-

Posts

6,389 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Canute

-

SBD-3 Dauntless 1:48 Hasegawa - Edwardkenway-FINISHED

Canute replied to Edwardkenway's topic in Non-ship/categorised builds

Nicely done Edward. -

Some Tamiya kits, both aircraft and ships, have these poly-caps that get built into the model ahead of time, so the prop or turret snaps in to permit turning the part. A 1/48 He-219 I'm contemplating has them, along with a pretty hefty metal chuck that sits under the cockpit. The UHU was tricycle gear do it would be a tail sitter without this bob-weight.

-

Launching a massive airstrike off a straight deck carrier looked like a zoo. How many a/c were there on 1 ship. 90 or so? They'd jam them in anyway they could to make them all fit for launch. They had to launch in a sequence, usually fighters first to provide air cover, scout dive bombers next and finally, the torpedo bombers. The rendezvous to build the whole strike package must have been incredible, getting separate carriers' aircraft joined up. I remember our Linebacker launches from Korat in 1972, Over 100 aircraft from just one base. We had 4 bases launching. We had flow plans with all sorts of timing. Aircraft were parked all over the base; anywhere we had space to load and launch. We all launched to a fleet of aerial tankers and hung on them until the code word for executing the strike or weather cancelling was broadcast.

-

North American P-51D Mustang by Asat - Airfix - 1/48

Canute replied to ASAT's topic in Non-ship/categorised builds

We had it in the F-4s, but that was when they were close to new. The MAC guys used it a lot in their cargo compartments. -

North American P-51D Mustang by Asat - Airfix - 1/48

Canute replied to ASAT's topic in Non-ship/categorised builds

Looking good, Lou. Cockpit floors still use that, although they seem to use a tape nowadays. -

Bell UH-1H Huey By lmagna - Dragon - 1/35 - PLASTIC

Canute replied to lmagna's topic in Non-ship/categorised builds

Doesn't matter, Lou. They look good. very nice work. -

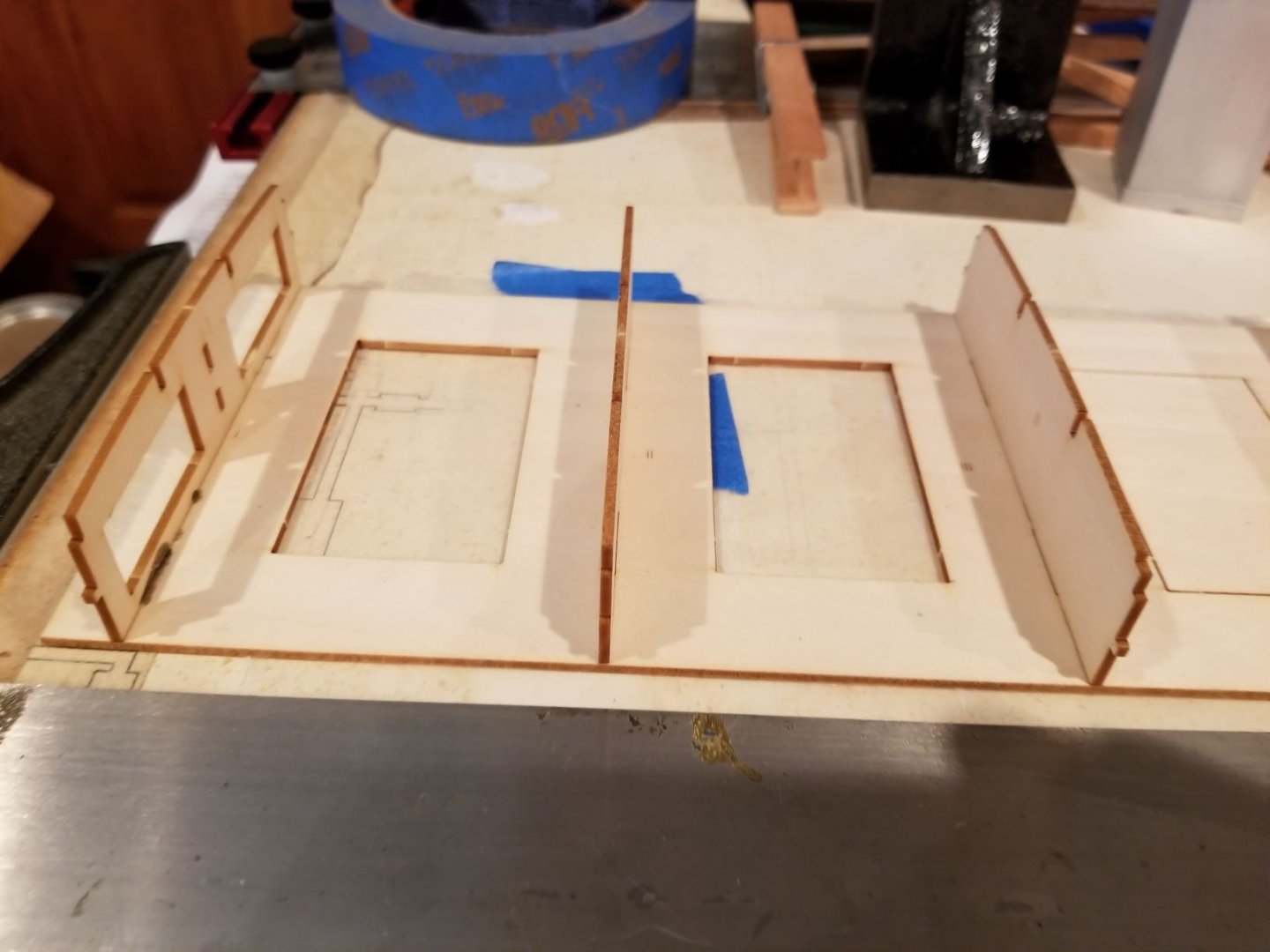

Well, more work done and I found a real prize buried in my RR cache: a pile driver barge. Could become the follow on to this little scow. On to the current work. The framework is pretty basic: floor, five bulkheads, some stringers and 2 end braces. Thanks to the laser cutting this craft has sheer and camber built in. The ends are identical, with buffer wood added in. Have to go back and add some creosote stain to these buffer boards. And this shows the camber, too. The stringers are added to support the deck and everything is left with the glue drying. I need to go back and touch up a few spots and fill in some gaps in the side strakes. Thanks for reading.

-

1931 Cadillac by CDW - FINISHED - JoHan - 1:25 Scale - PLASTIC

Canute replied to CDW's topic in Non-ship/categorised builds

Great job with the paint. Like EG says, looks real. -

Carl, where's the fun in just a cockpit. Geewhiz, mate. We want to see more to that airplane. So, you are not expecting anymore parts to continue with this build. OK, I get it. I'm just a little too literal sometimes. And there is no wayinell I'd ever say anyone is dumb, especially looking at the artistry displayed by the folks on this forum. P.S. The DB605 is the Daimler Benz engine of the Me109G

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.