bigcreekdad

-

Posts

412 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by bigcreekdad

-

-

Looking forward to my next build. Decided on a non warship, and settled on the schooner America. There are several kit choices out there, and I'm curious as to what others who have built her think. I'm kinda leaning to Model Expo's reintroduced America kit.

Thoughts please?

- BobG and EricWilliamMarshall

-

2

2

-

Decided to try a tugboat, or other working vessel for my next build. Would prefer plank on frame, or other non solid hull kits. Any recommendations? Thanks in advance.

-

-

I was at the point of adding the first drop plank below the wale, when I put the whole thing....ship, wood, and fittings back in a box and started something else. That was over a year ago.

It was like having writers block. Every time I tried approaching how to make this I just put it aside. IMO, I was really having a nice build up to this point, and I was afraid (still am) of coming up with something that I would just accept and move on.

Any Cheerful builders out there experience this particular stumbling point? Is so, how did you move beyond it?

- mtaylor and Ryland Craze

-

2

2

-

-

One of my more recent activities this Covid crap has spawned is paint by number. Surprisingly relaxing, inexpensive, and they actually look fairly (IMO) good.

You'd think that after doing a few of the above, with many minute shapes, that painting the inside of the gunport would be a breeze. Well, not for this cowboy anyway. I still end up with traces of the paint (red) on my lovely pear outer planking.

Before I make it worse, any suggestions for removing it?

Thanks

-

Wow....thanks for all the feedback. I've got a bit of homework to do.

- thibaultron, Canute and mtaylor

-

3

3

-

I used to at least rip decent planks. Now, I van't get the width so be continuous through the whole cut. After 6 or so inches, it starts decreasing. Frustrated. Thoughts?

-

I may have misled....I only use clamps for planking above the wales, and for bending and drying a plank to fit the curve of the bow.....these are the times that I get the dents from bad clamps. I also use clamps on wood for many other tasks when ship building.

I'm really just wondering if anyone has a source for good quality small and medium clamps.

Thanks

-

I'm sure everyone has seen, and maybe used, those red handled and tipped clamps. I'm sure many will agree they are junk. The protective tips eventually will either come off or west through. They also have varying degrees of tipping power....some much tighter than others . AS such, they become useless for things like planking as they end up leaving dents.

Are there any really good small clamps out there. I would pay for quality, but haven't seen any. such thing. Any thoughts?

-

Not sure how, but I lost one of the two. Does anyone know if there are replacement clamps?

-

Ditto on the folding table. I use two of them and they work fine. Don't go too cheap....sturdier the better.

- mtaylor, Canute and Keith Black

-

3

3

-

Second planking with very nice kit supplied pear wood. A

lmost finished. I did some preliminary sanding and applied a coat of gun oil. This made a few imperfections stand out, and I will now repeat the process at least once. While I've seen tons of better planking jobs on this site, I'm kinda pleased with my efforts, and, as I stated in my initial post, I just hate to cover most of this with copper. And, likely will not. To each his own I guess. Also...keel needs lots of work yet. Might just use a dark stain...any thoughts?

lmost finished. I did some preliminary sanding and applied a coat of gun oil. This made a few imperfections stand out, and I will now repeat the process at least once. While I've seen tons of better planking jobs on this site, I'm kinda pleased with my efforts, and, as I stated in my initial post, I just hate to cover most of this with copper. And, likely will not. To each his own I guess. Also...keel needs lots of work yet. Might just use a dark stain...any thoughts?

- Keithbrad80 and mtaylor

-

2

2

-

Eugenio...just looked at build log....fine looking job!

- mtaylor and Eugenio Treviño

-

2

2

-

Starting the second planking of my Speedy build. After that, copper plating is close. I've only coppered one ship (Pickle). and I just didn't like the look of it. I much prefer the unpainted wooden ship. I even mix woods a little for contrast. Another thing...I try to do my best (still a ways to go) on the second planking and to copper over most of your efforts is a bit of a downer. Finally, most of my hull will be planked with pear wood....a beautiful wood....why cover that up? But not coppering doesn't present a real ship of that period.

What are current thoughts from the group?

- mtaylor and Eugenio Treviño

-

2

2

-

-

This has been a great build log to follow. Especially because of the very clear and close photos.

Great looking ship!

-

-

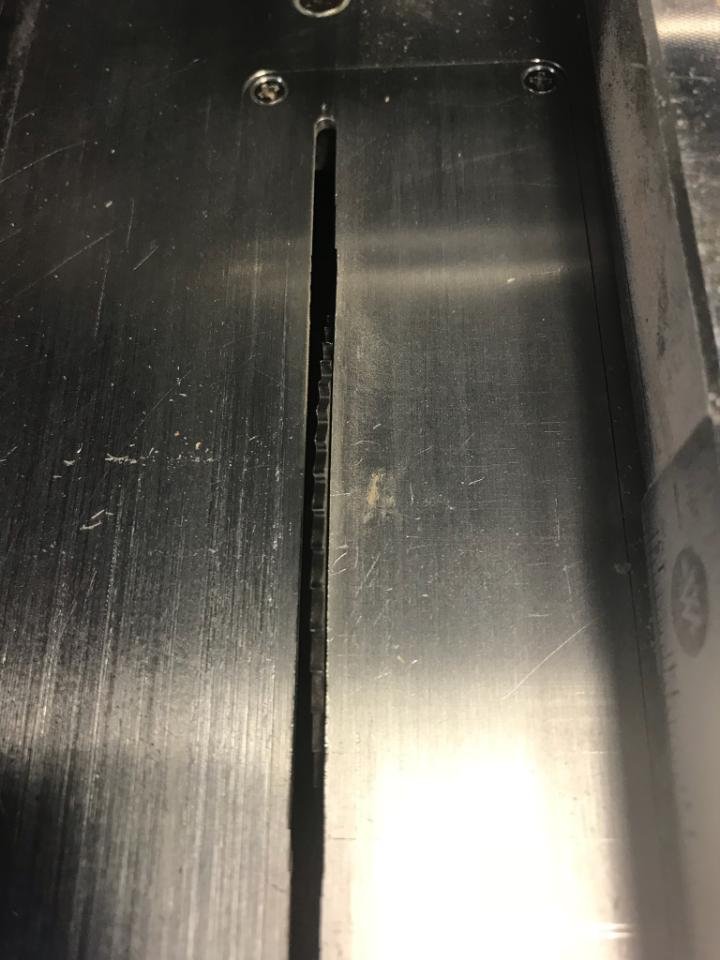

WAs intending to do a little heavier cutting and I installed the original blade. However it seems to be biting one side of the cover. When using slitting blades I also noticed the blade was very close to the cover on the right side (looking at it).

Any thoughts?

SEE THE PIC ATTACHED TO SEE WHAT I MEANT ABOUT BLASE BEING SO CLOSE TO SIDE> THIS IS A SLITTING BLADE.MY CARBON BLADE THAT CAME WITH THE SAW RIBS RIGHT AGAINST IT.

-

-

I received this excellent kit for Christmas, and you are doing such a fine job, I know I'll be referring to your build log often once I start it. It will be a little bit yet, as I'm just starting the second planking of my AVS.

I always struggle with planking to try to get it right, and am still not where I would like to be. Adopting Chuck's method of bending has helped a lot, but I need much more practice IMO. I have been using a hair dryer, but it just doesn't seem to get quite the bend I would always like and I see you are using some type of heat gun. I wonder if that might work better than the dryer. Any thoughts?

-

-

Just what I was thinking of....Thanks!

- thibaultron, Canute and mtaylor

-

3

3

-

I have a shop vac I use in the basement, which I can connect the hose to the byrnes saw, scroll saw, thickness sander and disc sander. Works well, but I do most of the actual assembly, including sanding, in my den. When doing so, I usually wear a protector. This protects me, but does nothing about the dust it throws into the air. I've been thinking about jury rigging a small shop vac, to which I can somehow fix the hose intake semi permanently to my bench and sand over the top of it.

Anyone ever try anything similar?

- thibaultron, mtaylor and Canute

-

3

3

Lively of Baltimore 1813 by Jeffb - FINISHED - The Lumberyard - 1/48 - first complete wooden model ship build

in - Kit build logs for subjects built from 1801 - 1850

Posted

Darn Jeff

I just went through your log. Wonderful job! I asked for a new kit for Christmas. If I had been through your log a month ago, I would have put the Lively on my list instead of another kit. Maybe a future Christmas list item.

Very well done lad!

John