The alligator clip in the image is applying tension to the line while some CA glue dries.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

I really wasn't suggesting that you make the buckets, but just to look at his technique. You both used the dowel to support the construction. Then again his other stuff looks real neat too.

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Have you seen Salty Sea Dog's build. He didn't make a pump but he did make a bucket starting at post 335 basically the same way you did. He also made a bunch of other miniatures you might find interesting.

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Are those individual slats in the pump barrel body? If so, how did you assemble them? I think they look a bit more realistic than mine. At the time I was following Mr. Hunt's practicum religiously and not looking at the plans closely very much.

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

I found the binnacle a fun little project (comment 179): Yours is beautiful. Is there a reason why your scratch built looks about 50% bigger than the cast metal one supplied by the kit?

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

There is a short discussion of the Horseshoe Plate in one of our forums here: What is That Thing? There is also a link there to Chuck's Confederacy model (see Chapter 8, last page) where he uses a photoetched horseshoe. It does provide a good visual as to what it should look like.

- 264 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

I had the same problem bending those #$%^& ribs. I've been thinking it might have been easier to cut out the ribs (and more of them) from airplane plywood or boxwood directly to shape and skip the bending. You would have ended up with a stronger frame and planking would have be easier. That is assuming you knew how to shape the ribs in the first place so you could cut them out.

- 131 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.