slow2cool

-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by slow2cool

-

-

I am working on the same build. This is the first ship I have done with sails and ratlines.

For some strange reason that I don't understand I really like doing them.

Seems like it makes the ship the ship.

You have done a great job on your ship, I am sure the rest will be just as good.

Joe

-

Hi Rainbow

Looks like you have a very good start. Planking is a learning thing. Different types of ships will be harder then others.

The most important thing I learned is the planks should lay down without much force. I use the same bending tool as use have. It works well for bending the wood for the hull. I also use a curling iron at times.

For your first build and the tools you have you are doing really great. I started out with a lot of wood experience, ( I built rc airplanes, and other wooden projects ) and had a boat load of tools ( power and hand tools )

You will get better, and it will be easier with every build.

Joe

- Elijah, Rainbow and Jolley Roger

-

3

3

-

On the other hand.......who besides you will know???? Does it really matter?? I know you will know and it may bug you.....got something better to do with your time ;o)

Just seems, especially for your first ship, such a small issue that would only be noticed by an experienced builder....or maybe not even then.

I've heard in many builders descriptions, that when they didn't know which belaying point was correct, they lay the line free and attached at the nearest point not causing any crossovers. So even the best sometimes do what is expedient but not exactly accurate.

But if you are going to fret about it, redo the rigging.

Tom

Thanks Tom

I was going to go back to the future but, couldn't find a DeLorean, Mr Peabody wouldn't let me use his way back machine, so I will let it be.

Joe

-

-

-

-

Joe, The lights are made up from plexiglass turned to shape ( using files ) Than glued to a wood base. Four holes evenly spaced around the light were than drilled and "U" shaped small wire was inserted into the holes and glued. A piece of flatten wire is than wrapped around light and glued in place. The light is than cut from the wood base and a squared wood mounting piece added. mounting piece is than shaped and the whole thing painted.

That's the easy version.

Thanks for the info. I will tuck it away. I never would have guessed doing it that way, it sure sounds good to me.

Joe

-

-

Great work, looks like you work some magic of your own.

- Piet, CaptainSteve, NenadM and 2 others

-

5

5

-

Thanks so much for the info, my kit never even came with the red plastic

Joe

-

-

Bob is right you won't find it as future. I also have a old bottle, and found a new one at Ace Hardware. What you will look for is acrylic finish.

I also use it for a sealer, primer, and finish. I find it 101 uses for it. Also great for putting on photoetch parts. Never thought about making windows out it until I saw your log.

-

I use my airbrush for so many things. I spray acrylic floor finish for my clear coat. You can look at my King of the Mississippi. Plus any other colors that I need. A little off topic, the acrylic floor finish will give you a great clear coat, it cleans up with water and is self leveling. I have used it as a under coat, or base coat for a top color. It will fill in gaps and pours with enough coats and when you spray on the color coat it finishes as smooth as glass.

As for the airbrush, it all depends on how many models you are going to make in your life.

You will need a fair size compressor, I have a pancake type. I did buy one of those very little ones that are for airbrushs, but I found it was always playing catch up and not giving me enough pressure.

The airbrush I would say that will give you the most bang for your money would be http://www.amazon.com/Paasche-TG-3F-Double-Gravity-Airbrush/dp/B002N0QA9A/ref=sr_1_3?s=arts-crafts&ie=UTF8&qid=1454448860&sr=1-3&keywords=paasche+airbrush

It will do

- Achieve patterns from a hair line to 1-1/4-inch

That's what you want, there will be times when you want a hair line, and if you are painting the hull you will want 1- 1/4 inch

Clean up is also easy, you want a brush that is easy to clean

Joe

-

-

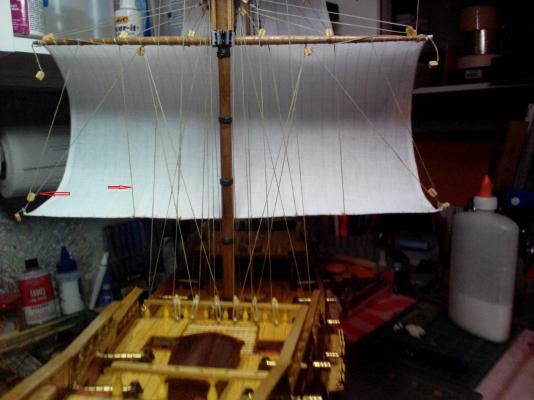

This is the 1st ship I have made with sails and rigging.

My next one will not have the sails, I will just have the rigging.

What I would like to know is from the pic, what and how would I do with crew lines and bunt lines ( the red arrows ) ???

Would I just not put them on at all ???

Would I put them on and tie them to the yard ???

What is done on a real ship that does not have the sails on it???

Thanks

Joe

-

Just to let you know the windows I made are very fexible. I find a lot of uses for Future Floor Wax. I put it in my air brush and finish my models with it. It is very forgiving and self leveling. It's almost imposible to mess it up. If I paint wood I use it as a base coat, sand it down a little, paint the finish coat, it comes out very smooth and looking like glass.

-

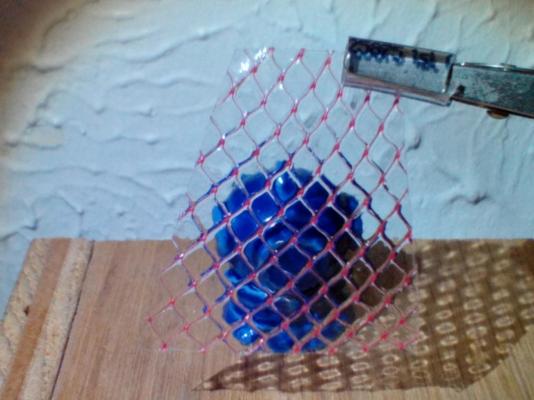

Pics of windows using future floor wax and food coloring

1st pic is using cling wrap for backing, comes out very clear as you can see by the divers helmet in back of window

2nd pic using cling wrap and food coloring in the wax then pouring on netting

3rd pic using wax paper for backing, this gives a frost look, the red windows are food coloring mixed with the wax and put on with a paint brush after the clear wax dried

4th pic using wax paper for backing and mixing food coloring in the wax then pouring on netting

Thanks for letting me post Popeye

Joe

- GLakie, popeye the sailor, Sjors and 9 others

-

12

12

-

Hi Popeye

I did a test using Future Floor Wax, with clear wrap, and wax paper

I did it with clear floor wax and some with food coloring in the floor wax

Is it okay to post the pictures on your log???

Joe

-

I have been followong your build. When I have some time I was going to try making windows. What I had in mind was to use the netting, but I was going to try future floor wax. It is still water based, so I was thinking about using food coloring. Not sure is I should put the food coloring in the wax then pour it into the netting, or try the food coloring on the wax in the netting when the wax is dry

Corsair by Rainbow - OcCre - 1:80 - first wooden model kit

in - Kit build logs for subjects built from 1501 - 1750

Posted

I have a disk sander from Micro Mark. It seems I use that more then any other tool. I set it up for " 0 " clearence. If you don't know what that is let me know I will send a pic.

Also I have a dremel, and a dremel drill stand that I use for drilling, but also set up for a milling machine. If you would like to see I can send a pic.

I think you will need some type of sander soon. Trying to do all that sanding by hand get old real fast.

I am following your build so let me know if I can be of help, or shoot me a message.

Joe